Gypsum plaster: varieties and uses

For the application of decorative coating often requires the creation of a perfectly flat surface of the walls and ceilings. Particularly popular among plaster mixes are modern materials based on gypsum. Thanks to special impurities, the area of their application is no longer limited to rooms with moderate humidity. Some types of gypsum plasters are suitable for use in bathrooms and building facades. And the possibility of their use as a decorative finishing cover opens up new spaces for creativity.

Special features

Gypsum plaster is a modern finishing material that is used for applying both rough and finishing coatings.Basically, gypsum-based mixtures are recommended for interior decoration with low air humidity. But new technological additives and some additions to the process technology allow the use of gypsum plasters in the bathroom, toilet or for outdoor work.

Such modifiers are bulk fillers with different fraction sizes and polymeric or mineral additives. They make the solution easier and more plastic, and also improve its setting with various kinds of surfaces. The gypsum component regulates the microclimate of the room by absorbing moisture from the cold air and its subsequent impact when the temperature in the room rises.

Gypsum plasters are suitable for repairing small and large surface defects, and they are easy to use.

Specifications

Gypsum plasters differ in their technical characteristics from cement and lime plaster mixes. The characteristics of these parameters mainly depend on the base component, which is a naturally occurring mineral - gypsum.The differences between the properties of the solution and the finished coating are determined by the technological additives present in the composition of the mixture.

Regardless of the manufacturer and the characteristics of the ingredients, the following characteristics are inherent in the finished plaster coating:

- Environmental friendliness. The surface of the material does not emit harmful substances even when heated and wetted.

- Thermal insulation. The thermal conductivity of gypsum plaster at a density of 800 kg per m3 is in the range of 0.23-0.3 W / (m ° C).

- Noise isolation. Gypsum refers to soft materials and absorbs noise coming from outside.

- Vapor permeability Natural ventilation and a comfortable microclimate in the room are achieved due to the absorption and release of moisture by the material, depending on the temperature and humidity of the air.

- Frost resistance. The frozen surface can withstand temperatures from -50 to + 70 ° C.

- Hydrophilicity Gypsum absorbs water very well. With excessive wetting, the material acquires the structure of the dough.

During the work, it is necessary to observe the air temperature from +5 to + 30 ° С. The room should be well ventilated, but it is necessary to exclude drafts.Direct sunlight on a dry layer of plaster may cause cracks.

Material consumption for plastering 1 m2 of surface with a layer of 1 cm ranges from 8 to 10 kg. In one go you can apply a layer of mortar up to 5-6 cm without reinforcement, with the installation of a reinforcing mesh up to 8 cm is applied.

The setting of the compound usually occurs within 1 hour after application, the surface dries out after 3 hours, and it can take from 7 to 14 days to build strength.

Manufacturers offer gypsum plaster in the form of dry powder and ready mix. Supply of dry material for the preparation of the solution at the point of sale is carried out in paper bags, the volume weight of which can be 5, 15, 20, 25 and 30 kg. To prepare the mixture, 2 parts of such a plaster are kneaded using 1 part of water. The finished material is supplied in the form of plastic paste in 20 l buckets.

Composition

The main component of gypsum plaster is aqueous sodium sulfate, which is commonly called gypsum or alabaster. Stones from this mineral of natural origin are subjected to long-term firing at high temperatures, and then crushed to the desired size of the fraction. The smaller the size of the particles, the better the quality characteristics of the finished raw materials.The gypsum component is responsible for the binding properties of the mixture.

Additional ingredients in the form of fillers of natural or artificial origin give the required properties to gypsum-based plaster. They make the mixture easier, reduce material consumption and increase the strength characteristics. Also, the size and shape of the filler particles give the surface a different texture. Such components can be ground sand, polystyrene foam, foam glass, vermiculite and perlite.

The thickness of the applied layer depends on the size of their grains:

- fine-grained are applied with a thin layer of 8 mm;

- medium-grained: coating thickness up to 5 cm;

- Coarse-grained are used for the device of a thick layer.

For bleaching plaster mixture in the composition include titanium or zinc white, which are metal salts. Lime fillers in addition to bleaching change some features of the solution. Lime-gypsum plaster sticking occurs after 5 minutes, after 30 minutes the surface hardens, and strength is gained in 1-2 days.

Polymer and mineral additives are used as plasticizers and regulators of the setting and hardening time of the mixture.These components give the composition additional plasticity and improve adhesion to the treated surfaces. The exact composition and technology of production of such elements are not disclosed to the consumer for commercial reasons.

Dry plaster is diluted only with water, without adding any additional ingredients. Depending on the desired consistency of the solution, the amount of water can be adjusted. The liquid mixture is suitable for finishing coating a flat surface or decorating. As such, it is easily distributed along the wall.

The thick mortar is used for roughing, embedding cracks, chipping and potholes.

Storage conditions

The shelf life of any gypsum plaster is not more than 6 months from the date of production. When buying, you need to pay attention to the condition of the package, it should not be breakthroughs and damage. Overdue or exposed to moisture mixture loses all declared characteristics. It can not be stirred until smooth. The application of such a solution will be difficult or impossible.

Advantages and disadvantages

Like any other building material, gypsum plaster mixes have their own advantages and disadvantages.

Among the advantages are the following:

- The low weight of the compound does not increase the load on the foundation and reduces labor costs during operation, especially facilitating the alignment of ceilings.

- Due to good plasticity, it is easily spread over all vertical and horizontal surfaces, even with a thin layer.

- 95% consists of natural ingredients and does not harm health. It does not emit toxic substances even when in contact with water and high temperatures.

- Plaster has good adhesion with almost all surfaces.

- It is characterized by high vapor permeability, due to which moisture does not accumulate under the layer of gypsum, and natural air circulation occurs in the room.

- It is not subject to shrinkage, therefore at the correct observance of technology on a surface cracks are not formed.

- Completely fireproof. The material is not subject to fire at any temperature.

- Independently recovers after flooding. If neighbors fill in from above, in some days the stain will dry and will disappear.

- Not prone to fungi and mildew.

- You can get a smooth or textured surface with the desired shade, without resorting to additional decoration.

- Unlike cement plaster, the consumption of gypsum mix is 1.5-3 times less. The minimum layer thickness for cement is 20 mm, for gypsum - 5-10 mm.

There are gypsum plaster and a few drawbacks:

- It is not protected from moisture. In wet areas and with strong wetting, it is possible that the plaster layer will erode or be swollen.

- Low impact resistance. Mechanical effects may cause chipping and scratching.

- Under a layer of gypsum plaster metals are susceptible to corrosion, as gypsum constantly absorbs moisture.

- All work needs to be done before the solution begins to set.

- The cost of gypsum plaster mixes is about 20% higher compared to cement.

What is different from gypsum?

Despite the fact that the plaster is called plaster, the correct name of its main component is alabaster. This substance is presented in a mixture in the form of fine powder. Gypsum is a generic name for a rock, from which material necessary for human needs is subsequently obtained.

Modern gypsum plasters differ from ordinary gypsum by additional properties of the solution due to the presence of polymer additives and various inclusions in its composition. Thanks to them, the texture of the surface, the rate of setting and drying change.

The material becomes more plastic, easier to fit, has enhanced strength characteristics.

Kinds

Manufacturers basically divide the types of gypsum plaster compositions in two ways.

Depending on the location of the treated surface:

- For interior work using cheap universal plaster mixes.

- For exterior works and surfaces in rooms with high humidity, more expensive facade mixtures or moisture-resistant gypsum plaster are used.

Given the further processing of the finished area:

- Home - is done to align the walls and the subsequent application to them of a decorative coating.

- Finishing - at the same time carries out function of a rovnitel and a decorative layer.

When choosing plaster you need to carefully read the manufacturer's instructions. Usually it indicates which surfaces the use of this mixture is recommended for, and what method of application is better to use - manual or machine. Mechanized treatment creates a more durable and even layer, but for work requires special expensive equipment. If the plaster is water resistant, it will definitely be indicated on the packaging.

Polymeric and mineral fillers make the mortar structure easy and elastic, therefore almost all gypsum plasters are suitable for surfaces made of various materials. They are intended for leveling the ceiling, as well as wooden, clay and concrete walls. Perlite plaster on the basis of gypsum will help to significantly reduce the consumption of material, improve its strength and thermal insulation properties. Gypsum cement plaster creates a strong layer of the finished surface, which will be thinner than ordinary cement plaster and will dry much faster.

The largest selection of gypsum plasters is presented in the form of dry mixes. But if there is no certainty that it will be possible to independently prepare a solution of the desired consistency, you can purchase ready-made pasta. To get to work with the use of such a solution, you just need to open the container. This material is more expensive than dry mixes and is suitable only for manual application. It can not be diluted with water or plasticizers, otherwise it will lose its properties.

Colors and texture

The vast majority of ordinary gypsum plaster mixes are presented in white and gray,Sometimes there are shades of blue, pink or beige. The color of the mixture depends on the gypsum that was used in the composition. Given the field being developed, the intensity and shades can vary greatly.

By production decorative plasters are painted with special colors., and their color range is almost unlimited. In order to choose the right tone, it is recommended to familiarize yourself with samples and catalogs that must be presented in specialized stores. Venetian plaster can also be used to decorate the walls. A surface that looks like granite or marble is created by applying several thin layers of different shades. Then a special wax is applied that creates the structure of a smooth stone.

To create various textures, special fillers are added to the gypsum plaster: small stones, mica, sand, cotton and wood fibers, and ground brick. With their help, you can not only imitate a wooden or stone surface, but also to achieve the effect of velvet or leather. Styling walls "under the brick" and the creation of patterns carried out with the help of special decorative rollers and stamps.You can use the materials at hand, such as brushes or plastic bags.

Which is better to choose?

So that after finishing the room with plaster, the quality of the coating is not in doubt, you need to opt for materials that comply with GOST. The parameters of gypsum plasters for interior work are indicated in detail by GOST 31377-2008.

In dry condition:

- moisture content of the material should not exceed 0.3% of the total mass;

- weight 1 m3 in loose form - 800-1100 kg, in pressed form - 1250-1450 kg.

In solution:

- the use of water per 1 kg of the mixture should be in the range of 600-650 ml;

- setting time for manual application - 45 minutes, with machine - 90 minutes;

- consumption per 1 m2 with a layer of 1 cm for manual application - 8.5-10 kg, with a machine application - 7.5-9 kg;

- moisture retention without runoff - 90%.

Finished surface:

- compressive strength - 2.5 MPa;

- adhesion to other surfaces - 0.3 MPa;

- density per 1 m3 - 950 kg;

- vapor permeability - 0.11-0.14 mg / (mch · Pa);

- thermal conductivity - 0.25-0.3 W / (m ° C);

- shrinkage is not allowed.

For surface treatment, there is a special SNiP 3.04.01-87. These are the requirements for the evenness of the application of plaster and its moisture. Deviation from the horizontal and vertical per 1 meter is allowed within 1-3 mm, and for the entire height of the room - 5-15 mm.There should be no more than 2-3 irregularities per 4 m2, and their depth is limited to 2-5 mm.

The maximum humidity of the base is 8%.

For wet rooms, plaster should be chosen, which the manufacturer recommends for this purpose. The usual composition for work in such premises is not suitable. To give the coating additional moisture resistance, a deep penetration primer or concrete-contact on an acrylic base is applied to it. For the same purpose, you can use waterproofing mastic. Such mixtures should be applied in several layers on a completely dry surface.

Before you finally decide on the choice of plaster mix, you must first get acquainted with the reviews of various manufacturers and compositions. Acquire materials can only be in specialized stores, and when buying is recommended to consult with a specialist.

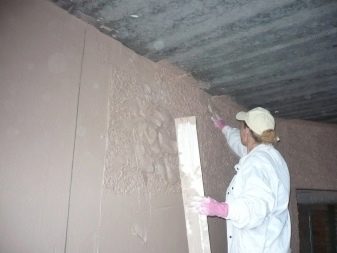

Application

Gypsum plaster is usually used in rooms with low humidity. The mixture is great for the bedroom, nursery and living room, because it does not use substances that can harm health. Initially, gypsum mortars are designed to align the walls for wallpaper and painting.They are convenient for fixing drywall seams.

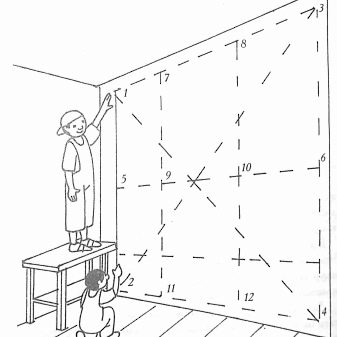

In order to obtain an even quality coating, plaster is spread on the surface in thick layers. Leveling is better to do the rule, but in his absence, you can use a spatula. The walls are aligned from bottom to top, parallel to making the movement the rule left and right. When working on the ceiling, the rule is pulled over.

A layer of gypsum can gnaw, so it needs to be periodically pulled up and leveled.

After 20-30 minutes after application, you need to cut off the excess mixture with the rule and smooth out the irregularities with a spatula. After about 1 hour, if the layer is not deformed by pressing with a finger, it should be moistened with water or a primer. When the surface becomes matte, you should rub it in a circular motion with a spongy metal or plastic trowel. Excess mortar from the grater during grouting should be removed. Then you need to level with a spatula the entire layer of plaster.

After 5-6 hours, the grout is recommended to be repeated. After that, the surface is polished with a spatula or a special trowel. These actions are designed to make the coating perfectly smooth and close large pores.Such a surface does not need to putty, and before painting and applying other decorative coatings will be enough to treat it with a primer.

For the machine method uses special expensive equipment, which, if necessary, can be rented. Gypsum plaster is mixed in a designated container and is fed through a hose. Layers in this case are overlapped, leveling is done in the same way as with the manual method. This treatment creates a more uniform layer, which positively affects the quality of the coating.

Payment

On average, the material consumption per 1 cm layer of plaster is 8-10 kg.

It directly depends on the following parameters:

- manufacturer and features of the mixture;

- surface evenness;

- layer thickness.

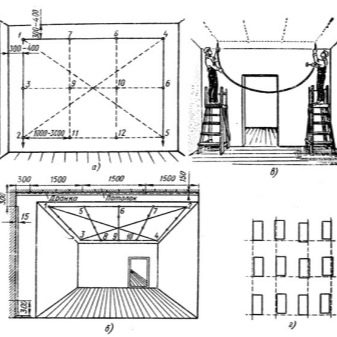

To determine which layer of plaster is needed, you need to check the difference in the wall block at 3-5 points on each side. To do this, a cord is stretched at the same level on the same level, and several cords at an equal distance from each other are strictly vertically down. It is necessary to measure the distance from each cord to the wall: the shortest distance will indicate the most prominent point, and the greatest - to the maximum dam.

Then the difference between these distances is calculated, and the result is divided by 2. This will be the main layer thickness. An additional layer thickness of at least 3 mm and 10-15% per margin is added to this value.

So, if the wall falls to 3 cm per 1 m2, it will take about 2 kg of the mixture.

How to prepare a plaster solution?

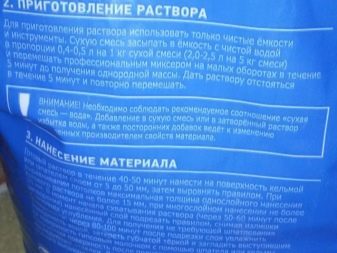

Independent production of the solution from the finished dry mixtures must be done strictly according to the manufacturer's instructions.

There are also general guidelines that are suitable for almost all formulations:

- In a container with 1 liter of water, the temperature of which should be in the range of 20-25 ° C, you need to fill up 2 kg of the dry mixture.

- Mix thoroughly with a construction mixer or drill with a special nozzle. In extreme cases, mixing small volumes of the mixture can be done with a spatula or trowel;

- Leave the solution for 3-4 minutes to gain strength and ductility. Stir it again. The resulting mixture should not be drained from the instrument and have lumps.

All manipulations for the manufacture of the mixture must be done in a clean container and clean tools. The number of ingredients for each new batch must be carefully measured,as the difference in the composition of the mixture can lead to poor-quality coating.

There are recipes for self-made plaster based on gypsum:

- On 4 parts of gypsum add 1 part of sawdust and 1 part of glue for tiles.

- In 1 part of gypsum make 3 parts of chalk in the form of powder with fine fractions and wood glue in the amount of 5% of the total mass of the mixture.

- One part of the gypsum is pre-soaked in water and mixed with one part of the lime dough.

In the first two recipes, the dry ingredients are first mixed, and only then they are diluted with water to the desired consistency. Stirring is carried out in two stages with a break for 3-4 minutes. Various plasticizers can be added to such mixtures. PVA glue is applied in the amount of 1% of the total mass; tartaric or citric acid and special plasticizers are allowed.

Lime also gives the solution plasticity and increases the time it sets and dries.

How to dry?

Surface drying should occur in natural conditions. Indoors there should be no drafts and working heaters, the required air temperature is not lower than +5 and not higher than + 25 ° С.Direct sunlight on the coating is not allowed. Do not accelerate drying with a heat gun or any other heating equipment.

After 3-7 days, the room must be thoroughly ventilated to remove moisture from the plastering layer. The plaster will completely dry and pick up strength only in 1-2 weeks. The finished surface should be smooth and bright. Then it can be glued tiles or wallpaper. And the moisture content of the coating for painting should not exceed 1%.

What to paint?

A wide variety of paints are suitable for painting walls and ceilings over gypsum plaster: oil, glue, acrylic, latex and water-emulsion. The composition and characteristics of the most suitable for gypsum is a water emulsion due to its porous structure. The only paints that can not be used on gypsum coatings - it is lime.

When using oil and acrylic paints, the surface should be treated with a not very hard metal brush to get a rough coating. This is necessary so that the paint adheres well to the plaster and does not peel off from the walls after drying.

Before painting, make sure that the moisture content of the gypsum plaster does not exceed 1%. For such measurements a special device is used - a moisture meter. If the surface meets all requirements, then it must first be treated with a primer. Priming is performed in 2-3 stages so that between the application of layers there is a period of time for which the previous layer is completely dry.

The primer will remove excess dust from the surface and improve adhesion between coatings.

Important nuances

Gypsum plaster is suitable for many surfaces. It can be applied to cement and lime plaster, drywall, wood and paint. Also, gypsum mixtures are allowed to work on gas silicate blocks, logs, chipboard and expanded clay-concrete. Such surfaces must always be primed. For most of these materials, an ordinary universal primer in two or three layers will be suitable, and concrete contact plates will be better applied to concrete floor slabs and paint.

Before you begin to apply the plaster plaster, you need to carefully prepare the surface. All old decorative coatings are completely removed, remove grease stains, glue and dust.If the wall or ceiling was previously painted, it is recommended to remove the paint layer completely. To do this, you can use a scraper or grinder with a grinding nozzle. Lagging layers of old plaster must also be removed.

It is necessary to remove all metallic elements from the surface being treated, since the gypsum layer increases the effect of corrosion on them. Metal parts that can not be removed, are abundantly coated with an anti-corrosion compound.

Large cracks, chips and other significant defects must be covered with cement mortar.

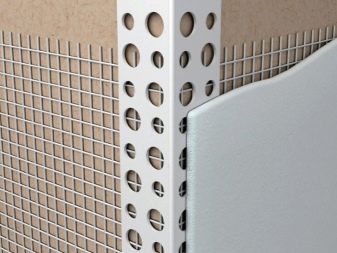

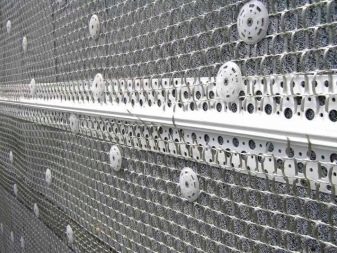

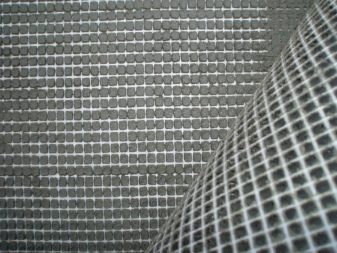

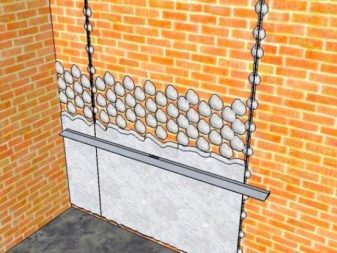

The minimum layer for some plaster mixes is 5 mm. But the optimum thickness for the layer of plaster is within 1-2 cm. In cases where there are major defects on the surface, it may be necessary to increase the coating thickness to 8 cm. Under these circumstances, you will need to reinforce the surface with galvanized or plastic mesh. Also, the reinforcement of the walls must be done in new buildings to prevent deformation during shrinkage of the building.

To install a reinforcing mesh on the entire surface of the wall, you need to apply a marker for each 35-45 cm with a marker.On these marks, holes are drilled using a perforator, and plastic rods from dowels are inserted into them. The mesh is cut into small rectangular pieces and overlapped with screws. The distance from the wall to the reinforcing material should not be more than half a layer of plaster.

Deflections are not allowed on the reinforcement cage, and when touched it should not occur vibration. To correct such shortcomings, to strengthen the structure between the cells of the grid, wire in the shape of a letter Z is threaded. A plaster mix is thinner in consistency on the inside of the grid. This layer is left for 10-20 minutes for drying and only after that put a thicker outer layer.

You may also need to install guide beacons. As them, you can use an aluminum profile for drywall, which after drying the layer of plaster needs to be removed. You can make beacons of gypsum mix yourself. To do this, a vertical strip is constructed from the solution and is leveled using a level. It is possible to work on gypsum beacons in 3-4 hours.

After the plaster has completely dried, it is necessary to check the color uniformity and evenness of the surface. You can check the color only with the right bright light. On the finished coating is not allowed the presence of cracks and chips, and it should not be perfectly smooth or very porous. On the surface only small pores are required. If there are shortcomings, then a second thin layer of plaster should be applied over the finished coating.

To work with plaster materials you need to take into account many nuances. For example, you can add cement to gypsum, mix it with alabaster or sawdust. Various additives inform the solution of new properties and textures. With any plaster solution you need to work very quickly. If it hardens, then soak the frozen mixture for further work with it will not work.

Manufacturers

Domestic and foreign manufacturers supply gypsum plaster of various compositions and purposes to the market. Practically each of them has a mixture in the product line for interior and exterior use, as well as for application by hand and machine. An accurate rating of companies for the quality and prices of gypsum mixes does not yet exist, so the choice of material can be made only on the basis of a comparison of technical characteristics.

Ideal parameters of plaster plaster "Etalon" for interior work from domestic producers:

- color - light gray;

- the amount of water for solution preparation is 0.55-0.6 l / kg;

- thickness of one layer - 2-30 mm;

- compressive strength - 40 kg / cm2;

- temperature during the work - from +5 to + 30 ° С;

- the solution is suitable for use within 1 hour;

- consumption per 1 mm layer - 0.9-1.2 kg / m2.

At Etalon plaster for machine application, all characteristics coincide, except the time for work, which is increased to 100 minutes.

Plaster "Teplon" from the Russian company "Younis" is suitable for interior work and is applied both manually and mechanically:

- White colour;

- the amount of water for solution preparation is 0.4-0.5 l / kg;

- thickness of one layer - 5-50 mm;

- compressive strength - 25 kg / cm2;

- temperature during the work - from +5 to + 30 ° С;

- the solution is suitable for operation for 50 minutes;

- consumption per 1 mm layer - 0.8-0.9 kg / m2.

Plaster "Bolars" also produced in Russia and has the following parameters:

- White colour;

- the amount of water for solution preparation is 0.44-0.48 l / kg;

- thickness of one layer - 2-30 mm;

- compressive strength - 25 kg / cm2;

- temperature during the work - from +5 to + 30 ° С;

- the solution is suitable for use within 1 hour;

- consumption per 1 mm layer - 1 kg / m2.

Turkish gypsum plasters from Dr. companies are also popular. mix. satin, Rigips, Siva and many others.

How to make plaster plaster on beacons, see the following video.