Features of insulation of the house outside the mineral wool under siding

Before finishing a private household with a siding, it is recommended to consider an issue of effective heat insulation of walls. For summer cottages, the simplest facing is enough, but if you expect to live in a house in the winter, you should think about a more thorough and thorough insulation.

Special features

There are many materials that have high performance and can serve as a reliable insulation.

The most common:

- minwat;

- basalt fiber plates;

- foam plates 3 cm and 5 cm thick;

- penoplex.

All of the above heaters are completely safe, in terms of ecology, they are also quite affordable, working with them is not difficult.

Rock wool is most often used for wooden buildings.

This material is inexpensive and has a number of unique properties:

- provides effective air exchange;

- easy to install;

- it is durable if it is operated correctly.

Pros and cons of the material

For insulation of the house under the siding is usually used mineral wool (plate of basalt fiber). The material is not afraid of moisture, it is hygroscopic and is able to reliably protect the coating from negative external influences, including temperature. Insulation consists of fibers that are made from rocks. The material is in good demand because of its low price and high efficiency.

Another remarkable quality of this insulation is its complete non-inflammability. Rock molecules do not give the opportunity to ignite cotton, which it is impregnated. Also insulation resistant to various deformations.

Thermal resistance of insulation is approximately the same as that of the 195-cm layer of silicate brick. Cotton wool is also not amenable to aggressive chemical compounds. It does not decompose and does not grow moldy, fungus or spores of the simplest microorganisms do not start on cotton wool.

Before starting work on the insulation of a brick or wooden house, mineral wool is impregnated with a special solution that has hygroscopic properties. Thus, a layer of insulation can serve as an additional waterproofing protection.

Mineral wool today is presented in a wide range.

Varieties may differ from each other according to different criteria, including density.

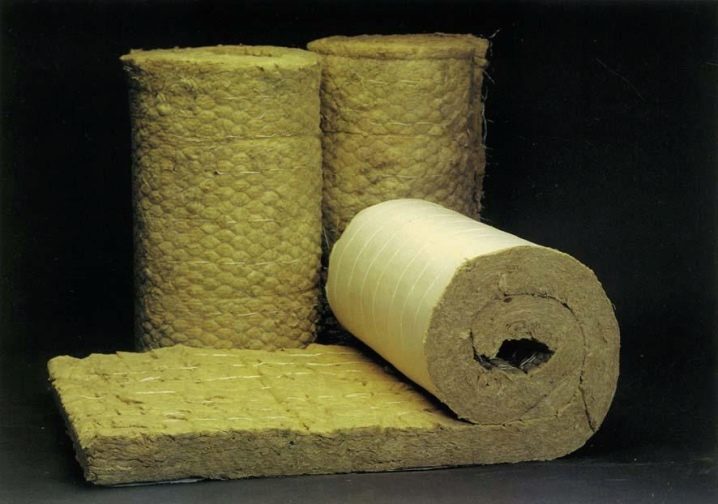

- From 35 to 50 kg / m3 - very soft, airy material. It is realized in rolls and bags, it is possible to warm them with horizontal surfaces.

- 75 kg / m3 is a slightly more rigid material, they also sheathe horizontal planes.

- 120 kg / m3 is a more rigid mineral wool, it is equally good to use both for walls, and for floors and ceilings.

- From 148 to 170 kg / m3 - has increased rigidity. It is used most often for warming floors in attics, as well as vertical planes.

- 220 kg / m3 - very dense material, can withstand heavy mechanical loads up to 10 MPa.

According to the composition of the mineral wool is divided into the following types:

- glass wool;

- stone;

- slag.

Like any material, mineral wool has its advantages and disadvantages:

Benefits:

- low price;

- does not conduct heat;

- does not burn;

- long service life;

- does not contain toxins;

- possesses high coefficient of vapor permeability;

- you can mount it yourself.

Disadvantages:

- large proportion;

- poses a threat to the skin and upper respiratory tract.

Mineral wool is usually insulated:

- wooden buildings;

- brick houses;

- built of concrete slabs.

Standard thickness parameters are 5-10 cm. Mineral wool is sold in the form of rolls or slabs.

What mineral wool to choose?

When choosing a suitable material, you should definitely pay attention to some points. In mineral wool an important indicator is the number of fibers that are present in the structure of the material. It is very important to understand that the weight of the fibers and the weight of the wool itself are not the same thing. The best mineral wool is one that has better fiber, it allows you to most effectively resist high temperatures.

The density indicator describes the following characteristics:

- static form even with prolonged use;

- good resistance to mechanical stress.

The density of mineral wool ranges from 32 to 167 kg / m3.

The density indicator from 43 to 110 kg / m3 makes it possible to use cotton wool for finishing the ventilated facade. If the density of mineral wool is higher than 110 kg / m3 (140-160 kg / m3), it means that cotton wool can be used for processing with decorative plaster “Bark beetle”, “Lamb”, “Mosaic”.

Most often, mineral wool of lower density (from 30 to 50 kg / m3) is used for insulation. Such material is used only indoors and is covered with plasterboard or clapboard. Also, this wool can be used for insulation and sound insulation of the roof.

To choose the right wool for facade insulation, it is recommended to remember the quality of the material. Domestic mineral wool is heavier, its density is about 150 kg / m3 (manufacturers "TechnoNIKOL", "Thermolife", "Danova"). European companies offer a lighter material with a density of 110-115 kg / m3 and even lower. The coefficient of thermal conductivity of such wool is better. In heavy wool there are more binding components, Western manufacturers reduce the presence of resin and pay more attention to the quality of the fiber.

As a result, such products have better characteristics, while the weight of the material is noticeably lower (by 20-30 percent). In fairness it should be mentioned that the cost of such insulation is much more expensive than domestic.

When purchasing insulation, it is recommended to weigh the pros and cons. Russian mineral wool is not worse than European in quality, but it may differ in weight.

Mounting technology

The work related to the thermal insulation of the facade under the siding consists of several main stages.

- Before attaching mineral wool to the walls, they should be thoroughly cleaned and pierced. The smallest cracks, as well as chipped and chipped stones, are sewn up and sealed with cement mortar. Depths are leveled; if the slopes are damaged, they are repaired.

- Then the surface is treated with an alkyd or acrylic primer.

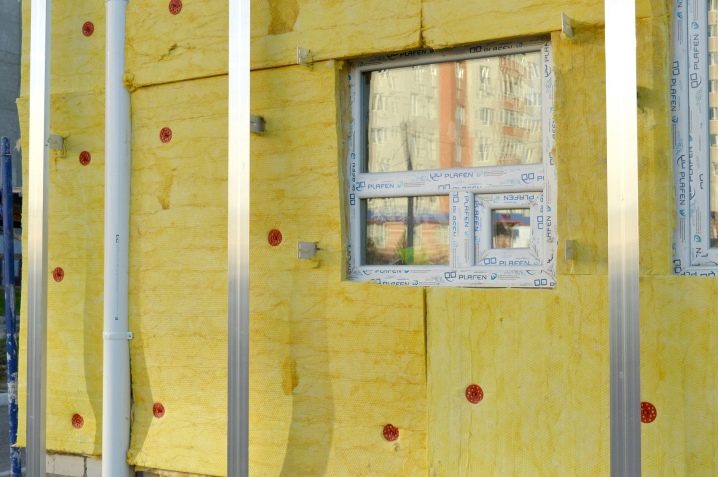

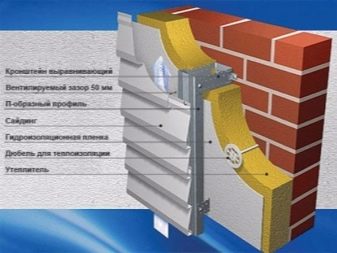

- A crate is made of bars of 3.5x4.5 cm. They are attached to the wall with dowels.

- A vapor barrier is being made; for this, PVC film or mastic is usually used. The first option is preferable, it is inexpensive and reliable, the material is easily mounted on vertical planes with a stapler.

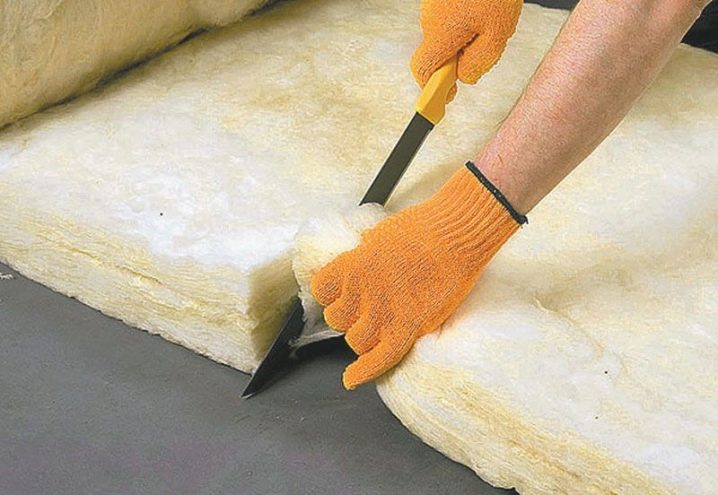

- Then mineral wool is laid as a heater. It is easier to work with mineral wool in the form of plates, only they need to be fastened stronger, in order to avoid slipping.

- When we are warming a log house, it is imperative to provide for waterproofing in the form of a special diffuse membrane.Its design allows the removal of excess moisture from the plates, which is formed due to the appearance of condensate. Its appearance is inevitable, especially during the cold season. The temperature outside can be below zero, the wall of the house is warm - this is a real prerequisite for settling the smallest drops of moisture on a vertical plane. If you do not take care of protection, then within a few years the walls of the house will deteriorate.

- During installation, it is imperative to leave ventilation gaps. Between the siding and waterproofing outside leave a small space of 3-5 cm, using special slats. This allows moisture not to settle on the surface, but to evaporate due to intensive air exchange.

- Minvata is perfectly combined with metal and vinyl, so this material is considered the best solution for siding. Before you make the crate, the bars should definitely be missed with a special antiseptic primer, as well as refractory mastic.

- The thickness of the bars depends largely on the thickness of the layer of mineral wool. It is also very important that the insulation is securely fixed in its “cell”.It is best to mount the plates in a staggered manner; at the same time special attention should be paid to the joints, they should be isolated.

- After installing the insulation, a special membrane is placed on top that will protect the material from wind loads and moisture. Such a “cake” effectively allows air flow through and retains excess moisture.

- If the insulation is mounted on brick walls, they should be pre-cleaned. Microparticles of the material should not peel off and remain on the palm. At installation of a heater on stone and brick walls galvanized guides for an obreshetka are used.

Specialists have developed recommendations on the choice of insulation, depending on the climatic conditions of a particular region. For example, for the Central, North-Western, Far Eastern and Ural regions, the optimal insulation layer thickness is 20 cm. For the Southern region, a layer 15 cm thick is sufficient, and for the Siberian region - 35 cm.

In order to qualitatively insulate the facade of the mineral pool you will need the following tools and fixtures:

- dowel-nails;

- anchoring;

- drill;

- Bulgarian;

- special glue;

- level and plumb;

- primer.

Useful recommendations

If we consider specific brands, then experts recommend to pay attention to the following products.

"Beltep Facade 12"

Basalt insulation "Beltep Facade 12" is used for insulating load-bearing structures. The second name of this wool is stone.

It has the following properties:

- does not burn;

- does not absorb liquid;

- does not contain toxins.

Material is produced in the form of slabs with dimensions of 60x100 (120) cm, density of 135 kg / m3.

"Technofas"

Insulation "Tehnofas" (manufacturer "Technonikol") has a thickness of 10 cm. The basis for the creation of this material is basalt, obtained after processing of rock.

Advantages:

- does not burn;

- does not absorb moisture;

- efficiently stores heat;

- good sound insulator.

It is used in the construction of both private houses and administrative and industrial facilities. The energy-saving effect reaches 40%, is notable for its good resistance to moisture and temperature.

"Rocklight"

Heater "Rocklight" (thickness 5 cm, manufacturer "TechnoNIKOL"). Raw materials are extracted from rocks. Insulation is very effective, is an excellent sound insulator, does not contain toxins.It is very popular among the owners of private houses.

For details on the use of mineral wool for home insulation under siding, see the following video.