Do-it-yourself siding installation

Cozy home begins with a beautiful facade. Affordable and easy way to finish - installation of siding with your own hands.

Advantages and disadvantages

For facing materials for exterior work they have many requirements. They must be light at the same time, strong, durable, attractive in aesthetic terms, easy to use and cheap. Few materials are able to satisfy all the points of this (incomplete, since in fact the requirements are more diverse) list. But siding falls into the category closest to the best option. He performs and protectiveand decorative functions at the same time. At the same time, the cost of the material is quite acceptable.

Its unique properties are explained by the production technology. The basis is taken of high quality raw materials, the composition of which is carefully calculated by technologists on the component ratio. Then this raw material is processed on expensive high-tech equipment and passes quality control at several stages.

For each type of siding uses its own type of raw materials and their manufacturing techniques.

Each panel consists of several layers. The inner layer ensures the stability of individual panels and the entire structure as a whole. It, in turn, may consist of several thinner layers. And the outer layer is resistant to atmospheric phenomena. He is a decorative.

Siding thickness depends on how it was produced. Basically, this division of methods is valid for vinyl and basement siding.

- The first method is mono-extrusive. He implies that the siding panel is made from one kind of mixture (compound). In the heated state, the mixture passes through a profiling hole, which tells it the desired shape, and then it cools, while maintaining it.

- The second method is co-extrusive. Compounds here are used in quantities of two or more. This is determined by the required thickness and technical characteristics of the siding. It also goes through a layer-by-layer molding process in molds and solidifies in the right position.

Hot production contributes to the fact that all the ingredients of the compound (base, stabilizers, modifiers, plasticizers, pigmenting particles) form a monolithic alloy.

This provides the following advantages of veneer material.

- When using different in component composition of raw materials and different production technologies, a wide assortment line is obtained. A large number of siding allows you to sheathe the facade of the house with panels of different colors, properties and textures in accordance with the design ideas and climate features.

- The material can be used for exterior and interior plating.

- The relatively small weight of the panels makes it possible to mount siding on the facade of any type. It can be a concrete, brick, plastered, block, wooden facade. In this case, the operational state does not matter.The old tree will be completely blocked, and the crumbling plaster can be sanded without spending time and money on the restoration of the layer.

- Siding helps to improve sound insulation and insulation in the room. That is why it is used not only in private houses, but also for decoration of municipal buildings, schools and kindergartens. This significantly saves the cost of heating in a large room.

- Suitable for facing summer cottage, apartment building, wooden cottage, outbuildings

- If necessary, it is convenient to lay waterproofing materials and insulation between the panels and the wall of the house.

- The material is convenient for installation work in one hand. The instructions from the manufacturer are clear enough to proceed to the finish, with no experience in the field of repair.

- Panels from different compounds do not crack when installing fasteners.

- The surface of most species is hydrophobic and washable.

- The material is resistant to freezing. This ensures its integrity during severe frosts, and also allows you to mount walls with a thermal break (a layer that protects the walls of the house from freezing and condensation when the temperature rises).

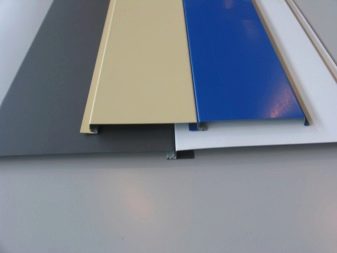

- Quality siding panels have the same thickness over the entire length and uniform color.

- Do not fade in the sun, do not fade from water, because the pigmented substances fuse with the rest at high temperatures.

- Different siding options in color and texture are combined with each other.

- Unlike natural wood, stone or facing bricks, siding is a cost-effective finishing material, and its installation is less time consuming.

- Provides a neat and beautiful view of the facade of the house for a long time. The duration of the operation of the material with high quality - up to half a century.

- Easy disassembly when re-finishing.

The disadvantages of facing siding.

- The key to quality is the manufacturer’s good faith. It is difficult to check it, so product flaws are most often found after repair.

- The brighter painted panels, the less they are resistant to fading from exposure to ultraviolet radiation.

- Only metal siding possesses impact resistance and resistance to mechanical stress.

- Each type of siding has its own limited color palette.

- To finish the facade requires a large number of panels.It is not always possible to purchase them from the same batch, and products from different ones may differ from each other in the hue of the color scheme.

- Most species are not fire resistant.

- High prices for components.

- The manufacturer’s warranty period for the product may change, or even completely void when using components from other manufacturers.

Kinds

Conventionally classify siding varieties according to several criteria: objects of use, material production, design of the top layer. In addition, the parts themselves for assembly vary in shape, thickness and size. So, for lining solid surfaces of a large area, you will need panels in the form of lamellas with a locking system, and for finishing corners, base and other difficult sections, these will be smaller parts and complex shapes.

The width of the siding can be single (the detail consists of one strip), double (a fir-tree or “ship's timber”), triple (one detail consists of three strips superimposed on each other in the form of a fir-tree).

Classification by objects of application implies division into siding for exterior, interior and intermediate finishing.

The material for lining the facade of the building should be more resistant to fading, hydrophobicity, frost resistance. For premises on the border of a street-house, for example, unheated balconies, you need siding, which is characterized by good tolerance to temperature changes. For internal finishing is important impact resistance, resistance to mechanical stress, aesthetic qualities.

Siding is used when facing such objects:

- roof;

- slopes and corners of the house;

- the foundation and basement floor (for finishing semi-basement floors, specialized ground siding is produced);

- window decoration;

- construction of fences;

- finishing non-residential buildings (baths, garages, warehouses and others);

- facing the facade of the building (and here you need front siding);

- finishing of balconies and loggias;

- interior finish of the veranda or terrace;

- vestibule rooms in a private house between the front doors;

- interior finishing: kitchens, bathrooms, bathrooms, other types of rooms.

For interior decoration is important appearance of the panels, their size and direction, so manufacturers produce not only horizontal but also vertical siding.Among its advantages, in addition to the advantages of horizontal siding, also fire resistance. It is often a decisive element for the selection of decorative finishes, since the SNiP establishes its fire resistance standards for different types of premises.

Building standards regulate the maximum allowable formaldehyde content. and toxic substances per 100 grams of weight of finishing material. Their number is indicated in the passport of the product as an emission class. For interior decoration only the first class is permissible; for the exterior one can use other types. Also, the interior material has a more variable color range, and the vertical direction of the panels contributes to the visual change of room parameters.

On the construction market there are several types of siding, differing in material production:

Acrylic

For nonprofessionals, ideas about siding are limited to its varieties of polyvinyl chloride and plastic, and even metal products are already surprising. There is nothing strange in the fact that few people have heard about acrylic siding.However, its technical characteristics are many times higher than the characteristics of vinyl panels. It withstands a larger temperature range (from –50 to +70 Celsius), is less susceptible to fading, fire-resistant, durable, and its service life exceeds several decades.

The cost of acrylic siding, respectively, is higher than vinyl.

Aluminum

With a relatively light weight, it is more resistant to damage than other types of metal finish on the facade of the house. The undeniable advantage of aluminum is that it is not susceptible to corrosion. Rain, snow, washing him not afraid. The paint is good on the aluminum plates, which retains its bright color and presentable appearance for a long time. It is less plastic than acrylic, and during construction it can be its disadvantage.

Concrete

This is the “cheap and angry” option in relation to the decoration of the facade with facing brick or natural stone. Against the background of conventional vinyl siding, of course, it turns out more expensive and more difficult.

Concrete siding is made of cement-sand or cement-plaster mixes. Cement-based substances often require additionalcomponents to increase strength, so as a reinforcing element in the composition are added a variety of fiberglass. The hydrophobicity of the material increases plasticizers. Color pigments are responsible for the color. Since concrete siding is used as a stone substitute, the color palette is limited to natural shades.

In addition to the aesthetic qualities, concrete siding is different and good performance. However, there are disadvantages. Its large weight requires additional procedures for preparing the surface of the walls. They need to be strengthened by calculating the potential load.

The second lack of concrete products is the fragility of the upper layer. With regular mechanical effects, chips and cracks appear on it.

Vinyl

The most common type of siding, which is made by mixing various components, heating them, and placing the compound in the mold. This is a practical and stylish solution for home decoration, but not always the best. So for the lining of the basement and the lower floor finishing vinyl siding may not be enough. It is recommended to use its type - basement.It is more durable due to the additional layers and components in the composition.

Another type of polyvinyl chloride material is “ship siding”. (maybe metal). It is more durable and moisture resistant, but remains flexible and comfortable to work with. The peculiarity of such siding is that it imitates the surface of a wooden board for shipbuilding.

Wooden

The manufacture of wooden panels according to the technology resembles the production of chipboard or fiberboard, because its basis is fine wood fiber. In order for the material to become resistant to moisture and strength, additives and plasticizers are added to the mixture. A protective layer is applied on top. It allows you to preserve the color and structure of the tree from burnout, moisture, mechanical damage.

With the help of wooden siding, you can return a beautiful view of the facade of the house of wood, if it has lost its beauty over time. They are also often trimmed with modern panel houses to give them a more aesthetic look.

Wood panels lose plastic panels on moisture resistance and metal siding - on fire resistance.Their service life is lower than that of plastic-based siding, and the price is slightly higher.

Copper

A rare form of siding. It gives the opportunity to beautifully veneer the roof and facade of the building, while providing ventilation under the finishing material. This ensures that no fungus, mold or condensation will appear on the facade of the house. However, there are several drawbacks. Copper is easily deformed during installation, it oxidizes and loses its attractive appearance under adverse weather conditions and constant precipitation.

Metal siding

The most complex type of panels in terms of structure. It consists of five layers: a metal base that provides stability and durability to the panels, a primer composition, a polymer layer that is responsible for the texture and color of the siding, a protective lacquer coating that prevents fading of the paint, a protective film. Upper film is a temporary measure. It protects the panels from damage during transportation and installation. It must be removed.

Metal siding is the most durable of all and is not susceptible to fire, but over time it can become unusable due to the constant exposure to moisture.

Cement

Such a material is made of first class cement (in which there are fewer impurities) with the addition of fine sand, cellulose fibers, minerals, plasticizers and dyes. It imitates the texture of wood, facing bricks, stone and other materials for decorative decoration of the facade. Possesses flexibility, elasticity, hydrophobicity, badly burns.

Often for cement and fiber cement siding requires an additional procedure - painting in the desired color.

This material has several disadvantages: it is expensive, weighs a lot, remains fragile, despite the reinforcing fibers in the composition, and in the process of work cement dust is formed, because 80-90% of the material consists of mineral components.

The decorative function of the siding is very important, so the manufacturers expand the product range every year. So, on the market you can find smooth and textured, colored and neutral panels. Many of them mimic more expensive coverage.

Common options are siding with imitation of bricks, natural stone, wood of expensive breeds (in the form of a bar, planks and rounded logs), glossy and matte, white and colored panels.

Calculation of the amount of materials

The prefabricated construction of any kind of siding consists of a large number of elements. Components differ in shape, thickness, method of attachment and purpose.

In addition to the panels themselves, additional fixtures will be needed. Consider them from the lower level (foundation) in the process of finishing to the top (roof).

Socle siding is used to protect and add aesthetic appearance to the foundation. Its peculiarity is that it consists of not oblong and narrow panels 3-4 meters long, but wider and shorter details. They are interconnected as puzzle pieces. The decorative surface of the basement siding often copies the finish with natural stone.

The upper edge of the foundation, as a rule, protrudes several centimeters forward (and sometimes several dozen centimeters). To the design looked solid and had no gaps, the top of the basement siding and part of the foundation is finished with "ebb". This detail resembles a small step in its shape and connects the foundation and the wall of the facade of the building.

The transitional element from the "low tide" to the lining of the walls is carried out with the help of an element called the starting bar. It fixes in place the lower siding panel of great length.

The next obstacle in the path of the longitudinal panels - window openings. For their finishing, you will need battens, a finishing profile (plays the role of a groove into which the decorative part is inserted, and the window profile or the jamb itself (it is a decorative element). The platband can be smooth or carved.

The transition from the profile to the longitudinal panels is again carried out with the help of the ebb and starting strips.

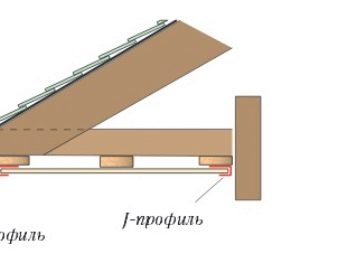

Problem areas such as internal and external corners require special attention. For them, the package includes parts with the appropriate names - the inner corner and outer corner. There are also parts called J-corner or J-plank and F-corner, which cover problem areas such as eaves and connecting lines between the platbands and the wall of the facade. When the length of the panel is not enough for the entire length of the wall, the connecting part is used - H-profile. Completes the designer of horizontal or vertical siding panels finishing strip.

J-profile provides a transition from the wall of the house to the roof and is needed to install soffits and overhangs. The protruding part of the roof slope (bottom) closes the wind board or soffit.These parts have perforations on the surface so that air can circulate under the roof.

When all components are defined, it is necessary to calculate their number. It should be as accurate as possible so that all elements fit together without gaps and cracks. Otherwise, manual adjustment will be required, and this is already difficult to do without any installation experience.

Calculate the amount of material is not difficult. The main thing is to do it conscientiously, consistently and considering that the siding is not attached directly to the wall, but is fixed on a special crate from the profile. Sometimes you need to add the thickness of the insulating layer.

So, to find out how many panels and accessories you need, you need to measure the walls around the perimeter of the house, as well as all window and door openings.

Despite the fact that the opposite walls should be structurally identical, they are measured individually at two or three points in height and width. If the results are different at several points, it is necessary to round in favor of a larger indicator.

The width is multiplied by the height and according to this data, the specialists in the store will help to determine the number of panels (including a few in stock), based on the width and length of one panel.That is, the total area of one wall is divided by the area of the panel, and the resulting number is equal to the amount of material per wall.

For stock, you need to purchase 10-20% more material. The extra 10-20 panels will be able to cover the unexpected siding consumption or fix installation errors. Many people forget about spare parts, buying them only after they are really needed, but this is a mistake. Details from different batches will not be absolutely identical in hue, thickness and characteristics anyway, and this will be especially noticeable on the facade.

From the total area of all walls is deducted the area of the window and door openings. With triangular wall fragments a bit more complicated. Here the base of the triangle and its height are measured. Then the “width” should be divided into two and multiplied by the “height”.

Then you need to sketch the shape of the walls, windows and openings, signing on them all the values. This will help not to be mistaken in the calculations in consultation with a specialist.

It is not so difficult to calculate such additional elements as external and internal corners, J, F, H-profiles, starting and final slats, soffits and wind boards. They are used in a straight line, which means it’s enough to know its length.The resulting number is divided by the width of one piece, and then another 10-15 percent is added to the material for unexpected expenses. If there is an opening or other obstacle on the line of use of the dobor, its dimensions are subtracted from the total length of the section, which is finished with additional elements.

When purchasing components and siding, you should not forget that it is mounted on a special crate. The crate levels the surface of the walls, which simplifies the installation of siding and allows you to create a gap between the finishing material and the house wall for air ventilation. In some cases, additional warming is required, protection from moisture and condensate, then the crate is used for laying additional materials.

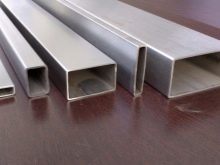

Metal U-shaped suspensions, steel or wooden profiles, fasteners, self-tapping screws, improvised materials and tools are necessary for lathing.

Metal products are universal, wood is more suitable for use with a moderate level of humidity.

Profiles should have a cross section of plus or minus 60 by 30 and a sufficient level of rigidity to support the weight of the structure.

The number of suspensions and profiles is determined depending on the pitch of the batten, that is, from the distance between adjacent parts of the frame. It should not exceed 40 cm for heavy materials and 60 for light ones. The width of the wall is divided by the step width, and the resulting number is equal to the number of profiles that must be set to 1 wall.

Self-tapping screws are purchased at the rate of 1 piece for every 20 cm along the length of the profile and hangers.

Instruments

A set of tools for installing siding do-it-yourself is small, and its components can be found in almost any home.

First of all, we need devices for measuring the surface area under the lining: a long ruler, a carpenter's square, a tape measure, colored chalk.

The next group of tools will be needed during the installation of a metal (wooden) profile and hangers. To correctly determine the starting line on the edge of the wall, from which the installation of suspensions begins, you need to use the construction level. A simple plummet will do. The line needs to be drawn so that it does not blur. It’s convenient to use a marker or a bright chalk. To fix the suspensions and profiles on the wall need a screwdriver.A hammer may be useful.

Directly during the finishing works, you will need the following tools: a Bulgarian or a handsaw with fine teeth (cutting the siding into fragments of the desired length), a hammer drill, a rubber hammer, and tools for dismantling unsuccessfully mounted panels.

Do not forget about protective equipment: comfortable clothing, gloves, glasses.

Warming

One of the main advantages of siding is that it is easy to “hide” a layer of insulation under it. This significantly saves heating costs during the cold season and maintains a comfortable temperature in the room year-round.

That the heater served for a long time and efficiently, it is important to choose the right materials. This is not only the insulation itself, but also intermediate layers that will protect the house and the walls from condensation, overheating and other problems that can occur if the insulation is not correct.

Properties of good materials in the warming layer:

- the ability to pass air and "breathe";

- resistance to moisture and fire;

- resistance to freezing and temperature changes;

- ability to improve sound insulation;

- environmental Safety;

- durability.

The choice of insulation - the most crucial moment. Consider materials with suitable properties.

- Extruded polystyrene foam (sometimes called penoplex). In fact, it is the last generation foam plastic. Since the foam of the old sample begins to crumble for 5-10 years (and the siding is many times longer), it quickly loses its effectiveness as a heater. But polystyrene foam has all the necessary qualities. It is moderately dense, porous, light (does not load the profiles), cheap, durable, resistant to moisture, allows the walls to breathe (if not to mount butt), protects from cold in the winter and does not create a “steam room” in the house in the summer, as well as perfectly drowns out background noise from the street.

- Mineral plate (cotton wool). It is characterized by high density and durability with a small thickness, meets the requirements of building codes, provides ventilation, is biostable, and improves the insulating properties of the house's plating. But there are also disadvantages to the mineral insulation: in the absence of waterproofing and moisture ingress on it, the material loses up to 70% of its heat insulating properties. Dust accumulates over time. Cheap costs only low-quality mineral wool, and a good amount will have to be spent on a good one.

Basalt wool, glass wool and ecowool have similar properties, but they are more often used for warming indoors.

- PPU Sprayed polyurethane foam is an effective insulation, but requires special equipment for the application. Since the mass is applied to the wall in a liquid form, it is possible to use it before mounting suspensions and profiles, due to which the “cold islands” will not form in the construction. But when spraying PPU on the wall does not remain a ventilated gap. The wall will not breathe. Otherwise, this material is superior to others in its technical characteristics.

- Foam glass. Worthy alternative to sprayed foam. Working with foam glass is easier due to the fact that the material is sheet. It has a porous structure, low weight, insulating qualities at a high level, resistance to moisture, decay and fire, is able to breathe, easily cut into fragments of the desired thickness, does not shrink with time. Its service life exceeds the service life of many types of siding. Its significant drawback - the high cost. But if it is possible to make an expensive lining, it is better to use foam glass than other materials.

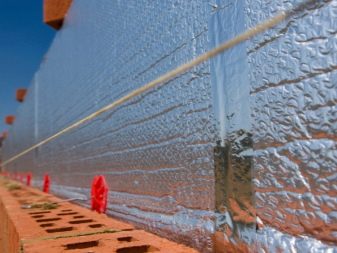

- Foil sheet insulation. Such materials, as a rule, have a porous structure and are made from varieties of foam, and sealed from above in a reflective "shell". This gives them an undeniable advantage - the ability of insulation to keep heat in the house at sub-zero temperatures and the ability to prevent the room from overheating from the inside at high temperatures outside.

Do not forget about waterproofing and vapor barrier. These thin layers will prolong the life and increase the efficiency of insulation, but their absence in most cases reduces the effectiveness of the material to nothing.

Waterproofing is a layer of thin PVC film or other thin sheet material that overlaps the insulation. That is, it is located between it and the siding and is necessary in order to prevent moisture from entering the insulation.

The vapor barrier is also made of a fairly thin material, which is mounted on the reverse side - between the insulation and the wall of the house.

To work with these materials, you will need scissors or a sharp knife (cutting out fragments for hard-to-reach places), construction tape and a construction stapler.

The material is purchased with a margin of 20%, since it is necessary to lay it with an overlap of 15 to 30 cm.

Step-by-step instruction

When all materials are selected and purchased, it is time to begin installation. The technology is universal for all types of siding, the work is carried out in stages.

- The first stage is preparatory. It is carried out after all measurements and calculations, therefore we exclude them from the list of actions. What really needs to be done as a preparation is to inspect all surfaces of the walls, especially difficult areas, for the presence of defects, irregularities, interfering elements. They are recommended to be eliminated in order not to injure the insulating materials and panels. The “nodules” of the cement mortar in the masonry must be carefully crushed with a hammer, and all the “creases” on the foundation are also leveled. It is important not to overdo it. Sticking nails and fragments of reinforcement need to bite off with pliers or bend and drive into the wall. Lagging layers of plaster chipped and sand. Old surfaces can be further primed so that they are not covered with fungus under a layer of insulation and facing material.

- The second stage - the device vapor barrier. It consists of several steps: cleaning the walls from the old coating, if it exists, processing the gaps and gaps on the surface of the walls, drying the walls. Laying the vapor barrier on wet walls makes no sense. This is a work down the drain.

For vapor barrier it is better to choose foil sheet materials of small thickness. They are rolled upwards and fixed on the wall by pre-fastening in the form of adhesive tape. A little later, when the sheathing is mounted, it will fix the material firmly and securely.

- The third stage is the installation of the batten. For the variant with insulation, it will be the first of the two and is carried out from spacers. For the variant without insulation, this crate is the first and last, consists of suspensions and profiles. Universal metal profiles are most often chosen, and nonprofessionals have a question: what's the point in insulation, if there is still a big heat loss through the batten? Exit - underlaying paronitic gaskets or basalt cardboard under the profile in the places of attachment. To fix them will help mounting brackets.

The construction of the batten is recommended to be installed in accordance with the type of siding. For the horizontal one scheme, for the vertical another. In both cases, you need to start from the edge and first install the guides. Their location must be strictly vertical or strictly horizontal, and the line is drawn with a level or plumb. Otherwise, the siding will not rise as needed or curvature will be noticeable.

- The fourth stage is warming. The material is laid in accordance with the manufacturer's instructions. At the same time, it cannot be deformed, because it can lose its properties.

- The fifth stage - laying waterproofing. This material (without tension) should cover the entire insulation. From above and below it must be carefully fastened, and the width of the sheet material is laid with an overlap. Often, manufacturers note on the waterproofing film an edge line - the overlap should be no less than what it indicates. It is fixed with a stapler and scotch tape. This is followed by the installation of the second obreshetki.

- The sixth stage is plating. It requires compliance with three simple rules that will ensure the success of the event:

- Maximum tight fasteners are required. "Tightening the locks" between the parts, it is important to leave a small gap of about 1 mm.This will protect the material from cracking and also simplify the dismantling process in the future.

- Fastening should be done in the middle of the installation windows, and not at the edges.

- You should not drive the trim panel into the hole until it stops; it is better to leave a small gap.

Sheathing should be performed in such a sequence.

- Dismantling of drains, door panels, platbands from window openings.

- Crate (including insulation). The extreme lag should be set exactly at the corner of the wall.

- Mounted start plate (above, at the base of the gable). Then the outer corners, aquilon and starting profile. The initial board is inserted into the slots until it clicks, then you need to check the backlash (stroke 1-2 mm). If it is observed, you can install fasteners.

- Similarly, the remaining panels are mounted. Make a check for backlash required for each panel.

- Along the way, window and door apertures, internal corners, and other elements are made with siding.

- The last panel is attached without latching to determine if it needs to be customized. Then the final plank or J-profile is mounted, and the board is already inserted and latched into it.

- Gable trim (triangular part of the wall under the slopes of the roof).It is somewhat more complicated than facing a rectangular wall. It is important to observe two nuances: trim the ends of the boards exactly along the slope of the corner of the wall, fix the ends of the boards in the J-profile (the usual finishing strip will not hold). The rest of the technology remains unchanged.

- Eaves trim. It is carried out according to the scheme specified by the manufacturer. For high-quality installation it is necessary to use special eaves moldings, profiles and perforated spotlights.

In this way, you can house your house with siding yourself, without spending much time on it.

Typical mistakes

Before installing the siding panel with your own hands, you should study all the subtleties and peculiarities of the process in order to avoid common mistakes. They will subsequently cause a lot of problems, affect the effectiveness and lifetime of siding and insulation.

The main mistake is incorrect counting of materials and the lack of spare (which is rarely superfluous) details. As a result, the alleged lining without flaws turns into a veneer with obvious defects. Not only does this affect the aesthetics of the facade, it also deteriorates the tightness of the coating.This creates the risk of moisture on the intermediate layers and damage to the insulation.

The second most popular mistake of self-taught installers is not to use waterproofing. And if polyurethane foam survives such treatment, the mineral wool will swell, begin to put pressure on the siding and lose up to 80% efficiency.

No less blunders - to mount the panel butt against the outer wall and snap the locks to the stop. Siding is made of materials that taper and expand under the influence of ambient temperature. If you do not leave a gap of a few millimeters, it will simply crack in the first very cold weather.

It is not recommended to screw the screws into the “body” of the panel. It has a perforated side for mounting. The screw is screwed into the center of the hole, not at the edge. It is forbidden to fasten construction details to the outside with non-galvanized (rusting) nails. There will be rust on the panels, and they will stay worse.

The last mistake is not gross, but it is also better not to make it. It's about using glossy panels. Yes, they look better, but not for long. And they heat up faster matte.

Beautiful lining examples

- A variety of siding types by material, shape, color and texture makes it possible to implement design solutions in the design of the facade. For example, the installation of single matte siding of light shades has already become a classic solution. The installation of the colored “Christmas tree” in a double or triple version will make the facade concise, but bright, as is characteristic of modern design trends.

- Beautifully, well and expensively look at houses and cottages, sheathed with basement siding from the foundation to the roof. Modern fiber cement siding as accurately reproduces the relief and texture of natural stone and brick, so from the side it will be difficult to distinguish such styling from a real stone.

- It is always relevant for a private house wood trim. Light siding fits perfectly into the style of Provence, darker shades and imitation of raw wood will be appropriate in the style of country. “Shipboard timber” with a pronounced texture and siding, imitating expensive wood species, will recreate the elite design of the classics in a modern interpretation.

How to mount siding with your own hands, see the video below.