Dry plaster: types and uses

Previously, when preparing the plaster, it was necessary to spend time mixing lime, cement, or gypsum. Now, any modern consumer can purchase ready-made dry plaster for interior finishing work for a lumber, frame house, for exterior decoration of another building, for interior finishing. Before applying to the surface it will only need to be diluted with water.

Another popular type of dry plaster is a sheet of plasterboard, it is considered very convenient to use. We will understand the types and nuances of the application of various dry plasters in more detail.

What it is?

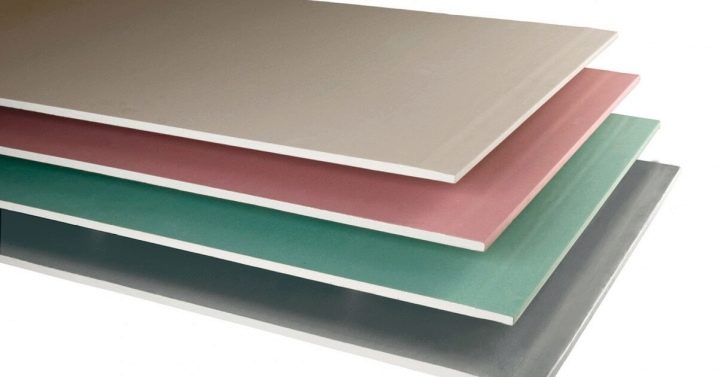

Dry plaster can be sold in the form of a free-flowing mixture, which requires dilution in water. Sheet materials are created on the basis of gypsum (in such a plaster of its approximately 93%). Manufacturers trim a sheet of paper or cardboard on both sides: it does not allow the plaster to collapse, crack.

The composition of sheet plaster also includes organic substances that differ in viscosity (for example, starch). They increase the strength of materials, make them more durable. Drywall is universal, it is used for finishing a variety of surfaces. For this reason, many modern consumers choose just such a plaster.

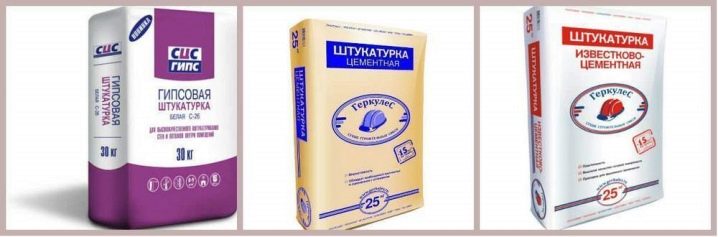

Varieties of mixtures

If we talk about plasters that are diluted with water, it can be noted that there are several basic varieties of such solutions. Mixtures are lime, cement or gypsum.

Plaster

These materials are very popular because you can work with them very quickly. Their composition includes not only gypsum, there are also polymeric fillers. Such mixes get for internal finishing works.The main advantage of gypsum plasters is the lack of need for finishing, because the base is very smooth. The disadvantages of such materials are low strength and fluid instability.

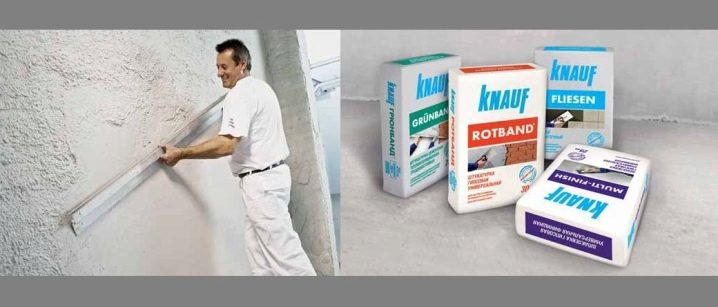

Before using gypsum plaster, remove all dirt from the wall and make it as flat as possible. Preparing the mixture, focus on the proportions that the manufacturer indicated. Carefully read the instructions. To apply the material to the surface, use a spatula: the layer will need to be as smooth as possible. This coating usually dries in a day, and completely hardens in about a week.

Calcareous

This is the most traditional option that has been used by consumers for many years. The composition of such materials include cement, sand, lime. This plaster is used to finish the internal surfaces: it is not resistant to the effects of liquids, and therefore not suitable for external walls.

The main advantage of such compositions is the low price, but they are not durable and dry in two days, not earlier.Such coatings become as hard as possible in about a month.

Cement

Cement dry plasters are universal: they can be used for both interior and exterior. The main components are sand and cement, additional components increase adhesion and make the material more viscous polymeric fillers.

Such coatings are not suitable for wet substrates. For this reason, it will be necessary to thoroughly dry the surface before applying the plaster. It is also necessary to use a special deep-penetrating primer. The coating dries in three days (but it can happen faster), it completely hardens in a week.

To work with plasters that are diluted with water is easy enough. It is only necessary to exercise the utmost care, attentiveness and take into account the recommendations that are listed in the instructions. When purchasing is very important material characteristics: pick it very carefully, taking into account the features of the surface.

If you can not decide which type of plaster is better, gypsum or cement, then we offer to watch the next video.

Features sheet materials

Sheet plaster has many advantages.

Especially strongly consumers are attracted by the following advantages:

- Ease of installation. If you install sheet material, you do not have to wait for a while before finishing. It is also worth noting that the installation itself is carried out much faster and easier than putting ordinary plaster.

- Soundproofing. Such material is a barrier to sound waves.

- Fire resistance This coating will not spread or sustain flames. Only cardboard or paper topcoat will suffer.

- Safety for human health. Sheet plaster created without the use of harmful components. When heated, such materials do not emit harmful substances.

It is also worth noting that sheet materials are not as expensive as liquid plasters. This advantage is decisive for many consumers.

Dry sheet plaster has not only pluses, but also minuses:

- Insufficient resistance to liquid. Even if you apply a special waterproof coating to drywall, it will not be able to withstand the effects of water for a long time.If your apartment is flooded, you will need to finish the ceiling or walls again.

- Insufficient strength. It is not recommended to hang heavy items of furniture and appliances on plasterboard walls.

Installation work

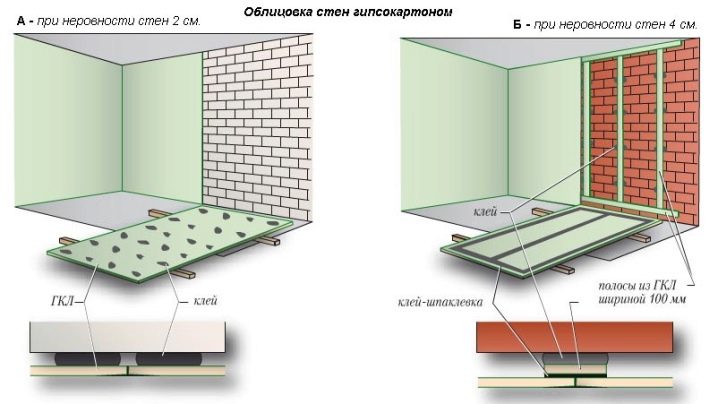

Sheet materials can be installed in different ways. Two methods are commonly used.

On glue

With this method of installation drywall fixed on the base with adhesives. You can buy a special mixture, it is diluted in water. On packs, manufacturers usually indicate proportions. You should get a uniform and sufficiently thick material that is easily applied to the substrate.

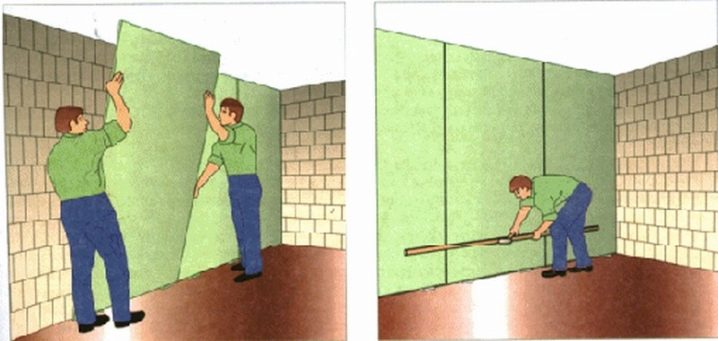

Drywall has a significant weight, so do not carry out installation work alone. It is recommended to engage in the installation of such material with an assistant.

Installation on adhesives is as follows:

- First, clean the base on which the plaster will be applied. You can do this with a sander or sandpaper.

- Apply primer to the ceiling or walls. Due to this, the surface and adhesive will adhere better to each other.

- Wait for the primer to dry and use glue, apply it in the center of the wall and around the perimeter. On the surface there should be quite a lot of adhesive. Glue can be applied to drywall itself.

- Lean the sheet against the surface. With the help of the construction level it will be possible to check whether it is installed correctly.

When the finish is complete, wait for the adhesive to dry (the right time is usually indicated on the package). Using finishing putty, close up joints between plasterboard products. Then it will be possible to proceed to the finishing finish: to glue the wallpaper, laying tile coatings, applying paint. This is the easiest way to install sheet materials, this method is suitable even for an inexperienced person.

On the frame

Installation on the frame is not similar to the previous method. It will be necessary to first prepare the aluminum frame: then dry plaster is attached to it using self-tapping screws.

Installation work is carried out in the following order:

- Clean the surface, prepare it for installation. It is necessary to remove the potholes, get rid of irregularities. Otherwise, the frame will not hold well.

- At the bottom of the wall, install the horizontal profile. The design is based on this element. Using the building level, you will need to pre-mark the base.

- Then an upper profile is installed on the ceiling.

- Then install the vertical posts. They will connect the lower and upper elements. So that there are no gaps when installing drywall, follow the step of 40 cm. Using the building level, check whether the vertical elements are evenly spaced.

- Using a screwdriver and screws, fasten the drywall to the frame. Make sure that there are no gaps between the sheets: they should be placed end to end.

Expert advice

If you want to achieve good results and get high-quality and durable coating, you need to take into account certain rules.

Remember the following points:

- All engineering communications should be dealt with before using dry sheet plaster. Build them in advance.

- In rooms where there is a high risk of fire, use fireproof coatings.

- Do not install dry sheet plaster at very low temperatures.otherwise, cardboard or paper will be peeled off from the drywall.

- Do not use ordinary sheet materials in rooms where there is very high humidity. Stop the selection on sheets that have a moisture resistant coating.

Consider the manufacturer's recommendations and strictly follow the instructions, in this case, the results of finishing work will not disappoint you. If you are not sure that you will be able to select the appropriate material yourself, consult a specialist in advance.