Repair of heating radiators: features of the process and sequence of actions

Repair of heating radiators is a rather unpleasant and difficult task. In addition, this process is expensive, if you pay for the work of professionals. Therefore, to avoid costs, you can do it yourself. To do this, follow the sequence of actions, as well as have the necessary tools and materials in the house.

Battery classification

A battery is a heating device consisting of several sections through which water or another liquid circulates. They are made in the form of metal columns. Elements of radiators are interconnected by means of a nipple system. Battery joints are sealed with rubber gaskets.

They themselves have a height of 35 centimeters to one meter. The power of batteries depends on the number of sections, as well as on how much heat transfer area is. Heating radiators can be of different types and made of different materials. It can be copper, and cast iron, and aluminum, and brass, and even bimetallic batteries.

Material

First you need a little more detail to consider heating radiators to understand which material to prefer.

Cast iron batteries are most often installed in apartment buildings. These are very powerful and compact instruments that are immune to the quality of the water circulating inside them. They have good heat dissipation. In addition, such a material is not afraid of corrosion, which makes the battery more durable. Since they have a huge weight, cast iron radiators are very heat-absorbing. But at the same time, this quality complicates both the installation work and the maintenance process of the heating system.

There are some drawbacks to such batteries - this is the rapid deterioration of the seals, as well as the constant destruction of the nipples, which can lead to leakage of radiators.In some cases, a plaque forms on the walls inside the battery, which greatly reduces its heat transfer.

Radiators made of aluminum, have a large heat dissipation. They have a very small space for water inside. Aluminum radiators are very convenient, because if you install them, you can adjust the temperature in the room.

Such radiators are of two subspecies: extrusion and cast. In the first embodiment, each section has three components that are interconnected tightly. The second is a solid cast battery.

Such radiators are rather easily destroyed under any pressure drops. But at the same time, these are very light structures that are not difficult to install. They quickly accumulate gases, which leads to the air system.

Bimetallic radiators consist of steel elements inside the structure itself. This gives them the ability to withstand a lot of pressure. The water that is in the radiators is isolated from the aluminum that makes up the battery. The only drawback of such radiators is the relatively high price.

Design

Batteries for heating have the following designs: tubular, panel and sectional; it must be taken into account when repairing.

Panel radiators are made from two sheets of steel. They consist of specially made recesses, which, when welded, turn into channels for circulating hot water.

Such radiators are lightweight. The surface of each radiator is not only additionally degreased, but also covered with a layer of enamel. But such a subspecies quickly corrodes and therefore has a short service life.

Sectional radiators are a bit similar to cast iron batteries. Their difference lies in the welding of similar joints that are very securely fastened to each other. These batteries are very durable, but the high price hinders their popularity.

Tubular batteries consist of structures that weld together. Work on finishing the joints significantly reduce the likelihood of the flow of radiators. Their disadvantage is that the steel is not thick enough. But they have unusual shapes and sizes. Therefore, they can be used in interiors in different styles.

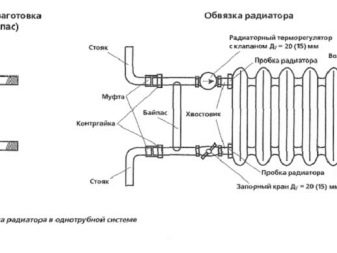

In order to repair the radiators, it is necessary to know all the main and additional elements that are included in the design. Many components depend on the type of battery, but all the main elements are the same.

These include:

- The channels or sections within which there is a circulating fluid.

- Connector rings, which serve to close the inlet pipe from the panels.

- Branch pipes for connection of underwater and branch pipes. They come in different shapes and sizes.

- Plastic rod, through which the split rings are fixed.

- Plugs (plugs) that are located on the side of the battery. They serve to drain the water.

- Ball valves and valves installed to shut off the water.

- Thermostat that adjusts the temperature inside the room.

- Mayevsky's crane, which is installed to relieve pressure in the heating system. In some cases, these may be automatic taps designed for this function.

- Elements connecting sections of radiators. It can be silicone gaskets, and steel bushings, and other connectors.

- Battery holder.

- Some radiators may include a pump for better circulation.

Types and signs of breakdowns

Before the start of the repair, it is worthwhile to consider in more detail what kind of damage to the heating radiators are and also to study their signs. There are such faults that only specialists can handle. For example, if noise is heard in radiators, the reason is most likely that the entire heating system is airy. In such cases, the master can not do. After all, which radiator is faulty can only be determined by a special device.

Wrong selection and connection of the radiator

If the ratio of the heating system does not coincide with the technical characteristics of the radiators, then they will not suit each other, and connecting them will be quite problematic. So, if you take the usual pipes and pick up copper adapters, and the battery case turns out to be aluminum, their contact can provoke corrosion of metals. Therefore it is worth choosing the batteries very carefully and installing them correctly.

Leakage

If they appear, then this is the first sign that the radiator has burst and there are malfunctions in the operation of the entire heating system.This may be the wrong connection of the battery to the pipeline, and clogging, and the destruction of threaded nipples, and many other reasons.

Big weight

If you take in the cast iron radiators, it is worth noting immediately that they have a sufficiently large weight. This becomes the biggest problem with their installation. After all, even a small error in the installation work can lead to system malfunction. The presence of weak brackets will cause the battery to skew, and later even cracks may form on the wall.

High pressure and water hammer

Even with excellent technical characteristics, cast iron is still not an ideal material. It is susceptible to excessive loads that are created by the circulation of water in the system. If a hydraulic shock occurs, then in the places where the sections join, one can see the leaking formed.

Mud

Together with the coolants, various impurities and small particles of rust or even dirt are carried through the pipeline. This often leads to channel blockages. If the radiator is not rinsed in time, it may begin to leak. Also, battery pollution often leads to the fact that they will not warm up sufficiently high quality.

Worn gaskets and nipples

Very often, due to the wear of the pads, the radiator itself flows. The reason may be a very low quality of water in the heating system. Then the owner sees how sometimes water drips or even flows in these places. To avoid this, you need to tighten the nipple in time.

Trouble-shooting

If it is not possible to replace the old battery with a new one, then in case of a breakdown it is necessary to fix everything as soon as possible. The best option would be to call professionals. But if the house has the necessary tools for the repair of the heating system, then everything can be repaired with your own hands, without waiting for the master and without draining the water.

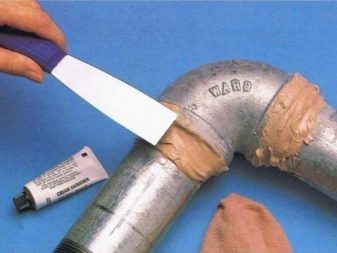

There are several ways to repair the radiator. It all depends on what kind of malfunction occurred. If there is a leakage at the junction of the battery, then it can be fixed with a medical bandage and epoxy glue. Such a restoration does not require much effort. To repair a leak, it is not necessary to remove the battery. You can even fix the problem without touching the radiator. You can also use cold welding. Since it resembles plasticine in some way, with its help you can simply cover up the flow.

If the leakage is big and the bandage does not help, then it is necessary to temporarily apply a small piece of rubber and tighten the leak tightly.

Sometimes with a strong leakage, the best repair option in an apartment will be the removal of a radiator. Of course, for the prevention of repair it is better to do after the end of the heating season. But it usually happens when the need arises.

Training

To properly troubleshoot, to work you need to be well prepared. First you need to find a leak, which is sometimes immediately visible. However, there are such leaks that are very difficult to find. In such cases, it is necessary to dismantle the battery and place it in a large dish with water, or in the bathroom. Bubbles will come out from the place where the hole is located.

After determining the location of the leak, the necessary tools and materials are prepared:

- Cable. It is better if it is thin and steel.

- Putty. This may be cold welding, epoxy, polymer sealant and other materials necessary for this.

- Bandage or fabric that is used to secure the putty.

- Metal clamp or electrical tape.

Ways and means

Since radiators are made of different materials, it is worthwhile to consider in more detail the ways and means of their repair.

To repair aluminum batteries, there are several ways. First of all, it is the replacement of sealing gum. To do this, it is necessary to dismantle the radiator and completely disassemble it into sections.

In order to eliminate the leakage in the aluminum battery during the heating season, it is necessary either to replace one section or completely remove the radiator. However, sometimes it is impossible to do. And then the best way is to use cold welding.

If there are very small defects in the radiator, then you can use solder for aluminum. But all this will be only a temporary measure, so that you can make a full repair at the end of the season.

Argon welding is considered the most reliable way to repair radiators, but it requires special training. However, when dealing with aluminum radiators, you need to remember that this material is very soft and requires careful attitude to itself. If you use them correctly, the issue of repair will never arise.

Since in no case it is impossible to solder aluminum, the question immediately arises as to which means are suitable for sealing the battery. Best suited for this flux of rosin and iron. They are covered with a previously cleaned surface of the radiator, and after solder is injected directly under the flux. Such a quick repair is suitable only for small leaks.

There are also several ways to repair cast iron radiators. The fastest and most effective option with a medical bandage. To do this, it is necessary to soak it well with glue, then wrap it tightly around the leak and wait a bit. After the glue dries, the repair must be painted over to the radiator tone. This simple method will ensure the tightness of the battery for a year or two.

You can also use a metal clamp. This ring is made of metal and has sealing plates. They are attached with two bolts.

Another way to repair cast iron batteries is cold welding. Its composition resembles plasticine. It is applied quite simply. It is worth a little stretch it until smooth and stick to the damaged place.Cold welding is not afraid of high temperatures, so it is used for very small leaks.

Work order

Repair work of different types of radiators is not too different. However, it is worth a closer look at them. After all, if the owner decides to do the repair of heating batteries with his own hands, then only step-by-step instructions will help to sort out some situations.

The first is to consider the order of repair work of aluminum batteries. First you need to prepare the surface of the radiator and apply a flux of iron and rosin on it. Next, with a heated soldering iron, you must wipe the area that was damaged.

After the rosin spreads over the entire damaged surface, lead-tin solder having an admixture of iron filings must be injected. The sealed aluminum battery must be painted again. Before this, the old paint must be wiped off with a special wash. Then process the sandpaper. The final touch is the battery painting enamel or heat-resistant paint. If it consists of sections, then you need to start with painting intersectional sections. The radiator must be completely cold.

Another thing - the repair of cast iron radiators. Immediately need to equip a place for repair. To do this, under the battery must be put or a piece of film, or oilcloth. For greater reliability, you can also put a bucket for excess water.

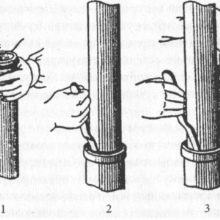

After that, you can begin to clean up leaks. Very often this is a joint located between the battery sections. If so, then you need to remove the old paint and the remnants of the destroyed strip. This can be done with a thin cable, which has small nodules at both ends. They need to clean up all damage to the metal. Rinse the cleaned area with either gasoline or acetone. This is done to more securely fasten the winding on the battery.

The next step is to blur the leak. To do this, it is necessary to mix either a metal powder or an epoxy resin and apply it on a tape made of cloth. Then the tape with the finished mixture must be very tightly wound on the butt of the radiator. It should be wound two or three times for stronger fastening. If zinc white was used as a putty, then there should be five layers.

Next, using a metal clamp to fix the area, which is smeared. To do this, it must be fixed with bolts and nuts, and the connection must be located opposite to the place of flow. Instead of the clamp, you can use electrical tape or rubber. Selected material must be wound several times the place of leakage and fix the wire.

After the end of the heating season, it is better to replace the repaired radiator or at least a separate section. If there is no such possibility, then it is necessary to repeat the processing of the damaged area again.

Even a bimetallic radiator is not immune from faults. Most often it is clogging with rust. To remedy this situation, it is necessary to clean the entire heating system.

Before starting work, you need to remove the radiator and disconnect it from the system itself. On the floor you need to lay an oilcloth. If the battery does not have a stopcock, the water must be drained from the entire system. Next, using a pipe wrench, you need to disconnect the radiator from the common system, drain the water from it and take it to the bathroom to do the cleaning.

In the bath itself must be placed a wooden pallet, so as not to damage it. Then it is necessary to remove the plugs from the battery and rinse it with a strong jet until clean water flows.If this does not help, then you need to apply additional tools that can affect the material, for example, ordinary vinegar. It needs to be poured into the bath for some time, and then also rinsed the battery under strong water pressure. Next, the plugs must be installed in place and assemble the bimetallic battery.

Useful tips

Doing repair of heating radiators, should heed the advice and recommendations of experts. This will help avoid unnecessary mistakes.

To slightly increase the heat emanating from the batteries, you need to paint them in a dark color. This is especially true for cast iron radiators.

Experts recommend installing radiators at a distance of 10 centimeters from the window sill, and the distance from the wall to the radiator should be at least 20 centimeters. If you disrupt the proportions of the installation, the heat flow will be disturbed. This will significantly reduce the efficiency of the entire heating system.

To increase the flow of heat into the room itself, it is worth sticking heat-insulating film on the wall behind the battery, the surface of which is made of foil.

The optimal distance between the floor and the radiator is from 12 to 15 centimeters.If it is more or less, temperature drops will lead to drafts in the house.

It is also worth considering that if the battery is connected in the opposite way, the power of the entire system will decrease by 7 percent.

A very important role in the efficiency of the heating system is played by the place of installation of the battery. The best option would be to place the radiator under the windowsill. At the same time, heat transfer will reach 97 percent. If the battery is partially closed, it will reduce heat transfer to 93 percent. When the radiator is completely closed, it will decrease to 80 percent.

The best option for apartment buildings would be cast iron radiators. After all, they not only withstand all the loads, but practically do not break. But even with the appearance of leaks, the problem is easily solved: they can be glued without even summoning the master to the house.

If we talk about bimetallic and aluminum radiators, then these are quite effective models. However, buying them is worth remembering that they can not be repaired. The only thing you can do is flush the battery or replace it with a new one.

To avoid radiator malfunctions, you need to choose the models themselves. But if the leak is still formed somewhere, do not panic. It is better to soberly assess the situation and see what can be done to eliminate it.

In emergency cases, you can solve the problem yourself, without seeking the help of professionals. Therefore, at leisure, it is better to study the features of the process and the sequence of actions. Indeed, in some cases, the delay in the repair work can lead to freezing of the radiator, and subsequently to its cracking.

About the properties of the process and the sequence of actions in the repair of heating radiators, see the following video.