Finishing the ceiling with plastic panels do it yourself

It is difficult to overestimate the importance of plastic in the life of modern man. This material has penetrated into the most diverse spheres of human life, and in construction and decoration it is completely used absolutely everywhere.

One of the most stylish and practical ways to finish the ceiling is steel PVC panels. A specialist with little experience in repairing or even a beginner will be able to assemble them.

In our article we will talk about how to build a ceiling of the panels on your own and save on the wages of finishers, whose services are not cheap.

Choice and difference from wall

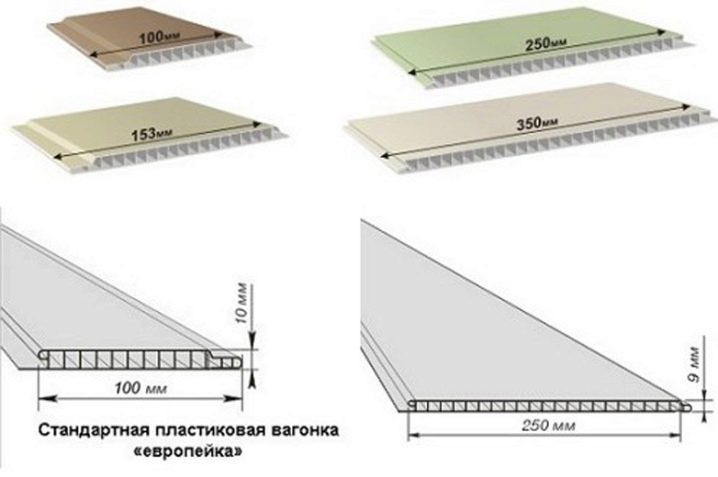

Ceiling PVC panels consist of two sheets of plastic, which are attached using special stiffeners. Along the length of the sheet, on one side there passes a large, and on the opposite side, a small anchoring strip. The large one serves for fixing the PVC sheet to the frame, and the small one - for adhering the sheets to each other.

All parts on the side have a spike, which contributes to greater structural strength. Ceiling panel manufacturers ensure that the product has a service life of 10 years.

Ceiling panels are conventionally divided into several types.

By type of compound emit:

- suture - after installation, the visible presence of a joint between the individual parts is noted here;

- seamless - the joints remain invisible from the outside.

Depending on the color solution, there are several types.

- Monochromatic panels are simple, but at the same time practical products, they are resistant to UV rays. Do not change their shade throughout the entire period of operation.

- Varnished - the surface of such panels is treated with a glossy layer of varnish, which strengthens the panel and also gives it a stylish decorative look. The disadvantages of such models include the appearance of scratches with minimal physical impact.

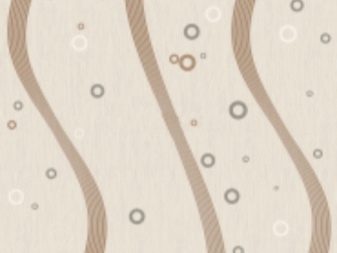

- With a pattern, a pattern is applied on the outside of the products. Such panels are made of softer plastic, so their price is lower, but the service life is also shorter.

- Laminated - panels imitate natural wood and stone,they are extremely sensitive to the effects of sunlight, under the influence of UV rays begin to crack and lose their consumer properties.

Plastic panels have several advantages compared with other finishing materials.

- they last longer than materials of natural origin;

- reliably protect the ceiling from the adverse effects of external factors;

- The material is easy to use, they are divided into sheet, tile and lath. it is easy to take care of them and it is possible to conduct electrical wiring under it (for example, plaster does not allow laying of wires).

Panels can have different sizes. The length of the ceiling plates is 270, 300, 400 and 600 cm. And the width ranges from 10 to 25 cm. Long panels are most often used in spacious rooms (industrial compartments, garages), and shorter are widely used in the repair of residential houses and apartments .

The shape of the panel is divided into sheet, tile and slatted.

- Sheet panels, as a rule, are large, they are fixed to the ceiling using small nails, and the holes are rubbed with special sealants.

- Tiled panels in their design resemble the usual tile-tiles, are small in size, are distinguished by aesthetics and ease of use.

- Rack materials look like lining, and are mounted in the same way with the help of special construction brackets.

Ceiling panels differ from wall analogues. Walling is much harder and more durable, as they must withstand additional load (shelves / furniture / other decorative elements). Plates for the ceiling opposite, are subtle and fragile. They have a low weight, which greatly facilitates their installation and fixation on the ceiling. At the same time, it is easier to damage them, but this cannot be considered a disadvantage - there is a minimum of physical impact on the ceiling, so the panels simply do not need to have a dense structure.

Pros and cons of the material

The main material for the production of ceiling panels is polyvinyl chloride, This is a very durable material with a number of undoubted advantages.

- it has a low cost - any average Russian can afford stylish PVC cladding;

- it is distinguished by universality - it is used in rooms of any type, style and purpose;

- hygroscopicity - plastic does not absorb water, shows resistance to the adverse effects of the external environment, does not deform and does not sag under the influence of humidity and temperature drops;

- the material is impact-resistant and wear-resistant - it is not exposed to damage due to medium and low force impacts, but of course, if you hit it with an ax with all your strength, it will break, but the material is protected from minor scratches and chips;

- long plastic life is well known - if the product is of good quality, then the most unpleasant thing that the owner of a plastic ceiling can expect over time is an insignificant color change, and even then only when he is under constant sunlight exposure ;.

- PVC panels are resistant to aggressive acid-base compounds, they can be easily washed with any cleaning agent;

- The material is characterized by good sound insulation and is a great choice for those who love peace and quiet;

- PVC panels are not terrible for floods - if neighbors flood you suddenly, then the panels are easy to remove, dry and hang back;

- If one of the panels loses its original gloss or breaks, then it can be easily and simply replaced, such repair does not require the replacement of the entire ceiling covering.

However, not without material and flaws. In particular, the ceiling should not be installed in rooms where high air temperature is constantly maintained. In such conditions, the coating is quickly deformed, fix it will not be a single opportunity. Plastic, especially if it is of poor quality, can release harmful and toxic substances. That is why you should abandon its use in bedrooms and children's rooms.

High-quality building materials a priori must be combustible. In practice, unfortunately, it turns out differently, and then not to avoid a tragedy. To avoid this, you should purchase products only from trusted manufacturers.

Calculation, tools and accessories

As already mentioned, the thickness of modern ceiling panels is in the range from 5 to 10 mm, the width is 250-500 mm, and the length ranges from 2,700 to 3,000 mm.

To calculate the required number of panels, you must calculate the area of each panel, for this its length is multiplied by the width. Then you should make similar calculations and calculate the ceiling area. Everything is simple here: the ceiling area should be divided into the area of one panel, and then add 15-20% as a reserve.If as a result of the calculations a fractional number is obtained, it is better to round it to a larger one.

It is equally important to correctly calculate the required number of rails and metal profiles. To do this, you can make a scheme: draw a reduced ceiling plan, apply longitudinal lines, setting a distance of 500-600 mm between them - this is how the amount of material needed is obtained. Well, the number of screws is calculated on the basis of the number of profiles and the standard fixture fixation pitch of 30 cm.

In each calculation you need to add stock. As practice shows, people with little experience often have to buy the necessary components for finishing.

Training

When carrying out the preparatory work preceding the ceiling, it is not enough to calculate the amount of materials needed. It is worth focusing on the presence of cracks, chips and other surface defects.

The following is a complete list of tools that may be needed in the work.

- A hammer drill will be needed when mounting the frame.

- Screwdriver is used for fastening panels to bars or metal profiles. In principle, a puncher can be used for this purpose, but it is rather heavy, therefore it will be difficult for a beginner without experience to cope with it.

- A construction stapler will be needed if the ceiling panels are mounted on brackets.

- Level is used to improve the accuracy of markup.

- Marker - for various marks.

- Roulette.

- Circular saw or jigsaw - will be required during the installation of the frame for cutting the profile elements.

- Ladder. Since it is supposed to work at height, therefore, you need a fulcrum. In the absence of a ladder, you can use a regular table, but a professional tool is still safer and more reliable.

- Rubber mallet - used when fitting PVC panels.

- Corners.

If you plan to design decorative items, you should purchase a molding.

After all the necessary calculations have been made, and the tools have been purchased, you can proceed to surface preparation and finishing directly.

To do this, do the following:

- old coating is removed;

- all lighting and electrical equipment is disassembled;

- the ceiling is cleaned of dust and dirt.

After that, the surface of the ceiling should be tapped with a hammer - this will make it possible to detect defects that must be corrected before starting work.

Preparation is finished by applying a primer.After the surface dries out, start installing the ceiling itself.

Mounting options

All work on finishing the ceiling with PVC panels can easily and even be carried out by a non-professional. However, you should know the main nuances of the various methods of installation.

As a rule, the panels are fixed either frameless or with the use of a hinged frame.

Crate

One of the ways to mount the panels is to mount on the frame. This is especially true when it comes to uneven surfaces. The basis of the frame - crate. This is a device that allows for high-quality installation in any type of premises (with a high level of humidity, unheated, etc.). To install the frame does not require the involvement of specialists, all the work can be done by hand.

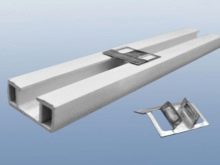

To fix the crate, you should use a wooden bar, strips of plastic or metal profile.

The choice of material depends on:

- the height of the irregularities on the surface of the ceiling;

- moisture level in the room;

- experience of the master with materials of different types.

Plastic crate is easy to install.It can be used in rooms with any level of humidity, in addition, plastic is a cheap material, which is also a plus of such a batten. Since the PVC frame elements are small in thickness, these floors can be glued in rooms with low ceilings. In this case, the height will be reduced quite slightly.

However, on the shelves of plastic profiles for crates are rare guests. Find them in the free market is quite problematic. The disadvantages of overlap should be attributed, and the ability to use only on flat surfaces. If the base defects exceed 5 mm, then it will not be possible to achieve perfect coverage.

Metal and wooden crates are more popular due to their affordability, durability and resistance to adverse weathering. These materials have long and firmly established themselves as the most optimal for the production of cladding for the ceiling and further fixing the ceiling tiles.

Suspended frame

High-quality finish ceiling panels - although a simple matter, but it requires great care and thoroughness.

Frame construction is used in rooms with high humidity, as well as in poorly heated rooms. Otherwise, the coating is quickly deformed, and with time it will completely become unusable and simply disappear.

The frame is a crate, which is mounted with a standard pitch of 40 cm. Then the panels are screwed directly to the suspended frame. You can sheathe them with nails or screws.

You should not cut the panels in advance, it can lead to unpleasant surprises and waste material damage. It is more expedient to cut the plates after the fact, applying to the crate and fixing the boundaries of the required element.

Lastly, it is necessary to dock the panels and decorate the joints; for this purpose, use skirting boards and polystyrene borders, which are installed with the help of liquid nails.

As you can see, there is nothing difficult in fixing panels to the ceiling; even an amateur in decoration can handle the work.

Frameless method

A simpler way to install ceiling tiles is considered the frameless method. In addition to the above materials, in this case, you will need glue on which the plates will be fixed on the ceiling.

Recommendations for the implementation of such work:

- the treated surface is cleaned from dust and dirt, and then primed and covered with an adhesive (optimal use of a notched trowel);

- glue should be applied on the reverse side of the panel either in strips or pointwise;

- the panel should be attached to the ceiling with a force of a few seconds;

- after the pressure stops, the panel can be released and its location corrected.

This method has one major drawback - it does not allow to sew spotlights, LED strips and other light elements, therefore, for example, a two-level ceiling will not be sufficiently effective. That is why, even before the start of work, you should consider a way to strengthen the panels, so that later you will not regret the lost opportunities.

Manufacturers

Venta - Belgian company, a leader in the construction market. Under this brand are manufactured panels with a variety of technical parameters and design. More recently, the company has mastered the production of panels with digital printing.

Forte - manufacturer from Italy, having a world name. Successfully produces and sells its products on the market since 1969.The company is obliged by its success to introduce the most advanced technologies, to constantly improve the management of the organization and to strictly control quality systems. The company tries to put on the market products in the widest range, which allows to realize any design ideas in your home.

Russian factory "Planet Plastic" from Moscow has been presenting its products in the domestic market since 2001. All production is based on the use of imported materials and is carried out on foreign equipment. The company offers its customers more than 150 types of panels.

Another manufacturer - "Ural-Plast" from Magnitogorsk. Production capacities of the company also work at the expense of imported equipment, the breadth of the range here is shaped by stylish, original and truly exclusive designs.

Manufacturer "AnV-plast" from Krasnodar declared itself in 2001 and in a short time achieved success in its industry. The company adheres to the principle of support of the domestic manufacturer, so all raw materials for the manufacture of PVC plates are purchased only from Russian companies, which significantly reduces the cost of products and allows us to make it available to most compatriots.

Installation of plastic panels on the ceiling, see the following video.