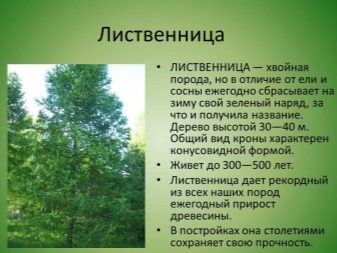

Larch block house: distinctive features and standards

Finishing work using materials that mimic wood is relatively inexpensive (when compared with the use of real wood), but many still prefer naturalness. The block house made of larch is very popular today, because this material is distinguished by aesthetics and excellent performance characteristics. This article discusses the standards and distinctive features of such products, especially the implementation of plating.

Special features

The block house can be used for exterior decoration or for interior work. This material looks like a timber.There are products that resemble otsilindrovanny logs. This is a panel with compensation grooves (with several or with one). Her back is flat.

The block house is made in a specific order. Each of the stages is very important.

- Billets of the required size are created. Manufacturers sawn logs on a special machine.

- The blanks are placed in special chambers where drying is carried out. The humidity of the tree after this procedure does not exceed 15%.

- Milled faces of products. The panels give the desired shape and size. To facilitate fastening, manufacturers cut the grooves and ridges in the longitudinal ends.

- At the end of the process, the quality of the products is evaluated, sorted and placed in the packaging.

To create high-quality building materials are suitable only larch, growing in areas that have a rather harsh climate.

Such wood has many advantages, it retains its operational qualities for as long as possible.

pros

You can highlight the main advantages of larch.

- There is a lot of resin in such wood.Because of this, it is almost not susceptible to the occurrence of rot and is very resistant to insects. Additionally, it is not necessary to process larch with protective agents, because it is already reliably protected from various external influences.

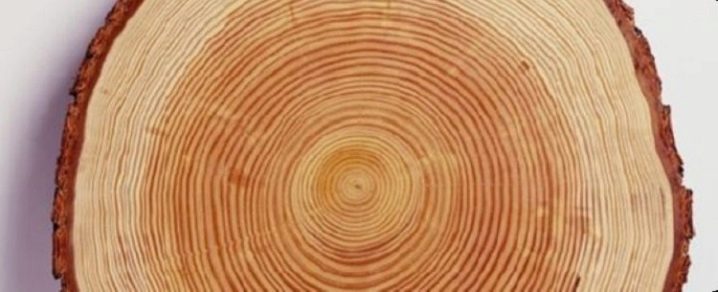

- Larch - very showy, beautiful wood. It has an attractive texture. On cross sections, annual rings are very well seen. Such materials come in different shades: from rich brown to delicate pink. The surface can be further tinted.

A feature of larch that is very attractive to consumers is natural shine. It can persist for many years.

- With the help of such wood you can create a special atmosphere in the room, provide additional comfort. For this reason, the larch block-house is especially often used specifically for interior decorating. Such material is characterized by thermal conductivity: in rooms decorated with larch, it is rarely cold. Another important positive quality of such materials is a pleasant coniferous smell.

- This tree is quite flame resistant, for examplein pine this indicator is much lower.

- Such wood is very durable. In this case, over time, the strength of products only increases. If we consider the physical and mechanical properties of such a tree, it can be noted that in this respect it is even better than oak. The fact that larch piles support the famous Venice confirms the remarkable performance characteristics of this wood.

In larch there are nutrients that are in the air and have a positive effect on human health.

Since this material is characterized by increased resistance to moisture, it is often used for saunas, baths, terraces, moorings.

Minuses

Larch has certain disadvantages, most of which are closely related to its merits.

Among the minuses of this material can be identified several positions.

- Since this wood has a very high strength, problems may arise if you want to carry out repairs or change something. You may encounter difficulties with surface treatment.

- One of the distinguishing features of larch is quite high humidity.The panel can be significantly deformed during the drying process. Because of this, cracks occur on the product.

To avoid such problems, it is necessary to place the tree in special chambers (for thorough drying).

- Larch logs have a very dense structure, for this reason, such products are quite difficult to transport. Transport difficulties increase the cost of wood. Larch is very expensive.

- Since there are many pitches in this tree, it is difficult to process. Conventional saws spoil in the shortest possible time, so you have to use special expensive tools.

Due to the large amount of resin in larch, fragile adhesive joints are obtained.

However, this does not apply to the block-house, because such compounds for such materials are not provided.

Varieties and sizes

Modern manufacturers offer a block-house of larch of different varieties. Some popular options are available to consumers.

- "Economy". There may be minor defects: dropped knots, blue, chips, small cracks.

- "Classic". There should not be chips, through cracks, blue, dropped knots. However, a small number of knots are allowed.

- "Extra". There are no significant or minor defects. Products are selected as carefully as possible.

- "BUT". No mechanical damage, however, the presence of resin pockets and knots is allowed (but there should be few such defects).

- "B". There may be defects, knots, but in limited quantities.

- "C". Perhaps the presence of through cracks, not very large resin pockets and knots.

Narrow products are imitations of eurolining. Such a block house is usually used in the implementation of interior decorating. Large panels imitate logs, they are most often chosen for outdoor decoration.

Manufacturers

Today, larch block-houses are offered by different companies. Choosing the appropriate option, one should give preference to reliable and consumer-trust producers. It is worth highlighting in particular several companies offering a block-house made from high-quality wood.

- Alpha Profile is one of the leaders in the Russian market.Previously, this manufacturer offered exclusively siding materials, but now it also specializes in the production of block houses. The price of such panels is quite acceptable, but at the same time they are of very high quality.

- "Les-Ar" also offers high quality products at an affordable price.

- "Forest of Karelia" - a producer who uses trees from northern forests. Such materials are characterized by a long service life, durability, remarkable quality. For the processing of blanks manufacturer uses the latest high-tech equipment. Antiseptics and flame retardants are applied to the finished panels. Products are dried in special chambers.

If you do not have the opportunity to purchase an expensive natural larch block house, you can opt for a cheaper imitation of a wooden surface. Such products are offered by the Russian company Deke Eksrugin. Consumers find this manufacturer reliable, it has been operating for more than ten years.

The company offers panels of different shades: products that imitate natural material are not as limited in terms of colors as wood.

Calculation and preparation

To determine the optimal panel size, length and width, the required number of products, it is necessary to carry out the calculation. To do this, use a calculator, building roulette and take into account the recommendations of professionals.

First multiply the width of the surface by its height. So you define the area of the wall. Then you will need to know the area of all doors and windows. Then subtract the area of the doors and windows from the area of the wall. This will be the working area.

Focusing on the number of panels per 1 m2 and on their sizes, determine how many products you will need for facing the wall. Perform the calculation for each surface that you are going to finish.

Before the implementation of the finishing work will need to prepare the foundation. Remove from the surface all existing contamination, make it as flat as possible. It will also be necessary to remove various protruding elements that may interfere with the installation, for example, antennas. If any of the base elements are not stable enough, fasten them.

Prepare the panels themselves before use. Unpack them and store them for about two days in the place where the installation work will be carried out.Place products on a dry and level surface.

Installation

Installation work is carried out in a specific order.

- Provide vapor barrier. Here you should focus on the type of surface: for example, if the wall is made of brick, you can skip this step.

- Using timber, create a vertical crate. Apply to it an antiseptic and fireproof formulations.

- Between the crates of the crates will need to install insulation.

- Insulation should be closed with moisture and windproof film. This will prevent liquid from entering.

- Install the blockhouse. It is better to do this using screws. In this case, you will need to pre-make holes in the panels. To ensure ventilation of the coating, leave small gaps above and below.

- It is recommended to apply a primer to the panels and varnish them, which is based on wax.

Larch block house is well suited for finishing the facade and interior walls, it can also be used for ceilings. Such panels are used for a variety of bases: brick, concrete and so on. The block house is suitable for both the new and the old house.

Selecting suitable panels, study the end part of the materials. If the block house is high-quality, the annual rings are quite tight. Such coverage will last as long as possible.

It is recommended that an antiseptic be applied to the panels every 5 years (despite the remarkable performance characteristics of such materials).

It is better to choose special tinting coatings: “Neomid”, “Texturol” and so on.

On how to make a block house with your own hands, you can learn from the video below.