Heated floor: features, pros and cons

Floor heating is no longer an innovation in the modern world, such a system in their premises was used by the ancient Romans. To determine the choice of warm floors for your home, you need to study this system in more detail.

Special features

Main characteristics:

- Unlike modern heating radiators, which warm up the apartment unevenly, floor heating systems allow warm air to rise and stay in the lower part of the room.

- There is a possibility of self-regulation of temperature conditions.

- Heated floors are designed to heat a fairly large area.

- Underfloor heating, thanks to its automated system, can maintain the required temperature.

- Absolutely safe to use, because they are hidden by flooring materials. Therefore, systems can be safely installed even in children's rooms.

- Environmentally friendly material.

- Due to the variety of varieties of warm floors, you can pick them up under any floor covering.

Types of warm floors

Underfloor heating systems are produced in two types: electric and water. At the same time, electric floors have their own types of heating. To decide on the necessary design of heating, it is recommended to get acquainted with all types.

Device and work scheme

Electric floors are:

- Cable

- Infrared.

- Matte.

Electric cable floors are heating cables.which are mounted under the finish coating. Heating occurs only through the cement screed. The thickness of the screed must be at least 4-5 cm. This system is used both as a primary and as an additional source of heating.

Electrical cables in the design of heating can be single-core and two-core. The difference is only in the connection system: a single-core cable is connected only with one end, and a two-core cable with two.

Infrared floors are a construction consisting of an infrared film. Concrete screed for this type of heating is not needed, the film can be installed directly under the floor covering (carpet, laminate). The heating elements in this case are carbon strips.

The film is made mainly in a width of 0.4 mm and a length of 50-80 cm. The installation does not take much time (just a couple of hours). The only drawback of this type of heating is the high cost of construction.

Matte designs are electrical cables embedded in a special reinforcing mesh. The principle of heating does not differ from cable systems. There is only one difference - it is simplicity and ease of installation. The width of the rolled mats can vary in the range of 50-80 cm.

The required length of the mat can be made independently by cutting along special lines. The design is issued complete with ready self-adhesive solution.

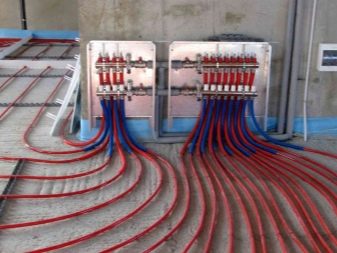

Water heated floor is a radiatorinstalled on top of the floor slab. Concrete screed performs the function of protecting the floor from mechanical stress. Subject to the technology of laying water heating, it can be used as the main source of heating without the use of radiators.

Installation of this type of heating is usually carried out in private buildings, for example, in frame houses on piles or in areas of limited area (kitchen, bedroom, hall).

This is due to the feature of installation work, because after installation the floor covering increases its weight. In high-rise buildings it is strictly prohibited. If such a structure is used as an additional source of heating, a mixing unit is required. The principle of operation is the circulation of hot water through plastic pipes, resulting in heating of the floor covering.

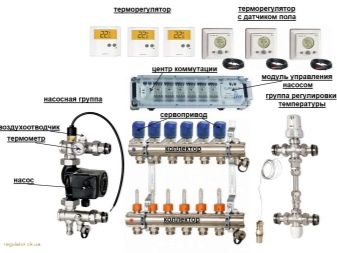

In the warm floors of the electric type, the heating temperature is controlled by the electrothermal regulator, the same adjustment is possible in water systems. Its function is performed by a servo. This mechanism controls the temperature of the water entering the heating circuit. At lower temperatures, the knot unit adds the required amount of water from the boiler to achieve the desired temperature.

There is a jumper in the area of the circulation pump.On which the two-way or three-way valve is located. After opening the valve, the rest of the coolant is mixed in.

The mixed fluid through the circulation pump goes to the thermostat, which controls the thermostatic valve.When the required temperature is reached, the water supply stops or, on the contrary, resumes. Thus, there is a heating and temperature control using a thermostat - the easiest and most economical way.

Also, the system includes an integrated controller that controls electrical drives. Thanks to this mechanism, in critical situations the controller cuts off the water supply to avoid leakage of fluid.

Advantages and disadvantages

Advantages of electric floor heating:

- A rather short heating period.

- The service life of more than 50 years with proper use and high-quality installation techniques.

- Simplicity of installation works and low cost of component parts of the electrical system.

- Possibility of use in any premises.

Minuses:

- A large amount of electricity consumed.

- Electromagnetic radiation (except film construction).

- Exceeding the standard heating temperature can lead to the destruction of flooring and furniture.

Advantages of a warm water floor:

- Profitable system, but only for large rooms (more than 30 square meters).

- It functions in a de-energized room.This happens if the boiler is equipped with a function without electricity.

- Electrical work can be performed independently, without any special skills.

Disadvantages:

- Installation of a warm water floor is carried out in a private house, in an apartment it will be quite difficult to do this. Special permission is required for utilities.

Electricity consumption of different types of systems

Before installing the "warm floor" system, many think about the amount of electricity consumed by the system. You can calculate the power consumption yourself, without the help of specialists.

It is important that when calculating the cost of electricity does not take into account the central heating (stoves, electric radiators, etc.).

Regardless of the brand and cost of construction of an electric floor heating, for the allocation of 99 watts of heat, heaters use 100 watts of electricity. It turns out that the output and use are almost one to one. If the instruction says that the heating power is 200 W per 1 m2, it means that 200 W will be used for electricity.

An example of the calculation of electricity for heating a room of 14 square meters:

- To heat the room is enough to install the floor on 70 percent of the total area. Hence, we will apply in the calculation of 10 m2.

- Consider a system with a capacity of 150 watts. Multiply the floor space by the power and get 1.5 kW.

- If the floor is turned on 8 hours a day, then 1.5 x 8 = 12 kW per day. For the whole month, 360 kW is obtained.

- The result obtained is multiplied by the tariff rate (approximately 2.5 rubles). As a result, it turns out that in a month the cost of energy consumption is 900 rubles.

According to these indicators, energy costs are small, but in the presence of a thermostat, energy consumption will decrease by several times.

Electricity consumption directly depends on the thermal insulation of the living space. The electric floor heating system is regulated and controlled by a thermostat. The temperature regulator shuts down the system when a certain indicator is reached. If the house or apartment has poor insulation, all the heat will come out through walls, windows and doors. As a result, the amount of heat loss is equivalent to the cost of electricity.

Installation of warm floors

Installation of a water heating system is quite a laborious task, unlike installing an electric floor.Installation can be performed in the finished room, but it is better to consider this question even at the stage of housing construction.

Water warm systems are installed in two ways:

- Dry method. Metal strips, which have grooves for pipe installation, are put on the construction of foam polystyrene mats or wood plates. Their purpose is a uniform supply of heat. The tubes are placed in the grooves. Next, installation of the finishing floor material (laminate, tile, parquet).

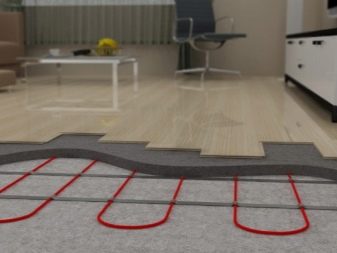

- Wet method. In turn, fit insulation, pipes, a layer of screed. The finishing floor covering is laid on the screed layer. Before thermal insulation, waterproofing is installed, which prevents water from leaking into the lower apartments. Pipes can be covered with a reinforcing mesh that acts as a load balancer. Over the entire area of the thermal system, it is necessary to position the damper tape.

Mainly used the second method of installing a warm water floor, consider it in more detail:

- A damping tape is placed around the entire perimeter of the heated surface, which prevents heat from escaping.

- Heat-insulating material is laid on the draft basis.A suitable option would be polystyrene foam (polystyrene foam), ordinary foil will not work. The density of the material must be at least 35 kg / m2.

- Then the reinforcing mesh is installed with an interval of 5 cm. The pipes are connected to it with the help of special fixings. The pipe is laid in two ways: "snake" and "snail". The most popular method is in the form of "snail", which ensures uniform distribution of heat.

- Further, beacons are installed, on top of which the coupler is poured. The thickness of the screed must be at least 3 cm.

- The final step is to install the flooring.

Installation of electrical heating design. Depending on the type of heating structure, the installation work will be different. The first step will be the preparation of the base, which should be perfectly smooth.

First you need to determine the location of the thermostat, which is responsible for managing the system. It is recommended to place it at a distance of at least 30 centimeters from the floor. To do this, the wall is a groove for the appliance.

The order of the main work:

- Thermal insulation is laid on the leveled subfloor.

- On the perimeter of the premises have a damper tape.

- It is desirable to lay a heat-reflecting material on top of the insulation material, which reflects the heat going down. If the design of the heated floor is made under the screed, then it is necessary to use a metallic material, and not foil.

- Thermal insulation mounted heating elements. The ends of the electrical cables are supplied to the junction box with a thermostat and connected to the appropriate terminals.

- Perform functionality testing.

- After checking the performance can proceed to the coupler. Before you install it, you need to lay a reinforcing mesh over the heating mechanisms.

- After all installation work, it is necessary to turn on the power supply for a couple of days for heating. To prevent the material from cracking during the drying of the screed, it should be moistened periodically. A plastic film is laid over the screed. After that you can proceed to the finish.

How to make installation of a warm water floor, look in the following video.

How to choose for different rooms?

Under the porcelain stoneware or tile, heating elements with a capacity of from 100 to 130 W / m2 should be provided in the floor heating design.Under the laminate and wood in the bedrooms and living rooms use heating in the form of infrared construction.

To create a wooden finish for a water-heated floor, it is better to use exotic woods. Such materials have excellent thermal conductivity and high resistance to deformation.

Water heating is mainly used for floor materials such as porcelain stoneware or ceramic tiles. Such coatings are resistant to various loads.

Manufacturers and reviews

Popular manufacturers of warm floors that have proven themselves on the positive side are the Korean brand. WarmluxFinnish brand Enstr, companies from Germany, etc. British manufacturer Energy He recommended his products not only in his homeland, but throughout the world. Its products have an excellent ratio of price and quality, as well as an advantage for this brand is environmental friendliness of products.

Manufacturer from Korea Caleo produces the most reliable film heating systems. Such materials can be laid under the laminate, various wooden coatings, parquet, carpet, linoleum.The main advantage of this design is complete self-regulation.

Film heat-insulated floor from the Russian producer "National comfort" It proved to be an affordable price and long service life. This is confirmed by numerous reviews of buyers of these products.

Company Electrolux (Israel) manufactures products in an ideal price / quality ratio. Mechanical and thermal protection is carried out due to the aramid yarn present in the structure. This material is much stronger than steel, it is even used in the manufacture of special clothing and body armor.

The undisputed leaders in the sales ranking are the companies:

- Ensto;

- Spyheat;

- Rexant;

- Ceilhit;

- Devi;

- Aura;

- Rehau;

- Heat plus;

- Equation;

- Warmstad;

- Rexva.

Useful tips:

- For each room it is recommended to install a separate thermostat in order to be able to regulate the heating temperature, depending on the room.

- It is necessary to connect the underfloor heating system only after one hundred percent curing of the screed. If you decide to test the system for functionality in an unprepared structure, this can lead to problems in operation and system failure.

- Cement-sand mixture for floor filling is prepared in the ratio of 1 to 3. You can pour the structure with a special mixture (self-leveling floor for screed).

Many buyers draw an analogy between a built-in water convector and a floor heating system, but it would be more correct to say that the first option is a simplified version of a heated floor. The principle of operation and installation technology are different.