Automatic air vent: what can be a shut-off valve for the radiator and why is it needed?

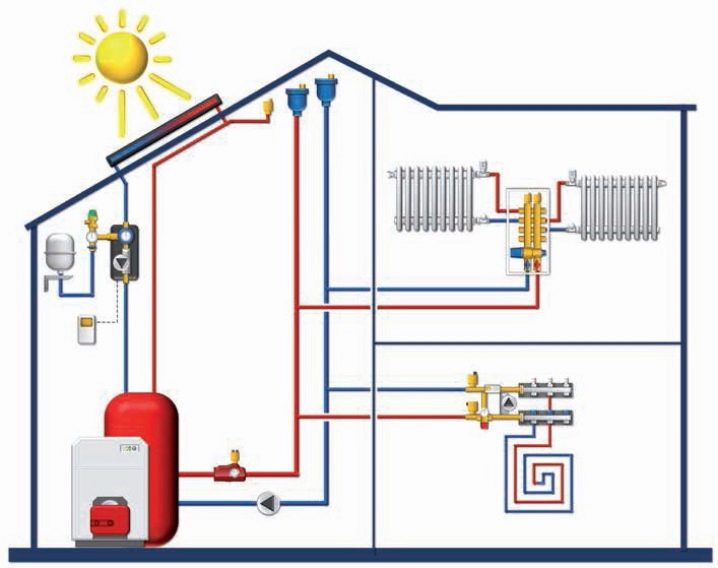

Automatic air vents are auxiliary elements in heating circuits, but they play an important role in closed heating systems. At the same time, in open systems with natural movement of a heat agent, with an expansion tank, it is possible to do without a valve for air discharge.

What it is?

Automatic air vent for heating systems is a small element for bleeding air and gas masses from liquid media.Its use allows you to avoid contouring the air, to quickly fill the heat pipe, to avoid the formation of air pockets and to start back the air masses when emptying the pipeline. Therefore, this element plays an important role in the heating circuits.

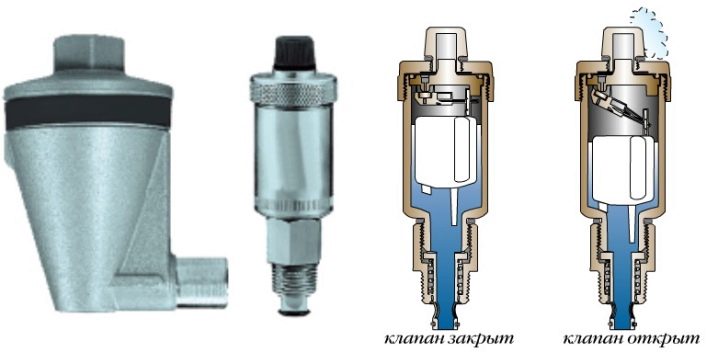

The body of the automatic valve for gas release has a hollow polypropylene or Teflon float, air valve and air collector. The air valve is equipped with a plug to avoid leakage of thermal media when a valve fails.

Air vent must be located in any closed system with forced circulation of coolant that moves through the pipes under pressure. As a certain amount of gas and air accumulates, they are automatically vented from the system. Airing the circuit is dangerous because there are failures during the movement of thermal media, noise and hydraulic shocks are generated, and there is also rapid deterioration of the nodes of pumping units and other equipment. In some cases, the airlock completely stops the circulation of the fluid.

Air masses in thermal media are dissolved. They are formed at sharp pressure surges, temperature conditions and accumulate at the top of the heating circuit. Automatic air vents are installed on those places where the formation of a large volume of the gas-air system is possible. For example, faucets are mounted for heating equipment, for a heated towel rail.

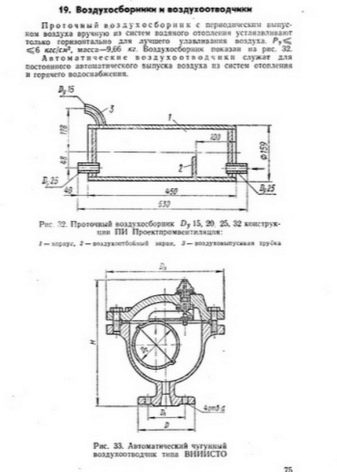

In addition to the air vent, can be installed and separators - pipelines with different diameters. Under reduced pressure, air bubbles appear, which then accumulate in a pipe with a large diameter, from where they are discharged with a separator.

Consider the main causes of airing in the heating circuit.

- Use as a heat carrier of ordinary tap water, which contains oxygen in dissolved form. When heated, water releases this element in the form of small gas bubbles. After some time, the bubbles merge and form an airlock.

- Coolant velocity too high with which it fills the heating circuit. At this time, the air does not have time to bleed.Therefore, the heating circuit must be filled slowly.

- The leakages of any connections through which air flows into the system.

- In the heating circuit installed pipelines without anti-diffusion layer that does not allow oxygen.

- Poor organization of the heating system can also cause gas jams. Most often this is due to the illiterate slope of the heat pipes and, as a result, the air remains in this section of the pipe.

- Contact with gas / air mixture after repairs.

Features and varieties

Technical features of automatic cranes:

- operation time: 25-30 years;

- maximum temperature of water and other non-aggressive liquids: no more than 120 degrees;

- room temperature: not more than 60 degrees;

- pressure: 10-12 atmospheres;

- threaded connection: 1/2 or 3/4;

- thermal agent: water and non-aggressive liquids.

The quality of automatic air vent should meet all the requirements of GOST and quality certificates. Every year the device of automatic valves for the release of gases are improving.

Modern manufacturers are trying to eliminate unpleasant moments that may arise during the operation of air vent.

- Use reflective plates at the inlet to avoid water hammering.

- Equipment fittings for quick dropping of small air bubbles. At the bottom of the tank is a filler designed to trap moving air bubbles.

- Equipment radiator plugs mini-valve.

Depending on the method of production, automatic float air vent can be presented in several forms.

- With a straight pipe or hand.

The most popular devices, since they can be installed almost everywhere:

- At the upper ends of the vertical risers. As the air tends to get to the top, the installed air vent will allow gas to be released from the upper points of the circuit.

- The composition of the security group of the heating device. The safety group is located on the suction heat pipe after the heat generator. This also includes a pressure gauge for measuring pressure and a safety check valve. An automatic valve is designed to remove the gas-air environment with increasing levels in the expansion tank. With proper equipment strapping, you can separate the device with a slam-shut valve 1⁄2 and remove the liquid medium using an air spreader,at the end of all work, you can refill the system with coolant.

- In circulation pumping units to ensure stable operation. Pumping equipment transports only liquid media, and the ingress of air mass into the unit will cause it to stop. But thanks to the automatic air vent, steam or air will be removed before it enters the pump.

- Corner.

- For radiators.

In closed heating systems, it is often the case that air-gas masses accumulate in hard-to-reach or remote locations. In the case when conventional valves cannot be installed, since the threaded pipe at the end is horizontal, angle automatic air vent will be the best solution to this problem. The nozzle of the device is rotated 90 degrees, which allows you to connect it to a horizontal pipe. You should know that the angled air vent practically does not differ from the traditional direct air vent and can be installed instead.

Many people, instead of the usual Mayevsky cranes, prefer angled type air vents. This is justified in cases when a large amount of gases accumulates in the heating equipment.The reason for this may be the chemical reaction of elements dissolved in the coolant with aluminum alloy radiators at high temperatures.

It does not make sense to mount the corner air vent as there are special automatic air vent types. Such devices are mounted exclusively on radiators and have the appropriate thread. They are also preferable instead of manual air vent on aluminum or bimetal heaters, where the alloy can interact with the coolant. In all other situations, radiator automatic valves are installed at the discretion of the owners. Conventional cast iron radiators in a centralized heating system are equipped with Mayevsky manual valves and a drain element.

For practicality and ease of cleaning, float automatic taps are available complete with a valve, which is the most compact adapter with a petal-type branch pipe. The adapter screwed onto the threaded connection is installed before the air outlet and is necessary for quick disassembly and cleaning, as well as replacement.Similar elements are equipped with automatic cranes from manufacturers such as Danfoss and Valtec.

The advantages of the model machine

Automatic air vent have the following advantages over manual cranes:

- functioning without the use of human labor;

- reliability;

- strength;

- resilience;

- long service life;

- stable work.

How it works?

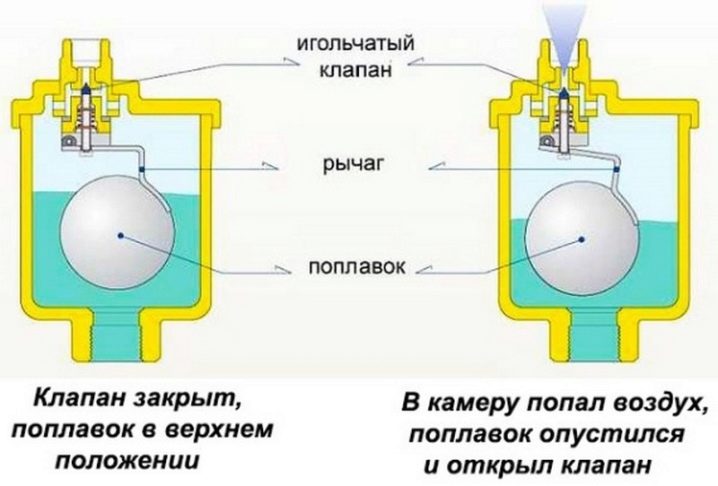

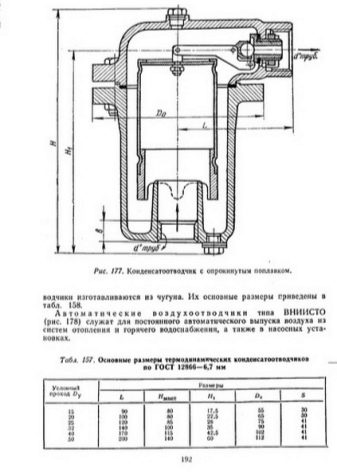

The air vent valve is a metal housing with a lower pipe. In the case there is a float made of polymers, which is connected with a needle-type valve. In the passport of the air vent all the details and principle of operation are described with the designation in the diagram.

Consider the principle of operation.

- The normal state of the air vent is when the liquid is filled with a float located at the top of the system, and a needle-type valve is closed. The air mass present in the circuit is directed into the chamber and displaces the liquid. The float slowly goes down and in a certain area opens a valve that interacts with the environment. As a result, the air accumulated in the chamber under the influence of fluid pressure is discharged through the open area.

- After the gas-air mixture has been discharged, liquid is directed into the chamber, raising the float to the extreme upper position under pressure. The valve closes and the air spreader goes into standby mode.

- When emptying the heating system, the automatic float valve also plays an important role. As the water level drops, the valve will open, air will be able to get into the system and speed up the emptying process.

Materials

Manufacturers Overview

Automatic air vent for gas discharge are:

- brass with polyethylene float, not susceptible to oxidation;

- epoxy cast iron;

- brass with nickel plating and polyethylene float;

- from a stainless steel.

Among the companies that produce automatic air vent for heating systems, the following brands have won a good reputation.

- Flamco from the Netherlands. It produces Flexvent domestic air vents. The body of parts is made of brass, products are mounted in the contours with a small amount of air masses. Mainly designed for batteries.

- Portuguese company Adca specializes in valves for the industrial segment and heating circuits. Products are made exclusively from stainless steel and installed in heating circuits with a maximum coolant temperature of not more than 300 degrees.

- Mankenberg Company manufactures high quality air vent. The main difference between the air vent of this manufacturer is the ability to install in heating systems with various types of coolants, even aggressive. The air vent is made of stainless steel.

- Granreg KAT produces valves for air bleeding, mounted on the system of water supply, heating and sewage. Russian-made devices are currently manufactured for heating systems - the KAT12 series, water and sewage circuits - the KAT50 series.

- Armstrong Company It is considered the most sought-after manufacturer of high-class automatic air vent throughout the world.

Installation

Installation of automatic air release valves produced vertically in the following sections of the heating system:

- in the security group of the heating apparatus;

- on collectors of the warmed floors;

- in the case when the highest point is not the battery, but the heat conductor, a valve for the release of the gas-air mixture is mounted in it;

- in a heating boiler if available;

- on the heated towel rail;

- on the shooter.

Also, the machine can be mounted in problem areas of the pipeline, where U-shaped loops are formed.

How to disassemble?

Often when using automatic air vent, it happens that they begin to flow. At the same time, plaque and mechanical deposits appear on the needle-type valve. In this case, the valve closes completely, the coolant flows out from there, that is, the valve flows. It is necessary to dismantle the device, disassemble it, use a soft tool to clean the needle, the saddle and other disassembled parts. With good cleaning, you may not know such problems until the next precipitation. For the assembly of the air vent it is recommended to use a FUM tape as a sealing thread connection, and the body is twisted by hand.

Tips and tricks

The first and most important advice of experts: do not buy automatic air vent Chinese-made.

As a result of savings, the following may occur:

- the omission of a heat agent together with the gas-air medium, which leads to the formation of smudges on the device case and a decrease in pressure;

- premature failure of poor-quality air vent;

- rapid wear of the internal float of the valve under the influence of water.

Recommendations for the choice of automatic cranes for gas release:

- in the event that children live at home, it is necessary to give preference to manual taps under the screwdriver, since the baby can get to the handle, open the tap and get burned with hot water;

- First of all, you should pay attention to the models with a shut-off valve, which will allow, if necessary, to quickly dismantle the element for repair or replacement;

- To protect against corrosion, you can choose models with anodized coating, it has no effect on the operation process;

- There are models with additional features that allow to improve the quality of heating, so if possible, you should choose an air vent that traps air bubbles.

The most important shortcomings of automatic type air vent are their exactingness to the quality of the heat agent.Due to the use of a dirty heat carrier, the air outlet is blocked. As a result, the exhaust valve will not close tightly. Therefore, it is recommended to disassemble the faucet more often and clean the accumulated dirt. Another common problem with automatic float valves is a leak in the area of the thread between the lid and the body. This is due to rupture of the sealing rings located between them. Rings should be replaced with new ones.

Since the automatic float valve is a device for frequent use, it must be frequently disassembled and thoroughly cleaned to avoid possible coolant leaks. This can be done without emptying the system and reducing the pressure. Shut-off valves are commercially available for this purpose. This device must be installed under the air vent. The crane will press on the lever, while the membrane sags and is in contact with the overall system. When dismounting the air vent, the shut-off valve will close the opening.

How the automatic air vent works, see the following video.