Features of the selection and installation of cast iron radiators

The modern market of heating devices is striking in its diversity. But the well-known cast iron radiators are still very much in demand due to its numerous advantages. They are durable, resistant to corrosion, unassuming in exploitation and extremely unreliable. But even the most reliable device may need to be replaced once.

Installation of a radiator can be done by hand. The main thing is to have the experience, the necessary materials and take into account the individual subtleties of installation.

Special features

All heating radiators, regardless of the materials used in their creation, as well as regardless of the shape and size, are equipped with an inlet and outlet.In the bulk of commercially available devices, these holes are duplicated to enable both the lower and upper connection.

Not all of the technological holes are involved in the installation process. To ensure the tightness of the device, special plugs are used, which are screwed into unused openings.

The necessary plugs (plugs) and fittings (connecting elements for joining with the pipeline) are not included in the standard package of the heating battery. As a result, you will need to additionally buy a special kit to install radiators.

Usually these kits are universal and suitable for cross-connection or side connection. But there are devices designed for the lower eyeliner inlet and exhaust pipes. In this situation, along with the main installation kit, it will be necessary to purchase a special node for connection to closely fitted connections.

Another important feature of the device of heating devices with a circulating coolant is the possibility of wall or floor mounting. In both cases, you will need to buy special mounting hardware - brackets.

Requirements

As a rule, cast iron radiators are installed under the windows.

At the same time it is necessary to follow certain requirements:

- It is necessary that the edges of the battery are strictly vertical.

- The offset of the center of the battery from the middle of the window opening should not be more than 2 centimeters.

- The distance from the top plane of the heating battery to the window sill should be no more than 5 centimeters. This is required for ease of repair, dismantling and maintenance of the device.

- The distance from the floor to the radiator must be at least 6 cm in order to easily clean the floor under the battery.

- The distance between the wall and the battery is set in accordance with the material and thickness of the walls, as well as depending on the method of installation of the heating device.

In addition, remember that in one room all heating batteries are required to be installed on the same level.

Specifications

Cast iron is a classic material for the production of heating appliances. Just from it were made the first batteries of the pre-revolutionary time, some of which continue to operate regularly in our time.In cast iron radiators for a long time there was no alternative. In the Soviet Union, steel batteries-convectors began to be actively installed in the central heating system only from the 70s.

Cast iron batteries are made by casting. Improved technology has made it possible to improve the quality of the surface, and the current industrial heating device looks no worse than popular radiators from other materials. But the most aesthetic is the appearance of batteries made of cast iron, implemented by the technology of artistic casting - such devices can be a highlight of any room.

Each battery, like the designer, is assembled from several identical segments. They are cast in the factory from gray cast iron. The channels through which hot water flows may have an elliptical or circular shape. At the assembly stage, the sections are connected to each other by means of nipples, and the docking areas are subjected to additional sealing. For this purpose, heat-resistant paronite or rubber gaskets are used.

Cast iron radiators from different manufacturers differ in the following characteristics:

They may have different widths (depending on the number of sections) and height. The width of the battery depends on the area of the heated room, the number of windows in it, the thickness of the external walls, since the more sections are used, the more heat the battery will give. If we talk about height, it can vary from 35 centimeters to 1.5 meters. It is impossible not to touch on such an indicator as the depth of the battery, because it depends on how harmoniously these articles made of cast iron will look in the interior of the room. Depth can be from 50 to 140 centimeters or more.

Power and heat transfer are the most basic parameters of cast iron heating devices. Manufacturers in the technical documentation indicate it for one section. The average power of the radiator section is 160 watts. In terms of heat release, cast iron batteries lose by a factor of two to bimetallic and aluminum counterparts. But this imperfection is compensated by a small inertia.

Cast iron is much longer able to retain heat and emit useful energy. The greatest effect from cast-iron heating devices is manifested in heating systems with natural circulation (EC) coolant.

The weight of each section is from 3 to 7 kg. The number of sections may be different.Weight depends on the specific modification and parameters of the heated room. After installing the radiator, you can add or subtract sections as needed. The height of the section is 37-57 cm, width is 8-10 cm, depth is 7-12 cm. The volume of the internal cavity can be from 0.7 to 1.5 liters.

The working (or the greatest overpressure) is the load with which the coolant affects the process of constant circulation through the heating system. Typically, this indicator ranges from 6 to 10 atmospheres. As a rule, the greatest overpressure corresponding to 9 atmospheres is taken as the normal load.

The maximum (or pressure) pressure characterizes what the maximum load a battery of cast iron can withstand at the time of the occurrence of an unintended water hammer. When the heating system is being tested, a load is formed inside the lines, which is most adapted to the pressure test. Typically, in modern modifications, the pressing pressure is in the range of 12 to 18 atmospheres.

Battery life of cast iron is quite long - 25-35 years, or even all 50. And it is much longer than modern batteries made of aluminum or bimetal. Long service life due to the rather impressive size of internal channels, which prevents the occurrence of internal blockages. In addition, cast iron does not enter into chemical reactions and is resistant to abrasive wear.

Cast iron radiators are produced by various manufacturers and are distinguished by a variety of models. Among the most common are heating devices such as STI Nova, MS-140 and Conner. Therefore, we consider the parameters of these devices in more detail.

Battery MS-140M-500 - domestic products from old cast iron, having a depth of sections of 140 mm and a center distance of 500 mm. It is actively used in private homes, city apartments and industrial premises equipped with a water heating system. The limiting temperature of the coolant should not exceed 120o C. These radiators have been manufactured since the times of the Soviet Union.

MS-140M-500 is a sectional and two-channel radiator. The number of sections can vary from 4 to 7. The volume of one section is 1.45 l. The nominal heat flux is 0.16 kW.The radiator is completed with 2 deaf and 2 end-to-end plugs, inside there are 4 gaskets made of heat-resistant rubber.

The power of one section of this radiator is 160 watts. The working (or highest overpressure) of the radiator is 9 atmospheres, and the pressure test (or maximum) is 15 atmospheres.

The weight of the cast-iron radiator MS-140M-500 depends on the number of sections. Thus, the weight of one section is 6.7 kg. The mass of the 4-section battery is 28.2 kg with dimensions of 388x588x140 mm, and the cast-iron battery with 7 sections weighs 48.9 kg with dimensions of 853x588x140 mm.

Cast iron radiators MS-140M-500 meet all the requirements of specifications and GOST. They are made of gray cast iron brand SCh.

"STI Nova" are domestic radiators with cast iron radiators. They have high quality and attractive appearance. It must be said that STI manufactures products of the middle price segment.

The parameters of STI Nova 500 batteries are as follows:

- The working (or the highest overpressure) of the device is 12 atmospheres, the pressure test (or maximum) - 16 atmospheres. Due to this, hydraulic shocks are not terrible for this model.

- The heat output of the radiator is 1.5 kW, which is enough to warm the room,the area of which will not exceed 15 m2.

- The design of this radiator is remotely similar to steel or aluminum radiators.

Basic technical information on Conner cast iron batteries:

- power - 120-180 W;

- the maximum temperature of the coolant is +110 degrees;

- the greatest radiator overpressure is 12 atmospheres, but the device is able to withstand a pressure of 20 atmospheres, hydraulic shocks to the Conner batteries are not terrible;

- Batteries have wide channels, therefore do not create strong local resistance;

- overall parameters, mass and capacity of sections of this modification is slightly lower, which of the above models.

Benefits

Among the advantages of cast iron batteries, it is necessary to designate resistance to the aggressive characteristics of the coolant. It is predetermined by the material of their manufacture - cast iron does not corrode for a long time, even at elevated temperatures.

All sorts of chemical additives in the coolant, as well as the iron oxides formed in the water pipes, are also not capable of causing the destruction of pig iron.

In addition to resistance to corrosion processes, such radiators have the following advantages:

- The possibility of repair in case of leakage and blockage.

- Thermal inertia.

- Acceptable price. If we compare the cost of batteries made of cast iron with the price of bimetallic devices that have recently become fashionable, then the first option will be much more profitable under the budget. And if you need to buy radiators not for one room, but for several, then the savings will be very, very solid.

- Can be operated at high pressure and high temperature. The working pressure of cast iron radiators is equal to 9 atmospheres and higher and depends on the modification and manufacturer. They tolerate water hammering and are therefore often used in district heating systems.

- A large percentage of the heat due to radiation.

- Easy installation.

- Long term work. If you periodically flush cast iron batteries, as well as replace gaskets between sections as needed, they will respond to such care with gratitude. They will last about 50 years, regularly heating your home.

Cons of products made of cast iron, turning into pluses:

- Long heat. Yes it is.The cast-iron battery heats up for a long time, since it is not a thin steel case. But imagine - there is a bitter cold outside the window, and the heating was suddenly turned off. Bimetallic, steel and aluminum radiators will cool down almost immediately, and the good old cast iron will still be heated for some time.

- Great weight. Awkward and heavy cast-iron radiator is not everyone able to lift alone, but thick walls give a heavy weight to radiators, due to which heat is kept for a long time.

- Unsightly view. Conventional cast iron batteries of the Soviet Union, of course, do not shine with beauty. Today exquisite art cast iron products are produced. Their surface is decorated with patterns in a wide variety of styles.

Kinds

Cast iron radiators can be:

- Single channel. In the structure of batteries of this type in each section there is a channel through which the heat-transfer fluid flows. Heating devices of this type are easy to clean, as a result, they are mounted in medical institutions.

- Dual channel. In one section of heating devices of this type there are 2 channels, which increases the thermal efficiency.

- Three channel. The characteristics of the thermal efficiency are higher compared to other types, while their mass and depth are much greater than those of their counterparts.

In two- and three-channel radiators, fins are used, which increase the heat output. Sections can be styled in a variety of styles, from retro to futuristic. At times, a metal casing covering the battery is used.

Two-channel type radiators are in demand because they are compact and have excellent heat output.

Also, radiators made of cast iron are divided according to the method of mounting:

- Wall mounted. Fixed on the wall through reinforced brackets. This method of attachment is traditional.

- Outdoor. Radiators are equipped with four legs. They are part of the extreme sections, because they are hard to break off. Batteries of this type do not require additional hardware - the wall will remain intact. Behind them it is convenient to carry out cleaning, since the distance from the wall can be much more than with the classical method of fastening.

Dimensions

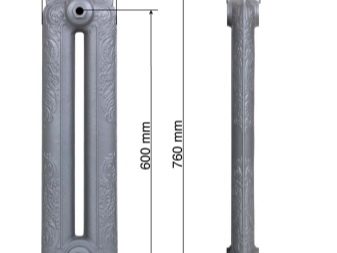

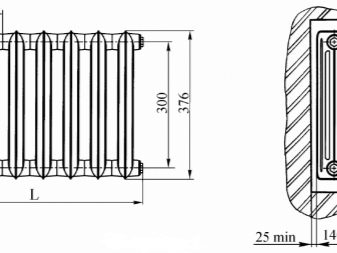

Despite the fact that the main criterion adopted by all manufacturers is the distance between the axles, but there are deviceswhich, having the same center distance, differ in height, width and depth.

Main settings:

- the distance between the axes is quite diverse and can vary from 220 to 900 mm;

- the height of the cast-iron radiator varies from 330 mm to 950 mm;

- depth is 85-200 mm;

- the width of the product can be from 45 to 100 mm.

Given this vast range, all products are divided into standard cast iron radiators, low and high. In each of these categories, one can find well-known “accordions”, antique-made devices, and luxurious palaces either in a modern style with a flat exterior panel.

How to choose?

The choice of cast iron radiator should be made in accordance with the technical characteristics specified in the manufacturer's manual. In addition, the indispensable conditions are the installation of the device according to the manufacturer’s instructions, as this will help prevent possible breaks.

To make the right choice of cast iron battery, it is worth knowing a few points that need to be paid attention to.

First of all, you need to decide on the type of radiator. It can be cast or sectional.If the choice fell on the first version, then there is something to think about. Monolithic product has a fairly decent weight, as a result, for its installation will need special holders (brackets). For such components will require some space under the sill.

Therefore, if the depth of the niche is not enough, then you can opt for a radiator with legs and simply acquire a sectional model, because it has a flat configuration. Therefore, additional space will not take.

When choosing a sectional model, you need to make the correct calculation of power, otherwise in the winter time the room will not be heated enough. If for some reason there is a problem with the acquisition of a beautiful product and you decide to buy the Soviet monolithic version, then you can close it with a decorative screen. But here we must remember that the decoration will take a certain amount of heat on itself.

Therefore, it is better that the screen was not solid, but, for example, in the form of a grid. As a rule, in an average-floor house, the greatest excess pressure is 9-10 atmospheres. But the battery is better to buy with a pressure reserve, for example, under 12 atmospheres. In order for the room to be fully heated, the width of the battery must be 75% of the width of the sill.

Since in modern water pipes cleanliness of water leaves much to be desired, besides it has impurities of abrasive components, then for mounting a radiator in a high-rise building one should choose a model with thicker cast-iron walls.

Installation

Installation of heating batteries is a responsible process. Neglect of the basic principles can lead to a weak degree of heating of the structure. The result may be forced repairs in the apartment or replacement of the heating battery in the winter.

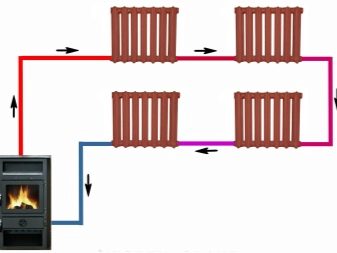

The first step is to establish how the heating system is organized:

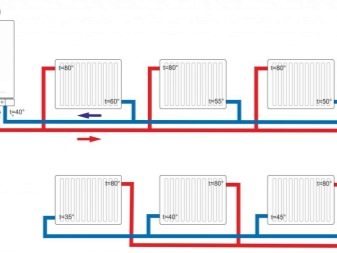

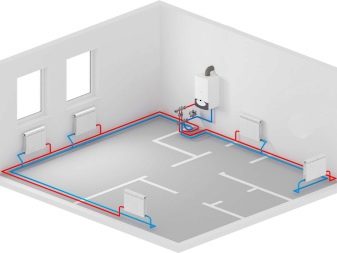

- The simplest wiring of one-pipe heating system involves a serial connection. To replace the batteries, it is necessary to completely shut off the hot water supply and drain it. This type of organization makes it difficult to replace cast iron batteries in a high-rise building. In winter, all apartments will be left without heating during the works.

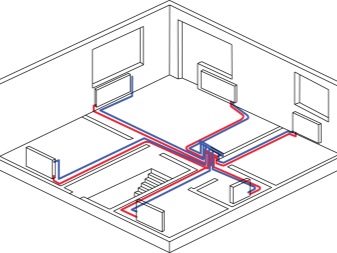

- The two-pipe heating distribution system is the parallel connection of each battery to two pipes: the outlet and the hot water supply. This is not an easy installation system, which has an advantage over a single pipe: at the stage of laying the systemthermostats can be put on the batteries to control the temperature in each of the rooms.

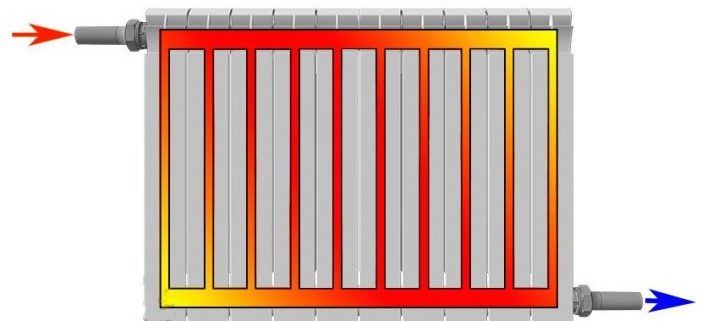

A big role is played by the method of connecting radiators to the heating system. The most common connection is on one side. The supply pipe is connected to the top of the battery, and the discharge pipe is connected to the bottom, which contributes to the optimal heating level. If hot water is supplied from the bottom, the supply pipe is connected to the lower branch pipe. As a result, heat transfer is reduced by an average of 6%. One-way connection allows you to put a jumper (bypass) between the discharge and inlet pipes. Such a transition in combination with valves that regulate the flow of water into the battery, make it possible to control the amount of heat in the room and install the pipe without disconnecting the central heating system.

The bottom connection is used if the pipes for the discharge and supply of the system go to the floor. They are arranged vertically and take up little space, do not spoil the overall appearance of the room.

Diagonal (cross) connection is more often practiced with large batteries, in the structure of which there are 12 or more sections.The supply pipe is connected to the upper part of the radiator on one side, and the discharge pipe is connected to the lower part on the opposite side. This method of installation, compared with one-sided, makes it possible to warm the remote sections of the battery.

It is necessary to take into account that the mass of batteries made of cast iron is much higher than the mass of aluminum radiators, which can be freely mounted to one. For high-quality installation of construction of cast iron must be invited to the aid of several people.

You can also contact the utility service responsible for maintaining your home. You can contract specialists who take into account all the details and in the event of accidental consequences will be responsible.

To install batteries from cast iron, you need the following tools:

- construction level;

- screwdriver;

- electric drill for making holes in the wall;

- roulette;

- sealing tape, sealant;

- marker or pencil;

- short and long keys for combining radiator sections.

Additionally, it is worth getting a torque wrench (wrench with built-in dynamometer).It will help to perfectly tighten the details in the pairing points. If tightened slightly, the battery in the joints may not withstand the pressure of the heating system, which will lead to leakage. And if you drag, you can break the thread. This will also trigger an emergency.

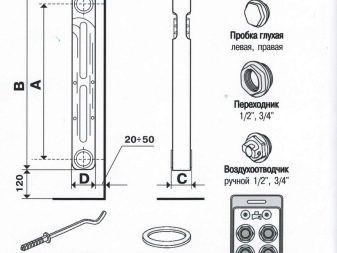

The battery pack contains separate parts for installation.

To install the radiator on its own may require:

- Drives for threaded connection of pipelines suitable for pipes of the central system.

- Depending on the connection plan, couplings, angles, adapters are necessary.

- The gates serving for overlapping of water from accessories of the battery.

- Adjusting valves to reduce the volume of the flowing fluid, which give the possibility of adjusting the heating temperature of the radiator, but are not suitable for complete shutdown, as a result, are mounted together with a shut-off valve.

- A tap to remove air that may accumulate in the pipes and prevent normal heat exchange. Mayevsky's crane (air valve STD 7073V (according to TU 36-710-82) is better not to use for cast-iron central heating batteries. It may not withstand the water hammer that occurs in this system.Significant contamination of the circulating water rapidly clogs the faucet, it will need to be replaced.

- Brackets for fixing the radiator to the wall. Their length depends on the type of wall and its depth. If it is trimmed with panels or plasterboard, which is located at a distance from the wall, then it is necessary to take into account the length and choose the appropriate fasteners.

- Bypass - when mounting the batteries in a single-pipe heating system.

It is necessary to determine in advance how many sections will be required. The standard principle of calculation is as follows: in accordance with all modern standards and rules applicable to heating systems designed for water, approximately 0.1 kW of power is required for one m2 of space. This figure is typical only for residential premises, for non-residential enough and 0.05 kW, or even less, depending on the true purpose of the room. For a more accurate selection of the number of sections of the radiator there are special tables.

If you take this note, then simple calculations can be performed by the formula

P = (S / P1) x100, where P is the required power, that is, the number of sections, S is the area of the room, P1 is the power of one section.

In this elementary equation, a single member is unknown, namely, the heating power of one battery section. As a rule, it is 150 watts, therefore, in all formulas, it should be taken to correspond to this indicator.

The sections are connected by means of nipples (nipple-nuts) in the lower and upper parts with the help of a special nipple wrench. This is a tool that has a flat end at one end (in the form of a blade), and a hole at the other, into which a metal bar or crowbar can be inserted to facilitate work.

The nipple nut is a piece of pipe with a groove under the sealing rubber ring and threaded at both ends.

In the holes of the sections there is an internal thread. From one end - right, from the other - left. On the connecting nipple-nut a similar system. Two mating sections must be placed on a flat plane, preferably on the bars - they will be more free to slide along them. Wear rubber gaskets on the nipple nuts, placing them in the middle. Bringing the sections at a distance equal to the length of the nipple-nut, gently screw the nipple into several turns by hand (it will twist into both internal threads of the section).

Similarly, the radiator key is inserted from the other edge of the section and alternately turning the key, then one nipple-nut, then another, we connect the sections together. We also attach other sections in the same way. If rubber seals are made from high-quality heat-resistant rubber, their lifespan will correspond to the battery life.

After assembly, the battery should be subjected to hydraulic testing on a specialized stand.

When painting batteries after assembly work, it is better to use a special heat-resistant paint, which must withstand temperatures of 80 degrees, not soften and do not emit harmful substances into the atmosphere. For the most part, use paints based on acrylic or alkyd enamel. Acrylic-based paints have a long service life, alkyd enamels are cheaper. You can also use water-dispersion paints, which bear the manufacturer's marking that they can be used to paint heating devices.

Before applying the paint, it is necessary to prepare the surface:

- Remove the remnants of old paint, dirt by washing.If the old paint holds firmly, you can apply a new layer on top of it.

- Sand the surface with sandpaper. It is better to use a drill with a special nozzle or a brush for metal.

- To degrease a surface with usual solvent or acetone.

- Apply a coat of primer corresponding to the paint used. Let it dry.

- Apply paint. To paint the radiator inside, use a special curved brush. To begin coloring it is necessary from above. The first part is painted inside the battery.

- Paint is better to apply in two thin layers. Each of the layers should dry well. So the paint last longer.

Before changing or installing batteries from scratch, it is necessary to drain the water from the heating system. If possible, it is best to use a pump.

If the replacement or installation of a radiator is made in the winter and central heating is working, the replacement must be coordinated with the utilities. Old batteries and mounts must be removed.

Before you get to work, you need to decide on the installation site. The heating device is placed on the site where the most significant heat losses are observed.Usually this is a place at the windows. Loss of heat is not excluded, even if you have modern energy-saving double-glazed windows. On the simple frames of wood is not even worth talking about.

If there is no heating device under the window, then cold air descending along the wall “spreads” along the floor. Installing cast iron batteries to the wall in this place will change the situation. Rising warm air prevents the flow of cold currents.

Another area of heat leakage is the area near the entrance door. True, this problem is usually faced by tenants of apartments on the ground floor and owners of private houses. In this situation, heating devices are installed as close as possible to the entrance. Choosing a place according to the layout, do not forget about a sufficient place for leading the pipeline.

Looking after the model of a cast iron battery, take into account the climate of your region. Acquisition of a device with high heat recovery will be justified only for very cold areas. Residents of the middle band will have enough radiators with average parameters, living in the southern latitudes suitable low appliances with a minimum number of sections.

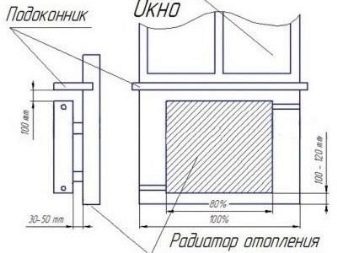

The installation of cast iron radiators should be carried out in accordance with the specific rules of location relative to the floor, window sill and walls.

To install, you must install the middle of the window opening. Then from this point it is necessary to measure the distance on the left and right to the fasteners.

To facilitate the assembly procedure and at the same time get rid of the formation of cold zones, place the radiator at a distance of 8-14 cm from the floor. Between the radiator and the window sill there should be a distance of at least 10-12 cm in order not to disturb the thermal convection and not to reduce the thermal power. Between the wall and the battery, the distance should be at least 3-5 cm.

The number of sections depends on the area of the heated room. But each manufacturer may have its own rules on how to mount the battery. Therefore, do not forget to carefully study the conditions contained in the instruction manual.

Connecting a cast iron battery to the heating system is a bit more complicated than installing aluminum radiators.

This process includes the following stages:

- Determination of screw-in points for brackets (holders) for subsequent fixation.If the battery is not one, you can use a template of thin plywood. In the plywood, drill the place of installation of the brackets and through them mark up at the points of the future location of the batteries.

- The number of holders is set as follows: one bracket is required for one meter of heating surface. The battery should be well fixed and not dangle, otherwise cracks may form over the interface to the pipes. If the radiator is heavy and the wall is not strong enough, it is better to use coasters.

- Holes with a depth of at least 12 cm are drilled, brackets are installed in them and fixed with cement mortar. For better grip with the pipe, the ends of the holders should be rounded.

- The thermostat is screwed to the battery from the connection to the pipe. On the other hand joins the air vent.

- If there are no taps in the heating system to shut off the water, it is necessary to fasten them to both pipes. With a single pipe heating system, a bypass installation is required.

- Install the battery on the brackets, align the accuracy with the help of the building level.

- Connect the structure to the heating system by means of evacuation. It is important to observe tightness. For reliability, you can use welding.

To check the quality of the connection, it is necessary to test the entire system using a crimp method. It is better to use the services of a specialist to ensure the quality of the work performed.

Conventional cast iron batteries are relatively bulky and have a not very presentable appearance. To improve their appearance, you can put decorative screens of a suitable color. An alternative method of heating is a shade for a cast iron battery.

If there is no possibility to use an ordinary heating method, the battery tenant is able to ensure uninterrupted operation of the heating system. It is a metal tube with a spiral soldered in its cavity. Between themselves, these elements are isolated by a special filler. Connects ten to the piping system as an accessory. In addition, ten, mounted in an old battery of cast iron, is fully capable of heating a small greenhouse, garage or other household structure.

The installation of radiator tens makes it possible to take advantage of all the advantages of electric heating - reliability, ease of operation, high efficiency. But unlike electric heaters, these devices are mounted directly into the system, as a result, they are completely invisible and do not require additional space.

Tips for installing a cast iron battery - in the next video.