Metal siding under the beam: characteristics and examples of cladding

Despite the variety of cladding materials, wood remains one of the most popular coatings for exterior decoration. This is due to its noble appearance, as well as the special atmosphere of warmth and comfort that the material gives. However, its installation requires considerable financial expenditure, and then regular maintenance. In the absence of the latter, wooden surfaces get wet, rot, undergo the formation of mold, and inside - insect pests.

To achieve an attractive appearance and maximum surface imitation is possible using metal siding under the beam.It accurately copies the wooden texture, but it is easy to install and maintain, durable, durable, economical.

Special features

Metal siding on its surface has a longitudinal profile relief that, when assembled, follows the shape of a log. Also on the front side of the profile using a photo-offset printing applied a pattern that mimics the natural texture of wood. The result is the most accurate imitation of a bar (the difference is noticeable only upon closer examination). The profile is based on an aluminum or steel strip with a thickness of 0.4-0.7 mm.

To obtain a characteristic log for a rounded shape, it is subjected to stamping. Next, the strip passes the pressing stage, and therefore has the necessary strength. After the surface of the strip is covered with a protective zinc layer, which is additionally passivated and primed, thereby providing protection against corrosion, as well as improved adhesion of materials. Finally, a special anti-corrosion polymer coating is applied to the outer surface of the material, which protects the material from moisture. As a rule, polymers such as polyester, pural, polyurethane are used.More expensive models may have additional protection - a layer of varnish. It has heat-resistant and antistatic properties.

Thanks to this production technology, metal siding easily and without damage to itself transfers temperature drops, mechanical shocks and static load. Of course, in terms of reliability and strength, metal siding is much better than vinyl.

Advantages and disadvantages

The material enjoys great consumer popularity due to its advantages:

- resistance to changes in air temperature, due to the low coefficient of expansion of the material;

- wide temperature range of operation (-50 ... +60 C);

- resistance to environmental effects due to the presence of a protective coating, as well as resistance to squally wind, which is caused by the presence of an anti-burglary lock;

- fire safety;

- the use of the material allows to achieve a dry and warm microclimate in the house, due to the fact that the dew point shifts beyond the lining;

- originality of appearance: imitation under the timber;

- corrosion resistance;

- long service life (reviews suggest that the material does not have serious breakdowns and malfunctions, unless, of course, the installation technology is observed);

- simplicity of installation (thanks to the lock joints, the material is assembled according to the type of the children's designer, and therefore self-assembly is possible);

- strength, resistance to mechanical damage (with a significant impact, the vinyl profile will break, while only dents remain on the metal);

- the ability of the material to self-cleaning due to the streamlined shape of the profiles;

- variety of models (it is possible to choose panels for profiled or cylindrical timber imitating different wood species);

- the ability to use panels on top of insulation;

- profitability (in the process of installation there is practically no scrap left, since the material can be bent);

- high installation speed, since no pre-alignment of the walls is required;

- the ability to create a ventilated facade;

- low weight of the material, and therefore, the absence of excessive load on the supporting structure of the building;

- wide scope of application;

- the ability to mount profiles in the horizontal and vertical direction;

- environmental safety of the material.

Like any material, a metal-based profile has disadvantages:

- high cost (compared to metal vinyl siding will be cheaper);

- ability of profiles to heat up under the influence of sunlight;

- in case of damage to the polymer coating does not avoid the destruction of the profile;

- if one panel is damaged, all subsequent ones will have to be changed.

Types of panels

From the point of view of design, metal siding for timber can be of 2 types:

- profiled (straight panels);

- rounded (figured profiles).

The sizes and thickness of profiles can vary: length in different models can be 0.8-8 m, width - from 22.6 to 36 cm, thickness - from 0.8 to 1.1 mm. As you can see, the band can be wide and narrow. Practice shows that the most convenient for installation are panels with a width of 120 mm with a material thickness of 0.4-0.7 mm. Profiles of European manufacturers can not have a thickness of less than 0.6 mm (this is the state standard), while the bands of domestic and Chinese manufacturers have a thickness of 0.4 mm. It is clear that its strength characteristics and price depend on the thickness of the material.

There are the following types of metal siding under the timber.

- Euro beam. Allows to achieve similarity with the veneer wooden profiled bar.Available in single and two critical versions. The two-profile profile has a greater width, so it is easier to assemble. It has a width of 36 cm (of which 34 cm is useful), a height of 6 to 8 m, and a profile thickness of up to 1.1 mm. The advantage of EuroBrus is that it does not fade in the sun.

- L-timber. "Elbrus" is often called a variant of the Eurobar, because it also mimics a profiled bar, but has smaller dimensions (up to 12 cm). The dimensions, with the exception of the width, are similar to the Eurobar. The width of the "Elbrus" is 24-22.8 cm. In the middle of the profile there is a groove resembling the letter L, for which the material got its name.

- Ecobrus. Simulates a large width maple plank. Material dimensions: width - 34.5 cm, length - from 50 to 600 cm, thickness - up to 0.8 mm.

- Block house. Imitation of the rounded bar. The width of the material is up to 150 mm for narrow profiles and up to 190 mm for wide. Length - 1-6 m.

The following types of materials can be used as an external coating profile.

- Polyester It is characterized by plasticity, richness of color scale. The service life is 15-20 years. It has a PE label.

- Brushed polyester. It has the same characteristics as a regular one, but the service life is only 15 years. It is usually marked as REMA, less often - PE.

- Plastizol. It has improved performance, and therefore serves up to 30 years. Marked PVC-200.

Impressive service life is also distinguished by siding coated with Pural (operation period - 25 years) and PVDF (serves up to 50 years). Regardless of the type of polymer used, its thickness must be at least 40 microns. However, if we are talking about plastisol or pural, then their thickness may be less. Thus, the 27 μm layer of plastisol is similar in its properties to the 40 μm layer of polyester.

Design

From the point of view of color, there are 2 types of panels: profiles that repeat the color and texture of a natural wooden beam (improved eurobar), as well as material, the tint of which can be any according to the RAL-table (standard eurobar). The variety of color solutions also depends on the manufacturer. For example, the metal siding of the Grand Line brand includes about 50 shades. If we talk about foreign manufacturers, then the products of ALCOA, CORUS GROUP company can boast with a rich color range.

Imitation of siding under the timber can be performed under the following types of wood:

- bog oak, as well as a textured golden equivalent;

- pine with a well-defined texture (a glossy and matte version is possible);

- cedar (characterized by a pronounced texture);

- maple (usually with a glossy surface);

- walnut (in different color variations);

- cherry (a distinctive feature is a rich noble shade).

When choosing a profile shade, remember that dark colors look good on a large area facade. Small buildings trimmed with siding under a stained oak or wenge will look gloomy. It is important that batches of different manufacturers for the same wood may differ, therefore profiles and additional elements should be purchased from the same brand, otherwise there is a risk to get different shades of the log.

Scope of application

The main scope of the use of metal siding for timber - facade cladding, since its performance characteristics do not change under the influence of environmental conditions. The panels are also suitable for exterior cladding of the basement of the building. The material used to finish this section of the facade should be characterized by increased strength, resistance to mechanical shocks, moisture, snow, reagents.Metal siding meets the specified requirements, and therefore is successfully used as a base analog. Variants of use of the material also due to the brand that produces it. For example, the siding of the company "L-timber" can be used both in the horizontal and vertical direction, as well as used for filing the eaves of the roof. Versatility of use is also characterized by the profiles of the brand «CORUS GROUP».

Metal profiles for timber used for finishing single and multi-storey private houses, garages and outbuildings, public buildings and shopping centers, industrial facilities. They are widely used for decoration of arbors, verandas, wells and gates. The material is suitable for use in regions characterized by aggressive environmental conditions. Installation of profiles is carried out on the batten, which can be a tree treated with a special composition or metal profiles. The use of metal profiles under the beam allows the installation of thermal insulation materials: mineral wool roll materials or foam.

Beautiful examples

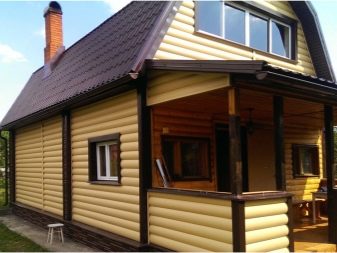

- Metal siding for timber is a self-sufficient material, the use of which allows to obtain noble buildings made in the traditional Russian style (photo 1).

- However, metal-based siding for timber is successfully combined with other finishing materials (photo 2). Win-win is a combination of wood and stone surfaces. The latter can be used, for example, for finishing the basement of a building or protruding elements.

- When using panels, the remaining elements of the building can be made in the same color scheme as the metal siding (photo 3), or have a contrasting shade.

- For smaller buildings, it is better to choose siding under light or golden shades of wood. And so that the building does not look flat and monotonous, you can use contrasting elements, for example, window and door frames, roofing (photo 4).

- For more massive buildings, warmer siding colors can be used, which will emphasize the nobility and luxury of the house (photo 5).

- If it is necessary to recreate the authentic atmosphere of a village house, then siding imitating a round timber will suit (photo 6).

- Architectural unity of the house and enclosing structures will be achieved by covering the fence with siding imitating a log surface. It can completely resemble a wooden surface (photo 7) or be combined with stone, brick (photo 8). In addition to the horizontal location of the siding, vertical installation is also possible (photo 9).

Features of mounting metal siding, see the following video.