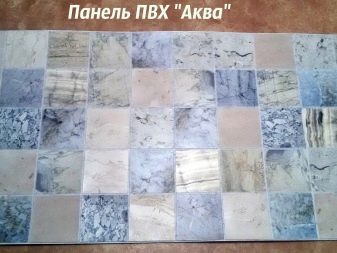

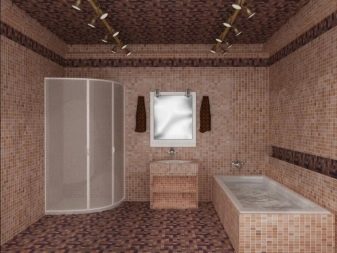

PVC panels with imitation tiles in the interior

For many years, the tile occupied the leading positions among the materials for interior decorating, while at the same time facing the rooms with high humidity did not have equivalent analogues. Despite the fact that operations with this material take a long time, require a technically trained performer and are quite expensive, they have found an alternative relatively recently.

In place of difficult-to-use ceramic tiles came inexpensive, with a mass of useful properties of PVC panels. Polyvinyl chloride has been known for a long time and has been actively used in industry, but gained popularity in the field of surface cladding not so long ago, due to the modernization of production and the improvement in the quality of vinyl panels, including their environmental safety.The product is absolutely competitive and easily occupied the niche of budget repairs.

The use of the material does not require significant costs, the work takes place in a short time and allows you to significantly change the interior without undue effort.

Features PVC coating under the tile

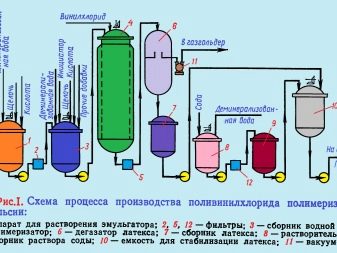

For polyvinyl chloride, invented more than a century ago, they could not find practical application for a long time, and only after World War II did production become widespread. Today, the material is actively used in industry, in particular, for the insulation of cables, the manufacture of films, floor mats and, of course, windows, doors and cladding panels.

Up to a certain point, the use in everyday life was not particularly popular, it was believed that the material was harmful to health. Today, the situation has changed dramatically, production has gone through a complete modernization, and it can be stated with confidence that plastic panels are absolutely harmless. The only situation in which PVC can be dangerous to humans is the release of harmful substances in the combustion process.

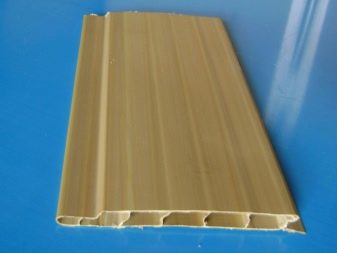

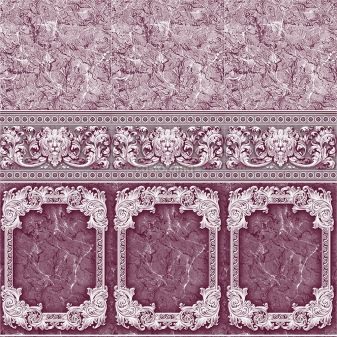

The panels consist of several layers., the inner part is a perforated substrate, and the outer one is a smooth laminated coating. A special film that is resistant to mechanical damage protects the surface of the product and guarantees, if properly used, up to 10 years of excellent appearance. An innovative approach to drawing a picture allows you to create images of any complexity and texture.

The unique coating has several advantages:

- increased water resistance;

- durability;

- heat resistance;

- easy to install;

- the surface is smooth, does not hold dust and dirt;

- ecological clean;

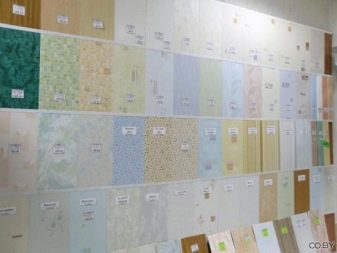

- a wide range of colors and textures;

- opportunity to implement personal ideas in design;

- masks the imperfection of the walls under the coating;

- does not require technologically complex care;

- perfectly amenable to cleaning;

- resists mold and mildew;

- affordable price.

Disadvantages:

- in the process of burning, they emit harmful substances potentially dangerous to humans;

- with a sharp temperature drop subject to deformation;

- In the first days after installation, a special smell of plastic is emitted; if poor quality raw materials were used in the manufacture, the odor may persist.

Types of panels

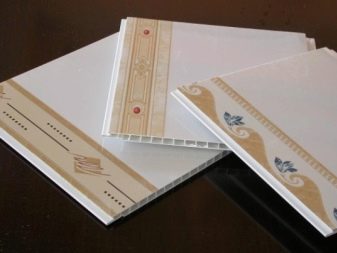

PVC trim with imitation tile is different in shape, there are three main types: sheet, square elements and plastic panels.

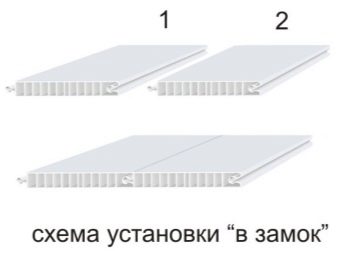

Plastic panels are characterized by high installation speed. Length 260 - 300 cm. Width from 15 to 50 cm.

A characteristic feature of square panels is the possibility of a personal choice of color layouts; you yourself create a unique pattern or ornament. The size of one side is from 30 to 98 cm.

In addition to fixing on the wall or crate (depending on the type of construction), the elements are attached to each other with a “thorn-groove” lock.

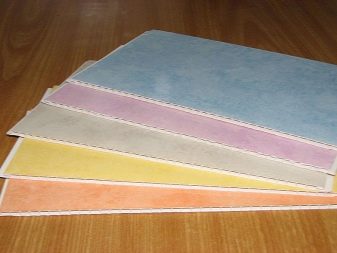

Sheet - looks like plywood sheetsThey are called PVC plates. The length is 80 - 203 cm, the width is from 150 to an incredible 405 cm. They are fixed with glue or nails, the joints are filled with colorless sealant or covered with a special batten.

Overall parameters of products are standardized by the manufacturer, their range is very wide. For example, the size of one side can vary by tens of centimeters.

Due to the unique features and quite affordable price, the material is ideal in order to significantly and quickly change the appearance of the room for little money.

Panels due to design features provide a wonderful thermal and sound insulation.

PVC panel selection options

There are external signs by which determine the quality of the coating for the bathroom and kitchen, be sure to pay attention to them.

- Always buy products from the same batch, otherwise you risk getting panels of different color that will be very noticeable. This is a very important point, be sure to spend reconciliation.

- Carefully inspect the panels for external damage and deformation at a right angle.

- The panel lock must have strength and at the same time sufficient elasticity. Flexing should not lead to deformation.

- Avoid too cheap coatings, these are products from recycled plastic and will last for a very short time.

- The pale yellow color of the panel material indicates a violation of storage conditions (in the open sun) or the use of low-quality dyes.

- An important factor affecting the strength is the distance between the stiffeners (partitions), the optimal 5 - 10 mm.

- The stock of cladding material must be several m2 larger than the actual size, it is necessary to take into account the inevitable costs for a segment in the corners.

- All dimensions specified by the manufacturer should be rechecked for compliance with the actual size, especially if the products are Chinese.

How are the panels under the tile?

Before you begin to mount the cladding on the wall, consider all the pros and cons of the available methods of installation. Fixing with glue or liquid nails has its drawbacks; if necessary, it will be very difficult to dismantle the panel.

It is easy to fix a tile imitating tile on the walls; there are two main ways.

Glue fixation

To use this method is obtained infrequently, one of the prerequisites for its use is as flat as possible walls, which is rare. For pasting you need a good quality glue, perfect "moment".

The surfaces to be glued must be clean and necessarily dry. The wall is pre-prepared, cleaned of the old coating and dirt. The working surface is leveled, the defects are filled with a solution, the excess is knocked down by a perforator. The wall is sequentially coated twice with a primer, and only after the surface is completely dry can the installation process begin.

Before work, be sure to read the instructions for use of glue and follow it consistently.

Installation of panels under the crate

Mounting cladding on the frame (crate) has Significant advantages with respect to the fixation method discussed above:

- no need for perfect wall preparation;

- design features mask communications, and, if necessary, provide easy access for repairs;

- crate is easy to assemble yourself.

When choosing material for the lathing, preference should be given to the metal profile. The construction of wood is not suitable for long-term operation in rooms with high humidity, wood deforms over time, and the assembled coating will lose its original appearance.

At assembly it is necessary to adhere to certain rules:

- fasten the structure at least 50 cm;

- the profile is always perpendicular to the direction in which the finishing is going;

- it is better to place the panels vertically, this will help to avoid water penetration at the interface;

- for fixing cladding use screws or nails, if you used wooden slats;

- always use additional accessories for decoration - baguettes, baseboards and the like.

Another interesting feature of this finishing material is the ability to change parameters depending on temperature conditions. The dimensions of the three-meter panel with a temperature difference from -10 to 40 degrees change by 1 cm. This property must be taken into account during installation, the panel must be brought into the room in advance and assembled at a temperature below normal. This will give the opportunity to get the most monolithic surface.

Experienced builders recommend temporarily using PVC panels for cladding bathrooms in houses of new buildings, for the time it takes the building to shrink naturally, and only then, after 3 to 5 years, to select ceramic tiles.

Features care for PVC panels

Vinyl is unpretentious to maintain, but needs periodic cleaning and has limitations on the use of certain chemicals.

What can be washed:

- water and a soft, lint-free cloth, this is enough for a successful fight against dust and minor dirt;

- in case of more severe contamination, special cleaners are used;

- the original brightness and richness of the colors will help return the 10% solution of ammonia.

What can not be applied:

- abrasive cleaners, they will damage the surface;

- solvents and degreasing agents, it will destroy the original appearance;

- alkali.

Make it a rule to pre-test on a small, secluded site any means that are going to apply.

Using

Modern synthetic polymer demonstrates positive characteristics, sufficient to press on the construction market of finishing materials recognized leader - ceramic tiles.

The inherent features of PVC panels allowed to form a new philosophy of repair, which is fundamentally different from all that has been traditional for decades.

The democratic price and the absence of the need for the obligatory attraction of a professional master brought the repair work using PVC to a completely new level of accessibility. Repair has ceased to be a high-budget project, requiring huge investments in materials and wages of hired workers.Now it is a process in which anyone with acceptable means can demonstrate the skills of a designer and realize his fantasies.

The coating is universal and can be used for walls and ceilings, including in rooms with high humidity. The low weight, ease of assembly, the minimum amount of garbage and the almost complete absence of noise make the work with plastic an exciting experience accessible to everyone. The ability to choose the shape, color and various textures of the panels will satisfy the most demanding customers. Today thin panels of lilac color are very popular.

Professional repair teams are happy to veneer PVC wall tiles at prices more interesting than when working with ceramic tiles.

How to install PVC panels with imitation tiles in the bathroom, see the next video.