Underfloor installation: rules and tips for laying

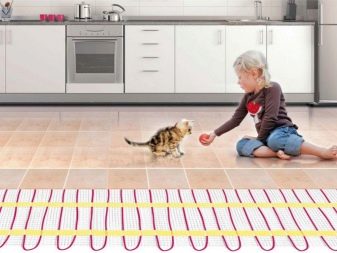

Modern housing is unthinkable without a heating system - a warm floor. It is mounted both in a country house, and in the city apartment. It perfectly combines not only with the floorboard, but also with laminate, ceramic granite, tile.

Special features

Installation of a heat-insulated floor can be carried out by any adult. For this, it is not necessary to have a skill or experience. Any device is completed with instructions for use, with strict adherence to the plan installation does not take much time.

Heat-insulated floor, unlike batteries and radiators, warms the surface evenly, can work from generators, does not dry the air.

The thermal sensor and the thermostat are also included in the electric floor heating kit. The thermostat is displayed on the wall, the whole system is connected to it and the entire setup is done directly through it. By the way, the thermostat can be both mechanical and electronic.But about everything in order.

Main types

There are two types of warm floor - it is water and electric. Electric floor heating, in turn, is cable, film and rod. Separately, I would like to highlight the infrared heat-insulated floor - this is a novelty originally from South Korea and in recent years this particular type has enjoyed great popularity among consumers and installers.

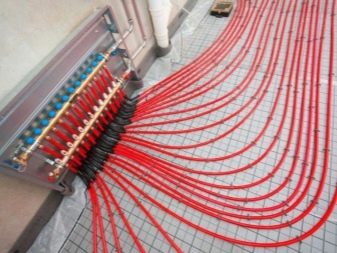

Heated water circulates through the pipes of the water heated floor, which contributes to the warming of the room - this is a kind of improved radiator system that can be installed not only in the cottage under construction, but also in the erected private house.

Laying of a heat-insulated floor is carried out on wooden overlapping - according to logs, the option of mounting on a concrete base is not excluded.

Unfortunately, installation of a water heated floor is prohibited in city apartments because of the probability of flooding of the neighbors from below.

Most often, when laying water floor heating is used Finnish technology. It implies the use of GVL plates instead of a dry screed - these are gypsum-fiber sheets. Gypsum sheets differ from drywall in the presence of a uniform structure that does not have a shell.The composition of gypsum fiber board includes gypsum and cellulose - these are environmentally safe components that are recommended for use in children's institutions.

With regards to the electric floor, it can be mounted both in urban apartments and in country houses.

But remember that when laying a cable electric floor in a wooden box there is the likelihood of a fire.

A special material that does not require a concrete screed is heated in the film-based electrical floor heat. Due to this, the time spent on laying the heating system is significantly reduced. Film floor with bimetallic heaters and with a carbon film. The second variety is often sold in finished rolls, which can be cut to size.

The carbon electric rods are composed of carbon rods, for their installation you need a concrete screed or special glue. By the way, the cable electric floor can be mounted without cement screed, if it is sold in the form of special mats, it is enough to lay a floor covering on such mats.

What coatings are recommended for?

In the building stores there is a huge amount of flooring, it is laminate, and parquet, and linoleum. This list is endless, but it is important for the consumer to know which one is suitable for the heating system.

It is possible to lay a heat-insulated floor under a tile. By the way, the thermal conductivity of a tile is the highest of this, that it is heated in less time, but it cools faster than anyone. To heat a tiled floor, high power heaters will be required. Alternatively, the distance between the heating elements can be reduced.

On the second line of the improvised ranking is linoleum. Its coefficient of thermal conductivity is five times lower than that of tile. On sale you can find two types of linoleum, suitable for underfloor heating - these are natural and vinyl linoleums. The first ones are sold under the brand name Marmoleum, and the second are made from PVC.

By the way, vinyl linoleums are cheaper. It is very important that the linoleum was of small thickness, and the presence of insulation in this case is not necessary.

Further, the flooring, carpet, laminate and cork go down the rating. Cork retains heat the longest. But it is important to know that wooden floors can begin to crumble, if the temperature control unit is set to a temperature in excess of 28 degrees. By the way, it is for this reason that laying of laminate and parquet is not recommended over a water-heated floor. But if there is already a parquet floor in the room, then it should be covered with an oil protective layer.

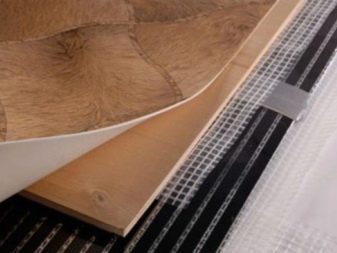

Laminate, suitable for heating system, has a special label On its packaging, it is very important that it corresponds to 32 class of wear resistance, and its thickness does not exceed 10 mm.

Keep in mind that if a cheap laminate is installed indoors, it will quickly become unusable. But even this is not all under the action of high temperatures, the process of releasing formaldehydes, substances hazardous to human health, will begin. Therefore, if there are small children or allergies in the family, then such sex is strictly prohibited.

Often, experts recommend making the installation of porcelain stoneware floor. It's no secret that ceramic tile is an environmentally safe material that, even when exposed to high temperatures, does not emit harmful substances.Porcelain stoneware has a high rate of wear resistance, moisture resistance, it is easy to care for it. Most often, tiles are laid in the bathroom, in the corridor and in the kitchen, this building material is not suitable for children's rooms.

Thin tile is suitable for rooms not loaded with massive furniture, in which a maximum of two people live. When this is achieved the maximum temperature. Water absorption value should not exceed 3%.

Which to choose?

Many people choose water heated floors, because during their operation there is practically no electricity consumption, which means you can save a lot. This type of warm floor is connected to the general heating system, but it must be borne in mind that gas consumption increases, so it is desirable that there is an own boiler room. Savings become noticeable only when heating large areas.

I would like to note once again the fact that in urban apartments connecting to the central riser of a water heating system is strictly prohibited. It’s not worth the risk, because otherwise you have to pay a huge fine and dismantle,And this additional spending.

Cable electric floor heating consists of wires that produce heat when heated. The cables are double insulated, and their connection is made using couplings that are reliable and tight. Due to this, such a warm floor can be laid in rooms with high humidity.

Cable electric floor heating has a democratic value compared to their competitors. But for its installation requires cement screed, which increases the height of the floor. For unheated rooms, including balconies, the power of the product must be high, but for corridors and bathrooms it is enough that the average figure is 130 watts.

Heating mats are the same wires, but fixed on a special grid. This fiberglass net is made; the product is presented in rolls for sale. Mini mates are perfectly combined with tiles and are recommended for installation in the kitchen, in the bathroom and in the hallway.

The infrared electric heat-insulated floor does not need a concrete coupler. It is suitable for laminate and carpet. It will take only two hours to lay it down, without waiting for the time it takes for the screed or glue to dry.

The main feature of such a warm floor is the absence of dirt and dust, which is characteristic of other species. Installation on both walls and ceiling is not excluded. But, unfortunately, this new product is not cheap.

An important role when choosing a warm floor is played by the condition - is the heated floor the only way to heat the room or is used as a supplement to the main one. Under the second condition, all the above options will do.

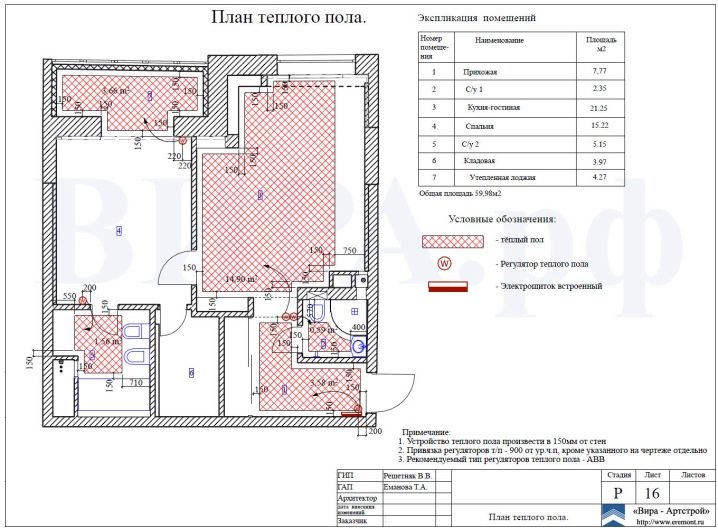

If the warm floor is the only source of heating, then you need to consider that for maximum effect, the heating system should cover up to 70 percent of the entire surface. At the same time it is not necessary to lay the warm floor under the overall furniture. When choosing a cable system, the wires are laid as close as possible to each other, thanks to which maximum heating is achieved.

By the way, so miniats should not even be considered, they will not be able to give the desired effect in the cold season.

Summing up, it can be noted that only electric heated floors can be installed in the apartment. At the same time, they are suitable not only for “dry” rooms, but also for balconies, saunas and bathrooms.Since the heating elements do not depend on central heating, an electric underfloor heating can also be switched on in the summer period. Such a warm floor is easily installed and regulated and will last for several decades.

Cable warm floor implies further pouring of cement screed, when using rolled heating systems, screed is not needed, but it is desirable that the base be leveled.

By the way, infrared heat-insulated floor does not fit under the tile, because the tile is laid on glue, but it will not be able to bond with the base of the heated floor. Exit the situation can be using drywall or glass-magnesium as an additional layer, then laying the tile on the infrared floor heating is also possible.

For linoleum and carpet, the ideal option would be to use an infrared heat-insulated floor, since its thickness is less than that of competitors, respectively, due to this the maximum effect of thermal conductivity is achieved.

Water floor heating suitable for country cottages, in which the floor space of over 60 square meters. But such a system needs prevention and a separate boiler room.Components are not cheap, so the installation of water heated floor will cost a pretty penny.

General principles of laying different options

In order to make the installation of the heating system with your own hands, several tools are required. First of all, a tape measure should be at hand and it is desirable that it be at least three meters. A laser rangefinder is also suitable as a replacement. Pliers are also useful, and a level of construction is required to level the surface. Wrenches and adjustable wrenches will be needed when installing a water heated floor, and if you have to lay the heating system on the glue, you will need a comb comb.

To dismantle the old floor may need a screwdriver and a nail puller, knives for cutting a special heating film, a bolt cutter for working with reinforcing mesh and a compressor for crimping after installation. Screwdriver is useful when sheathing plywood sheets.

In special cases, grinding machines, welding machines and perforators are used. Flow meters are used at industrial facilities, and ordinary meters are quite common for domestic consumption.

Step-by-step instructions are useful to those who want to learn how to put a cement screed on their own and install the heating system:

Electric

For example, consider the option of laying a cable electric floor heating, because for it you also need to pour a cement-sand screed, unlike other varieties.

It is important to make a plan before the start of all repair work, in what specific places the cable system will be laid, it depends on the location of furniture and household appliances.

Remember that there is no need to heat these places, as a rule, large-sized furniture rarely gets replaced, which means you can save a lot on electricity. And besides, the cable is not able to withstand such weight, the wire will eventually quickly become unusable.

After the plan has been drawn up and the required footage has been purchased, the old floor must be dismantled. If the old base has small cracks they need to be expanded. This will require a punch, the maximum size of the cracks should be equal to a centimeter. And the protrusions and bumps need to be leveled with the base.

The surface is cleared of debris and dust, richly wetted, the formed cracks are sealed with concrete. Everything is checked by construction level.It is required to fill in with a cement screed only if the drop is large.

After drying, the surface is impregnated with liquid waterproofing, in the future you need to put insulation. It should be borne in mind that the lower the thermal conductivity of the substrate, the better. It is necessary to pay attention to its thickness, and from what materials it is made.

To increase heat reflection, the top layer of the substrate is often wrapped with aluminum foil. When this is achieved the maximum effect - the rate increases by thirty percent. But it is important that the insulation was shielding.

Popular materials - foam and extruded polystyrene foamwhich are most often used as a substrate, unfortunately, under the action of gravity, their thickness decreases with time. Due to this thermal conductivity increases. In order to avoid this, you need to correctly calculate the load, it is for this that a plan is drawn up.

By the way, for cutting foamed polystyrene ordinary scissors are required. The substrate of synthetic materials is not only easy to cut, but also mounted.

Some manufacturers additionally equip their products with protrusions or apply special markings, thus facilitating the installation of a heated floor. Unfortunately, synthetic substrates can release harmful chemicals, so you should not buy cheap products. In principle, it is possible to lay on the screed and the substrate of natural materials, but at a cost it will be more expensive, and its effectiveness is lower.

The insulating layer also has soundproof and waterproofing qualities. With the first one everything is clear, extraneous noises will not get into the room, and with regards to the second, it is not a secret to anyone that a concrete or cement base can release steam, respectively, condensation forms. If there is no protective layer of polyethylene, the moisture begins to spoil the heating system, which can later lead to a fire or electrical shock.

It is important to take into account the topcoat of the floor, for heavy floors - tiles and stone, it is desirable to use extruded polystyrene foam, and foamed polystyrene foam will also be suitable for the laminate.

In the future, on the substrate is required to install the slats, in the shops there are polymer strips. At the production stage, the manufacturer equips them with special snaps. Getting a cable in them, it remains only to fix the connection.

Mounted rails perpendicular to the thermostat, or rather, the wall on which it will be installed. By the way, the thermostat does not necessarily have to be located in a prominent place, the main condition is to respect the height from the floor - ideally, its indicator should not be less than 0.3 m and exceed 1.2 m.

Before laying, it is important to retreat from the wall a small distance of 20 cm. The ends of the polymer strips should not touch other walls, the maximum allowable distance is 5 cm from the wall.

In the future, it is necessary to connect the sensor with the laid cable system. Wires are led to the baseboards, then to the box and the thermostat. Additionally, you will need to go through the wall to hide the wiring leading to the electrical panel. It is important to observe the scheme, how many sensors and how to make the connection - all this is described in the manufacturer's instructions.

Remember that all work with the electrical network is made only after de-energizing the room. Otherwise, there is a high probability of electric shock and fire. The resistance is checked by a special device - a tester, its indicator should correspond to the factory data specified in the product passport.

The cable system of a heat-insulated floor means finishing filling. The screed is either cement-sand, or from special mixtures recommended by the manufacturer. The thickness of the screed - 6 cm. The process of pouring from the window begins and gradually moves towards the interior door.

After the screed has dried and before laying the floor covering, it is necessary to adjust and check the performance of all elements. If everything meets the standards, and there are no deviations, then the installation of a heated floor on this is considered complete.

By the way, mats and infrared heated floors are connected in a similar way, but, as noted earlier, for them, cement screed is optional.

It is enough to lay the heating mats on an even cleaned surface, fixing to the floor using a self-adhesive film.And with regards to the step between the wires, the manufacturer took care of this, on the grid the cable is already fixed with the same distance between the heating elements.

Water

Other requirements are imposed on substrates for underfloor heating. First, they must be made of durable materials. These include plywood, chipboard sheets, extruded polystyrene foam. They have a high durability ratio. Secondly, they must be moisture resistant.

Modern versions of the substrates have special grooves in which the tubes easily fit. Due to this, the installation of a heated floor is easier and faster, and the distance between the tubes is the same. For good thermal insulation, products with a foil layer are recommended.

The pipes used at installation of a water heat-insulated floor can be made of copper, metalplastic and from the sewed polyethylene. Copper pipes, in addition to having undemocratic value, also require an additional protective layer. Pipes of cross-linked polyethylene inconvenient in the process of laying.

Installers often use metal pipes., they are available at any hardware store, they are cheap, easy to install, and, unlike cross-linked polyethylene pipes, are not straightened during operation.

As well as before buying an electric floor heating, first a diagram of the room is drawn. It shows the furniture, the distance from the walls, the pitch between the tubes.

By the way, the pitch should be from 10 to 15 cm, and the length of the circuit should not exceed 120 m. Otherwise, the pressure in the system will be low, respectively, and the room will not be properly heated.

Installing a water-heated floor on a concrete base will differ little from the previously described option for installing an electric cable heating system. Will require potting screed. Therefore, in this section, an example of installation on lags will be given.

First of all, it will be necessary to level the subfloor, all defects must be cleaned and processed with the help of a sander. Swings are checked by building level. A damper tape is attached around the perimeter of the room.

Waterproofing should be laid on the leveled surface. If the floor is wooden, then plastic film is not recommended as a waterproofing layer, it is better to look at substrates made of natural materials.Since moisture can accumulate under polyethylene, which in turn will have a negative effect on wood. Fixing waterproofing is using adhesive tape, and fit the mounting tape.

Lags are placed on top of the waterproofing layer, the distance between them will depend on the area of the room. The overlap should be firmly fixed to the base. Between the lags fit insulation - mineral wool. Extruded polystyrene foam can also be used.

Experts recommend to install water floor heating technology Uponor. Aluminum plates can be used as a reflector, and pipes should preferably have a 16 mm section. The main feature of this method is the laying of wooden boards, as the base. By the way, the thickness of the board should not exceed 20 mm.

For installation, you will need a standard set of carpenters and scissors, which are used to cut off the ends of the pipes. Boards are fixed to the logs with a screwdriver, it is necessary to retreat 30 mm from the wall. It is desirable that the distance between the boards was equal to 20 mm. Each subsequent two boards should have a distance of 150 mm from the wall - and from both sides.

After mounting the wooden floor, aluminum plates are laid on top of it.They are fixed by a furniture stapler. Aluminum plates break easily, so their installation does not take much time.

Metal-plastic pipes are laid into the grooves of aluminum plates with a “snake”, they are fixed in a hole by simple pressing of the foot. Since there is an indentation from the wall, then when turning, the tubular system easily fits, does not crumple and does not break.

A plastic film and a waterproofing layer are laid over the warm floor. In the future, the installation of gypsum sheets. Since the hot water will come from the heating it is necessary to connect the entire system.

The knot of the kneading is a kind of head center. Before installing it is necessary to determine the place. Remember that all pipes, sensors, meters and taps will be connected to it, so it must be hidden from prying eyes. For this perfect collector cabinet.

Common mistakes

It is very important to make the right calculations before purchasing a heating system. Remember that the places where there is a large furniture and household appliances do not need to be heated. At the same time, it is necessary to understand that in the future the rearrangement of furniture is undesirable, since unheated spaces will appear.

Cutting the cable is strictly prohibited.To get out of the situation it is possible to reduce the step between the wires. In this case, the surface is heated to the maximum. It is important to consider the minimum bend radius. Usually its indicator is indicated in the passport to the product.

Installation of a heat-insulated floor is carried out only on a clean floor. The cable or tubes must not come into contact with the wall. Intersection of wires is also unacceptable - this can lead to overheating.

Connection of a warm floor is carried out only after complete drying of the cement-sand screed. Otherwise, the surface will crack, need additional repair.

Remember, a test check is a guarantee of the durability of the heating system. All indicators must comply with the recommendations of the manufacturer.

The sensor fits into the corrugation, it is done with only one purpose, to facilitate access to it. By the way, the sensor must be installed clearly in the middle, thanks to this correct calculations are achieved.

The cable should be laid with care, the wire can be bent or broken, which will lead to system failure. Before installation, it is important to read the instructions.

Sensors and temperature controllers are mandatory installed in every room where there is a floor heating system. The use of a centralized thermostat is not allowed. Save on this is not necessary.

Important nuances and expert advice

Remember that a plank floor is not suitable as a floor covering. Under the influence of high temperatures, it will quickly become worthless. But with a ceramic tile, linoleum, a laminate and a parquet board the warm floor is perfectly combined.

Before laying the finish coating experts recommend taking a picture of the heating system. In the subsequent such photo can facilitate repair of a heat-insulated floor.

It is important to understand that if a decision is made to install a warm floor, then the carpet will have to be abandoned. Natural carpets and synthetic carpets do not conduct heat, but only absorb it.

By the way, when heating synthetic fabrics, chemical compounds that are harmful to human health may form. This is especially important to consider if the family has small children or allergies.

No need to save on the solution, in the end it will lead to the formation of air pockets. In this case, overheating is possible.And, of course, the inclusion of a warm floor for quick drying screed is unacceptable.

To properly lay the water-heated floor you need to install the insulation layer without gaps. Adhesive tape is used for this, overlapping is acceptable.

Connection of a water heated floor should be carried out by the master, otherwise the likelihood of unforeseen situations is great.

Successful examples and options

- Modern options for warm floors can be laid, including in rooms with high humidity - in kitchens and in bathrooms. In this case, the heating system is perfectly combined with porcelain. Porcelain tile has a high wear resistance, moisture resistance, so accidental damage can be avoided.

- Heating mats are also suitable for laminate flooring. At the same time, the laminate must be moisture resistant and have at least 32 wear resistance class.

- By the way, the electromagnetic field occurs only in the cable electric floor heating, and from this it follows that the heating system can be installed in children's rooms. Influences on health of the child mats and infrared floors do not have.

- If the country cottage has its own boiler room, then a water-heated floor is often installed, this is due to the savings. When heating large areas can significantly save on electricity.

In conclusion, I would like to note the fact that modern heating systems are easy to install. So, it is up to any adult to carry out the installation of a heated floor; it is only important to observe the technological process and listen to the advice of specialists.

It is only the buyer who decides which heating system to choose, but remember that it’s forbidden to install a hot-water floor in a city apartment.

How to make installation of a water heat-insulated floor, look in the following video.