Press fittings: characterization and installation

The manufacture of water pipes and other pipelines of metal-plastic is widespread. These are light and reliable constructions that show themselves from the best side. But that is why the consumer is obliged to know all the subtleties and nuances of specific products that are components for pipes.

Special features

Press fittings are designed to provide a stable and reliable joining between pipes made of metal-plastic. Now you can find various types of such parts, the difference between them on the device is small. The body (or rather, its geometry) determines the classification of connecting products.

Available in batches:

- tees;

- couplings;

- corners.

The main part of the fitting is the sleeve, for the most part it is made of stainless steel. For crimping with a special tool while still in production, the liner is designed so that the pads of the fixture fit exactly and exactly. With careful compression according to all canons of technology, it is possible to maintain the geometry of the structure for many years to come. The clip also plays its role - it is a ring made of a material with high elasticity. It depends on the prevention of the action of galvanic currents at the junction points.

Using

To mount such parts, use special crimping press manual or hydraulic type. A wide variety of structures designed to be connected allows, without any difficulty, to create wiring of the widest spectrum. When it is required to stretch a linear highway, adapters or connecting couplings come to the rescue.

But when turning, branching, are used:

- corners;

- triple wiring;

- elbows;

- crosses.

The advantage of fittings designed for metal-plastic pipes is their suitability for connecting to pipelines made of steel.When parts with identical diameters are to be joined, couplings are used. But transitional designs help to join the segments of the highway and the individual parts of dissimilar materials or differing in size.

Benefits

Both internal and external threads can be produced on the nozzles. Due to unified dimensions, metal-plastic parts can be connected to the copper sections of the main lines. On condition of proper installation of fittings, it is possible to provide a very high-quality nonseparable connection. It is characterized by mechanical strength (at the docking points, the working pressure easily reaches 10 atm. Without any risk to the part). Long use of the fitting is another advantage.

Manufacturers often give a guarantee of 50 years, but only in the case when all the manipulations with the product meet the technological standards. Crimp fitting is better than other designs also because it does not require mandatory monitoring and maintenance. It is very good, when highways of the hidden execution are mounted or filling by concrete is done.Such compounds do not lose their practical advantages even with thermal expansion. And because they can be safely applied even in heating systems and in hot water circuits, it will not cause any problems for the consumer.

The installation itself is easy and quick, eliminating the need for mastering specific tools or special training. Such manipulations are available even for beginners; they will mostly need press crimping tools. By using fittings, you can reduce the total number of pipes and additional fittings. And because the total costs for the arrangement of water supply or heating systems are lower. The coincidence of the overall terms of use of the fitting and metal-plastic pipeline allows you to synchronize their repair and replacement.

Even where there is a very strong corrosive environment, press fittings are guaranteed to stand. This property they retain during the entire operational period. The developers were able to achieve their optimal use for the circulation of both cold and very hot (by household standards) water.

But you still need to understand that the manipulation of press fittings are related to high technology. And the overall simplicity, reliability of the joints do not reduce the requirements, for example, to the selection of suitable tools.

What tool can be used

The choice of special ticks is represented by both the simplest manual and more powerful hydraulic models. At home, when it’s necessary to install a pipeline or repair it only occasionally, a hand-made functional is enough. By the quality of the created joint, if everything is done correctly and accurately, there will be no difference from professional devices. It is important to consider that all models are optimized for a specific diameter. There are tools that come with liners.

Then a lot depends on what set of liners are supplied. Along with the simplest press tongs, there are more advanced designs. So, if the tool is marked with the letters APC, it means that the device automatically tracks the reliability of the formed joint. It is impossible to open the press before the end of crimping. The APS marking indicates that the tongs can not only adapt to the various dimensions of the fittings, but also distribute the effort most accurately.But if OPS is written on the tongs, then the tool is equipped with stepped clamps and is able, thanks to this, to multiply the applied force.

How to choose a good fitting and mount it

Marking the case will tell a lot to the connoisseur. Those firms that make high-quality docking elements will simply not use cheap printing equipment. Therefore, any inscription, even a single character, is printed clearly and expressively, excluding the slightest vagueness or misinterpretation. It is equally important to evaluate the mass of the structures, since normal fittings are made from selected brass. If someone tries to assure that lightweight products are just as complete, this is just a clever marketing move or some kind of misunderstanding.

It is worth looking at the appearance of the fitting. If it is made of a thin layer of metal, it will not work to get a reliable joint. Professionals confidently say that buying cheap items in small retail outlets, especially if they operate informally, people doom themselves to re-laying the pipeline. In this regard, investments in high-quality and expensive variety of components justify themselves in abundance.

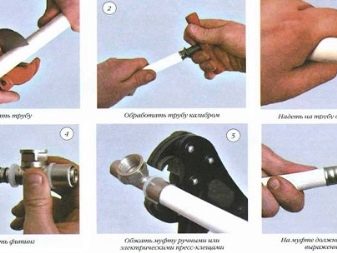

First of all, pipes should be cut (this also applies to structures made of cross-linked polyethylene). Measuring the desired area and cutting it at a right angle with a special tool, process the end faces.

Using the caliber, correct the ovality that inevitably arises when the incision is made. Following this, the chamfer inside is removed with a phasket-picker or a sharp knife. If you use a simple knife, you will have to further refine the right place with sandpaper. Only when all this is done, you can strung the fitting on the pipe, be sure to check whether it sat tight. There are such models that do not require fixing crimp couplings. Then these same couplings are put on the pipe and a fitting is inserted into the part, over which sealing rings are fixed. At the points of contact of the metal-plastic pipe and the metal element, in order to protect against electrochemical corrosion, an insulating gasket is required.

Tying a fitting of various execution, take a sleeve in a clip and reduce, there will be no emphasis of handles yet. With quality work, the metal part becomes arcuate, and the fitting receives a pair of identical bands in the form of a ring.Processing must be completed at one time. Repeat crimping should not be. This will only cause damage to the connection, so the defect will be irreversible. Therefore, it is necessary to prepare carefully for work and take into account all the smallest nuances, free up time so that nothing would interfere.

Such connections, if they are performed properly, can be no less qualitative than when using welding - and their tightness meets all requirements. It is recommended to use a fitting of the same brand under which the connected pipes are issued. If the choice has not yet been made, you can safely apply designs from Henko, Valtec. The products of these concerns are of high quality and very popular. It is easy to apply such details even to beginners.

We must not forget that press fittings can be designed not only for metal-plastic pipes. Pipelines made of steel and copper are connected using a special kind of elements, and all three types cannot be replaced mutually. Therefore, even when buying it is worth asking for what purpose this or that part is intended.

The fitting for the steel pipeline is devoid of fitting, it is just a sleeve in itself, which is crimped with tongs. An attempt to compress a metal-plastic pipe without a softening "intermediary" will end with its deformation.

In the next video you will find the principle of working with press fittings for Valtec stainless pipe.