Features and recommendations for the choice of bimetallic radiators

The heating system of any room is an important part of communications, the effectiveness of which depends on its competent assembly. The main element in it are batteries. To date, the plumbing market offers a huge selection of heaters. After traditional cast-iron radiators, bimetallic models are most in demand.

What it is?

The main structural idea is to use two metal alloys with different technical and chemical characteristics. As a rule, the internal surface of the heater is made of stainless steel, because it has to constantly contact with the heat-transfer fluid. Steel also has anti-corrosion effect, besides it is resistant to pressure surges.The outer side is made of aluminum, which is characterized by a high rate of heat transfer. Thanks to this combination of metals, the heating element has an increased efficiency. Such models are most convenient for an apartment connected to a central heating system, since pressure surges are possible in it, and the use of low-quality heat transfer fluid.

High-quality bimetallic radiators must comply with the requirements of GOST, which will allow using them without problems during the entire service life (about 25 years).

Device and principle of operation

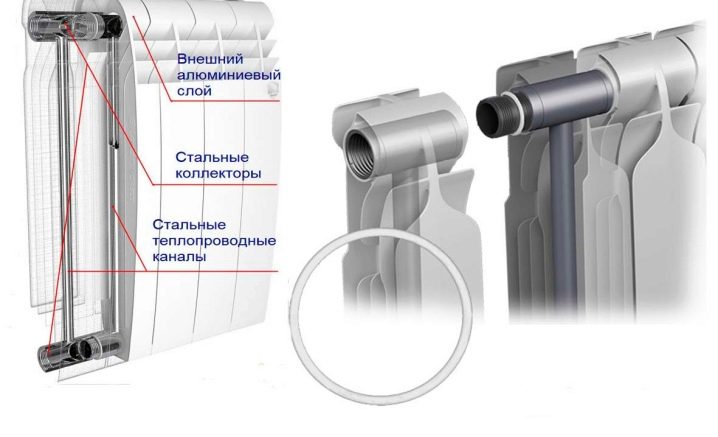

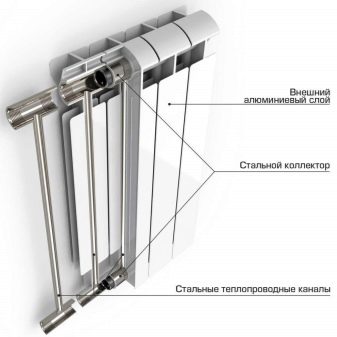

The main elements of bimetallic heating batteries are two parts.

- The core is filled with coolant. Since it interacts with an aggressive environment, it is made of steel or copper. These metals have high resistance to corrosion. In the composition of the inner element, we can distinguish such two components as:

- collectors are made from steel. They are necessary to connect radiators to the heating system. Stainless steel can withstand pressure surges, and copper is additionally resistant to electrochemical processes;

- heat-conducting steel channels.

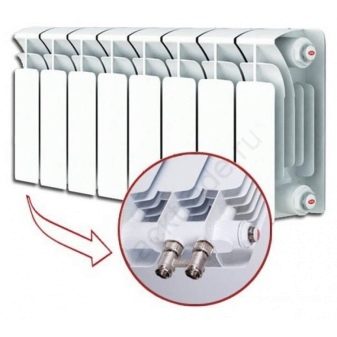

- Outer layer Aluminum is used for its production as an excellent heat conductor. The aluminum case is able to quickly change its temperature, making it possible to regulate the heat transfer. The overall design consists of two horizontal steel pipes connected by vertical steel pipe webs, through which the heat-carrying fluid or vapor is passed. This system is covered on top with aluminum fins or a monolithic body. The heat exchanger has a complex configuration due to convection ducts. Sections during production are joined by spot welding. During installation, structural parts are mounted using rubber gaskets or nipples made of steel.

The radiator is based on the physical phenomena of convection and radiation.

The principle is as follows:

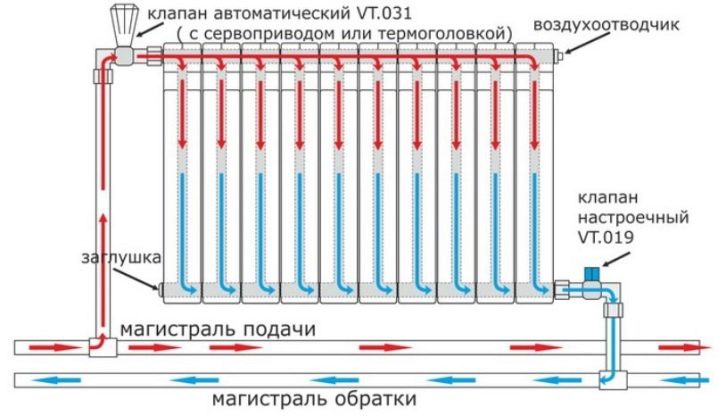

- the heat-carrying fluid is heated to a high temperature in the boilers and is centralized through the pipes. Thus, the coolant enters the radiator;

- The steel core, interacting with the heated fluid, transfers thermal energy to the aluminum case, which in turn heats the room.

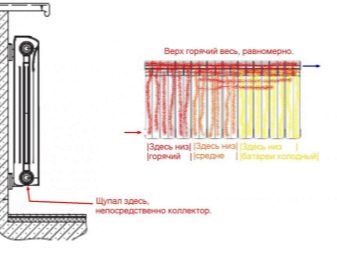

In some cases, when bimetallic batteries are connected to a centralized heating network, a problem arises - the first two or three sections of the faucet heat up, and the next ones remain slightly warm or completely cold. Experienced specialists first check radiators for airing. Air could get during installation.

If this is not the problem, the following methods should be used:

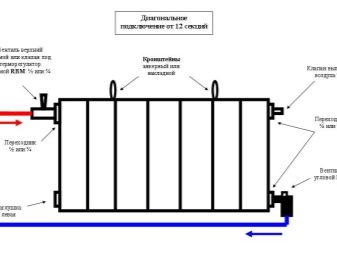

- connect the radiator diagonally;

- use a flow extension that increases heat transfer efficiency.

It should be noted that the second option is only suitable for radiators that are connected to the heating system using valves with an American. In addition, experts note that it is not easy to buy stream extensions in stores, therefore it is better to use various manuals and instructions for making such a part yourself.

The instruction is as follows:

- For work, you will need a piece of copper pipe with an outer diameter of 18 mm. The wall thickness must be at least 1 mm. In addition, you will need a coupling for soldering, silicone gaskets, solder, a gas burner, as well as a set of tools that will allow you to cut off the desired piece of pipe and clean the metal after cutting;

- before starting work, turn off the tap and drain the heat transfer fluid;

- remove the radiator from the brackets, since it is more convenient to carry out installation work on a flat floor surface;

- check the condition of the silicone gasket. If there is damage, it is better to replace it;

- the required length is cut from the copper pipe using a pipe cutter. For an even cut, experts advise placing it strictly perpendicular to the tool;

- the edges are machined with a face brush and brushed with a stiff brush. In no case can not use sandpaper, because then solder copper parts will be extremely difficult;

- Further, the process of soldering the sleeve with a pipe is carried out, for which a flux is applied to them with a brush, which should be done carefully, in an even thin layer. If you overdo it, then frozen drops of flux will cause a loud sound when the coolant circulates inside the radiator. The prepared parts are inserted into each other and heated by a torch. As soon as the flux has acquired a silvery shade, solder is applied to the joint. Due to the high temperature of the pipe, it will independently flow and fill all voids.If the flux began to curl into drops, the process should be stopped;

- pipes should be pressed against each other for 1–2 minutes until they cool down completely;

- length adjustment is made depending on the water supply;

- the obtained extension cable is inserted into the battery in the opposite direction to facilitate the movement of the coolant in the radiator with lateral connection;

- the battery returns to its place and is connected to the central heating system;

- if necessary, remove excess air.

When installing the flow extension, it should be noted that it is used in case of a large number of sections of a bimetallic radiator.

Main types

The classification of radiators depends on various parameters and factors.

By type of material

For the manufacture of heating batteries using various materials.

- Cast iron. Models of cast iron appeared in the XIX century. The material is characterized by low inertia. This means that it heats up slowly, so it takes some time to warm up the room. However, the cast iron also cools slowly, therefore, the heat is held for a long time, providing a comfortable microclimate.The material is quite strong and durable, it does not corrode and is cheap. Impressive weight is the most significant disadvantage of cast iron radiators.

- Steel. The thermal conductivity of this material is similar to cast iron. Since the wall thickness is less than that of cast iron counterparts, the steel heats up faster. High inertia allows the use of temperature controllers in the design of heating products. Steel parts allow you to vary the design of radiators. A significant disadvantage is low resistance to corrosion, which reduces the service life.

- Aluminum. For the manufacture of sections used aluminum alloy with silicon additive. The metal is very light, so the weight of the batteries is small. Aluminum has a high degree of thermal conductivity and an excellent heat transfer coefficient. Aluminum batteries have all the advantages of this material, including good inertia, which allows you to adjust the temperature. A significant disadvantage is the softness of aluminum, so the radiators are characterized by low resistance to physical impact and a weak threaded connection.As well as aluminum heating products depend on the quality of the coolant, its acidity.

- Bimetal The radiator is made of two types of materials: copper or steel as the core and aluminum for the body.

By type of construction

There are two types of bimetallic radiators, depending on the type of construction.

- Sectional models are a composite structure consisting of several sections. Such models allow you to choose power by changing the number of individual sections. For the connection using various seals. The main negative factor is the presence of joints, which increase the risk of leakage. As well as the places of the compounds are exposed to the coolant with high chemical activity, for example, antifreeze.

- Monolithic radiators are more stable and reliable. Their technical characteristics are higher than sectional analogues. Due to the lack of joints, heating devices can withstand heavy loads.

If we compare the performance of these two types of bimetallic radiators, we get the following result:

- the service life of monolithic models reaches 50 years, whereas for sectional ones it is a maximum of 25 years;

- working pressure in the heating system for the second type is allowed within 100 atmospheres, for the first - up to 35 atmospheres;

- thermal power of one section in both variants - from 100 to 200 W;

- the cost of monolithic options is higher;

- modifications with a solid core can not change the technical parameters, the sectional ones have such an opportunity.

By location

Depending on the location of the battery is to identify several types.

- Horizontal batteries - This is a standard familiar option. They are installed most often. Such models have a huge range. The changing parameters are: dimensions, performance and design. To attract consumers, manufacturers pay attention not only to the technical component of the bimetallic radiator, but also develop unique design lines. Now on the market are color, texture, combined options using different design techniques.

- Vertical radiator. Houses with high ceilings and large rooms need to increase the area of radiators. Vertical models are called upon to cope with this task, since in the case of horizontal variants they will have to encircle the entire room around the perimeter.Such modifications will help solve the problem with heating, if there is no space under the window, for example, the windows start right from the floor. They can be installed in the interstitial and interwindow piers, which will save usable space without losing the functionality of the batteries. Bimetallic vertical radiators not only heat, but also serve as a unique piece of furniture. The simplest option in the form of stainless steel wall pipes with a chrome-plated coating is used in modern styles with an industrial slant.

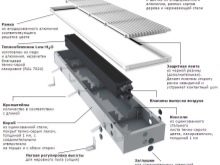

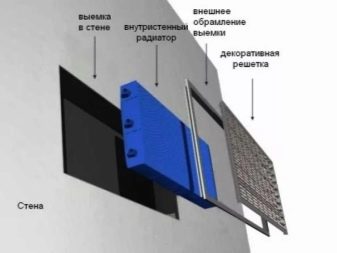

- Built-in model. Radiators of this type appeared due to new technological possibilities. They are a win-win option in cases where conventional batteries cannot be installed or difficult. For example, in a room with a large glazing area, experts suggest bimetallic radiators built into the floor. For their installation in the floor, special channels are made, and on top they are covered with a special protective grating made of wood or metal.

Underground models are of two types.

- Corpus. In this case, the heating structure is embedded in a special box that plays the role of a channel.The body is made of a thin sheet of galvanized metal and is covered with thermal insulation. The dimensions of the manufactured hull models of bimetallic radiators are as follows: the width is 5–25 cm, the height is 10–70 cm, and the length is from half a meter to several meters. Powerful models additionally supply fans that are powered by electricity.

- Packageless. In order to install these models in the floor, you must first build the box yourself, because it is not included in the kit. As a rule, the channel is made rectangular, its size should be 10 cm larger than the size of the radiator in order to ensure natural air circulation.

There are also built-in modular structures for walls and other openings. If you install such a model in the partition between the rooms, then it can heat two rooms at the same time. Some designers build bimetallic convectors in furniture.

Specifications

All bimetallic radiators have a number of important technical characteristics that you need to know before installing them.

All parameters are specified in the technical documentation for the product.

- The most important among them is the ability to withstand high pressure inside the heating circuit. It should be understood that this indicator should have a margin of safety, since in the central system there are sometimes hydraulic shocks at which the pressure sharply becomes higher than the worker. High-quality bimetallic heating batteries must withstand 40 atmospheres and more.

- Heat transfer is characterized by such an indicator as the heat output of the radiator. It is measured in watts and kilowatts (watts and kilowatts). This indicator depends on the number of sections and can vary, so the power of one section is indicated in the data sheet. One section of a bimetallic radiator can have heat emission from 100 to 185 watts. Calculation of power for space heating is carried out on the basis of SNiP, which shows the heat transfer table. For example, for an area of 1 square meter and a ceiling height of up to 2.7 meters, the calculated heat output will be 100 watts.

- Another important indicator is the volume of coolant. The smaller it is, the better. In bimetallic analogs, it is 0.16–0.18 l per section.For comparison, in aluminum it varies from 0.25 to 0.46 l.

- Resistance to the chemical components of the coolant. Here the degree of acidity and slagging of the working fluid is important. For steel and aluminum cores, this coefficient is approximately the same. Copper is more chemically stable. As for abrasive particles and suspended matter, which are present in the coolant, it is desirable that they be as small as possible. Since the walls of metal cores are thin, they are susceptible to abrasion, and moreover, pollution clogs pipes. The ideal option for installing bimetallic radiators is its own heating system, but with a centralized connection, you can choose a good option.

- The service life is guaranteed by each company itself, but on average for bimetallic analogues it is 25 years.

- Overall parameters depend only on the manufacturer.

- Depending on the model and size, the weight of the entire product varies.

Advantages and disadvantages

If we consider the advantages of bimetallic radiators, it is worth highlighting the following:

- high heat transfer coefficient;

- the possibility of installing a thermostat, which allows you to independently adjust the temperature and volume of the coolant. This property contributes to the economical use of heat and, accordingly, reduces financial costs;

- sectional design. The number of sections can be chosen depending on the area of the heated room. In addition, it allows you to repair or change sections independently of each other;

- reliability. Radiators withstand pressure surges up to 37 atmospheres. Due to corrosion resistance, bimetallic batteries do not fail even at high acidity of the coolant;

- possibility of installation in any heating systems.

- durability. The term of operation is within 20–25 years;

- streamlined shape allows for increased security;

- the panels do not heat up to the “dangerous” temperature, so they are fearlessly installed in children's rooms and hospital wards;

- a large assortment. For example, there are models without hanging on the brackets. They can be installed vertically using additional stiffeners;

- wide size range;

- extensive color range. There is the possibility of self-staining sections;

- small weight in comparison with pig-iron analogs;

- simple installation that does not require a lot of time;

- easy care

Like any product, bimetallic radiators have their drawbacks, namely:

- the difference between the expansion coefficients of aluminum and steel This is the main disadvantage of such models, which causes the squeak of the panels during long-term operation, reduces the strength of the structure;

- low quality of the heat carrier reduces the battery life;

- the cost of radiators of this series is higher than other analogues.

Comparison with other types of batteries

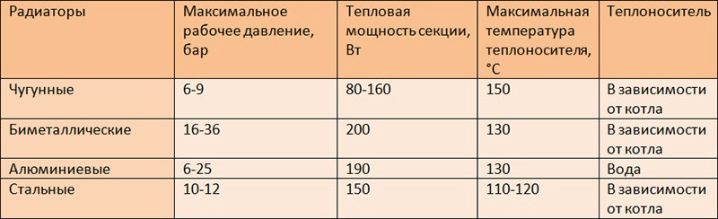

When choosing a heating radiator, buyers first of all pay attention to the material from which they are made. Many technical parameters depend on this, and this is the difference between the models.

Cast iron

This is a classic version of the heater, which has been used for a long time. Many believe that he has no alternative for durability and durability. The temperature of the heat-carrying fluid can be up to +150 degrees, the allowed working pressure is 15 atmospheres. The area of use is vast: from public to residential, technical buildings and work shops.Possible thermal power section reaches 160 watts.

The biggest advantage of cast iron radiators is their low cost. In addition, they are characterized by resistance to any type of coolant and ease of installation work during installation. Thick walls perfectly resist abrasives in the composition of the working fluid. If the system has severe contamination, it is better not to find cast-iron models. A small degree of inertia does not allow to regulate the heat transfer, unlike other analogues.

The principle of operation is based on the radiation of thermal energy, and not on convection. The latter warms the air and makes it drier, in the case of radiation, the objects themselves are heated. The disadvantages include a significant weight of the product. Many people point out a nondescript appearance as a minus, but this is a controversial issue.

Since manufacturers offer cast iron heating batteries of exquisite shapes decorated with forging, however, their cost increases significantly.

Steel

Radiators made of steel are available immediately in finished form. They are designed for low pressure up to 10 atmospheres and are very sensitive to corrosion.Since the steel surface heats up quickly, the degree of heat transfer is good. Thermal power can reach 5700 watts. In the case of a small temperature of the coolant in the heating circuit, steel modifications fit perfectly.

For heating small rooms, they are quite suitable. Unfortunately, the life of such radiators is the lowest. Experts do not advise to connect them to the central heating system, since they do not have a margin of safety, with a pressure surge can break through. And they are also afraid of heat carriers, in which there is a large amount of suspended matter, which leads to channel blockage. The most successful option for installing radiators of a similar design is an autonomous heating system with a gas or electric boiler.

Aluminum

Aluminum batteries have collected all the advantages of steel models: aesthetics, low construction weight and high heat transfer coefficient. In contrast to the cast-iron aluminum modifications allow the installation of thermostats. The main drawback is a weak screw connection. And also aluminum is exposed to corrosion in the presence of a high degree of acidity of the carrier fluid.In a private heating system, you can choose this type of coolant in order to reduce this effect and increase the service life. This condition is not feasible in a centralized circuit, so the use of aluminum radiators is inefficient.

Bimetallic

In most cases, this option wins among many. Bimetallic heating radiators are the product of the use of new technologies in the energy field. They successfully combine the advantages of steel and aluminum products. The steel core allows you to strengthen the connection and better resists corrosion. Manufacturers offer options with a copper circuit, which has a higher anti-corrosion effect.

Aluminum housing gives you the opportunity to increase heat transfer, because the material is characterized by excellent thermal conductivity. The only negative is a certain dependence on the degree of acidity of the coolant and its level of contamination. As well as the high cost of the product. In technical rooms and workshops, where it is necessary to heat large areas at low cost and low quality carrier fluid, experts recommend installing cast iron radiators.

Making a general conclusion, it can be emphasized that modern analogues of heating batteries benefit in their form. They are more subtle, ergonomic, without sharp corners, with a beautiful design. They are characterized by exact geometric lines and shapes, unlike cast-iron ones, so it is more convenient and easier to join sections. The high degree of inertness allows thermostatic regulators and control sensors to be installed on metal analogues, to supply them with other technical innovations. Installation work on installation has also become easier and faster.

However, they also have disadvantages, which the iron representatives of radiators do not have. These include durability. Cast iron is durable than any steel counterparts. Bimetallic and aluminum batteries are sensitive to contaminated coolants, cast-iron completely tolerate them. Acidity of the carrier fluid is important for the first and not important for the second. In terms of resistance to hydraulic impacts, cast iron radiators have no equal among all representatives of heating appliances. Based on the foregoing, the choice must be approached with extreme caution and carefully, especially with a centralized heating system.

Popular manufacturers and reviews

In the market of bimetallic radiators there are few manufacturers whose products have the unique property of matching price and quality. By compiling a rating based on consumer feedback, these include several Russian brands and Italian companies.

Italy

Global and Sira companies are best known in the domestic market. Their bimetallic batteries look aesthetically pleasing. The covering is more often executed in white, dairy and cream tones. In the line are adjustable modifications with a thermostat, as well as with the air vent. In the assortment there are models with different ways of installation, different configurations and sizes. Firms guarantee high reliability of products.

- Global. Italian products successfully withstand work in the harsh Russian climate. The core of the radiator is endowed with high anti-corrosion protection. The battery is able to withstand pressures up to 50 atmospheres. With all the technical advantages of radiator systems have a beautiful appearance and high heat transfer coefficient. The design consists of high-quality parts, all connections are made using sealed gaskets.Compact and democratic design allows you to fit a bimetallic radiator in any interior. The tests carried out make it possible to guarantee a service life of up to 20 years.

- Sira. In addition to excellent technical indicators, such as lightness and practicality, fast heating and high heat transfer coefficient, strength, resistance to corrosion, the radiators of this Italian brand have a graceful curved shape without sharp corners. The maximum allowable pressure can reach 170 atmospheres. The only drawback is the high price of products, but it is incomparable with absolute comfort and reliability in operation.

Russia

One of the well-known Russian manufacturers is the company Rifar. The production line is located in the town of Gai, Orenburg Region. Products are manufactured using modern technology, new technologies and innovative materials. In particular, Italian-made melting furnaces and robotized lines for applying powder paint are used. The maximum allowable performance of bimetallic radiators produced reach 135 degrees for the temperature range of the coolant and pressure in the system up to 20 atmospheres. Standard models have from 4 to 12 sections.By the individual order they are increased to 24 or reduced to two.

Rifar company offers different series of radiators, which differ in appearance and technical characteristics. However, all models, without exception, have high heat transfer, which is achieved with the help of an aluminum body made of flat fins.

- Rifar base - This is the most popular one. It is presented in three variants with different distances between the axes: 500, 350 and 200 mm. The first type is more powerful in the series and is used to heat cold, poorly insulated rooms. Base 200 is characterized by a closed rear surface. For installation there is an upper and lower connection to the heating system.

- Rifar Monolit. This series is designed for use in heating systems with high pressure up to 100 atmospheres. The design is patented by the company as fundamentally new. Its uniqueness lies in the presence of a non-separable steel multi-channel core. Solidity ensures reliability and no leakage.

The general technical characteristics of this series are as follows:

- 25 year warranty;

- high corrosion protection of channels;

- no joints between sections;

- the ability to use non-freezing liquids as a coolant;

- maximum permissible temperature of the working fluid +135 degrees;

- nominal pressure up to 100 atmospheres;

- simple installation. All fittings are standard;

- maximum safety allows you to install bimetallic radiators in children's and medical institutions.

The manufacturer offers the following models in this series: Rifar Monolit 500 and Rifar Monolit 350. The number of sections in each of them varies from 4 to 16. The most popular models with 4 and 6 sections.

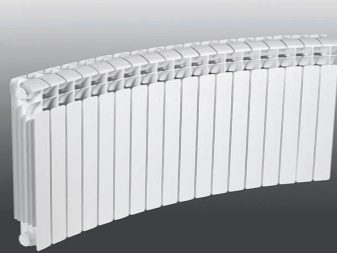

- Rifar Flex. Radiators of this series differ in the specified design. They can be given a curved shape, while maintaining performance. The warranty period of such modifications is up to 10 years.

- Rifar Forza. These radiators are the most powerful among bimetallic batteries and are used for heating large rooms. The manufacturer gives a guarantee on these models up to 15 years.

The Russian brand "Izotherm" produces copper-aluminum convectors of interesting design. The perfect solution is a removable steel polished case. The line includes wall and floor modifications.Their main difference is the presence of the back wall, because the wall has none. It is worth more to consider the most popular series.

- Atoll and Atoll Pro They have a copper-aluminum construction, which is hidden by a removable galvanized steel casing with powder coating. The design of its surface was developed by leading domestic experts. Any color scale, any drawing is possible. At the same time, technical characteristics do not suffer: the nominal pressure is 16 atmospheres, the temperature is up to +130 degrees, the power varies from 243 to 11174 W. As a heat carrier, only water or antifreeze compatible with copper is possible.

- Rodos differs from the first modifications of the material from which the body is made. This is polished stainless steel. The mirror metal surface will be an excellent designer find for modern interior styles, for example, high-tech.

Piligrim is another domestic brand. Products are characterized by increased corrosion resistance due to the use of copper cores instead of steel cores.

Other countries

There are manufacturers from other countries on the market of bimetallic radiators.Mars is a South Korean company. Products of this brand produces models with a copper core. Technical indicators are adapted to work in the Russian heating systems. They are characterized by high durability, efficiency and economy. Copper collector eliminates corrosive reactions for a long time.

As for the design, there is no particular diversity. Manufacturers of such models developed, based on the superiority of the essence over the form, obtaining a radiator of good power with compact dimensions. The design of bimetallic batteries with a copper core Mars is non-separable sectional. Each model consists of an odd number of sections from five to nineteen. On the one hand, solidity provides a more reliable design, reduces the risk of leakage, on the other hand, it also limits the possibility of increasing power by increasing the sections.

General specifications are as follows:

- working pressure up to 20 atmospheres. The maximum possible limit to 30;

- temperature range for heat transfer fluid is limited to +130 degrees;

- heat carrier acidity within Ph 7–9;

- standard sizes - 300 and 500 mm;

- section depth - 65 mm;

- weight depending on the model varies from 4 to 23 kg, which in principle is defined as small.

Models with 300 mm center distance can heat a room up to 19.5 square meters. Modifications of 500 mm - area up to 34 square meters. For city apartments connected to the central heating system, Mars products are quite suitable option in terms of dimensional parameters and operating pressure. However, when choosing, it is imperative to find out all the chemical components of the coolant in the heating circuit: the acidity and the content of suspensions, since these characteristics may not be suitable.

The Polish brand Regulus-system also produces bimetallic batteries using copper. The firm provides a guarantee for its products to 25 years, although the performance is slightly lower than that of the South Korean brand. The production, founded in 1994, mainly produced convector-type radiators. After the reorganization in 2001, the organization expanded, upgraded and continued production of bimetallic radiators. From the merits of the company it should be noted the high professionalism of the staff, multi-stage quality control of products, the latest equipment and technology.An extensive logistics network allows us to offer customers favorable conditions. The company presents its products in the markets of Russia, Belarus, Ukraine, the Baltic States.

In addition to the basic configuration, it is possible to order an individual version of the angular or radial shape. Fastening is provided wall, but the order of floor legs is possible. A characteristic feature of the bimetallic radiators of this company is the identity of both sides, so you can mount with any.

General technical parameters are as follows:

- working pressure must not exceed 15 atmospheres;

- coolant temperature - up to +110 degrees;

- thermal power depending on the model varies from 172 to 6000 watts.

The brand produces several series of bimetallic radiators.

- Regulus is a basic version with a rounded top panel and has a convection-radiation principle. Installation of side or bottom connection to the heating system is possible. Specifications in the middle range. The price range makes this model the most sought-after of the entire product line of the company.

- Sollarius. It differs from the basic configuration only in form, it is more square.

- Sollarius Dubel is an option with higher heat output. Models from this series are characterized by a doubled depth: 180 mm instead of 90 mm. In addition, in this series are represented plinth modifications with a height of only 12 cm.

- Sollarius Decor is a vertical copper-aluminum radiator that is designed for rooms where there is no place to install horizontal models. In addition, it can be an interesting design object in the interior. Complete set complemented by air vent and thermostat. Connection is possible only lower type.

- Sollarius S-Corner is an angular modification that has earned popularity in rooms with adjacent outer walls.

- Regulus Inside are models that are embedded in the wall. The manufacturer produces several types, including those with an internal fan. Radiators can be mounted in wall partitions, roofing or furniture niches. The design is modular, so during installation the quantity is arranged at the request of the customer.

- Regulus E-Vent has increased heat dissipation due to the built-in fan that connects to electricity. It can be turned off, and then the radiator is working normally.

Ukrainian plant "Mayak" produces a series of copper-aluminum radiators and convectors "Termia". The design of radiators differs from analogs in that not only the core in the form of a pipe, but also plates attached to it are made of copper. The design is covered with an aluminum casing, powder coated, which has undergone a firing procedure. The models have two types of connection to the heating system: side or bottom. For the latter, a thermostat is provided in the design. Installation of batteries is possible with the use of brackets or floor option - with installation on the legs. The basic complete set of a product is added with a manual vozdukhootvodchik in the form of Mayevsky's crane.

The main technical characteristics of bimetallic radiators are as follows:

- dimensions: width is 90 mm, height - from 200 to 600 mm with a step of 100, length - from 400 to 2000 mm;

- working power: 240–4240 W for batteries with lateral connection type, 270–4620 W - with lower connection type without thermostat;

- product weight varies from 1.6 to 15 kg;

- working pressure in the heating system should not exceed 16 atmospheres;

- temperature of the heat-carrying fluid up to +30 degrees;

- the manufacturer guarantees that radiators can work with any type of coolant: water, steam, different oils and antifreezes, as long as they are intended for copper pipes.

The design of the heat exchanger of convectors consists of 4 copper pipes with a section of 15 mm, on which aluminum fins with dimensions of 10x10 cm are installed. The distances between the plates are 5.6 mm. Connection - only lateral.

Technical parameters of copper-aluminum convectors are as follows:

- dimensions: depth is 125 mm, height - 450 mm, length varies from 400 to 2000 mm;

- convector heat output even at temperatures of +40 degrees varies from 710 to 3510 W;

- construction weight - from 2 to 14 kg;

- working pressure in the heating system within 10 atmospheres;

- warranty from the manufacturer - 10 years.

Models of Chinese manufacturers attract low price, interesting design and unique finish. However, as practice shows, reduced cost is achieved through the use of lower quality materials, due to which the service life is significantly reduced.

Which option is better to choose?

When buying, you need to pay attention to quality certificates, which will relieve from unpleasant surprises during use.It is impossible to focus only on the cost of the goods, because often the low price is due to the low quality of the materials used. For example, bimetallic radiators manufactured in China have a simplified design, which reduces the working pressure threshold. When buying bimetallic modifications of radiators, one of the important criteria is the characteristics of the heated space: dimensions, type of use (public, technical, residential). Depending on this model is selected, the method of installation and power. The variation is achieved by changing the number of sections, the presence of an automatic air vent.

First of all, it is necessary to determine the cross section of pipes extending from the central heating system.that will affect the choice of nozzles. Next, you should ask the pressure in the general heating circuit. Choose a model of the radiator should be with a margin of safety so that the radiator can withstand possible jumps. For apartment buildings of the old type, pressure within 5–8 atmospheres is characteristic, whereas for modern high-rise buildings this indicator is higher - 12–15 atm.It is better if the buyer knows the composition of the coolant, so you can choose the most profitable option that will last a long time. After that, measurements are already being made to determine the geometrical parameters of the battery.

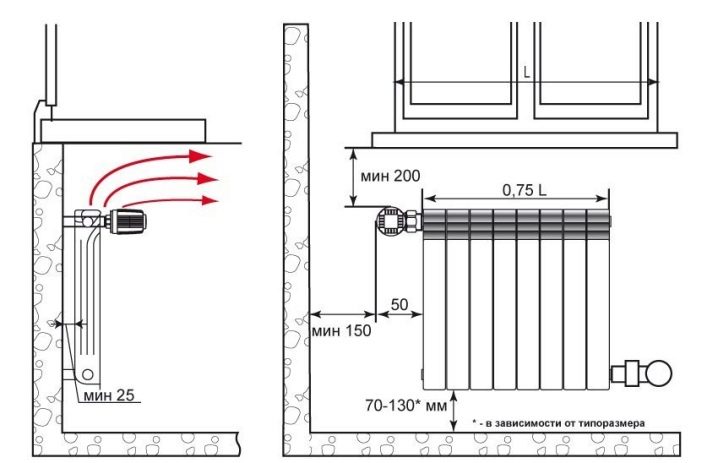

The optimal distances are as follows:

- from the window to the battery should be at least 10 cm;

- from the floor to the radiator - not less than 6 cm;

- if the battery is installed below the window, then its width should be 50% of the window width.

When choosing a sectional option, it is important to correctly calculate the number of sections.

To do this, you must follow the following algorithm of actions:

- determine the area of the heated room;

- find out the power of the radiator. It can be found in the price list or technical passport of the product;

- calculate the number of sections: K = Ph100 / M, where K is the number of sections, P is the area of the room in square meters, M is the battery power expressed in watts. For example, if the area of the room is 25 square meters. m, and the radiator power is 180 W, then K = 25x100 / 180 = 13.89. So, you need to install 14 sections.

Experts note that multisection models are less efficient, therefore it is safer to install several low-section batteries. In the proposed example, two five-section radiators and one four-section radiator.

This calculation is adjusted depending on the number of window openings in the room:

- if the apartment is angular and it has two external walls and two windows, then the calculation of the sections is increased by 20%;

- if the windows in the normal room face north, the calculation should be increased by 10%;

- if the choice is on a model that is embedded in the floor, then it must be remembered that their principle of operation is somewhat different from the wall version. The fact is that they will require a preliminary hydraulic calculation and adjustment of the operating mode of the thermostats.

An important factor when choosing is the aesthetic perception of the radiator. As a rule, heaters occupy a prominent place in the room, so they either try to hide them, using different types of buildings, or turn them into an art object, or build them into a wall. Many companies are seriously engaged in exactly the design component of bimetallic radiators. It is necessary to take into account the tastes of consumers, without reducing the quality of products. However, you need to remember - for the individual design will have to pay.

Due to the fact that the replacement of heating batteries is a costly and troublesome event,It is better to purchase bimetallic radiators from reliable manufacturers that guarantee a long service life of more than 20 years.

The checked licensed firms, besides a full package of documentation and a guarantee, provide other services: consultation, calculation of the required parameters for a specific room, delivery and installation of radiators on the spot. When buying, you should check the integrity of the protective coating of the case. Scratches and dents will cause aluminum to oxidize, a corrosive process will begin, and the appearance will be damaged in a short time. When buying a high-quality bimetallic radiator, the price starts from 400–500 rubles per section. Anything lower is likely to be of lower quality or fake. Inserts made of steel or copper in a bimetallic radiator must have a thickness not less than the wall thickness of the water pipe.

For information on how to choose a biometallic radiator, see the following video.