Features of repair of aluminum radiators

A curious pattern of problems in the vast majority of household appliances is their appearance at the most inconvenient time. Aluminum radiators, designed for heating, are not an exception, having the tendency to break during the winter heating season, when a consumer suddenly encounters battery leaks, their cold sections and the appearance of blockages in them that need to be fixed as a matter of urgency.

Repair of aluminum heating elements can be done by hand or require the involvement of professionals, depending on the scale of the malfunction.

Benefits

With all the attractiveness of this product, this type of heating battery has the lowest demand among consumers.The reason for this is the widespread opinion that aluminum radiators with a large number of flaws and complaints about their work do not have a significant service life.

This statement is only partly true, since batteries made of aluminum are capable of functioning at pressure drops above 20 atm. A small mass of aluminum radiators allows not only to easily transport these products, but also to install them without considerable physical effort, and the simplicity of their device often makes it possible to repair them on their own if necessary, with the necessary tools and minimal technical skills. A high degree of heat transfer creates the conditions for a very fast heating of the room and significant savings in energy resources.

In addition, they have a small amount of coolant, which causes almost instantaneous heating of the entire working area of the battery. Aluminum radiators have a stylish design, so that they are perfectly combined with any interior.

All these positive properties could bring these elements of heating systems to the top of sales. in its market segment, if it were not for the fact that they find the best application in heating systems for individual connection.

This is due to the fact that aluminum begins to corrode when there is no water in the system for a long time, because in central connection systems it usually coalesces in the warm season. This also includes its pH and chemical purity.

If there is an autonomous individual connection of the system, the quality of the carrier can be monitored, that is, it can be left in the system, but with a central heating supply it is almost impossible to do this.

Types of problems

The main "symptoms" of violations of the heating system, consisting of aluminum batteries, are the weak degree of heating of such radiators and the absence of air there, as well as the appearance of various noises and unpleasant knocking in the heating circuit. This also includes the presence of a leak in the body of the radiator or the appearance of plaque in the docking points between the elements of the entire system.

In homes where autonomous heating is equipped, these problems are easily detected when the system is started up in the mode set to the maximum.In this case, by creating a high pressure in the heating circuit, places of violation of its integrity will be revealed and it will be possible to detect problems that have arisen in it, whereas in houses where central heating is installed, it is almost impossible to carry out such measures independently. Solve the issue will have to by contacting the management company to attract their specialists.

It may happen that the testing of the system gave a good result, but directly during the heating season there were problems in it. In such a situation, an emergency disconnection from the damaged radiator system will be required.

Repair work

If aluminum batteries were mounted in the right way and their operation was carried out in compliance with all the required technical conditions, the period of their operation can significantly exceed the ten-year warranty declared by the manufacturer. In this case, repairs will not be associated with large labor costs, even if it is necessary to add additional sections.

Manipulations of a repair nature will then consist in overlapping shut-off valves and a riser, from which the coolant must first be drained.

To drain this carrier, install a container under the bottom connection valve. Then the lower valve is unscrewed to discharge the remaining water in the battery or, in the case of using such a heat carrier, antifreeze. After that, the upper valve is unscrewed and the radiator is removed from its place.

If the aluminum heater does not produce heat, then the root of this problem should be sought by bleeding air from the heating system. After that, you must wait until the batteries are warm enough, and if this does not happen, you will have to disassemble the radiator and check it for clogging.

Aluminum radiators consisting of sections contain a relatively small amount of coolant. Having refilled the previously removed battery with water, it is possible to determine whether or not such a quantity of water corresponds to the one indicated in the data sheet. If a discrepancy is found, it is necessary not to repair the radiator, but to flush it. To do this, it is necessary to pass a stream of water through a removed battery under a high pressure until such time as this water does not brighten.

If the problem could not be solved by such washing, then the radiator would need to be disassembled into separate sections and each of these elements should be washed.In some cases, if there is a very significant contamination of the radiator sections, you will need a brush, but not with a metallic pile, to remove dirt from the battery.

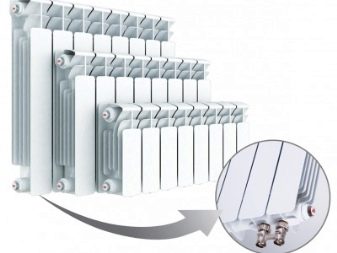

In some situations, the only way to bring the batteries into working condition is the complete replacement of damaged sections or their addition. If there is a lateral connection, such manipulation will not cause any special troubles, but in the case of the bottom or diagonal connection it will be necessary, depending on the situation, either to build up the pipe or, on the contrary, to reduce its length.

The disassembling of the disassembled battery into separate sections begins with unscrewing the nipples. To do this, the right nipple should be rotated with a wrench to the left - on the left thread. Accordingly, the left nipple needs to be turned to the right, since its thread is right. Performing this manipulation requires great care, because the nipple may well stick to the battery and you can disrupt the thread with a careless movement. In the end, will have to throw 2 sections together.

In a similar way, the nipples are alternately unscrewed in the remaining sections. After dismantling all sections, they are cleaned. The assembly is carried out in reverse order.

During the repair, it is necessary to check the condition of the threaded connections for all battery sections and inspect them for chips. Both nipples should be unscrewed and twisted several times in order to achieve sufficient ease with their further installation in place.

If the joining areas of the sections are coated with dye, then it should be cleaned with sandpaper to the aluminum of the battery itself. Otherwise, the paint will crack after a while, there will be coolant under its layer and microcracks will appear on the surface of the structure.

If after removing a layer of paint in the joint area a rubber gasket is found, it will be necessary to cut off that and put a new one in its place. When tightening each nipple on it stretches silicone gasket.

The next section is screwed on the back side of the nipple with continuous compliance with tight fit of each element until the entire structure is assembled.

When tightening the nipples in no case can not use force, so as not to disrupt the thread. If a leak of aluminum radiator heating occurred during the heating season, you should be wary of the hot coolant, so as not to get burns from it.

Replacing sections

Such work can be done in several ways, which, in particular, include the replacement of seals in the radiator. Such work requires the dismantling of the battery and its analysis into separate sections. If we are talking about eliminating leaks in the battery during the heating season, the most effective solution would be to use the so-called cold welding, if it is not possible to completely replace the damaged radiator or change the leaky section in it.

Minor defects can be repaired with solder for tinning non-ferrous metals, but such manipulation requires the skills of hard work and is a temporary measure that allows only “hold out” until the end of the heating season.

If you have the qualifications of a gas-electric welder with the consumer and the corresponding equipment, you should use argon welding to repair aluminum radiators, which is undoubtedly the best option.

When working with such radiators, one should be aware of the considerable softness of aluminum and treat it with particular care. At the same time, with proper installation and careful observance of the operating rules of these elements of the heating system, the problem of their leakage should not arise in principle.

How to repair aluminum radiators with their own hands, see the video below.