Acrylic liners in the bath: technical characteristics and installation features

The bathroom should be a territory of comfort. However, it happens that there is no money to replace the old cast-iron plumbing, or there is no technical ability to do this without damaging the wall, since no major overhaul was planned. In this case, manufacturers offer to resort to restoration by installing an acrylic liner.

Special features

Restoration by inserting a new surface into the bath was developed by engineers from Austria more than forty years ago. The method was patented only in 1996.He allowed to perform similar work at home. Acrylic liner in the bath is designed to quickly restore the appearance of plumbing. The main function is not only improving the aesthetic properties, but also blocking the damage to the enamel coating.

The insert is installed inside the product as a cover. It is designed to update the bath and protect it from mechanical impact and further destruction of the enamel.

To increase the life of the liner, you need to carefully approach its choice. An important criterion is the material. The insert should not be made of ordinary plastic or technical acrylic, such a product will become unusable in a few months after installation. Most often, medical acryl or double-layer ABS-acryl is used as a raw material. The technological process of manufacturing acrylic liners is not easy, it can not be done without special equipment in artisanal conditions. Quality products can be made only at the factory.

In the production of thin acrylic sheet at high temperature and under the action of vacuum bend in the desired shape.The thickness of the initial workpiece starts from 6 mm. Restoring old baths with the liner allows you to get without special expenses smooth and pleasant to the touch surface, which has certain advantages.

Advantages and disadvantages

Among the main advantages that influence the choice between buying a new bath and restoring an old one, there are several.

- Low financial costs. Cheap acrylic liners are more profitable.

- Short installation time. Professional installation time is 2 to 3 hours. In the case of installation by hand, it can increase to 5.

- Bath renewal without major repairs. During the installation of the liner, dismantling the old bath is not required.

- Good insulation, which is especially important when installing in a steel bath.

- Excellent thermal insulation allows you to keep hot water in the bowl for a long time.

- Self-installation is possible.

- High impact resistance, scratch resistance.

- Plasticity allows you to transfer deformations, especially in a tub of thin material, for example, steel.

- Long service life. Proven manufacturers guarantee up to 20 years of operation.In fact, with proper use, an acrylic insert can last a dozen years longer.

- Hygiene. Since the medical polymer has no pores, it is easy to care for it and bacteria and fungi do not start on it. It is also called ecoacryl. He is not afraid of household chemicals without abrasives, can be cleaned even with soap. Also, due to the non-porous structure, acrylic does not yellow, dirt and rust does not eats into it.

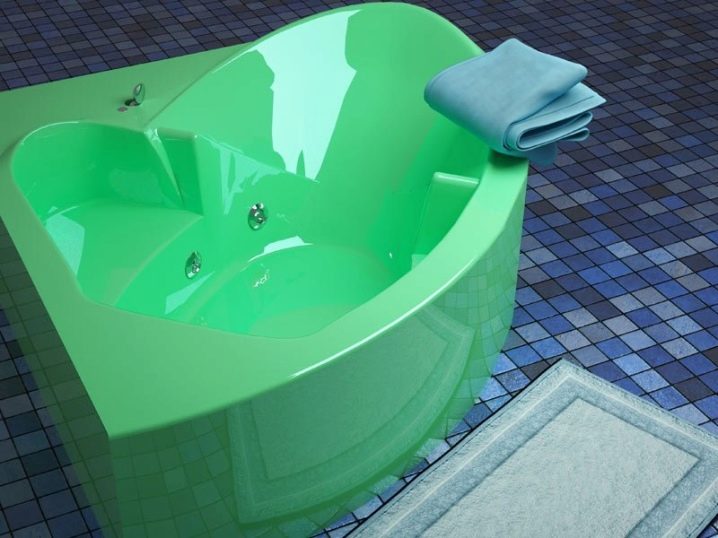

- The ability to choose a color that expands the boundaries of the usual bathroom design. Shades do not fade and are not erased during the entire service life.

- Acryl is not an allergenic material, so it is safe for health.

There are also drawbacks that should be considered before proceeding with its installation.

- Acrylic liner reduces the internal volume of the bath. However, experts claim that acrylic actually has a small thickness, so the decrease is difficult to notice visually. Rather, it is a psychological sensation.

- If there is a tile-like finish that goes directly to the sides of the bathroom, then they will need to be dismantled.

- Illiterate installation significantly reduces the service life of the product.

- Poor attachment of the liner inside the old bowl can cause the formation of fungus and mold if water gets between the two surfaces.

- If you do not follow the rules of operation, the restoration coating will quickly become unusable.

- In the bathroom with a liner is not recommended to bathe animals, because they can damage the coating with claws.

- Do not install the acrylic liner if the owner has a weight of more than 100 kg, as the product will crack under this mass.

Species

Inserts of acrylic material are of two types:

- Cast. Such products are made of sheet sanitary acrylic by pressing. In the production process, the sheet is placed on an aluminum or synthetic matrix, heated to the desired temperature and pressed under the action of a vacuum. At the stage of heating and molding, acrylic is stretched, which leads to a decrease in the thickness of the original billet. If the manufacturer as a savings will use thinner sheets, the walls of the resulting liner can be so thin that they can not guarantee the integrity of the product.

- Composite. The basis is ABS plastic, which is covered with an acrylic layer on top. Products differ in the short operational term. The production process allows to obtain a monolithic connection between the layers. However, the acrylic layer does not exceed 0.3 millimeter, which will not be able to provide high-quality protection against mechanical damage. Since plastic molding is easier, the cost of composite liners is significantly lower than that of pure acrylic coating.

Sometimes buyers are interested in the availability of vinyl restoration products. Professionals warn that vinyl liners for the bathroom does not exist. Since polyvinyl chloride is not a sanitary material, only windows, fabric, building finishes and other things that are not related to plumbing are made of it.

In order to meet all technological requirements, acrylic inserts are produced only in industrial conditions.

As a rule, the restoration surface is placed in an old cast-iron bath. This sanitary product is a classic, which has no analogues, but requires some effort for maintenance and installation.To date, manufacturers can not offer inserts for any model of the bowl, only the most common. Standard sizes in centimeters are usually 150x70 and 160x70. However, there are models with a length of 170, 180 and a width of up to 80 cm. The most common acrylic version in a sit-down font has dimensions of 120x70.

Acrylic material allows you to experiment with a hint bowl. The colored insert will become a designer element of the bathroom, on which you can put the main emphasis, to fantasize with lighting and color solutions of the surrounding space. The most common shade according to customer reviews is white and blue, but other colors look no less impressive.

Criterias of choice

The price of an acrylic liner in a bath is lower than the cost of a new product, but not so much as to change it regularly. Therefore, the choice should be approached carefully. Before buying an acrylic insert, first of all you need to correctly measure the measurements from the base.

It is recommended to make five basic measurements:

- bath length is determined from the outer edge;

- the length of the inner bowl is measured from the inside, not taking into account the width of the sides;

- internal width between the sides of the drain;

- internal width of the most expanded part of the bowl in the back area without taking into account the width of the sides;

- The depth is determined near the drain hole. Experts advise you to put a flat rail on the sides of the bath, from which it should be measured perpendicularly down.

It is recommended to take measurements even if the sanitary product has standard dimensions. This will help to more accurately select the insert. It is necessary to take into account not only the length and depth of the bowl, but also a different width in the area of the drain and near the back. It is not recommended to buy a product of smaller size, even if the shape of the bath is non-standard. The acrylic case should sit like a “second skin”, otherwise it will sag, deform and, as a result, crack.

Choose a quality product is easy if you follow the advice of professionals and pre-examine customer reviews.

Products must be certified. Proven manufacturers give a guarantee for several years. Also, the product should be accompanied by instructions with recommendations for proper operation and proper care.If the price of the product is low, but the seller refuses to provide a quality certificate or the warranty period is less than a year, it is better not to buy such an insert. In this case, there is a risk of acquiring a headache when in a short time the product becomes unusable.

The optimal thickness of the acrylic liner varies from 5 to 6 mm. If it is smaller, then during operation the layer will swell and crack. This criterion can be checked visually. The product should not shine through if you look through it to the light. In addition, a quality liner should not bend when pressed. When buying, you should pay attention to the fact that the surface is smooth to the touch, there are no defects in the form of flows, thickenings, cracks, its color is even.

It should be remembered that the products of foreign manufacturers may not be suitable for domestic baths. It is better to choose Russian firms that have large dealer networks throughout the country. The brands listed below have proven themselves. They, as a rule, use German and Austrian raw materials and equipment for production. These are companies:

- LLC ISKomp. The company has been manufacturing similar products since 1997. Products are certified, have all the necessary certificates. The activity is licensed in the Russian Federation. A patent for the production of in-ear baths was obtained by management in 1994. The manufacturer offers options for acrylic products of various colors and sizes. An extensive dealer network allows delivery to customers in all regions of the country. Any product kit must contain all supporting documents along with recommendations. Users appreciate the products of this company.

- Plastall. The company specializes in the production of materials for the restoration of baths of iron and steel. Its branches are located in several cities of Russia: Tolyatti, Moscow, St. Petersburg, Novosibirsk. As well as in neighboring countries (Ukraine, Belarus, Kazakhstan) and in the Western market. In addition to production, the company sells and provides installation services. The brand offers as a guarantee the first free sample, as well as a complete package of all documentation. In addition to the liners themselves, the company sells components and liquid acrylic.

- Seven Lux. Production areas are located in the city of Tolyatti. The company specializes in the production of acrylic baths, liners, pallets and panels for shower cubicles. The products are made on high-tech German equipment. It has all the necessary quality certificates and documents that confirm the originality of the technologies used. Products can compete with European counterparts.

- "Multiplast" - It is a large industrial and commercial holding, which specializes in the sale of household goods. The company's products are certified, in accordance with accepted technical standards and GOST RF. A developed dealer network allows an individual approach to each client.

If the bathroom has non-standard dimensions, then the pad does not fit it. As a rule, manufacturers are guided by the following standards: 120x70 cm, 130x70 cm, 140x70 cm, 150x70 cm, 170x70 cm, 185x85 cm.

If the base does not have similar dimensions, then in this case there are two ways out:

- registration of the order by the individual sizes;

- way "bulk bath".

The second method involves coating the surface of the bath with liquid acrylic. The quality characteristics of artificial enamel - glass, is several times better than epoxy paint.The main difference of this process from enameling is that the enamel is applied by brush or roller, and acrylic is poured onto the surface of the bowl.

The main advantages of the filling method include the following factors:

- Suitable for baths of any shape, as opposed to liner. It is especially relevant for the restoration of specialized bowls, for example, a jacuzzi.

- The internal volume decreases significantly less.

- During restoration work, there is no need to remove tiles or other decorative coatings from the sides. For their safety, it is enough to apply a building tape.

- If there are minor defects, liquid acrylic will fix them.

Before proceeding with the restoration of stakrilom, you should first familiarize yourself with the negative aspects of the method:

- acrylic fumes are harmful to health, so you should not be in the bathroom without protective equipment until it is completely dry;

- it is recommended to remove the siphon, as it may become clogged during repairs;

- significant defects: deep scratches and chips, it will not be possible to fill in;

- cash costs can be significant since acrylic is poured rather than brushed.

Subtleties of installation

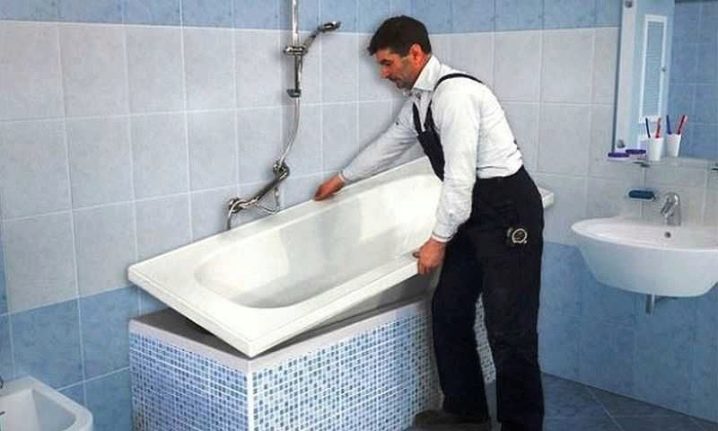

Installing an acrylic liner with your own hands does not take much time. Before you install the insert in the bath, it is necessary to carry out all the preparatory work: take measurements, prepare the bowl itself.

Training

After all the necessary measurements have been made and the liner is selected, proceed to the next stage, connected with the preparation of the bath itself. The first step is to find out whether the finish of the bowl closes. Many owners hide cast iron products under tile or paneling. In addition, the boards are often protected from the flow of water to the floor with plastic corners. Such parts, located directly on the bathroom, must be removed to release access. In case the edges of the bowl are built into the walls, you will have to very carefully analyze all the options for restoration. If there is an expensive tile or other finishing material, if the walls were not planned to be repaired in the near future, respectively, it is not possible to free the boards, you will have to wait with the installation of the acrylic liner. When restoration is still necessary, it is recommended to apply the method using self-leveling acrylic or by applying enamel.

The next stage - cleaning the old enamel. To improve adhesion when gluing surfaces, it is necessary to remove the smooth enamel coating, clean the rust and lime deposits. Coarse sandpaper is used for this. The process can be performed both manually and with the use of special mechanical devices, for example, grinders with an abrasive nozzle. Next, you should clean the bath of debris, remove fragments, wash thoroughly and wipe it. It is better to defat the surface before further action. You can use the less "dirty" way. In this case, the bath is washed using any cleaning agent. Then rub with baking soda to degrease the surface, wash and dry. However, with this treatment, the adhesion will be much worse.

After cleaning, the siphon can be removed. It is better to temporarily glue the drain hole with masking tape, as it may spill onto the floor when applying mounting foam.

Installation

Initially, you need to try on the purchased liner. If he ideally sat down, then replacing an old sanitary ware will take a little time.In the case when the surface is not perfect, it is adjusted to the size of the concrete bath. To do this, the acrylic insert is placed inside the bowl, mark the edge of the sides and the location of the drain hole with a marker or simple pencil. Professionals are advised to facilitate this process with a simple stylus. Pencil with a thick layer outlines the contours of the holes on the old coating, after installing the liner and slightly pressing on its surface will remain contour trace.

On the planned lines with an electric jigsaw, cut off extra centimeters. Drain holes cut out with a drill and disc nozzles. It is necessary to control the trimming process to prevent mowing and the appearance of burrs.

Next, you need a silicone sealant or glue, as well as a two-component mounting foam. Silicone is pre-applied to all drain holes and side edges. The procedure will allow to protect the bath from the ingress of fluid between the layers, therefore, protects against destruction and the formation of fungus. The inner surface of the bowl is evenly covered with special mounting foam.The thickness of the applied layer should correspond to the distance between the tab and the old bath. Large openings should not be left between the foam strips.

After the acrylic surface is placed inside the bath and pressed. Compression should be tight but careful so as not to damage the acrylic. Experts recommend using special clips and seals for this purpose. Particular attention should be paid to pressure on the bottom. If there is excess sealant during pressing, it should be removed.

The next step is to install the siphon. It is recommended to determine in advance of the fitting stage whether the old siphon is suitable for a new bath, the thickness of which will increase due to the liner. When installing the hole should be treated with waterproof sealant. When installing the drain, it is important not to overtighten the bolt, as this may result in deformation of the acrylic. If the insert cracks, a void will form between the surfaces, into which water will fall, leading first to an unpleasant odor, and then to the destruction of the acrylic layer.

Upon completion of all installation work in the bath it is necessary to pour water almost to the brim.Such a load will ensure uniform bonding and polymerization of the assembly foam. It is better to leave her in this condition for the night. Then you can do the design of the edges. To do this, either restore the tile covering, or paste a plastic protective border. Do not forget about waterproofing the seams of decorative and protective parts with sealant. After a day, the product can be used.

Care rules

In order for a new renovated bath to last a long time, you need to follow some rules.

Initial application.

- After installation, the bath can be used only after a day. During this time, silicone sealant acquires its technical characteristics.

- The post-installation tab must be filled with water in order to press it more strongly against the base, which will allow to glue the parts evenly. Drain water is not recommended for 24 hours.

- You should first wash the bowl with soap.

It is best to clean the acrylic liner with soap. It perfectly copes with pollution, cheaply costs and in addition disinfects.To carry out the procedure, it is enough to soap a soft sponge and rub it with the surface, then rinse it off with warm water. After it is recommended to wipe the bath with a dry, non-rigid cloth. If you clean after each use, the limescale and stains from the soap will not form. If contamination does occur, the desired area is cleaned with a soft sponge with a suitable chemical non-abrasive solution.

Experts do not recommend using a plunger if pipes are clogged. In this case, you should choose a special cleanser household chemicals. An important requirement for cleaning is accuracy, the solution should not fall on acrylic, it is better to use a funnel for pouring or pouring directly into the pipe. Since the polymer is not absolutely resistant to mechanical stress, it is necessary to protect its surface from the fall of various objects and strong impacts.

Strong brushes, abrasives and strong chemicals, such as Domestos or Komet, are strictly contraindicated.

Chlorine causes the first darkening of acrylic, and after its deformation and the appearance of holes. Solutions based on acetone, ammonia and similar solvents corrode acrylic material. Formaldehyde in the detergent composition makes it unsuitable for cleaning the bathroom.

In difficult situations and when heavily contaminated, experts advise you to rub stubborn stains with toothpaste. If this does not help, it is better to restore the surface. To do this, you must buy in the hardware store liquid acrylic. Sometimes manufacturers offer specially designed for such cases repair kit for plumbing. Acrylic composition is applied to the spots, after drying, polished with a soft flannel cloth. This method is used to remove scratches and cracks that are formed during operation.

Useful recommendations

Experts assure that a lot depends on a competent and correct choice. The durability of an acrylic liner is 70 percent dependent on its quality and only 30 percent on installation and maintenance. However, an illiterate installation may incur additional costs for repairing the coating. If a crack has formed somewhere during the installation, water will accumulate under the liner. This will lead to the appearance of fungus and disgusting smell.In this case, the restoration of acrylic. If everything is done on time, then its life can be extended.

Acrylic material is afraid of fire, it melts. If you put candles on the sides, then hot wax can burn a hole, so it’s best not to experiment. For the same reason, in no case should boiling water be poured into an acrylic bath. If the bathroom is to be repaired, then it is better to pre-cover the surface with a soft cloth so that the fragments of the tile do not damage the coating. To return the acrylic surface to the original shine, rub it with toothpaste.

If the acrylic insert is permanently damaged or needs repair, then you can remove it, but it will take some effort.

This is done like this:

- To begin to remove the siphon.

- Then the bulge of the will is cut open and across very carefully. Making a cut, gradually drain the water in case it has accumulated between the surfaces.

- Next, remove the cut pieces of the acrylic layer.

- If there was water between the bath and the inset, the mounting foam was saturated with foul liquid. It needs to be cleaned. In order to remove it from the surface of the bath, use a spatula. After smoothing with sandpaper.

- This is followed by garbage collection, wet cleaning and drying.

- Before the next stage of restoration, the surface is degreased.

- Next, you can insert a new tab or evenly apply liquid acrylic.

If there are doubts of choice, experts advise to pay attention to the following arguments before choosing between buying a new bath and an insert.

- Modern cast-iron baths are different from the products of the Soviet period, lower quality enamel. To cover was durable, it is necessary to choose expensive models, the price of which starts from 15 thousand rubles.

- If the apartment has plumbing from the Soviet period, then it is already many years old, and depending on the accuracy of its operation, it most likely lost its appearance. As a rule, old products are mounted in the floor and walls, which exacerbates the possibility of quick replacement. In addition, sometimes to make a bath, you need to expand the doorway. If the overhaul is not planned, then it is difficult to replace the plumbing.

- Even expensive models with enamel coating is difficult to wash off the yellowness and rust.

- An acrylic insert is on average three times cheaper than a bath.

- Even if after a certain time something happened and the liner was damaged, it is easy to dismantle and install a new one or restore it using liquid acrylic.

How to install acrylic liners in the bath, see the following video.