Features and rules for the use of flexible ducts for ventilation

Flexible air ducts for ventilation are a practical solution for creating a single exhaust system and are widely used in industry and everyday life. The high popularity of soft tubes is due to their clear superiority over rigid models in some performance indicators.

Specifications

Flexible ducts are circular or rectangular tubes that are installed in ventilation systems. With the help of flexible models, a pipeline of any configuration is formed without the use of shaped elements. For the manufacture of air ducts use a number of materials that differ among themselves in their performance and determine the scope of application of models made from them.Thus, PVC air ducts can be operated in the range from 5 to 60 degrees and are available in diameters from 2 to 20 cm. Pipes often have a transparent design, which makes it possible to control their internal state.

Aluminum foil models are also used for arranging ventilation systems. and are resistant to multiple bending, exposure to chemicals and fire. Laminated foil is often used for the production of flexible pipes. Corrugated products made of such material are characterized by low weight and high flexibility, which allows them to be mounted on any hard-to-reach areas of the ventilation duct.

Advantages and disadvantages

High consumer demand for flexible air ducts due to a number of undeniable advantages of these structures.

- Due to the soft structure of materials, flexible air ducts significantly quench the noise level emitted by the ventilation unit, air conditioning or exhaust.

- High resistance to aggressive environments and high temperatures allows you to mount flexible models in the premises of almost any purpose, including kitchens catering and chemical laboratories.

- Long service life and wide purchasing power of flexible pipes favorably distinguishes them from rigid structures and allows you to form a strong and durable duct, without saving on material.

- When installing flexible pipes do not need to use adapters, elbows and elbows. This greatly simplifies installation and significantly reduces its time. Air ducts are able to bend at any angle, and their fastening is performed using clamps and hinges. In addition, the use of flexible models significantly reduces the number of connections, which generally increases the tightness of the system.

- Compactness and low weight make soft tubes convenient for storage and transportation of goods.

- Flexible models can act as elements that compensate for the thermal expansion of the rigid parts of the duct.

The disadvantages include lower, in comparison with elastic models, heat resistance. Flexible air ducts are able to withstand temperatures not higher than 300–700 degrees, so the use of models for arranging ventilation in hot workshops is extremely limited. In addition, flexible pipelines are not recommended to be installed in a vertical position, if their length exceeds two floors or 5 meters.Another significant drawback of flexible pipes is their increased aerodynamic resistance, due to which the air velocity is significantly reduced, and the duct itself is subjected to serious mechanical loads.

With a ribbed inner surface, the flexible duct is prone to rapid contamination and needs frequent and more complex cleanings. The disadvantages include the need to use more fasteners. This is due to the danger of sagging of the flexible tube, due to which the number of fixing clamps and hinges must be increased.

Kinds

Flexible air ducts for ventilation are classified according to several criteria, of which the type of construction is fundamental. On this basis, the models are divided into frame and frameless structures.

Frame Models

The production technology of frame air ducts consists in winding thin strips of a certain material onto profiled rollers or a framework made of steel wire, the thickness of which varies from 0.5 to 0.8 mm. The spring type of performance gives the pipe high strength, and the coating of tape material - tightness.Such products are distinguished by good ductility, are capable of elongation and contraction, and can be bent by an angle at which the length of the arc radius is greater than or equal to two diameters of the pipeline. Simultaneously with the winding, rolling of connected parallel strip edges occurs. Thus, aluminum-wound pipes can easily withstand air speeds of up to 15 m / s. and temperatures from 30 to 300 degrees. The cost of one running meter of such a pipe is 50 rubles.

These models can be used in the arrangement of domestic ventilation hoods and air conditioning systems. The disadvantages include low noise insulation, and the impossibility of using it on long straight pipeline sections. However, to improve sound insulation properties, some manufacturers make tubes with the addition of basalt fiber, which has a superfine structure. A sound insulation layer of 2 cm is considered optimally effective. For installation on industrial objects, temperature-resistant multilayer models are used.

They are made on the basis of a steel frame, aluminum plates and additionally supplied with a layer of polyester film, which is installed on the inner surface of pipes and significantly reduces the loss of dynamic pressure.Models cover with insulating material or PVC sheath. Reinforced air ducts are capable of operating at a head of 8 kPa and a flow velocity of 30 m / s. However, the most powerful and heat resistant are flexible frame models of galvanized and stainless steel. Such products are installed in the ventilation system of hot workshops and are able to withstand temperatures from 60 to 700 degrees.

Polymer materials

In addition to metal, for the manufacture of frame models, use polymeric materials - polyvinyl chloride and polyester. Plastic models have a higher aerodynamic properties in comparison with metal products. The air flow rate in plastic ducts can reach 40 m / s. However, the temperature is limited to only 60 degrees. The inner surface of such models is smooth, and the outer one is represented by a grid of small protrusions.

- Flexible PVC models can be successfully used in the air ducts of the food, pharmaceutical, woodworking and chemical industries. Products differ in small weight and are not subject to corrosive processes.In addition to plastic for the production of flexible frame ducts, use textiles. The material has proven itself in cold hoods and is widely used in light industry and everyday life.

- Frameless models made of thin sheets of PVC or aluminum. This gives them the ability to easily stretch and change their length. The advantages of such products include low weight, the ability to install them in combination with suspended ceilings, low cost. The disadvantages are considered weak sound insulation and feasibility of use in systems only with low air pressure.

The second criterion for the classification of flexible ducts is the presence of insulating layers. On this basis, the models are divided into isolated and simple. The first ones are made in the form of multi-layer structures consisting of a frame, aluminum tape, polymeric materials, heat and sound insulation. Such heat-insulated models are ideal for the construction of ventilation in apartment buildings and private homes. This is due to the high level of sound insulation, which meets the standards of SANPIN.Models are not insulated are lightweight construction, having a frame or frameless execution and used in rooms that are not subject to strict requirements for noise.

Installation Tips

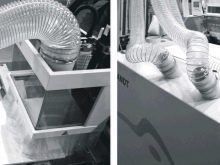

The installation of flexible ducts is small than differs from the installation of rigid pipes and ducts, there are still some nuances:

- the deflection of the pipeline in a straight section shall not exceed 5 mm between two adjacent fasteners;

- clamps and hangers must be installed every 100 cm for horizontal fastening, and for every 180 cm for vertical fastening;

- taking into account the twisting of the helix of the frame, the duct should be placed on the direction of swirling flow in the pipeline created by the fan;

- the connection of a pair of oncoming pipes into a single network must be made with an overlap, the width of which cannot be less than 5 cm;

- External joints of joints should be sealed with aluminum tape and taped with mounting tape;

- when installing external ventilation, the installation joint must be separated from the heat insulating joint by at least 10 cm.

The cleaning of flexible pipes should be carried out with brushes located on a flexible drive, with preliminary spraying chemical substances that dissolve grease and soften dust inside the system.

Flexible air ducts are an excellent alternative to expensive rigid models and, in the absence of strict requirements for temperature and flow rate, can be successfully used in domestic exhaust devices and in small-scale production.

Instructions on how to properly cut a flexible duct, clearly presented in the video below.