Siding block house: characteristics and scope of application

Block-house siding has specific characteristics, but it has gained popularity both among professional builders and among those who design their own private home. First you need to figure out what a “block house” is, what its scope is, how to use it correctly, including in interior design.

What it is?

Many English learners immediately had an involuntary association with the block structure when they heard the Russified version of the expression “block house”. Indeed, in Western countries, this expression designates a structure that is quickly erected from blocks, but just like a traditional house, is habitable. In Russia, everything is a little different.We have a newfangled expression "block house" denotes facing material, which is most often used for exterior decoration of a building, although there are also a lot of options for using "block house" panels for organizing the interior.

Due to the peculiarities of production and fastening, the material “block house” is often compared with eurolining. By and large, the "block house" is the same wall paneling, but made from other parts of the logs. If the wall paneling is able to guarantee a beautiful, even surface, then the “block house” helps in creating a lining that is as close as possible to real logs. Therefore, it is more often used on the street, and not indoors, because outside such a skin looks much more impressive than inside.

"Block-house" can be made of various materials, including wood, metal and even plastic. Each of these options has its own characteristics, and where one can be used, problems arise with the use of the other.

For example, it would seem that universal vinyl can be mounted anywhere, but in hot climatic conditions, where the temperature reaches 40 degrees, it is not recommended to use vinyl “block house” - it is much better to choose a wooden version.

"Block House" is suitable for decorating various wall coverings: concrete, brick, wooden, block and many others. In many respects due to its versatility, the material gained such wild popularity, first among a narrow circle of specialists, and then among the population. In addition to the fact that the panels can work on almost any original surface, they are easily attached. You do not need any special knowledge or skills: you just need to follow a few simple rules in order to install the “block house” correctly.

Speaking about the purposes of using these imitating timber panels, one can not fail to mention their functional side. In addition to the fact that the "block house" just looks beautiful, it also allows you to cover up all the shortcomings of the original walls.

For example, such situations often arise when an inexperienced master made some mistakes when he built a brick wall, and now the bricks lie unevenly, as they say, at random. The “block house” is suitable for such cases: it will cover all irregularities, but the aesthetics of the structure will be preserved, although not in the form in which it was intended.

Another function that is performed by the "block house" is insulating. Sometimes the walls are sheathed with these plates, not only in order to make the home more attractive, but also to further isolate the walls from moisture and drafts. In such cases, you need to act carefully, because the "block house" requires delicacy in circulation. As a rule, the blockhouse panels as a heater are used only by experienced craftsmen who know all the nuances of preparing and treating the bases.

Advantages and disadvantages

Siding "block house" - the same building material as the rest, so it is logical that it has both advantages and disadvantages.

Fortunately for many, the advantages of the panels are somewhat greater.

- If we consider the wooden version, we can say with confidence that the production uses only high-quality wood. As a rule, conifers are selected. This is due to several factors. First, more resinous conifers keep their temperature better. Secondly, they are durable. Thirdly, if it is good to warm the resin-containing wood, it will harden, becoming almost stone.This ensures maximum coverage reliability.

- Not to mention the aesthetic appeal of such a finish. High-quality wood imitation, created with the help of “block-house” -panels, is sometimes indistinguishable from real logs. This property of the material is used by many designers, considering that it is much cheaper to purchase such material than to build a truly log cabin right away.

- The material is universal, because it can be used for exterior and interior. Outside, wide lamellas are used, while narrow samples are chosen for interior decoration. By the way, if you decorate the walls inside the “block house”, you can get another nice addition in the form of a pleasant coniferous smell, which over the years does not erode thanks to the resin contained in wooden blanks.

- The panels are often sheathed wooden houses that are in an unsightly condition. This is due to the fact that it is not possible to return the former type of logs, while the “block house” finishing is a good opportunity to recreate the former chic of a log building, while significantly saving on its restoration.To prevent the panels from cracking, special gutters are made on their inner side that prevent corrosive changes.

There is a material and a few shortcomings that can not be ignored.

- Great difficulty is caused by the almost complete lack of ventilation between the rough base and the block-house panels. This can lead to the formation of concentrate on the inside, and it, in turn, can cause decay, fungus or mold on the main walls, if not properly treated. There are two solutions to this problem: the first is the creation of special ventilation holes, and the second is a good heating of the walls so that the condensate dries out on warm surfaces. Although the second option is more aesthetically pleasing than the first, it is much more expensive, because you have to spend significant funds on heating.

- Behind the panels will have to carefully care: they are easily scratched, warp, darken. Each year they will need to be updated with varnish, and once every five years carry out overhaul of the entire coating. Some lamellas may have to be completely replaced.All this causes many well-founded concerns, since it will require not only labor investments (and considerable ones), but also financial ones.

The material has both positives and negatives. Before you dwell on the choice of material "block house", you need to weigh the pros and cons. You may not be able to care for the coating on a regular basis. Then it makes no sense to mount such panels, because without due care they will retain the original attractive appearance for a very short time.

Production features

After the blockhouse mother became popular, the paneling became popular as well. This happened in the late 90s of the XX century - most recently by the standards of the construction market. Nevertheless, the "block house" quickly gained popularity, because it allowed to make the production almost waste-free.

The technology used to produce "block house" is called "square in a circle." This means that a square inner part is cut from a dry profiled log. In the future, she goes to the timber or board. The remaining side parts (flat on one side, and convex on the other) are used to make a “block house”.It is extremely rare for block-block lining to be manufactured as regular lining by treating a cut board on a special device - a milling machine.

As mentioned above, most of the time, blockhouse lumber is made from softwood, but this is not limited to this.

For these purposes, other types of wood are used.

- Pine. This is the kind of needles that is chosen more often due to its low cost and excellent quality characteristics. Pine wood produces a light “block house”, which cannot be called any outstanding, from an aesthetic point of view, but it is rather pleasant in appearance. Pine lamellae have a pronounced pattern, which is usually underlined with varnish.

- Larch. This material is one of the favorites due to the beautiful color and pattern of the tree. The wood has a noble look, it looks expensive and soundly. In addition, larch has extremely high strength characteristics. It costs a little more than pine, however, judging by the reviews, this difference is not so significant, if we take into account the overall difference between the species.

- Cedar. This tree produces a fragrant “block house” with high aesthetic and technical indicators. However, it should be remembered that cedar is a soft tree, so it’s not worth waiting for from it the same strength as from pine or oak. The positive property of the cedar "block house" is that, thanks to the special antiseptic properties of wood, the lamellae are practically not subject to rotting.

- Linden. Lime "block-house" is categorically not suitable for external work, but inside the room the wood has no equal. Since linden is a soft tree, working with it is very easy: it bends well, does not break. Lime boards are not affected by rodents, so you can not be afraid for the appearance of such walls. An excellent solution would be to polish them or paint: both that and that option will look good on a lime “block house”.

- Alder. Alder can be attributed to universal building materials. Due to the fact that it changes color in the air (it is white right after the log house, but it darkens with time), it turns out that the alder is stylized as a valuable tree species, for example, a walnut. To meet the “block house” of alder is quite problematic, since it is more often that a board for the floor is made of it, however, some still choose this material as a finishing material for the walls.

- Spruce. Spruce can not be called a dense material: it is only slightly denser than cedar. However, the “block house” is made of it no less often than of pine, which is due to the low cost of the material: there is as much spruce lumber as pine. The spruce “block house” is superior to pine in flexibility, which is often taken into account. Spruce has a low resinous content, so in climates with not very hot summers and cold winters such a “block house” would be an ideal choice.

- Oak. The most expensive of all. Oak is superior to all others in strength and aesthetic properties. The most beautiful are the Canadian oak, which has a pleasant dull color and a pronounced pattern, and a faded, which is characterized by dark, rich shades with silver streaks. As a rule, a “block house” of such materials is rather an exception to the rule, since one who can afford such material can build an entire house from it.

Varieties and Characteristics

Above was considered in detail the wooden "block house", which is the most popular. However, the whole list of available options is not limited to this.So, there are still artificial panels made of vinyl, with the help of which they skillfully achieve the appearance of a wooden surface, and metal, produced, as a rule, from galvanized steel.

Vinyl “block house” is a great alternative to classic wood if you are financially constrained. It has several advantages.

- Unlike wooden it is not subject to rotting and is non-combustible. For example, if the house lights up, the “block house” of wood will only support burning, while the vinyl analog will only smolder.

- The vinyl equivalent better tolerates mechanical impact, since vinyl is not as easy to scratch as wood. From this it is logical to conclude that the panels of vinyl longer retain a pleasant appearance.

- The amplitude of temperatures is much wider. Vinyl can withstand drops from -50 to +60 degrees without losing its technological characteristics.

- Perfectly recreates the sample material. If an array of wood is taken as a basis, then from a distance one cannot distinguish vinyl imitation from real wood. Both color and pattern are easily recreated by staining and embossing. If desired, you can even make an imitation of an aged surface, if you use the brushed “block house”.

- Vinyl does not fade.If, under the influence of constant ultraviolet radiation, the tree gradually cracks and loses its former color saturation, then this will not happen with vinyl: it is resistant to this.

- Vinyl panels are much easier to mount: they are represented by ready-made canvas, which you just need to place in the right way and fix. In the case of wooden slats, the situation is different: you need to stack one after another each of the “block house” boards.

- Caring for vinyl panels is much easier to implement than for wood. Here care is only in periodic cleansing and maintaining an attractive appearance. Periodically handle the "block-house" panels with varnish or polishing is not necessary.

As can be seen, the characteristics of the “block-house” of vinyl are superior to those of a wood analog, however, the tree has one advantage that does not overlap, it is a natural look. In the end, if there are problems with finances, you can choose not a classic high-quality “block house”, but options from a croaker or a laminated log, which are not inferior to traditional patterns.

Do not forget that there is also a metal "block house", which also differs in a number of specific characteristics.

- The youngest of all "block house" options. The metal version, painted "under the tree", appeared quite recently, but many immediately appreciated the convenience and functionality. Despite its recent appearance, metal options are popular.

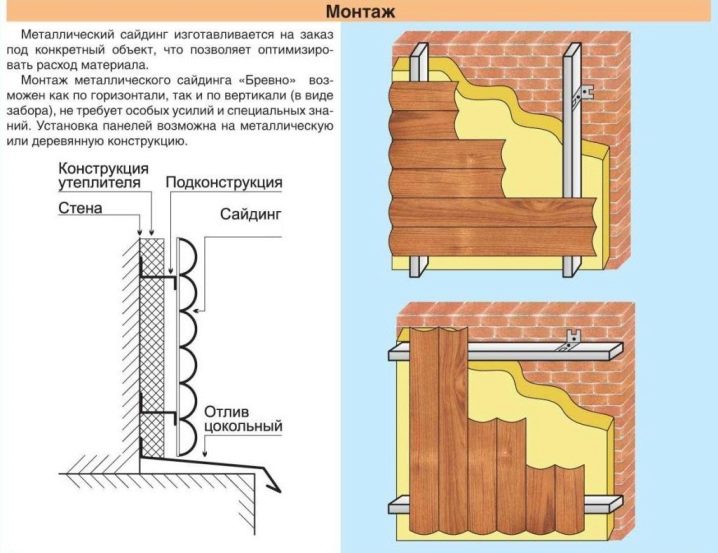

- Metal “block-house” panels are made of galvanized steel, treated and coated with various other substances, including primer, chrome-plated coating, polyester for insulation and so on. It is logical to conclude that this option is not used for the interior, while remaining mostly facing material.

- The range of temperature that the metal can withstand is even greater than that of vinyl. Here it is from -50 to +80 degrees.

- The "block house" of metal has an increased guarantee. Manufacturers claim that it can last up to 50 years.

- Like vinyl panels, metal do not burn. However, they are strongly heated under the influence of high temperatures, and such a strong heat can lead to further ignition of the base, if it is made of wood.

- Metal not only resists ultraviolet well, but also protects the walls of the home from the aggressive effects of the environment. Galvanized steel is not terrible various chemicals: alkali, acids, all kinds of toxic solvents. However, you still need to be careful, because these substances can easily remove the decorative layer.

- In contrast to the vinyl “block house” of metal does not prevent the walls from breathing, so the greenhouse effect in the space between the decorative panel and the base is not created.

- Since during installation of metal panels, it is necessary to further insulate the walls, in the future you can significantly save on heating the building.

- Metal, like wood, is environmentally friendly.

- Due to the small thickness of the panels, there are no problems when joining. The joints are almost imperceptible, and there is a sense of the integrity of the entire coating.

- Installation of the metal "block house" is very simple, so it can be done even by a beginner.

- The price of metal panels is quite affordable.

Before you choose one or another option, you need to carefully familiarize yourself with all the characteristics and specific features and only then make the final choice.

Returning to the topic of wood, it is worth noting that the “block house” panels are made in several categories: A, B, C or AB. They vary greatly in the quality of the raw materials used.

- Class A wood refers to raw materials of extra level. Only high quality samples are used here. They must have a perfectly smooth surface, flaws are unacceptable. You can meet only barely noticeable flaws.

- Class B wood may have small errors. It is permissible to have several knots or wormholes per each running meter, but they, too, should not be too noticeable: the classiness does not allow.

- Class C wood refers to the lowest grade. There may be rough knots, wormholes, deep cracks. Such material, accordingly, is cheaper, since it largely loses to the previous two in aesthetic terms, but this does not mean at all that it is worse in the operational sense.

- To class AB include the thickest panel. This category is intermediate. Knots and small cracks are permissible here, but still not in such quantity as in the case of class B wood.

Dimensions

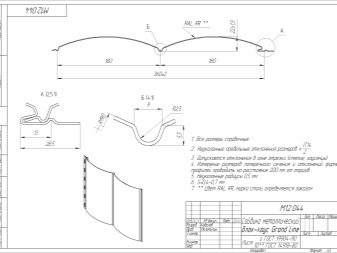

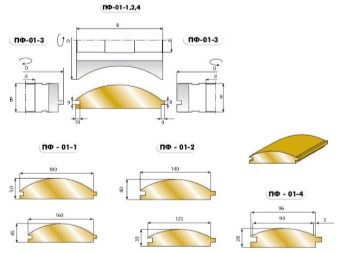

In total, in relation to the "block house", three parameters are measured: width, thickness and length. Each of these values is clearly spelled out in the standards of GOST, however, these requirements are not always met.

When choosing, you need to focus on typical indicators:

- 2x9x200 cm;

- 2x9x600 cm;

- 3x14x200 cm;

- 3x14x600 cm;

- 3.6x19x200 cm;

- 3.6х19х600 cm

Accordingly, the first indicator is the thickness, the second is the width, and the third is the length. Despite the fact that a number of firms produce siding “block house” of a different length, in Russia the most popular are these sizes.

Pay special attention to the width and thickness. The purpose of the “block house” depends on these indicators: is it made for outdoor accommodation, will it fit onto a balcony or just for installation inside the room.

- Narrow options (14 cm wide) are universal. They will look good in the large living room, and as a decoration of the exterior of the building.

- The widest options are only suitable for outdoor use. Indoors they will occupy a lot of free space because of their impressive thickness, as well as visually make the room smaller.

- Narrow lamellas most of all resemble European classic lining, so they can be widely used in the interior design of different rooms.

Be sure to focus on the size and thickness of the “block house” elements when choosing: they determine how harmoniously this type of eurolining will look in one place or another, fit into the surrounding space, and how well it will perform its practical functions.

Colors

As was clear from the previous sections, there is not only a “block house” of natural colors, but also a dyed one.

The issue of painting mostly affects metal and vinyl panels, but sometimes it happens that you also have to paint wood.

- The most popular color for processing "block house" elements is brown. This also applies to varnish and conventional paintwork. This tendency is connected with the tradition to stylize a “block house” from any material under the tree, since it has a specific form, and there are simply no other options. Brown can be a variety of shades, ranging from coffee with milk and ending with stained oak.

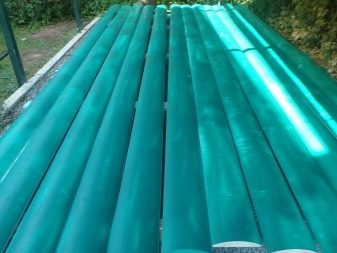

- The universal color is green. You can often find fences painted in this hue, but not so long ago there was a tendency in the design to give the panels an olive or pistachio color.The result is a fairly natural, but at the same time not conspicuous coating.

- Another unusual solution is yellow. Light shade called "lemon" perfectly helps to revive the overall look, making the house unusual and interesting. If you add a “block-house” pattern of veins, you get the original texture of some exotic wood. It is impossible to deny that such an approach is not a classic, but it has a right to exist, especially if you correctly combine the environment with this color of the house. An unusual solution here may be the coating "block house" -panel of wood with golden lacquer. This will help to achieve a beautiful pearly luster, but it is important not to overdo it with glitter in the composition.

- Along with pistachio interesting and rich emerald green color. Despite the apparent courage, this shade does not look defiant. On the contrary, it is easy to combine it with the surrounding nature, especially if there is a spruce grove next to the house or some coniferous composition is planted.

- It looks interesting coloring in red, stylized mahogany.Typically, for these purposes, choose alder, but suitable and metal, and vinyl versions. Such colors look expensive and sound, but it is important to choose high-quality samples, otherwise there is a risk to spoil the whole impression.

- Siding "block house" unnaturally bright colors (yellow, peach, boiled white) does not look very good. Here, there can be no talk of stylization, and the block house panels turn into what they really are — into a protective coating. In rare cases, saturated options may look appropriate if all other details of the decoration are chosen harmoniously: the door, window frames, roof and others.

Choosing one or another color, you should definitely think about whether it will not begin to annoy you after some time. If you know that you are a man who is inconstant, then it is best to stop at classic brown tones, having picked up the most pleasant and warm eye to the eye.

The house, sheathed "block-house", will not be able to repair again after two months: this would entail significant financial and time costs, and also lead to the fact that money for the last repair will be thrown to the wind.

Scope of application

It does not make sense to dwell on the facing of the facade, since this is already a matter of course. It is worth noting that the material “block house” can be used to decorate the premises for various purposes: it is suitable for living rooms and business premises. No less popular is the use of "block-house" -panels for the design of country houses, gazebos or other buildings that are not intended for year-round living.

There is an opportunity to harmonize the overall look, giving the main house and external construction common features, stylize them in a single direction.

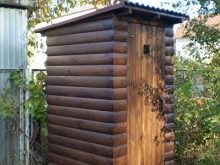

- An interesting solution is the design of the material "block house" separate shower or toilet. This will make the building more presentable if it is located on the street. Indeed, the "block-house" -panels look much more attractive than ordinary cladding boards with impressive slots between them. It looks especially nice if the bathroom is of relatively large size, for example, 3x4 m. Then it is sheathed with a “block house” and takes on the form of a mini-house, and the site in general seems more comfortable and habitable.

- In addition to the balcony, you can sheathe panels "block house" attic. Here they will look very useful, since the attic floor is usually not perceived as suitable for living - the “block house” is able to fix it. First, it will make the attic room more comfortable. Secondly, under the panels you can hide the insulation, thereby making the room as warm as possible, without walking drafts. Thirdly, thanks to the special method of fixing the “block house”, it will hold well on the sloping wall and on the ceiling, if necessary.

- A frame house decorated with a “block house” of any material will look more impressive and more durable due to the additional volume. Many prefer the "block house" instead of eurolining, since the latter often does not give the house the desired look, making it light and, as it were, "paper" in appearance. The “block house” imitates logs with success, and the frame structure turns into a hut or chalet, depending on the chosen material color. Especially good here looks wooden material.

- When decorating the interior space (bedroom, living room, kitchen, corridor), the “block house” is also indispensable, especially when it is planned to withstand the facade and interior decoration in the same style.Walls “under a bar” are typical for rustic, chalet styles, sometimes Provence, if any pastel and artificially aged material is chosen. When carrying out interior decorating, it is necessary to give preference to wood panels: only they are quite environmentally friendly. In addition, a pleasant coniferous smell will reign in such rooms, additionally disinfecting the air.

Installation Features

The first and main feature is the location of the "block house" elements. As a rule, they are not positioned vertically, because horizontal placement looks beautiful and harmonious. However, there are exceptions to every rule. Vertical location is chosen when covering fences or any side structures, for example, a shed. Another such arrangement can be used in the lining of interior spaces when you need to visually “lift” the ceiling. For example, they resort to this technique when covering balconies or attic floors, since it is here that it will not look strange.

When mounted outside the building, you will first need to create a frame of rails over the entire area of the walls. It is necessary in order to have something to mount the panel.The gap between the “block house” and the draft base is very important: it provides an additional insulating pocket.

You need to carefully prepare it: treat both surfaces (and the walls, and the panels on the inside) with antiseptic agents to avoid the appearance of a fungus in the future. The elements are attached to each other using the thorn-groove technology. It is necessary to place them with a groove downwards so that the condensate formed here will not be absorbed into the lamellae and cause them to rot.

Particular difficulties are caused by the processing of corners, both internal and external. As practice shows, the material can uncontrollably expand and contract, so, even perfectly fitting it, you cannot be completely sure that it will look just as presentable after several seasons. For this, an excellent solution was invented: you can use special "corners" of the fastening, which are mounted at the corners of the building. In width, they are only a few centimeters, so they will not be strongly striking. Thus, it is possible not to adjust the corner closely, leaving a small margin for shrinkage, and for aesthetic appeal to cover it with a “corner”.

Before being installed indoors, it will be necessary to allow the material to rest for a while.

This is done so that immediately after installation it is not deformed, thereby completely spoiling the entire appearance of the room. Keep in mind that a thin, narrow "block house" is more susceptible to deformation than intended for exterior decoration. In this case, the corners can be customized closely, since there are no such significant temperature fluctuations inside the rooms, and there is no fear that the material will expand or contract due to fluctuations in humidity and temperature.

Beautiful lining examples

Below are the ideas of registration material "block house". For each example, small comments are given to better understand certain features.

This example clearly shows how you can beautifully arrange the corners with the help of overlays. Due to the fact that they are matched to the color of the base material, they cannot be called highly visible, but the general appearance of the building immediately became much more aesthetic and more pleasant.

Most often, the interior design of the walls "block house" for the ceiling and floor materials are chosen "under the tree."It can be ordinary wall paneling, as in this case, or laminate panels - it all depends on the wishes and budget of the landlord.

The choice in favor of material category C does not always mean only savings. In some cases, the owners with the help of such tricks can give a very interesting and distinctive look to a country house. This is especially true when the selected material is in harmony with the environment. For example, if the house is located on the background of the forest.

If a room has a complex architecture, then using the material "under the bar" can visually facilitate it, while the room will not lose chic. It is important to choose the right details of design, such as lamps or balcony railings, as well as choose the highest quality wood.

It looks beautiful when the siding is combined in different colors of siding, as in this image. Please note that here the main color is traditional brown, and the dark shade in the finishing details fully coincides with the shade of the roof and foundation.

The frame house, decorated with panels "block house", immediately acquires a completely different appearance.The structure looks solid and impressive, while the general appearance does not create a depressing and heavy general impression - only associations with comfort and reliability arise.

Vinyl material sometimes can not be distinguished from the original wood, while it has many advantages, including color uniformity and perfect evenness of elements. Vinyl panels are easy to install, so that the owners will save on their installation.

"Block house" "under the slab" can look beautiful and harmonious not only when creating the exterior cladding. With proper approach and proper emphasis, the croaker becomes cozy and homely. However, this approach is extremely risky: the room should be well lit, and also have a lot of “soft” details: carpets, velvet sofas, ottomans, draped curtains, rugs and other similar items.

So, choosing a "block house" for finishing work, you get an interesting and beautiful facade or interior, while significantly saving on material.

From the video below you will learn how to sheathe a block house metal siding with metal siding.