PVC sandwich panels: properties and applications

PVC sandwich panels are very popular in construction work. The English word sandwich, translated into Russian, means multi-layered. The result is that we are talking about multi-layered building materials. Before you buy such a product, you must familiarize yourself with its features and purpose.

Features and Purpose

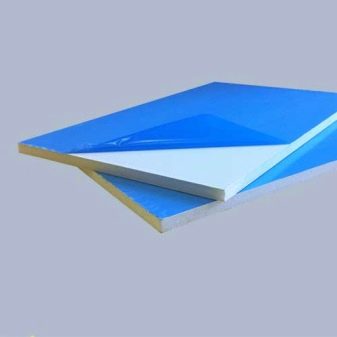

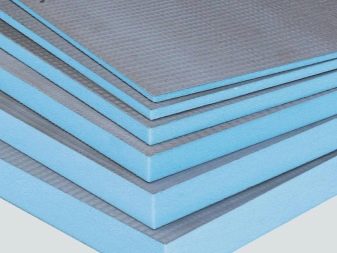

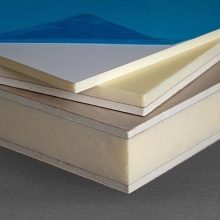

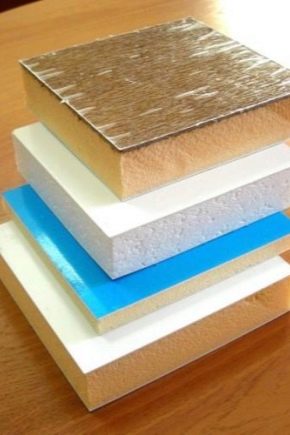

PVC sandwich panel is a material consisting of two outer layers (sheets of polyvinyl chloride) and inner (insulation). The inner layer can be made of polyurethane foam, polystyrene foam.PVC panels from polyurethane foam possess excellent heat-saving qualities. And also polyurethane foam is an environmentally friendly product.

Insulation of expanded polystyrene has a low conductivity of heat and low weight design. Polystyrene foam is different from polyurethane foam due to such properties: strength, resistance to chemical attack. The outer plastic layers have the qualities: resistance to impact, hard coating, exquisite external image of the material.

Expanded polystyrene is made in two versions.

- Extruded. Such polystyrene is made in sheets, which simplifies the installation technology. But such material is more expensive than foam.

- Polystyrene foam is available in sheets or blocks (thickness up to 100 cm). During installation, the blocks will need to be cut to the desired size.

Sandwich panels made of plastic are used for the installation of industrial and agricultural facilities, as well as in the creation of partitions in non-residential buildings.

Multilayer PVC panels are most popular in use, they are widely used in the decoration and insulation of the slopes of doors and windows.Polyvinyl chloride has a high resistance to alkali, as well as to temperature fluctuations.

The advantage of this material is that PVC is listed as a fire resistant material. Maintains temperature to +480 degrees.

Installation of PVC panels can be carried out independently immediately after the installation of plastic windows. Thanks to the insulating qualities of insulation provides maximum building insulation. Plastic windows with PVC panels will last for quite a long time, without requiring replacement of the material for about 20 years.

Construction sandwich panels are also used:

- in the decoration of window and door slopes;

- in filling window systems;

- in the manufacture of partitions;

- successfully used for decorative decoration headsets.

The demand for PVC sandwich panels is that they can be used at any time of the year and under any weather conditions. Not all building materials can boast of such qualities.

Properties and structure: are there any minuses?

The outer layer of the structure can be made of different materials.

- Hard PVC sheet. For the production of multilayer material used sheet material in white.Thickness ranges from 0.8 to 2 mm. The coating of such a sheet is glossy and matte. The density of the sheet is 1.4 g / cm3.

- From foamed PVC sheet. The internal part of the structure has a porous structure. Foamed sheets have a low density material (0.6 g / cm3) and good thermal insulation.

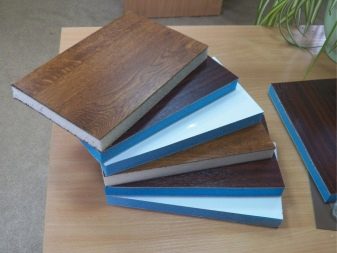

- Laminated plasticwhich is created by impregnating a pack of decorative, overlay or kraft paper with resins, followed by pressing.

Multilayer panels can be supplied with ready-made systems that do not require preparatory work on the assembly of the material. Finished structures are attached to the facing material with glue. The second variation of designs - such panels are assembled using self-tapping screws before installation technology.

Characteristics and parameters

PVC sandwich panels have certain technical characteristics.

- Low conductivity of heat, which is 0.041 W / kV.

- High resistance to external factors (precipitation, temperature fluctuations, UV rays) and to the formation of mold, fungus.

- Excellent sound insulation properties of the material.

- Strength. Compression strength of multi-layer panels is 0.27 MPa, bending 0.96 MPa.

- Ease and practicality in use.There is a possibility of self-installation without the help of specialists.

- 100% moisture resistance of building materials.

- A wide range of colors. There is a possibility of selection for any interior in the house or apartment.

- High fire resistance.

- Low material weight. Multilayer PVC panels, unlike concrete and bricks, have a load on the foundation 80 times less.

- Simplicity and ease of care for sandwich panels. It is enough to periodically wipe the PVC surface with a damp cloth, it is also possible to add non-abrasive detergents.

- The absence of discharge of harmful and toxic substances, thus does not harm the human body during operation.

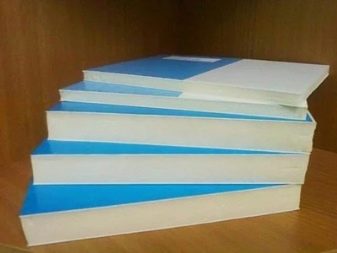

The standardized parameters of sandwich plastic panels for windows are between 1500 mm and 3000 mm. Standard sandwich panels are manufactured in thickness: 10 mm, 24 mm, 32 mm and 40 mm. Some manufacturers make panels of smaller thickness: 6 mm, 8 mm and 16 mm. Experts recommend using panels with a thickness of 24 mm.

The weight of a PVC layered plate depends on the internal filler. When using polyurethane insulation material weight will not exceed 15 kg per 1 square meter.

In some cases, mineral thermal insulation is used, then the mass increases by 2 times relative to the previous option.

Sandwich panels have unilateral and bilateral production. One-sided production of panels is that one side is rough, and the other side is finishing, which is thicker than the rough. Bilateral production is when both sides of the material are finishing.

The most popular color of the plastic panel is white, but PVC sheets are also made, which are painted for texture (wood, stone). To protect the PVC sheet panel from various contaminants and mechanical damage, the front part of the panel is covered with a special film, which is removed before installing the material.

When choosing a multilayer PVC panel, it is necessary to take into account some of the disadvantages of such a material.

- In order to cut the material to the required size, you need to act very carefully, it is better to use a circular saw with small teeth for this purpose, otherwise the three-layer slabs will break and separate. But you also need to take into account the fact that trimming of panels is possible only at temperatures above +5 degrees, at low temperatures the material becomes brittle.

- To install the sandwich panel will need the desired surface area. If the distance from the loop to the wall is small, then install the panel does not work, the stove will "walk".

- Installation is carried out only on the prepared surface. The quality of the installation will depend on the insulation of the room and the life of the material.

- High cost of material.

- After a certain time, yellow spots may appear on the surface of the slopes.

- Sandwich panels are self-supporting material, that is, the additional heavy load on the panels is prohibited, they can be deformed.

Buying sandwich materials, you need to take care of the accompanying plastic profile, which are made of U-shaped and L-shaped.

Profile form P is designed to install PVC panels in the passage in the joint area of the cladding material and the window frame. L-shaped rake is needed in order to close the outer corners of joining the slopes to the wall.

A slope slab is wound up under a short profile feather, and a long feather is wound onto a wall.

Subtleties of installation

Installation of multilayer PVC panels can be carried out independently, most importantly, follow all the rules and instructions for installing such materials.For example, window slopes consider the technique of mounting plastic panels at home.

Required installation tools:

- screws, liquid nails, sealant;

- mounting profiles;

- polyurethane foam;

- sandwich panels;

- mounting level;

- knife-cutter, electric jigsaw, scissors for cutting metal materials;

- electric drill;

- In some cases, experienced craftsmen use a grinder for trimming panels.

Novice builders need to use this tool with care, because overdoing with pressure, the material will break.

Before you start laying sheets, you must get rid of dirt (dust, paint, foam). Only on a clean base sandwich materials are laid. With existing mold, it must be removed, and the surface treated with special impregnation.

The existing cracks and gaps are sealed with foam. And it is also necessary that the construction level is at hand, with the help of which the corners are checked and the blanks are correctly cut.

- Preparation and measurement of slopes. Using the tape measure, the length and width of the slopes are measured in order to trim the panels to the size of the slope.

- Installation of profiles.The initial profiles of the U-shaped form (starting profiles) are cut and fastened with self-tapping screws, which are installed along the edges of the profiles, leaving a gap between them of 15 cm.

- The side profiles and the top PVC panel are installed in the plastic profile. Segments are fixed to the wall with liquid nails or foam.

- The areas of junction to the walls are covered with facing material from the L-shaped profile. The bordering profile is set using liquid nails.

- In conclusion, the junction areas are treated with white silicone sealant.

It is necessary to use assembly foam extremely carefully., because at the exit it increases in volume by 2 times. Otherwise, large gaps form between the laminated sheets and the wall, and all the work will have to be redone.

The slopes on the balconies and loggias of sandwich plates are made similar to the slopes of plastic windows in the apartment.

For better thermal insulation in such rooms, experts recommend installing additional insulation material.

Production technology

Modern production technology is based on the bonding of insulation material with covering sheets bypolyurethane hot melt glue and compression, which is performed using a heat press.

Required special equipment:

- the giving driving conveyor with changeable rate of automatic feeding;

- acceptance conveyor with variable speed automatic feeding;

- distribution unit of adhesive material;

- car assembly table;

- thermopress

This technology is a series of sequential operations.

- Operation 1. On a sheet of PVC applied protective film. It is placed on the giving conveyor, from which, when the system is turned on, it moves to the receiving conveyor. During the period of movement of the sheet along the conveyor under the knot, uniform application of glue to the PVC surface is performed. After one hundred percent distribution of the adhesive mixture on the sheet, the system is automatically turned off.

- Step 2. Manual sheet PVC is laid on the table for assembly and fixed on the construction lugs.

- Operation 3. A layer of polystyrene foam (polyurethane foam) is put on top of the sheet and secured with special installation stops.

- Resumption of operation 1.

- Repeat operation 2.

- The semi-finished panel is placed in a thermopress, which is preheated to the desired temperature.

- PVC plate pulled out of the press.

On how to cut plastic PVC panels correctly, you can find out a little bit from the video below.