How to choose a heater for the walls of the house outside under the siding?

Siding is very widely used for finishing a variety of residential buildings - both private and multi-family buildings. But the Russian climate makes it necessary to constantly take care of maximum heat savings. And because of this, the choice of high-quality insulation becomes important. At the same time, it should not only be of high quality, but also fully relevant to the characteristics of a particular dwelling.

Why do you need it?

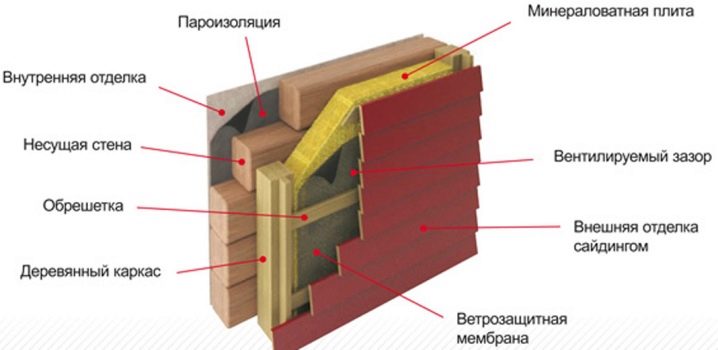

Heating buildings in the winter time requires huge costs and significantly affects the financial situation of residents. Only high-class insulation helps to reduce costs and ensure a high level of comfort at the same time. Wood and thick brick walls will not keep heat on their own, and when siding is still placed outside, it may increase the risk of housing cooling.It is imperative to take care of thermal insulation and the creation of a heat retaining gap between the main wall and the decorative surface. In full, these requirements apply to the frame houses.

Types: Pros and Cons

In any hardware store and on the market, consumers are offered a variety of materials and technological solutions, which are presented as universal products. But in reality this does not happen: a heater of a certain type has a strictly limited application, and only in tightly defined limits does it reveal its possibilities.

Among the inexpensive and technologically simple solutions, one of the leading positions is invariably occupied by foam plastic. It is light and can be attached to the base of the wall with dowels or special glue. The lightness of the material does not prevent it from having high rigidity and relative strength. Even when in contact with water, the heater will reliably fulfill its function, no matter how hard the frost is on the street.

The foam has objective disadvantages:

- the maximum lifetime of the material is only 15 years;

- steam permeability is insufficient;

- need for additional ventilation.

To insulate the facade walls, not every foam is useful, but only processed by extrusion (officially called polystyrene foam). This insulation is not subject to shrinkage, but requires increased sound insulation, as it sometimes increases the external noise.

Mineral wool is recommended for both metal and plastic siding., the best kind of professionals consider the plate size of 1000x50 mm. The rolls gradually sit down, and the risk is high in a short time to lose insulation in the upper part of the wall. The disadvantages of such a coating are a significant need for vapor barrier, the need to protect the material from exposure to moisture from the outside. If you install mineral wool, you need to take measures to protect against fine dust mist. The rest of the basalt insulation manifests itself relatively well.

Often in the catalogs of construction companies can be found the so-called penoplex. There is nothing unusual in it, since it is all the same expanded polystyrene, which is extruded at elevated pressure (this technological process creates a structure of small cells).In factories, penoplex is produced in the form of slabs with a thickness of 2 to 10 cm.

The advantage of the material can be considered a uniform distribution of air bubbles throughout the mass. Due to this property, it very weakly lets in heat and is little susceptible to water. During the tests, a number of thermal engineering examinations confirmed that when the penoplex was drowned for 30 days, it becomes heavier by 0.06%, that is, water can only penetrate the cut ends of the products.

Of the minuses it can be noted that this insulation is easily destroyed under the action of:

- acetone;

- formaldehyde;

- paint solvents;

- gasoline, kerosene, diesel fuel;

- oil paint and a number of other organic substances.

The complexity of the technology leads to the fact that the penoplex is more expensive than almost any mass insulation, excluding mineral wool. After laying it is necessary to close the surface of the material as soon as possible, until it was destroyed by direct sunlight. Like all derivatives of foam, even foil foam does not protect against the appearance of a house mouse in the walls. We will have to take additional measures to combat this rodent.A serious problem is the easy ignition of a heater of this kind, which even crosses out its acceptable density.

How to choose?

For walls trimmed with any type of siding, you need to choose insulation focusing on the following criteria:

- thermal conductivity level;

- the intensity of the absorption of moisture (liquid and from the air);

- its protection from the action of fire;

- required layer thickness.

Thermal conductivity (how much heat is retained) is a key parameter that characterizes a material as insulating. But also between their separate types it varies quite widely. So, the heat through the mineral wool gets the hardest, and the leakage will be the weakest through the foam. The bewilderment is in vain: the recommendations to choose cotton are made up taking into account other valuable material properties.

Insulators inevitably meet with moisture, precipitated from air streams, if the integrity of the “cake” is broken, drops (trickles) of liquid water can penetrate. Therefore, when choosing the final option, they always take into account how much water the substance absorbs without losing its useful characteristics.The easiest way is with the density of the material: the larger it is, the better it is to use this type of insulation. But we have to reckon with the complexity of the installation of heavier structures.

Fire safety is judged by how high the flammability of a substance. And the thickness of the layer being created is contradictory. There is no doubt that with its increase the thermal protection increases markedly. But we need a balanced approach, taking into account how dense the material used is. If it is very dense, it is desirable to use a less powerful layer.

Some manufacturers are trying to convince consumers that their materials are completely environmentally friendly, made from flax fibers or pure cellulose, and even the glue is chosen as natural as possible. To believe such promises or not, everyone should decide on their own, but it is better to think about why professional builders try to insulate the facades with more familiar products, without overpaying “for the environment”. The only exception is glass wool, it is really dangerous to health with the slightest violation of technology or insufficient protective measures.

For external use under siding is difficult to find better options than the already mentioned mineral wool and polystyrene foam. But in order for the result to meet the expectations of the builders, even the most severe frost did not affect the outside, it is necessary not only to choose the insulation, but also to apply it according to the recommendations of the professionals.

Mounting technology

The first step, according to the generally accepted technology, is the calculation of the required layer of thermal protection. In the suburbs of a house under siding, you can insulate with mineral (or glass) wool, the thickness of which is 50-100 mm, in particularly difficult conditions, this figure can be doubled by making a two-layer construction. It is best not to rely on your own engineering knowledge, online calculators or tips from familiar builders, but to request a calculation from the same company that will install the siding.

When the need for the exact amount of material is determined, it is time to prepare the surface.

It is performed as follows:

- all lamps and decorative parts are removed;

- dismantle drains;

- trim trim windows and doors (if they have already been delivered);

- rough surfaces of walls are freed from rotting areas;

- the entire surface of the wood is impregnated with flame retardants;

- if the walls are not wooden, but brick or artificial stone, you need to remove the influxes and pollution;

- then the concrete or brick is covered twice with a deeply injected primer.

Almost all types of siding installed horizontallyand therefore the crate should go vertically. The distance between its nodes depends on what facing will be applied, and on the width of the blocks of the chosen insulation. Most often, a gap of 0.6 m is envisaged, but under the layers of mineral wool and glass wool, the bars are mounted with an external step of 590 mm, then the coating will rise tightly and will not move anywhere. But the distance from one point of attachment of a bar to another at the bottom can not be more than 0.5 m.

To keep these parts on the wooden wall, self-tapping screws are used for screwing into the wood, specialized dowels are laid over the brick. Each bar is selected in such a way that it is equal in thickness to the insulation (we are talking about mounting directly on the wall surface). But when a frame is applied, they take either parts for a batten 5 × 5 cm, or special P.-shaped suspensions.

It is not necessary to mount the siding close to the warming material, leaving a gap of 40 - 50 mm, the builders provide reliable ventilation. But this solution requires the installation of additional crates, the creation of which is taken into account when calculating the amount of materials. When plates, rolls exceed 100 mm in thickness, it is advisable to give preference to the cross crate (it will allow to place layers of thermal protection at a right angle to each other).

Above the mineral wool, glass wool and foam it is always necessary to place a special membrane that protects simultaneously from moisture and wind from the outside. Studying reviews for such membranes, it is worth paying attention to whether they let steam well out. If this indicator is insufficient, serious problems may occur.

Canvases for protection against wind and water necessarily overlap each other by at least 0.1 m. When calculating the need for any component parts, you can safely add another 10% to the resulting figure. Then neither defective products or installation errors will not slow down the construction or repair.

Many novice builders and home craftsmen are attracted by the ease of creating crates from wood, which is manifested in the fact that:

- Installation can be done by hand without extra tools.

- The process is not expensive.

- Wooden crate itself minimizes heat leakage (in comparison with the steel counterpart).

- The design can be attached directly to the wall without adding brackets and other connections.

But positive characteristics cannot exist without flaws. Thus, the cheapness of the material becomes a less convincing advantage, given the need for treatment with flame retardants and means that inhibit the growth of microscopic fungi. Not so easy is the selection of bars of exactly the required length, which should be smooth in appearance and, in addition, dried to 10 - 12%.

Recommendations

When the insulation is chosen and purchased, and the work itself begins, nothing should interfere with installers. Therefore, although modern technologies allow to operate in any season, it is advisable to choose a dry and fairly warm day. Before laying insulation, it is required to remove everything that can become a hindrance - even branches of shrubs that can be caught on.

Ecowool in its practical characteristics is identical to the mineral analog, so that the only argument in its favor is increased security. These two materials perfectly absorb street noises due to the fibrous friable thicker. Ecowool will have to be fixed with special devices, and panels will not form from it. So almost always installation of this heater is trusted by professionals. If you can not pay for their services, you will have to consider other ways of thermal protection.

To insulate siding placed on wooden walls, preferably with the help of materials having the lowest thermal conductivity. It is about glass wool and extruded polystyrene foam. The main problem of stone, concrete and brick surfaces is a high level of steam passing, and only hydrophobic materials can effectively withstand it. For places where maximum protection against fire is required, mineral wool definitely comes first.

Instead of a membrane, part of the masters used hardening layers (made of metal mesh and mortar) to protect against wind and moisture falling outside. There are cases when mineral wool is placed in the form of the so-called enclosing form, when there are mats between two sheets of metal.Such a step helps to ensure the highest stability of thermal protection, but it forces one to think of the attachment of the lining to the outer sheet instead. By placing a warming material using extreme planks, you can set the location of the parts of the decorative material relative to the insulation layer most accurately.

Sometimes users do not know whether it is possible not to warm the siding at all and not to pay for additional materials and work. The answer will always be negative, even when the house is located in an area with a hot climate. After all, high-quality insulation helps not only to keep the heat inside, but also ensures the rational state of the section between the wall and the finishing panels. If condensate accumulates there, then even the strongest and most qualitative material will quickly become unusable. Therefore, the responsible owners are always carefully considering how to ensure thermal insulation under the siding layer according to all technological rules.

Video instruction on weatherization of a house with a siding facade see below.