Steel panel radiators: variations and advantages of use, installation tips

Steel panel radiators are used for space heating in closed-type heating networks, in low-temperature heating networks and other features. Manufacturing material - steel - provides good performance properties at a reasonable price, which distinguishes this type of radiator from devices made of aluminum and metal.

Radiators are available with various features, which directly affects their qualities. A large variety of models allows you to choose products for heating systems and rooms with different specifics.

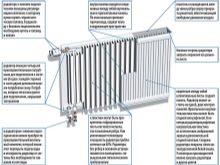

Design features

The steel panel radiator is a part of the heating system that is responsible for the transfer of heat to the environment. Such a product can consist of several blocks (from 1 to 3 panels), each of which can be made in a form that promotes maximum heat transfer.

Also the following characteristics are related to construction features:

- each panel is equipped with U-shaped ribs, which increase convection heating of the room by 50%;

- For the manufacture of the panel, two parts of pressed cold-rolled steel are used which are welded together (sometimes stainless steel is used for manufacturing), the standard thickness of the main part varies from 1.2 to 1.25 mm, and the ribs can be from 0.4 to 0.5 mm thick;

- Before painting, parts are primed by means of cataphoresis, after which a powder coating is applied (the main color of the products is white, but painting is possible to order in any other color);

- in the radiators of 2 or 3 panels there is often a decorative crate on top and solid panels on the sides;

- According to GOST, a standard single radiator has 2 nozzles on each side.

Specifications

For steel panel radiators, the main parameters are: pressure, heat transfer (thermal power) and operating temperature.

- Operating pressure. Products operate in two main pressure ranges.

- From 7 to 8 bar, which is typical for heating systems in European countries. Such a rule is due to the fact that the main building refers to the low- and mid-rise type.

- 10 bar. This indicator is used in most heating systems of the CIS countries (in particular - in Russia). For low-rise buildings (up to 5 floors) pressure of 4 bars is typical, for houses of a typical nine-floor building - from 5 to 7 bar, in higher buildings (above 14 floors) the pressure reaches 10 bar.

- Maximum working temperature. The standard for products of this class of radiators is a temperature of 110 degrees. Due to this indicator, they are not used in steam systems.

- Heat transfer. This is the main characteristic for any radiator - the efficiency of heat transfer from water through the metal to the room depends on it. This parameter is measured in watts and shows the amount of thermal energy transferred to the environment per unit of time.It is determined by heat transfer by features of the fins, panel size and mode of thermal operation of the heating system (water temperature).

According to the “EN442” standard, the thermal regime should have the parameters 75/65/20, where the first digit is the incoming water temperature, the second is outgoing, and the third is the air environment in the room.

In a mode other than this, the determination of the heat output of the steel panel radiator will require recalculation. For its accuracy, the factory product specification, correction factors and recalculation formula are necessary.

The main regularity is: the smaller the mode parameters, the more powerful radiators are needed to ensure the same room temperature.

Application features

Based on the design features and technical characteristics, a certain scope of application of steel panel radiators is formed.

The following points are characteristic:

- radiators are recommended for use in closed heating systems of private houses and new buildings heated by heat points and individual wall-mounted boilers;

- steel radiators are not recommended for use in apartment buildings with a central heating system and in private houses with a gravity system;

- The optimal conditions for steel radiators are heating systems with low-temperature conditions, in which condensing boilers are used (the optimum mode is characterized by an outlet water temperature of 50-55 degrees).

Kinds

Steel panel radiators are classified according to various criteria: according to the presence of convective fins, according to the connection option, according to the front panel version. In addition, there are various sizes of panels.

According to the presence of convective ribs, there are two main types:

- with convective ribs;

- hygienic panels without ribs, a distinctive feature of which is easy access to the inside of the product for cleaning, nor are they equipped with decorative grilles, but are used in rooms with increased requirements for hygienic standards.

Steel panel radiators are also divided into groups depending on the connection option.

- Side connection.

- Bottom connection. This product is equipped with two additional connections (3/4 HP or 1/2 BP), has a center distance of 5 cm and an integrated thermostatic valve insert.In this case, the thermostatic head must be purchased separately. The connections are located on the bottom right of the panel. There is also a variation with a central bottom connection, the nozzles of which are located on the bottom left. This single-pane version is quite popular.

According to the version of the front panel, steel radiators are divided into panels, the distinctive features of which are:

- ribbed surface;

- the plane and the smoothness of the surface - this feature is obtained by sticking a second smooth one onto a standard grooved panel;

- surface plane with horizontally or vertically intersecting grooves.

Steel batteries are also classified depending on the completeness of the radiator, the quantity and quality of the panels, as well as their size.

The type of panel radiator is indicated by two numbers: for example, in the number “21”, the first digit indicates the number of panels, and the second indicates how many of them are equipped with fins. In hygienic radiators, the second digit is always zero (for example, 30, 20, 10).

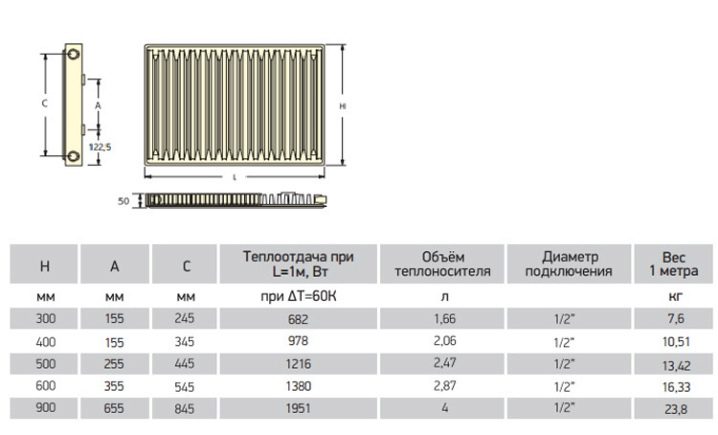

Dimensions of panel radiators:

- height of products: 200, 300, 400, 450, 500, 550, 600, 900 mm;

- product length: 400 - 3000 mm (with an interval of 100 mm).

Advantages and disadvantages

Steel panel radiators have a large number of different features, among which there are some positive qualities:

- reasonable cost allows you to choose radiators with high efficiency of thermal power, even with a modest budget;

- good heat transfer;

- a wide choice of types and sizes of panels allows you to choose the radiators of the required dimensions, which exactly fit the specificity of the room;

- a variety of connection options contributes to the convenient operation of the product with the extraordinary contours of the room;

- can be used in low-temperature heating systems due to the high heat transfer provided by fins;

- convenient thermoregulation is provided by low thermal inertia.

Also, steel radiators have their drawbacks:

- poor resistance to corrosion, which is weakened by the presence of oxygen in water (the worst period of time is the emptying of the system when the strength of the corrosion processes is maximum);

- devices deteriorate when there is dirt in the water;

- poor resistance to water hammering;

- low maximum working pressure (up to 10 bar);

- Due to the dominance of steel radiators convective heat transfer in the room should be good air circulation.

Manufacturers

When buying, you should take into account many features inherent in steel panel radiators and manufacturers rating. One of the main characteristics is the manufacturer, which determines the quality of raw materials and production methods that determine the final product. Given this, you should pay attention to several companies that have a good reputation.

Purmo

Purmo is a Finnish company with 60 years of experience.

The company's products are in demand in Europe and Russia for several reasons:

- high-quality assembly;

- double staining by electrophoresis, which ensures the strength and durability of the coating;

- product aesthetics that fit into modern design styles;

- wide range of;

- possibility of use in one- and two-pipe systems;

- Long warranty period (10 years).

Kermi

Kermi is a German manufacturer producing the highest quality steel radiators, the characteristic features of which include:

- modern design;

- high heat emission;

- a wide range of models of different sizes with the possibility of bottom and side connection;

- long operational term;

- electrostatic painting, made at a temperature of 180 degrees, which provides high strength and resistance of the coating.

PRADO

PRADO is a Russian company producing high-quality steel radiators adapted to the specific working conditions of hydraulic systems in the CIS countries and having good reviews. Can be used for single and double pipe heating. The material of radiators produced in Russia is high-grade steel 1.2 mm thick.

The company implements two main models:

- Classic with lateral connection of the heating main;

- Universal with lower type of heat supply and thermostatic valve.

Connection methods

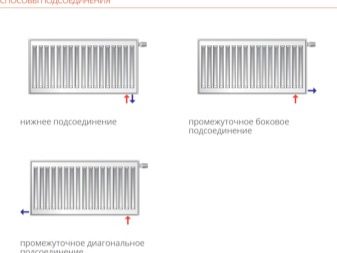

There are several basic options for connecting the coolant pipe to the radiator.

- Diagonal The variant which is allocated with the maximum thermolysis. With this method, a hot water pipe is connected to the upper branch pipe on one side, and the outlet line to the lower branch pipe on the opposite side.The passage of water throughout the radiator provides the highest heat transfer. If you change the connection vice versa (the incoming heat network is from below, and the outlet is from above), then the efficiency of heat transfer from the radiator will decrease by 10%. This scheme is chosen in the presence of long radiator panels and radiators, consisting of a large number of sections (more than 12). In order to improve the aesthetics, the supply pipe can be made inside the wall in the wall (it can also be held in the wall).

- Side one-sided. The supply of the heating system is connected to the upper bell of the radiator, and the outlet to the lower one. At the same time, the heat transfer efficiency (in comparison with the diagonal connection) decreases by 2%. If the connection is made in the reverse order (the supply pipe is at the bottom, and the discharge pipe is at the top), then the heat output will decrease by another 7%.

- Lower The inlet pipe of the heating system, as well as the discharge pipe, is connected to the radiator to the lower sockets from different sides. It is used when laying pipelines under the floor or on the wall (if there is no possibility to camouflage the pipe in the groove). The heat transfer efficiency is lower than the diagonal connection by 7%.

Selection and operation: tips and nuances

Selecting radiators for certain conditions, it is worth considering some features of steel panel radiators.

- For low- and mid-rise buildings, radiators with a working pressure of 8 bar should be used - this safety margin will ensure long-term operation without breakdowns.

- To arrange the side connection, you need to unscrew the thermostatic insert. The mount must be reliable.

- A prerequisite for effective heating with steel radiators is air circulation, as a result, it is not recommended to place the products too close to the floor and the window sill.

- It is better not to remove the original packaging until the installation is completed - so the coating will be better protected from damage.

- If a one-pipe heating system is used, it is necessary to add valves with increased flow capacity.

- When choosing radiators, it is not the width of the subwindow apertures that should be considered, but the necessary amount of heat and the corresponding heat transfer of the products.

In more detail about steel panel radiators will tell the following video.