How to choose a cable for floor heating?

Experience shows that the use of a heating cable is a solution whose effectiveness is in no way inferior to electric fireplaces and convectors. The “secrecy” of such a cable also deserves attention: being located under a decorative coating, it saves usable space, which is especially appreciated by the owners of small premises. The number of people wishing to learn how to choose this heating element for a warm floor is steadily increasing, and therefore this topic should be covered in more detail.

Special features

First of all, it should be noted that the high popularity of the heating cable is due to its impressive efficiency. It converts virtually all electrical energy into heat, allowing it to minimize losses and achieve optimal consumption of available resources.

This is especially noticeable if the application of insulation of the lower layer and the absence of errors in the process of installation work.

If we single out the situations for which the warm floor is considered the best solution, their list will look like this:

- the use of cold coatings (as an option, ceramic tiles);

- high level of humidity in the rooms (most often these are the bathrooms);

- lack of connectivity to central heating (relevant for walk-in closets and hallways, as well as insulated loggias and balconies);

- the need for heating of suburban real estate.

Another remarkable feature of the floors equipped with heating cable is the possibility of their installation under the most different types of coatings. It is enough just to get acquainted with the principle of operation and arrangement of such heating systems, as well as with their main varieties.

Operating principle

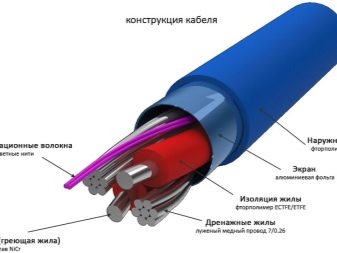

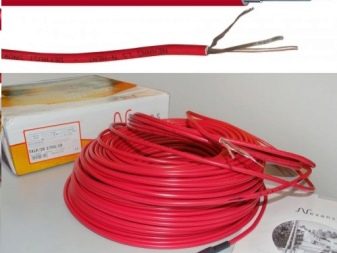

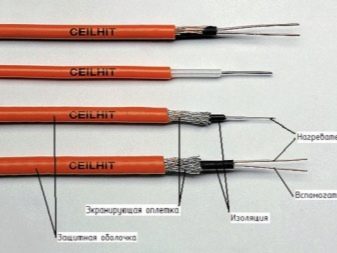

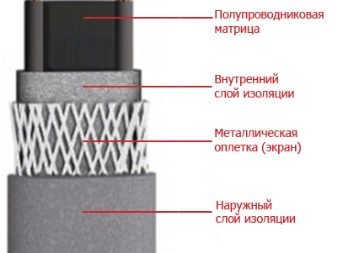

The operation of heating cables assumes the ability of their material, which is a special alloy, to convert electricity into heat. All of them have maximum water resistance,and their power is in the range of 10-30 W per 1 meter.

As for the forms in which such cables can be represented, these are:

- coils;

- sectional systems;

- rolls (mats).

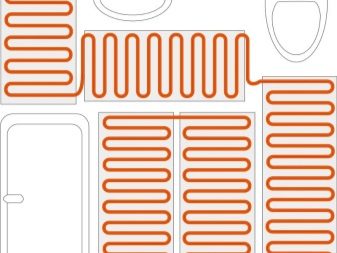

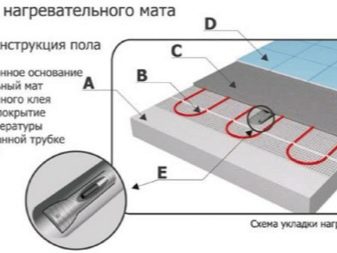

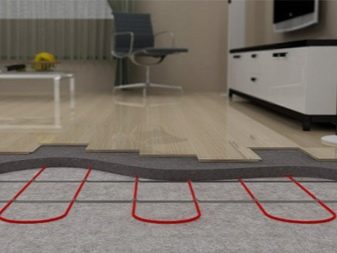

The last option is fixed by a snake on the reinforcing mesh, which can be cut, but under the condition that the wires providing heating and power will not be affected. Thus, heating mats make it easy to bypass furniture, appliances and other interior items. In most cases, such heating systems involve the use of a two-wire resistance cable, and the termination of their supply conductor is performed by means of a heat-shrinkable tube.

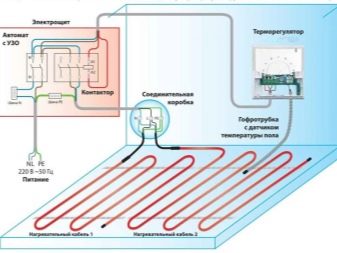

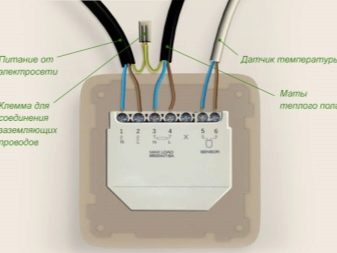

It is also worth adding that the composition of the heated floor includes:

- cable;

- temperature controller - manual or programmed;

- Thermal sensors - internal or external.

As a rule, at maximum load, the cable heats up to 60-65 ° C. Its standard values, which are relevant for normal daily use, are much smaller — on the order of 30 ° C.

But the insulation of the heating cable without problems withstands much higher temperatures - up to 100 ° C.

Primary requirements

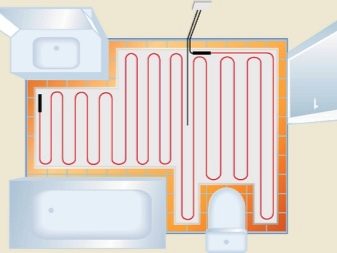

Before you start choosing a cable for underfloor heating, a property owner should draw up a detailed plan for their home. It should include accurate information about the location of stationary interior items, the surface under which to warm is impractical.

Next, you need to determine the heated area by performing a simple sequence of actions:

- multiplying the length of the room by its width;

- calculation of the total area occupied by furniture and appliances;

- subtracting the second result from the first.

After that it is necessary to calculate the total capacity of the planned system. This is very simple: for example, for a 100-watt carbon heating cable in a 25-square-meter room. m this value will be 2.5 kW.

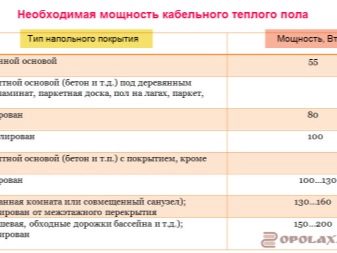

As for the power of the conductor, sufficient for full heating of the room, depending on the specifics of the latter, its values are:

- living rooms, bedrooms, hallways and kitchens - 100 W;

- bathrooms and toilets - 150 watts;

- balconies and loggias - 200 watts.

If the owner of the dwelling plans to use the cable in coils, then in his situation the calculation will be more complicated. This is due to the need to take into account several additional parameters, the main of which are the steps of the coils, the length of the heating cable and its power density.

In addition, the following requirements should be taken into account:

- for apartments, warm floor should play the role of an auxiliary source of heating, but not the main one;

- in buildings made of wood, you need a cable with a power not exceeding 2 kW;

- if the warm floor is installed for heating stairs, ramps and other architectural elements located on the street, its rated power should be 4 kW;

- the length of cable used to create one loop should not be interrupted;

- the passage of the conductor from room to room is unacceptable in order to avoid his refraction;

- the installation of one circuit is most justified for rooms whose area does not exceed 25 square meters. m

In addition, for arranging underfloor heating it is strongly recommended to use only complete accessories and spare parts, the characteristics of which are optimally combined with each other.

Kinds

Among all forms of cable release for floor heating, used in apartments, the most popular are mats - products that do not require the owner to perform most of the calculations. If you select a decorative coating, which is considered to be optimal, then this is a tile or ceramic granite.Two types of heating cable used in modern systems deserve special mention:

- Resistive. Such elements may include the presence of one or two wires. The two-core version is less complicated to pack, but its cost is somewhat higher than that of a single-core one. In such cables, one conductor acts as a heater, while the second provides power. Regardless of the number of veins, the presented view is ideal for a floor with a coupler, due to the fact that the concrete cools down very slowly.

- Self-regulating ("self-heating"). This type of cable is interesting because the heat they give depends directly on the temperature in the room. At the same time, in situations where the lack of heat is observed only on certain parts of the surface, the self-regulating cable will heat them most intensively. It is not hard to guess that such systems are more expensive than resistive ones.

The mats are also worth considering, the most demanded varieties of which include:

- Cable. This solution is a single-conductor resistive cable that is attached to the grid by a snake.It is reasonable to use these mats under the tile, which is explained by their small thickness.

- Carbon (carbon fiber). The described type of mats suggests the presence of rod heating elements connected in parallel. Their main feature is infrared radiation, generated as a result of exposure to electric current and acting as a heat source. It is noteworthy that the rods function independently of each other, providing heating according to the self-regulating principle. Carbon fiber mats, as mentioned above, it makes sense to lay under the ceramic tiles.

- Film. This mat, which also uses infrared radiation for heating, involves finding carbon rods in a polymer film.

It should be noted that such systems are sensitive to overheating, and therefore laying under stationary interior items is contraindicated for them.

Another noteworthy point is the impossibility of laying tiles on top of film mats. The fact is that the glue used for fixing the coating in question does not provide a connection with the film, which is why experts recommend using plywood or chipboard instead of tile for carpet or linoleum.

Installation

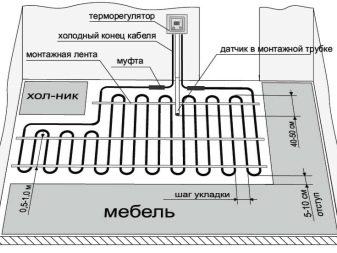

In most cases, the heating cable for underfloor heating is installed in the form of a snake, taking into account the following rules:

- the formation of loops in the cable should be avoided, as well as the intersection of individual sections;

- the distance between the warm floor and metal structures should be 5 cm (for a tree, this value is less than 3 cm);

- The recommended distance from the heating system to other heat sources is about 50 cm;

- the average pitch is about 8 outer diameters of the heating cable;

- the material used as insulation of the heating elements must be uniform;

- The cable connection and the cable end should be placed in a concrete tie.

In addition, during the installation process, no kind of damage to the laid conductors should be allowed. As for whether it is possible to shorten or lengthen the heating cable and whether it is allowed to cut it, such measures should be treated with extreme caution. The reason for this is quite prosaic: the length of the set implies a specific resistance value, which change can lead to incorrect operation of the system and even to its failure.

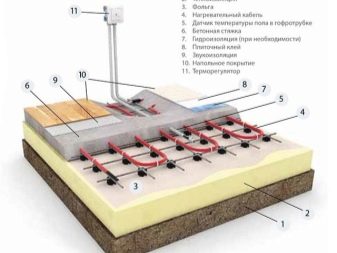

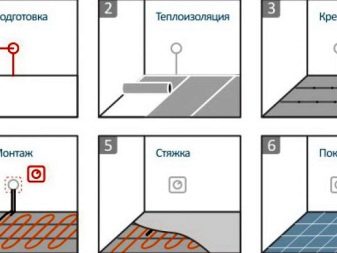

- The most common installation of heating cable in the coupler. To implement it, you need to step by step follow these steps:

- Preparation of the base. Provides for pouring a 3-centimeter layer of cement-sand mixture.

- Laying cold wire. Allows you to connect the thermostat with a floor heating system by creating a channel with a cross section of 20x20 cm.

- Installation of a bottom plate for a temperature controller.

- Placing a substrate capable of reflecting heat. Using this element under the cable allows you to speed up the heating of the system and reduce the consumption of electrical energy.

- Laying mounting tape. An alternative solution to ensure reliable cable fastening is reinforcement mesh.

- Pouring cement screed, having a thickness of about 40 mm. It is important that the solution fills all cavities tightly: this is the way to achieve the best heat transfer performance.

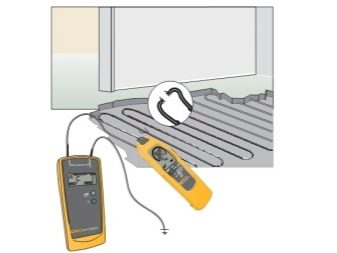

- Measurement of resistance - insulation and ohmic.

The final stage of the arrangement - laying decorative coating.

This event can be carried out after the complete drying of the screed - approximately 3 decades after it has been poured.

Professional Tips

One of the most significant moments on which the performance of the installed system depends, experts believe the first inclusion.

Its algorithm is presented below:

- The first day. The temperature control is set to 20 ° C.

- The next 3 days. The temperature increases daily by 2 ° C.

- Fifth day. Heated floor is ready for full operation.

If the installed equipment does not heat, then first of all the room owner must check whether the cable has been interrupted using a multimeter. When making measurements of resistance using this device, it is important to consider that it should not deviate by more than 5% from the values declared by the manufacturer. If there are serious discrepancies, only one solution remains - to find damage or breakage, “armed” with a device to search for hidden wiring in the walls. Having found the problem area, you can start repairing it (in this case it is better not to solder, but to use a coupling that provides the most reliable connection).

Another common cause of faulty floor heating is the temperature controller, or rather, the weakening of the contacts of its terminal block.In order to fix the device, just remove its front cover and carefully tighten the screw connections.

In conclusion, it remains to add that experts do not advise to save on the cost of purchased products. Cheap cable can quickly become unusable, due to its low operational resource. Given this circumstance, it is better to buy good-quality products from a top manufacturer that can "boast" the best reviews. Having made such a choice, there is no doubt that the warmth and comfort in the home will be provided, and for a very long time.

The difference between the heating cable and the heating mat, see the following video.