PVC wall panels in the interior of the bathroom

Bathroom - one of the most difficult rooms for repair. A large number of hard-to-reach places, the availability of communications, and plumbing lead to hard work on decorating walls, ceilings, and floors. Tiling a bathroom is a time-consuming process that requires patience, effort, and certain skills in finishing work.

Recently, it became possible to repair the premises using plastic PVC panels. They are less whimsical in the installation process, easy to clean: they have a smooth surface that is easier to clean than ceramic tiles. For finishing the bathroom with PVC panels, no special skills are required. Even a non-professional can cope with such work in a few days.And most importantly, at a cost of material is available to everyone.

Difficulties of choice

When buying, there are several important details that are worth focusing on.

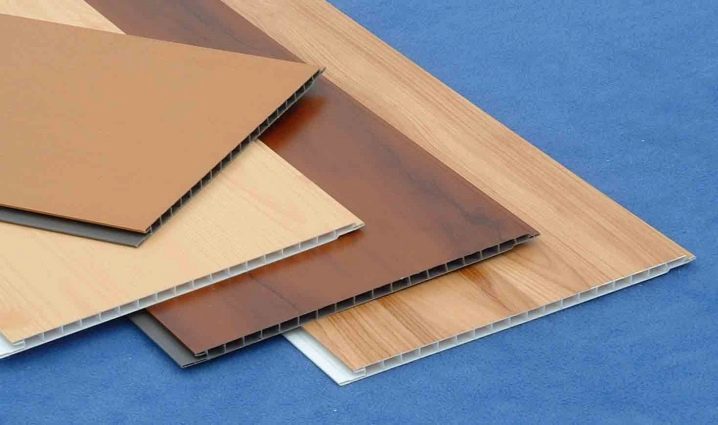

- Internal transverse ribs. The more of them, the more reliable the panel during operation. Hollow products are easy to break.

- Uniform pattern application. Products from different delivery lines may have slight differences in shade.

- No defects, dents, scratches, chips. It is necessary to carefully review each panel, otherwise with the subsequent exchange of goods with the same pattern and part number it may be from a different batch and differ in color.

- The smooth alignment of the two panels across the entire surface is checked before buying in the store. If at one end of the docking is tight, and at the other there is a gap of 3-4 mm, then it is better to refuse this product.

There is a way to check the quality of the plastic product. It is not applicable in the store, but it is useful in everyday life. A small piece of the panel is cut at the back along the entire length. The front part remains intact. The panel is bent forward at a right angle at the incision site. If the product does not burst during bending, it means that it is of high quality.

Standard sizes

The thickness of the PVC wall panels for finishing the bathroom vary. Too thin can be damaged during installation or transportation. Too thick product is difficult to place in narrow places. The best option would be a thickness of 5 to 10 mm. Depending on the manufacturer, the length of the panels is 260 cm, 270 cm, or 300 cm. This allows you to calculate the right amount of material and the possibility of combining different color inserts. The width of a standard product is 25 cm, some manufacturers have a width of 30, 35, 37.5 cm. The wide versions are 1 m and 1.2 m in size.

Depending on the size of the panel are divided into four types:

- rack and pinion;

- wall standard;

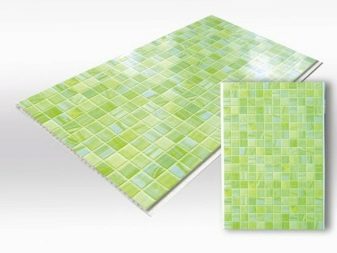

- tiled;

- leafy.

Slatted in width, the narrowest and for the decoration of the bathroom is not suitable. Sheet panels are too wide and are used more often to finish the facades of buildings.

For a bathroom with small dimensions, wide products can fit badly in size. Before buying it is better to calculate the number of panels in advance, depending on their width and length.

Advantages and disadvantages

As a finishing material, PVC panels have their pros and cons.

The advantages include some points.

- Durability and durability. This material is more difficult to damage after installation than drywall.

- Easy to install even on uneven surfaces. With minimal effort and effort, the interior of the bathroom is updated.

- The ability to hide pipes and other communications behind the box with access to the counters and valves. From the panels, it is possible to make complex structures, even small opening doors.

- Practicality and ease of care. The material does not absorb pollution. The smooth surface is easy to clean. PVC tolerates the use of modern detergents.

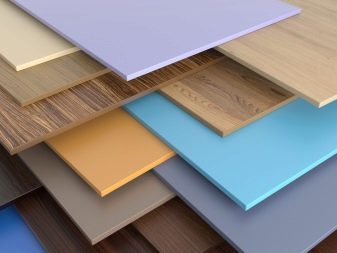

- Rich color palette. Modern manufacturers offer a huge selection of colors, patterns and textures of PVC panels, for example, 3D version or vinyl models. Sheathing the room can be any option you choose.

- Moisture resistance, the absence of mold or mildew on the surface of the product. In comparison with other facing plate materials: MDF panels, plasterboard, PVC panels are not affected by moisture.

- Resistance to temperature fluctuations.Tests have shown that polyvinyl chloride can withstand drops from -50 ° C to + 50 ° C. The material can be used in the country for facing gazebos or verandas.

- Low price. The material has a budget cost, and the purchase of ceramic tile is less profitable for the family budget.

Some minuses inherent in this material:

- brittleness during installation, requiring some care;

- heating elements should not be placed close to the plastic material, it is desirable to leave the gap about 3-5 cm;

- the space left between the wall and the panel during installation may undergo fungal changes that are difficult to see without dismantling.

DIY assembly

The application of PVC panels is done in two ways.

- The first way to frame or using crates. With the alignment of the wall and fastening directly to the surface using glue or liquid nails.

- Without leveling the wall on a prefabricated metal or wooden frame with fasteners, glue or liquid nails.

Frame method

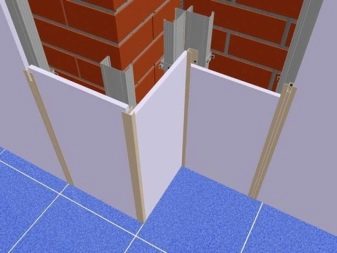

The first method is less laborious and expensive, does not require special skills in construction and takes less time.A metal frame or from wooden slats is applied on the entire surface with the help of dowels. The junction of the wall to the floor and ceiling must be marked with strips. Between them, horizontally and vertically in size, we nail or fasten with screws of the rail or a metal profile. To prevent the panels from arching, the distance between the horizontal bars should be left at least 40 cm.

If it is intended to hang shelves, cabinets, mirrors, then an additional bar is placed on the right level. Vertical racks must be placed in the corners on both walls, and between them we also attach several additional verticals.

It is necessary to start facing with plastic material from the far upper corner from the entrance. Moreover, both horizontal and vertical installation of the material is possible. Special attention is required when installing only the first panel. Accurately attaching the first panel, the rest are connected automatically. The panels are installed on fasteners, glue or liquid nails. When using lathing, it is possible to fix the finishing material with a construction stapler and staples.Between themselves, PVC panels are connected through the side grooves, tightly fitted to each other, with no visible seam. It is desirable to process the joints with sealant. A plastic molding is installed in the corners for a stable structure and aesthetic appearance.

At registration the molding, face, and also a plastic plinth is also used. The number is determined individually depending on the projections, angles and design features.

Advantages of frame method:

- simplicity of preliminary finishing works;

- replacement of the damaged part without the need to disassemble the entire row;

- the ability to quickly dismantle the structure.

There are significant drawbacks of the frame method:

- moisture can accumulate in the gaps between the wall and panels, which leads to the formation of mold;

- the already small area of the bathroom is reduced due to the thickness of the metal profile or wooden slats;

- internal clearance gives the structure fragility.

It is recommended to pre-treat the walls with a special mold antiseptic.

Frameless method

The second installation option involves mounting the panels directly to the walls or ceiling.To do this, it is necessary to pre-remove paint and other old materials from the wall, leveling the surface.

Significant advantages in this version:

- fragility of each element decreases;

- there are no gaps between the wall and the panel covering in which moisture could accumulate and cause the formation of a fungus;

- room sizes remain almost unchanged;

- fewer work related to measurements and making the frame.

The disadvantages are the impossibility of replacing the damaged part and the difficulty in dismantling.

How to carry out the decoration of the walls in the bathroom with plastic panels, see the following video.

Drawing and color

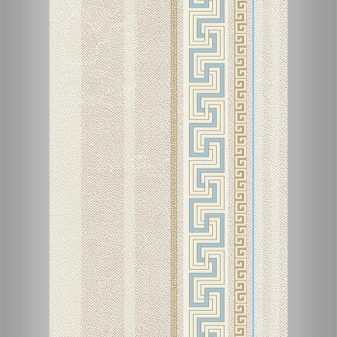

According to the method of applying a color coating, panels are laminated, printed and fully colored. When laminating a film with a pattern is applied to the panel, then the surface is treated with a special compound that allows you to keep the color for a long time. The second method involves printing a picture directly on a plastic surface. The drawing, made in such a way, is short-lived, quickly burns out and abrades during wet cleaning.

Monochrome panels are originally produced in a specific color. The coloring composition is added to the polyvinyl chloride base, and the panel is cast colored to the desired tone. Often produced pure white versions. Plain panels are also used for household decoration of the bathroom.

PVC panels presented in stores amaze with a variety of patterns and rich colors. The design of the bathroom can be issued in any color and style. If you choose light colors, it will visually expand the room, and it will not seem so small.

An interesting and unusual will be a combination of different color products. The alternation of light and dark shades around the perimeter will create the impression of an expensive and stylish finish. The wooden texture of the material will bring the bathroom closer to the country style and will resemble a sauna or a country bath. Now it is becoming a fashion trend.

The color of the walls and the ceiling under natural marble looks like an approximation to the classic design of the room. There were PVC panels with photo printing, a variety of patterns which allows you to create a unique design in the bathroom. This material is easy to combine with the use of other finishing materials.

Domestic manufacturers

- LLC "Ural-Plast" produces panels on the latest technology. Products successfully pass the quality check. The color scheme is rich and diverse. Price segment is average.

- Anv-Plast LLC specializes in printed or monophonic products. Price budget.

- Green Line engaged in the manufacture of plastic finishing material from environmentally friendly raw materials. The range is extensive: colors, patterns, textures represent almost all possible types and shades. The cost is average.

- LLC "Planet Plastic" manufactures its products based on the experience of European manufacturers. Used printed method of applying the pattern on PVC. Price category is average.

PVC panels are able to hide the defects of the walls, they are easy to install and easy to clean. They are well tolerated by moisture and temperature changes. Their rich color spectrum gives plenty of room for imagination, and low price saves the family budget. Stopping your choice for finishing the walls in the bathroom on this material, you can not worry about the durability and durability of plastic panels.