Features of the choice of flush tank with fittings

The trends of the modern world are forcing humanity to move forward, improving technologies, increasing the level of comfort in life activity. To date, there is a huge selection of various plumbing. If you do not understand in advance in the types and features of the device, you can choose the wrong mechanism or buy a product that may be of poor quality. Especially often this problem concerns the choice of cisterns for the toilet.

Types of toilet bowls

Among the sanitary products presented in stores, you can mainly see models made of ceramics, different in size and color.When choosing the model you like, you should ask the seller about the types of toilet bowls.

They are divided into several types of washout organization:

- Organization of direct washout. In this case, the water entering the toilet from the cistern moves straight, without changing direction.

- Organization of water discharge reverse action. This option is more functional than the previous principle of action. But this type produces much more noise when working.

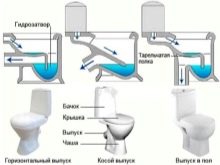

There is one more important aspect that you need to pay attention to when choosing a toilet bowl - this is a variant of the outlet. Toilets can be with the release of water horizontal, vertical or oblique action. This technical feature should be selected individually, having studied the features of connection to the sewer network.

The design of the toilet can also be different. There are devices in which the bowl is structurally combined with a flush tank, or the tank is located separately from the toilet bowl. When a separate location to the toilet, you must first secure the side table. It is a ceramic plate.

Rod stock for the toilet drain tank is the most common anduniversal option.

general characteristics

Before making a purchase, it is necessary to select the type of flush tank. This is due not only to practical purposes, but also to an aesthetic appearance. In addition, the plumbing design affects the final cost.

When choosing plumbing, the tank which will be suspended, will have to incur additional cash costs. This is influenced by the design of the device itself. It is assumed that the drain tank is required to be fixed at the required height. Thus, to join the cistern with the toilet, an additional construction from a pipe will be needed, which will be located against the wall between the cistern and the toilet. In addition, additional materials will be required for the pipe installation, and this will lead to additional costs.

Also it is worth paying attention to types of drain tanks as each version has special features.

Tank classification:

Wall hanging

This flush cistern was most prevalent in the 20th century, during a period of large-scale construction of houses called “Khrushchev”. The type of this design involves mounting the flush tank over the toilet high on the wall.This solution provides a strong water pressure when flushing due to the installation height.

This model has a minus. Hanging over the toilet flush tank looks extremely not aesthetically pleasing. It can be hidden behind a false wall. However, this will require additional cash costs. That is why the model is considered already obsolete.

Monoblock or toilet with flush tank

It is installed on the toilet bowl. This design assumes that the toilet and the flush tank are a single cast construction, or the flush tank is mounted on the toilet shelf. This design has been used since the 90s of the twentieth century. It is most convenient and practical in operation and maintenance. If the tank is mounted on a shelf, the first thing to do is to fasten the gasket. These items are self-adhesive.

The flush tank is mounted directly to the shelf using special bolts. These bolts should have a rubberized cone-shaped gasket. Bolts are placed inside the tank. When the nuts are tightened, the gaskets will seal the through holes, and you will not have to worry about leaks.

Now you need to fix the tank itself to the shelf of the toilet. To do this, you need to combine the holes in the tank with the holes in the shelf, and then tighten the tightening nuts.

Built

This design is gaining popularity. It is actually a plastic container, mounted behind a false wall attached to a concrete wall or to a special rigid frame, installed additionally, if the strength of the wall is insufficient. Fastening is carried out to the wall and the floor, which indicates sufficient reliability. This design is the most aesthetic, but has drawbacks in the form of the need to build a false wall and, as a result, difficulty in repairing.

Since the flush tank itself is located inside the false wall, only the drain button is displayed on the front surface of the wall. If necessary, access to the internal components of the tank is possible only through this button. Therefore the made accessories are reliable in operation.

Built-in tanks can be one-button and two-button. In the case of a two-button device, water is drained by pressing one of the buttons.

The advantages include the ergonomics of the device, the absence of noise when filling with water, the aesthetic appearance and the reliability of internal elements.

Differences by type of filling:

With side feed

Water is supplied to the tank from the top side. Very noisy design when filling the tank. Eliminate the noise can be lengthening the hose filling water.

Bottom feed

The water in the tank is supplied from below. This design is noiseless, but requires careful sealing in place of the feeder in the tank.

Drainage fittings are the same for both types and do not depend on the method of water supply.

Types of fittings

When choosing a flush tank, you should pay attention to some features:

- the volume of the tank itself;

- the location of the filling valve, through which the water supply.

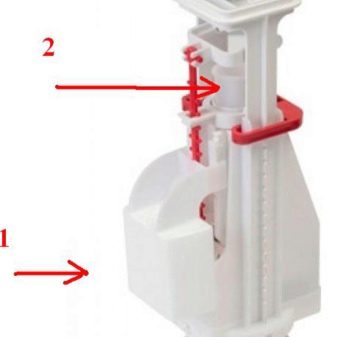

If the tank has a supply valve on top, then it is possible to mount the locking device on the tank already mounted. If the location of the inlet valve below, it is much easier to install the tank fittings before mounting the tank.

It is necessary to approach the choice of the repair kit for the flush tank responsibly. Since it should be suitable for your tank, it is important that it ensures the correct opening of the drain holes and its tight closure when filled with water.

The composition of all flush tanks is the same. There are mandatory stop valves and drain fittings. Thanks to the coordinated actions of these mechanisms, alternate drains of water into the toilet bowl and its subsequent set of water supply networks are carried out.

Each type of reinforcement has a number of features:

Valves

The function of this design is to ensure that the tank is filled with water to the required mark. After filling, it provides a water stopper with a special closing valve.

Drain fittings

The purpose of the drain fittings, as the name implies, is to ensure that the toilet is drained by pressing a key, a lever or lifting a handle. After draining the water, the drain valve design provides a hermetic shut-off of the tank's drain hole with a valve mechanism that eliminates possible water leaks into the toilet when it is filled.

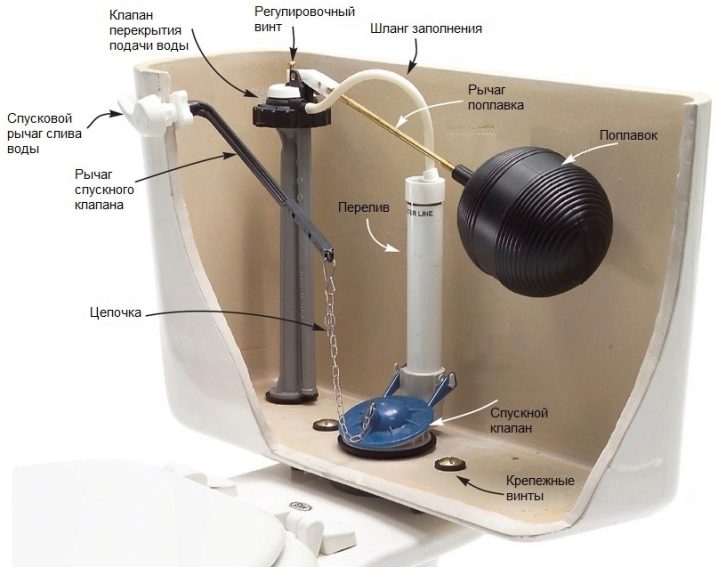

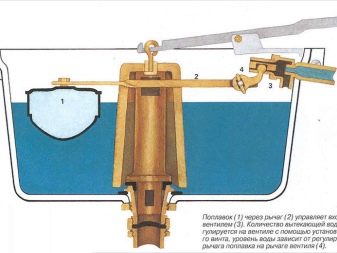

Functionally, stop and drain valves are combined into one whole and are a combination of the following elements:

- Drain or valve mechanism. It provides a flush to the toilet and is activated by pressing a button or a drain lever.

- The float mechanism is directly connected to the drain mechanism. It serves to regulate the water supply when filling the tank.

- A tap or valve for putting water into the tank is connected to the float mechanism. It opens and closes the water supply to the tank.

- The leverage system serves to combine the drain and float mechanisms.

- Rubber or polypropylene gaskets seal the installation of the main elements of the system.

The toilet cistern is filled with water very simply. Water flows from the water supply network through a hose that is connected to a reservoir via a supply valve. A float in the form of a closed container made of foam or plastic is also connected to this valve via a rod. Under the action of water (its set or drain) the float has the ability to move up and down.

As the tank is filled with water, the float valve rises with the upper water level and closes the supply valve. In the upper position of the valve with the tank fully filled with water, the valve closes the water. During discharge, the float valve drops with the water level. In this case, the supply valve opens, and the water through it begins to fill the tank.

By the method of draining mechanisms are divided into two types:

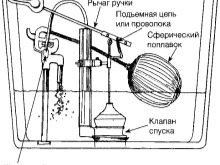

Stock

A vertical rod locking the drain hole is connected to a handle located on the surface of the tank lid. The mechanism is driven by raising the handle, with which the stem rises and releases the drain hole.

Push button mechanism

It is presented in the form of a number of models:

- with one mode - full discharge of water;

- with two modes - partial discharge and full discharge of water;

- Drain interruption mode, in which it is possible to interrupt the drain and unlock it.

The principle of the drain is no less simple than filling. By raising the stem or pressing a key (lever), the mechanism lifts the valve that closes the drain hole, and water flows into the toilet.

Valves

There are several types of valves:

- Croydon valve. It includes elements such as a saddle, a lever, a float lever. From the movement of the lever, the piston is set in motion vertically. This design is found in outdated models of tanks.

- Piston valve - the design that has received the most widespread. Here the lever is secured in a split pin. A lever with its movement actuates a piston that moves horizontally.The piston itself has a gasket. At the time of contact of the piston with the seat gasket closes the water supply.

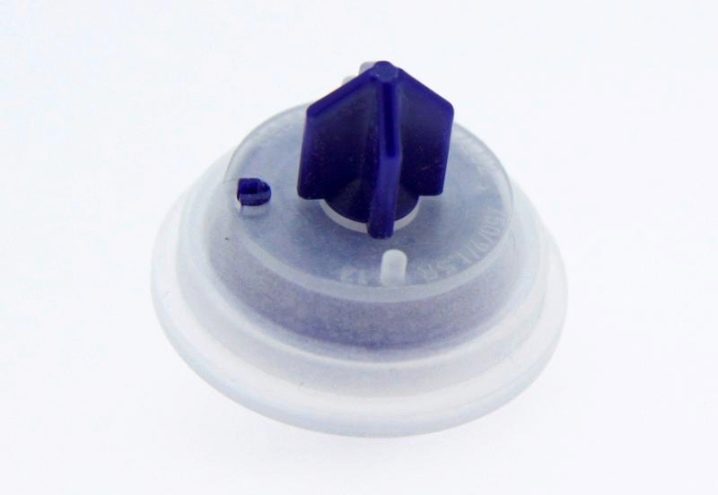

- Diaphragm valve. In this construction, instead of a gasket, a membrane is installed on the piston. When the piston moves, the membrane (diaphragm valve) blocks the water inlet. This design is much more efficient and reliable overlaps water without leaks, but it has a significant drawback, which is the fragility. But the manifestation of this deficiency significantly depends on the quality and composition of tap water.

Selection features

When choosing a cistern, special attention is paid to the design features of its viscera. Armature - both drain and shut-off - must be made of quality materials. In no case is it permitted to use steel materials in the manufacture. Steel in water is prone to corrosion, so the life of steel elements will be very limited.

It is more expedient to choose plastic components and mechanisms of the internal systems of the flush tank. Sealing and sealing membranes should be made of flexible and high-quality materials, such as rubber or polypropylene.

With regard to the type of drain tank, then you need to focus on the choice of personal preference. It is necessary to take into account such a nuance that wall containers have long been morally obsolete. The simplest and most accessible maintenance option is a monoblock or a toilet with an added cistern. Built-in models or floor-standing toilets with installation, the filling capacity of which is installed inside the wall, are also reliable and have wide application.

What to consider when installing?

The installation of the flushing cistern should only be done after the toilet has been installed, secured and connected to the sewer network. Before mounting the tank, it is necessary to check that the tank mounting elements, as well as the drain and valves, are complete. All parts must be of high quality, without visible damage and in sufficient quantities.

Bringing water into the tank is possible both in a rigid way and flexible. For the hard method is used water pipe. A flexible way involves connecting the water supply system to the tank through a hose. This method is most convenient and practical during operation. This is due to the fact that any damage or shear of the pipe can cause a depressurization of the joint with the tank and the occurrence of leaks.

After installing the plumbing fixture, it is necessary to adjust the fittings. It is necessary to check the operation of all elements in order to avoid possible leaks or overflows during operation.

Replacement parts

Plumbing stores typically offer flush tanks with internal fittings already installed and a full set of fixings. Therefore, the buyer can only install a sanitary appliance and start using it. Many do not even think about what mechanisms are functioning inside the tank, and how its work is carried out. But over time, the mechanisms begin to fail, and the user has to understand the features of the device in order to repair and purchase new parts.

The main problem with the purchase of spare parts is not in their absence, but in their quality. Only high-quality repair kit products ensure long-term operation of the cistern. Poor quality components can lead to unpleasant breakdowns. For example, regular leaks through the drain hole of the tank lead to excessive water consumption, as well as to stains on the white surface of the toilet bowl.

In case of failure of the cistern drainage mechanisms, a specialist should be called. Payment for plumbing work varies depending on the complexity and scope of work. You can try to figure out the damage yourself and repair the device yourself. To do this, you need to buy the necessary parts and use the instructions.

There are a number of the most typical problems and ways to solve them.

Constant filling of the tank with water can be explained by the following reasons:

- Wear valve inlet. In this case, a complete replacement of the node is required.

- The curvature of the spokes (rod) float. Align or replace part.

- Damage to the float, in which it loses tightness, and water seeps inside. A float replacement is required.

If water drips from the bottom of the toilet bowl, the reason may be hidden in the damage or wear of the bolts. A complete replacement is required. It is better to change the elements to bronze or brass, since they do not rust.

Water all the time flows into the toilet for the following reasons:

- The problem may be in the wear of the membrane. A complete replacement will be required. To do this, remove the siphon and install a new membrane, after which you need to put the siphon in place.

- The problem can also be damage to the float mechanism. It requires adjustment. In the correct position of the float mechanism, the water in the shut-off valve is blocked not less than 2 centimeters from the edge of the tank.

- If water flows in the place where the water supply network is connected, then a rubber band is worn out - a gasket in the place where the network is connected. It needs to be replaced.

The reasons why the water is not filling or filling slowly:

- Most likely, the problem is in the wear of the intake valve. It needs to be replaced.

- The problem may be in the blockage of the hose. It needs to be cleaned.

Sometimes it is necessary to carry out the replacement of the entire valve of the cistern. This is done when replacing one part is not advisable due to the large wear of all parts and possible breakage. Such work includes the replacement of the old sample.

The procedure will be as follows:

- close the tap of the water supply network and drain the water from the tank;

- remove the tank cover by removing the button or the handle;

- unscrew the hose network;

- remove the fittings of the drain column (depending on its type, the fastenings may be different), turning 90 degrees;

- remove the toilet bowl attachments and the toilet itself;

- remove all fasteners of the remaining reinforcement and remove the reinforcement;

- Install new fittings in reverse order.

In case of leakage at the point of connection of the water supply system at the built-in tank, it will be necessary to dismantle the casing of the toilet installation. Therefore, in the initial installation of devices to work should be taken very carefully.

Prices for components of the internal components of the flush tank may vary depending on the manufacturer, the quality of materials and mark-up store. Therefore, compare the cost of parts before purchase.

For information on how to replace and adjust the toilet bowl fittings (drain) with your own hands, see the video below.