The ceiling of plastic panels: the pros and cons

When it comes to finishing the ceiling, the market can offer a lot of finishing materials. Among other types of coatings today plastic panels are in the center of attention. They noticeably stand out against the background of analogs; they have a number of features, advantages and varieties. Consider the relevance of this finish, examine the popular design, size and subtleties of choice.

Special features

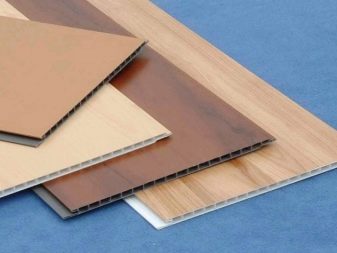

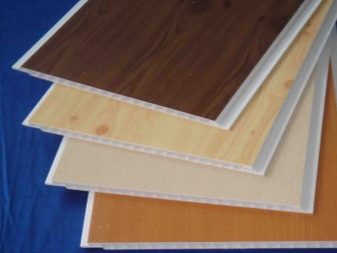

Plastic panels are a modern finishing material based on polyvinyl chloride (PVC). Composition is a sort of chemically resistant plastic. Externally, the design of PVC panels is similar to an elongated rectangle. It consists of two sheets of plastic of identical thickness, connected by stiffening ribs.They are perpendicular to the plastic sheets.

The cavities between the sheets cause the ease of this finish. The length of the panel has two mounting shelves: mounting and small. The first is necessary for fixing the panel to the ceiling frame. The second is used to connect the PVC sheets to each other. Locks of the wide side resemble the lock fasteners of laminate boards.

Panels are made of polypropylene chips with the addition of solvents and plasticizers. They are combined into a pasty mass using an industrial mixer. After uniform mixing, they are squeezed out through special nozzles of the production unit, while cutting along the length with a special guillotine. The width of the panel depends on the width of the nozzle used. After the plates exit the extruder, they are painted and then coated with varnish.

Plastic panels for the ceiling are different from wall analogues. For their production, plastic of smaller thickness is used. It is designed for interior decoration. Therefore, such panels are lighter and thinner than wall varieties. This is convenient for work and does not create an additional load on the frame.This is a separate type of panels that you need to consider when choosing: for vertical and horizontal planes they buy a different lining.

The use of panels for decoration of the ceiling significantly saves time allotted for the preparation of the base. You do not have to buy additional building materials to level the ceiling. No sanding or priming required. Installation is carried out on a frame, created by means of bearing profiles.

Such material does not absorb odors.

Advantages and disadvantages

The use of plastic panels for the ceiling has several advantages. We note the main.

- Installation of the ceiling, including cutting and mounting, is simple. It will take a little time, and the result will please the aesthetic appearance.

- You do not have to contact specialists: the work can be done independently without unnecessary waste and preliminary preparation of the foundation.

- Plastic panels are distinguished by an acceptable price. Their purchase is possible for everyone: it will not hit the planned budget.

- Ceiling plastic panels are distinguished by a wide choice of colors. You can choose varieties in any color and pattern, making a choice between a variety of texture and color contrasts.

- Plastic panels can be a bright accent of any design.They successfully fit into the interior of classical, modern, ethnic, ecological and vintage styles.

- They are convenient to carry. You can not be afraid that during transportation it will break.

- They are available to everyone. They can be bought at any hardware store, choosing to your own taste. If desired, you can decorate the ceiling with fragments of contrasting shades. This will bring freshness to the design and will emphasize the individuality of a particular room.

- Plastic finish is standard. Facing allows you to make the ceiling smooth, free of defects with little labor.

- Ceiling panels made of plastic are easy to clean. You do not have to scrub for a long time dust, dirt and soot. The surface does not absorb dirt, you can remove it with a damp cloth or a semi-dry sponge.

- Ceiling coating withstands temperature drop. Plastic is not deformed by moisture, it is protected from soot and fumes.

- If one of the elements breaks, it can be replaced. It’s easy to do, you don’t have to start from scratch.

- This coating hides all the shortcomings of the base, which is not a whitewash and painting.

- This facing material can be an independent decoration of the ceiling or its bright center. It goes well with ruga finish, so you can create a unique design in the style you want.

Due to the high-quality performance characteristics it can be used in different living rooms and utility rooms. You can decorate with this material the ceiling of the bathroom, bathroom, kitchen, dining room. You can make a bright accent with his help in the interior of the living room, study, home library, arrange the ceiling of the glazed loggia or balcony.

Sometimes these panels trim the ceilings of hallways and corridors.

With a thorough choice of material and texture, they will harmoniously look in the interior of a city apartment or a wooden house, as well as in the country. With seeming simplicity, it allows installation of two-level ceilings. If necessary, it can be removed and reassembled. The technology allows the laying of insulation between plastic panels and ceiling ceiling.

The use of plastic panels for the ceiling allows you to visually beat the design features of the premises. For example, with their help, you can zone the space. By choosing this decor, you can unobtrusively select one of the functional areas of the room.

Minuses

Despite a lot of advantages, PVC panels are not without drawbacks, we denote the main ones.

- Plastic is not designed for significant mechanical damage. If you accidentally hit the panel or touch it with a sharp object, scratches or chips will remain on the surface. This will in the moment make the surface of the entire facing careless. Thin sheets of plastic break easily.

- This finish looks easier compared to liquid wallpaper, wood imitation. To make the interior of a particular room special and stylish, you will have to choose the finish especially carefully, playing with the simplicity of the surface.

- With ease of installation and the possibility of masking electrical wiring, it is necessary to make concrete upper slabs of strobing.

- Not all products are made equally. The number of edges between the plastic plates is different. The smaller they are, the worse the panel, it affects the durability and strength.

Despite the fact that plastic ceiling panels take on different types of recessed luminaires, you need to select light sources thoroughly. You can not use to illuminate anything other than LEDs.They do not heat up like other lamps, so they will not melt plastic. Heating plastics is hazardous with harmful substances in low-cost varieties. At the same time, toxins are emitted into the air, causing significant harm to the health of the household.

Regarding the fixtures should be added: installation implies surface and pendant models. However, they should not be massive. The built-in dot LEDs with silver or gold-plated frame look great with them. Such lamps shine brightly, look stylish, decorate plastic.

Massive chandeliers are not combined with plastic panels: they are intended for classical design trends for which plastic is not suitable.

Types of designs

To date, all manufactured panels for the ceiling based on PVC can be divided into two types:

- seamless;

- sutures.

The design of seamless and suture varieties is almost the same. Both of them have castle connections. The difference can be seen on the ceiling: the junction of seamless patterns when connecting is rather narrow. The second products upon completion of installation resemble a ceiling lining with clapboard.At the same time, if the design implies, they purposely emphasize the size of the joint, focusing attention on the relief of the coating.

However, both of them are mounted on the same principle, the technology does not change. Both species are a river type of coating that does not give the effect of monolithic lining on the general background. There is no difference in the width of the plates: it depends on the nozzles used. However, seamless varieties are more loyal to the design of the ceiling with curly lines.

If at registration you use strips with a large width, combining them with plasterboard, you will manage to avoid docking. In this case, plastic panels can be an element of different levels. For example, they can be used to create linear structures. In some cases, they can be supplemented with a stretch canvas. However, narrow stripes visually break the design. It is necessary to decorate the ceiling with a solid approach.

The complexity of the designs may be different. With the help of plastic ceiling panels, you can make single-level and two-level ceilings. At the same time for the first mount the bottom frame. You need to carefully approach the creation of a sketch to design looked harmoniously.

And those and other rack designs can have a glossy and matte texture. This allows you to successfully enter into the design of the room panel, giving them the desired effect. For example, a glossy surface is reflective. This is used to visually change the area of a particular room and increase its walls. The use of matte texture allows you to make the necessary notes in the design, saving space from the gloss, if it is not provided in the furniture details.

Standard sizes

Plastic panels for hem rack ceiling are different. They are sold in packs of 6 pieces. Usually their thickness is 1 cm. In some varieties it is thinner (0.9 mm). The width of the strips can be 100, 200, 250 cm.

Especially good wide varieties: they give more room for fantasy. Their texture looks good with a stretch canvas. The use of matte and glossy coatings of large width allows you to perform a design with a transition on the wall. So you can select one of the functional areas of the room.

The length of the bands is also variable. The standard dimensions are parameters 270, 300, 400 and 600 cm. The presence of different sizes allows you to choose coatings precisely, minimizing overspending.Varieties of 4 meters long and maximum width allow you to make the design of the ceiling quickly and accurately. So that they look favorably, they are supplemented with a tension canvas of a contrasting color.

6-meter stripes are used in industrial areas with a large area. There is no need to use such products for the house or apartment. For these purposes, enough bands of 250x270, 250x300 cm. Sometimes wide panels are combined with narrow ones, positioning them in different directions.

Design

Design solutions of plastic ceiling panels are varied. Changing the texture and giving the desired effect is done through offset printing. Immediately, we note: plastic panels cannot create an effect, like in tension structures and plasterboard decorations. This is prevented by the seams between the fragments. However, their simple form and ability to combine with other materials for finishing the ceiling with a skillful approach to design allow us to realize the most unusual solutions.

For the most part, the design of the panels is a coloring in different shades. When choosing them, it is necessary to start from the purpose of the room and shade, not forgetting about the texture.For example, glossy products with a large reflective or mirror-like surface are undesirable for a bedroom or a place for recreation in a living room. Together with a visual increase in space, they will create emotional stress. This fact will exclude the possibility of rest, which is especially important for a modern person who gets tired of the rapid pace of life.

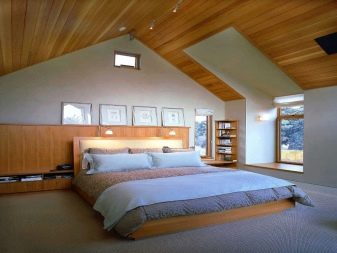

Plastic under wood looks originally. Using, for example, matte texture and shade of light wenge oak, you can create the effect of warmth and home comfort. Of course, to fill in all the space of the ceiling without decorating it is not always appropriate. Yes, and the lath ceiling looks beautiful, not in every style of the interior.

Much better would look like the ceiling, partially paneled.

For example, it will look more interesting if you combine plastic strips with drywall. It is worth considering an important nuance: it is really possible to trim panels, but this is permissible only along the width of the strip. Do not confuse them with other finishes: they have locks in length. Cutting them, you reduce the number of fasteners between the panels. It is better to use a drywall to create a figure composition.In this case, the panel is preferably laid around it, tightly combining with each other.

Sometimes the design involves laying the panels with a ladder or step. In other cases, facing resembles a panel. If you want to support the design in a creative direction, you can finish the finishing of matte texture panels under the array, gluing the fake flap over the panels. Such a design ceiling in the spotlight today. At the same time the design will look beautiful, natural. On the beams you can then attach the spot with a system for adjusting the angle of inclination.

If you plan to design the paneled bathroom ceiling, it is worth departing from the usual design in blue. It is better to use for the decoration of the room reception of contrast. You should not overload the room with an abundance of color: it is undesirable to use for facing more than two colors. White and beige shades are appropriate here. It will look good ivory tone. The texture is better to choose without reflectivity. For such rooms it is better to choose seamless varieties.

The original effect can give stripes 3D. However, their use should be deliberate.As a rule, such products change perception, creating a three-dimensional illusion. Sometimes, to see it, you need a large space. In a small room, this can create a negative atmosphere.

Subtleties of installation

After installing plastic ceiling panels, sometimes the coating needs to be removed. The reasons for this lie in the violation of technology, the use of materials unsuitable for the frame and the use of fake blanks of poor quality. Experienced craftsmen strongly recommend paying great attention to the frame material when installing the panels in the bathroom and kitchen.

Highlight the main points that cause installation errors.

- It is undesirable to use wood for this purpose. It is necessary to replace it with an aluminum frame. It will not sag and rust, so the jumpers will not change the original shape.

- Proper fastening involves the use of screws. Staples, which sometimes mount such constructions mount-installers, will not give a solid foundation. Such a ceiling will not be durable.

- Sometimes the cause of the strain is stucco. Thinking through each element of the finish, you make the frame not only light but also reliable.Properly select the screws.

- If the design is designed L-shaped profile, the use of the level is a prerequisite for work. To keep such a frame better, you can put it on a rotband.

- Installation of plastic strips is performed starting from the wall. In this case, we must not forget about the wiring and internal communications.

Tips for choosing

The appearance of the panels in the store sometimes seems more attractive. After installation, the colors can change the perception and visually split the ceiling into parts. For these other reasons, the choice should be solid.

Consider the main nuances that need attention.

- Going to the panels, pay attention to the smell. The quality material does not have it. The presence of a specific flavor suggests that the material in front of you contains toxins.

- Visual inspection concerns the form and geometrical. Pay attention to its correctness. There should be no curved edges and irregularities around the perimeter. Inspect each item for which you give money.

- Reliable trademarks that supply quality products to the market complement its documentation.Ask the seller for a certificate of quality and compliance with safety standards.

- View the clarity of the coverage. If there is a pattern on the surface, its lines should be expressive. Any blurring contours speaks of poor quality panels.

- Pay attention to color. Sharp acid paints speak about toxic components. They will not stay long on the surface.

- Bending resistance is important. A good product does not leave marks at several bends. If the seller is confident in the quality of the goods, he will demonstrate it.

- Ask the seller what the panels are for. A good seller will definitely emphasize the variety of plastic panels, indicating whether they are for walls or for the ceiling, and indicate the type of installation technology.

- Look at the side panels: they should have a lot of transverse stiffeners. Notch and sharp edges are marriage. Connect locks neatly in this case will not work.

Finding out the basic requirements for plastic panels, pay attention to the aesthetic component. Exclude from the design cheap gloss with a visual synthetic base. It is better to choose panels with imitation of natural material (for example, wood, stone, marble).If panels are needed as an accent on the ceiling, make a start from the main interior and purpose of the room.

At the same time take note: the brighter the panel and the larger the picture on it, the less elegance and simpler the look.

For the kitchen is appropriate gloss and cheerful colors. For the most harmonious effect you should not overload it with prints. Green, olive, sand soft colors of the colors will make a positive in the design of the ceiling.

When finishing the panels in the hallway or corridor, you can use plain white or milky coatings. Look good with ivory shade panels. Patterns are excluded: it is undesirable to overload the space limited in metric area with an abundance of variegation.

The plastic panels look great in the interior of the kitchen, combined with the living room or cooking area and the space for dining. In such cases, try to allocate a dining area insert from the panels. Sometimes they are connected by a golden rail, adding elegance. In other cases, the emphasis is on the texture, selecting a matte-colored coating with imitation, for example, wood painted white.

If you want to decorate the ceiling of the bedroom with plastic panels,try to use matte seamless material.

The priority is soft and gentle tones, allowing you to create a relaxing atmosphere.

Beautiful examples in the interior

In order to better understand how the ceilings of plastic panels look, let us turn to examples of photo galleries.

- An example of the allocation of dining space. Matte texture and white color create a pleasant atmosphere.

- Successful accentuation of the dining and dining areas with wood imitation material brings harmony to the atmosphere.

- The white color of the panels with suture technology will dilute the interior boredom, bring light spots and a feeling of lightness into it.

- A slight accent in bright colors is appropriate in the design of the kitchen. The dynamics are softened by a light tone of contrast.

- The original method of joining corners. Matt surface texture fits well into the situation.

- A low level marks the dining area. Built-in lights compensate for the lack of lighting.

- The embodiment of the Provencal style is possible with the use of a light shade of panels and matte texture.

- Laconic decision in the rural theme. This decor can be done no more than a day.

- Using panels with drywall allows you to create unique solutions.

- Reception of imitation boards against the background of the dining area looks interesting and stylish due to the combination of brown and gray tones in the interior.

How to install the ceiling of plastic panels, see the following video.