Threaded fittings: variations and selection rules

When organizing heat and water supply, as well as sewage systems, it is necessary to calculate not only the number and length of pipes, but also various connecting elements, such as fittings. The operational features of the system depend on their proper selection and installation, and the risks of leakage of coolants are minimized. Threaded fittings have recently become popular as fittings for connecting several pipe sections.

Features and Purpose

Threaded fittings are designed for installation on pipes in branched sections, bends and places of sudden changes in diameter. Their distinctive feature is to ensure maximum tightness.And also they are installed in places where additional installation is necessary, for example, wiring to heating equipment. The use of threaded fittings makes it easy to connect control and recording devices. The fittings help to change the channel, angle or divide one common flow into several, if necessary. Threaded fittings are very convenient for installation and operation.

The most important advantage of a connecting fitting is the possibility of their dismantling.

If necessary, you can even independently dismantle, disassemble and repair this item.

Despite its versatility, threaded fittings are endowed with the following disadvantages:

- many collapsible parts compared to press fittings;

- for installation will take a long time;

- In order to avoid the formation of coolant leaks, care must be taken to wind the pipeline of waterproof material;

- require proper maintenance compared to crimp flanges; the nuts have to be tightened regularly as they loosen over time and cause leaks.

Threaded connectors are sold in the form of tapered and direct connections with a protective coating of nickel, zinc or chromium. They are mounted on pipelines with a cross section of not more than 5 cm. In terms of functionality, they do not differ from each other, only with technical features.

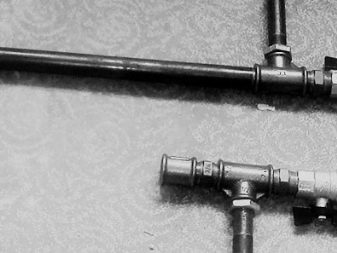

Kinds

Threaded fittings are divided into the following types:

- tees - are intended for connection of pipelines with any section;

- squares - change the direction of the heat pipe;

- couplings - for connection of fixed elements;

- branches - to change the direction of the pipe;

- plugs - for sealing products;

- nipple - to increase or decrease the pressure in the circuit;

- fittings - for ease of maintenance and operation.

Worth considering in more detail varieties of threaded fittings.

- Fasteners: metric and pipe (inch), which differ in thread pitch. Pipe thread is necessary for connecting in the circuits of water and heat supply, for connecting the nozzles of various circuits, filter elements and counters, as well as for cylindrical thread. The wall thickness of the pipeline depends on the maximum pressureformed in the contour. Metric is necessary to connect thermal devices and other recording devices. It is subdivided into internal (on nuts) and external (on unions) threads.

- Pipe drives - threaded connections on both sides. On the one hand, it is equipped with a five- or six-thread, and on the other, there are up to 30 threads. With the help of sgonki it turns out to attach fixed parts. A threaded fitting is installed in the threaded fitting, and on the other hand, a nut, coupling. The edge of the pipeline wrapped with flax and covered with a sealing ring. The coupling is screwed onto the edge of the pipe and is connected to the gantry. Flax is placed between the coupling and the nut using a crimp with a transition to the coupling.

- Taps are designed to change the direction of the pipe. Corner pipe bends are equipped with a ball, necessary to avoid buildup on the internal surface of pipelines. Bends are bent and steeply curved. In our country are popular products with a right angle. Steeply curved species have a small fold, which facilitates the arrangement of trunk pipes. But they do not compensate for the thermal expansion of pipelines.

- Tees are designed to create a complex construction of pipes, they fix the side connections to the central pipeline. They are divided into equal and transient. Adapters of the first type have the same diameter in all areas, and the second type - have different diameters. They are used with excess pressure and high temperature.

- Couplings facilitate installation when arranging pipelines without the use of welding equipment. At connection there is an opportunity to take pipes from different materials and section. The clutch classification depends on several factors:

- Internal or external arrangement of the thread. External thread is required for devices with different levels of stiffness, and internal - for devices with the same level of stiffness.

- Method of attachment. Transition - connects the two parts with different sections, equal pass - connects the pipes of the same diameter.

- The possibility of parsing the coupling. The use of collapsible models greatly simplifies their installation.

- Plugs are mounted in hard-to-reach areas, where it is often necessary to close the flow of the flow. They operate at a maximum temperature of the heat carrier +500 degrees and with an overpressure of up to 36 MPa.

- The fittings are designed for fastening depreciation elements, for the release of liquid and gas medium from the pipeline.

- Nipples are available in various forms: in the form of a hexagon, a barrel and others. Since this element has many detachable connections, the likelihood of leakage is very high, and it is also necessary to tighten the thread from time to time when loosening parts.

Materials

Products with threaded connections are made of brass, cast iron, bronze, stainless steel, copper. Brass and bronze threaded fittings are installed at the points of fastening and connecting pipelines made of copper. High reliability of parts is ensured due to the compression ring located on the inside of the fitting. For mounting the connecting thread, you only need a wrench, which tightens the nut to the required degree. It is necessary to be careful in order to avoid thread turning, which can lead to leakage.

Threaded connection of brass and bronze have the following negative properties:

- loosening the connection in case of untimely maintenance of the element, which leads to failure of the fitting;

- limited use with increased system pressure.

Copper threaded fittings are good because they are resistant to any temperature stress, simple to install and do not require much effort. Copper fittings are used to connect various types of pipelines. And they are protected from the corrosive destruction of the circulating fluid. Experts do not recommend using pipelines of various materials for the connection, as this will significantly reduce the service life of the circuit. If you still have to combine, you should avoid the combination of copper with galvanized or chrome-plated unalloyed steel. This combination leads to oxidative processes, as a result of which threaded products and end sections of pipes break down.

Steel threaded devices are required for connecting steel pipes "to the thread." It is easy to connect any shut-off and control valves to them. To increase thread reliability, it is necessary to wrap a fum tape on the part.

Threaded coupling devices made of steel differ in thread length, which depends on the type of materials and dimensions.The dimension table is indicated in the corresponding nomenclature, which is issued for people who dream of independently installing steel threaded devices.

Stainless steel threaded connections are designed to connect pipelines with different diameters. They gained popularity due to their functionality, affordable value and high quality. Inside there is a special sealing ring that allows the use of stainless steel devices for water and gas supply systems. The main advantage of connecting devices with a special seal is the possibility of repeated use even after disassembling or repairing a pipe section. Stainless steel products are common in the oil, gas, construction and petrochemical industries. And they are also used in every house in the heating circuits. These elements also allow you to change the direction of the coolant in the heat pipe.

Cast iron threaded fasteners have a long service life. The device is a threaded part on the end. Cast iron is also used in the manufacture of other locking devices.Pig-iron devices can be operated several times, they provide maximum tightness of the circuit. However, care must be taken to install a waterproof material. Ferrous metal products are notable for their low price, simple installation, during which no special tools are required. These are the most reliable and durable parts for metal pipelines. They have a significant drawback - it is low resistance to corrosion.

How to choose?

Most buyers opt for threaded fittings due to the lack of the need to connect two parts for soldering.

The choice of the optimal type of threaded fittings is carried out depending on the type, material of manufacture and operational properties, and the following parameters should be considered:

- fitting diameter, which should be equal to the cross section of the pipeline;

- thread inside and outside in millimeters;

- right or left;

- thread pitch;

- length.

Important! To organize the water supply, experts recommend choosing the right thread. It is located to the right of the heating equipment.The left-hand thread attaches the nozzles to the heating devices and is located on the left.

In the next video you will find more information about threaded fittings.