How to choose a drainage geotextile?

In the construction industry, when designing home gardens, the popularity and prevalence of geotextiles is growing. A wide range of products offered by modern manufacturers includes many trading positions. Products differ not only in quality, but also in operational and technical characteristics.

Competently selected geofabric is the key to stable operation of the entire complex. This material is necessary to prevent soil subsidence in drainage systems. But also do not forget about the exclusion of the diffusion of rubble into the water.

Brief description and scope

At the heart of drainage systems, geotextiles play the role of a reliable filter that prevents flooding of drainage material or drainage pipe. This is a special kind of building material. Mineral, basalt, synthetic and fiberglass are used for its manufacture. The product can be made in the form of linen, tape or three-dimensional structure.

The product is used in various industries (construction, light industry, medicine) and to achieve various goals:

- protection;

- reinforcement;

- waterproofing;

- ground insulation;

- filtration;

- drainage;

- registration of a paving;

- delimitation of layers of materials of different fractions (the formation of dense and durable layers).

Laying and replacement of geofabric should be carried out by professionals. Only in this case, you can be sure that the material will fulfill all the obligations assigned to it. To replace the canvas, you will need tools. This is a long and laborious process.

Use for drainage on land

Due to the wide distribution and accessibility, geofabric is actively used for arranging drainage systems.If the land plot is located in the area of soils with increased groundwater (near water bodies, rivers and other similar objects), then you cannot do without a high-quality drainage system. It is necessary in order to divert excess moisture from the site. But the system will also be useful if there is frequent and heavy rainfall in the area.

Water accumulates and destroys the foundations of buildings. As a result, there are prerequisites for shrinkage of the house and the formation of fungus in basements and basements. Excess moisture in the area prevents the flora from developing normally and bearing fruit.

All modern type systems do not do without the use of geofabric. This element is required to protect against water, which fills the structure with particles of earth. As a result, it is clogged, and the service life is reduced significantly. Durable, strong and wear-resistant geotextiles are actively used on the basis of private house adjoining sites.

Functionality

Geomaterial protects the system due to the fact that:

- takes the bulk of the total load;

- passes water, taking it away;

- opposes the process of subsidence of the soil;

- prevents particles of earth from clogging up the system;

- prevents silting of material and pipes;

- blocks the mixing of soil, coating and drainage filler.

These are the main aspects of the work of a special fabric. The material is ideal for drainage systems of various types, both open and closed (hidden).

Species

The composition and methods of manufacture

The material is divided into types depending on the method of production and composition. As a rule, modern geotextiles are made of polyester or polypropylene. Raw materials are abbreviated as PES and PP.

For the production of non-woven geotextiles using fiberglass or polyamide. And also on sale you can find options, which include components of natural origin (woolen or cotton threads). This material is called blended.

Production methods

In accordance with the method of manufacturing geotextiles are divided into two groups:

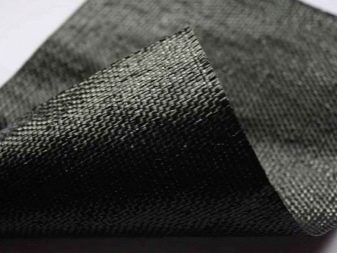

- geofabric (knitted or woven fabric);

- nonwoven geopolitno.

The first option is characterized by enhanced durability and stability. They are resistant to deformation processes. Such material is ideally suited for separating the reinforcing layer (construction sphere).

The product goes second in the list, has excellent permeable properties. It is chosen for the arrangement of drainage systems, regardless of the complexity of the soil (landscape design). We will evaluate each of the types in more detail in order to select the appropriate option for a specific situation.

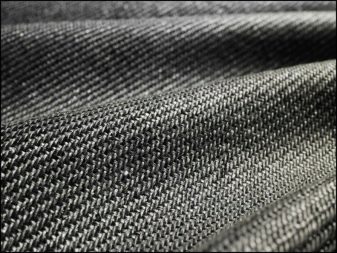

Geofabric

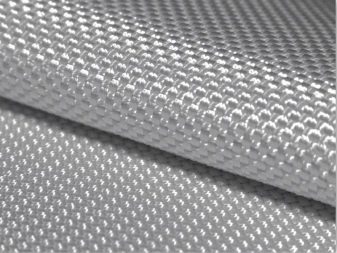

Woven material, in turn, is divided into two more varieties. Production material - polyester or glass fibers. In some cases, the canvas is produced in the form of a simple weave of threads, the thickness of which varies from 1 to 3 millimeters.

On sale there are options when the interlacing consists of different threads. The combination of material gives excellent stretching and elasticity. And also instead of threads used thin artificial material (stripes).

Cloths of this type perfectly retain their shape, have increased strength and can boast excellent water permeability. If the drainage system is located at a great depth, woven geotextile will fit perfectly and will cope with all the tasks. It is often used for basement drainage.

Warp geotextiles (knitted) also belong to this material group.

The woven fabric is made by knitting without interlacing loops. This option is inferior in strength due to the special structure.

Nonwoven Geotextiles

This variant of fabric is made from synthetic material (yarn or fiber). They are placed in two ways: randomly or oriented. The threads are made of polyester or polypropylene.

Most often, manufacturers use the monofilament method - one continuous thread for the entire canvas. And also popular technique in which the material is created from pieces of 5-10 centimeters (spatula geofabric). Product for drainage systems do not use.

Geotextiles are combined using various techniques:

- needle-punched method;

- method of hydrofinishing;

- pressing;

- welding (thermo);

- combination;

- extrusion.

Variety of structures

The operational properties of geotextiles are directly dependent on its structure. Depending on the task, choose a specific option. Functions such as water drainage, moisture resistance and much more are provided by the structure itself.

Lattice

Nonwoven fabric. Polymer strips are securely interconnected in a staggered manner, with the result that cells are formed.

Grid

By volume it is a flat fabric. Strips of material can be connected in various ways:

- at an angle;

- closely intertwined;

- perpendicular

The cells are larger and larger.

Geomat

The material characterizes the chaotic combination of fibers or filaments. Elements are fastened by three methods:

- thermal;

- mechanical;

- chemical.

Geomat has excellent flexibility and ease. It allows unobstructed water and air flow.

The geosynthetic fabric of a three-dimensional structure will reliably protect against the process of soil erosion.

Geoyachika

Large non-woven fabric with bulky cells. The second name of the product is a volumetric geogrid. The canvas is made in the form of honeycomb polyethylene tapes. The material is sealed by the welding method, ensuring a reliable and durable connection. Due to the transformation of the form it is convenient to store and transport.

Membrane

The section includes three varieties.

- Geomembrane - dense material. Geofabric impermeable to fluid.

- Bituminous geosynthetic - geofabric with bituminous layer.

- Clay-geosynthetic fabric. Material with a clay layer.

The main field of using memrans is the equipment of the bottom of artificial reservoirs: ponds, streams, lakes.

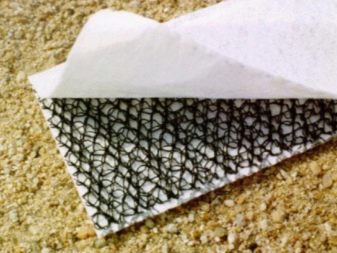

Glinomat

The material consists of three layers. Two outer layers - geotextiles, connected by needle-punching technique. Between them fit clay. After which they are securely connected by flashing.

Geopolos

Narrow canvas, the width of which does not exceed 90 centimeters. Fabric differs in technically issued edges. For the production of material is often used the method of cutting strips from a wide geosynthetic material.

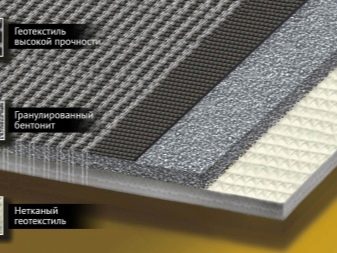

Bentomat

The rolled material made in the needle-punched way. Manufacturers combine woven polypropylene geomaterial with non-woven fabric. Special insulating layer is placed in the middle. It consists of a special granular sodium bentonite.

Geocomposite

Multi-layer geofabric. The minimum number of layers is two. There are two types: reinforcing and draining material. But companies also use the terms: armogeocomposite and geodren.

Main technical characteristics:

- high-quality product made with all norms, has excellent strength;

- tensile strength reaches several hundred kN / m, while the elongation is not more than 18%;

- increased density of geotextile, this indicator varies from 80 to 1200 g / m2;

- factors such as water and air permeability, service life, soil compaction and more are individual and need to be clarified when purchasing material.

Selection factors

Specialists have made a number of factors that must be paid attention to when choosing a geofabric.

Density

The first thing that should be denoted is the density of the web (mass of material per square meter). Rate this figure can be visually. The smaller the pores, the higher this characteristic. Small pores indicate a low bandwidth of the web. As a result, the silting of the system cannot be avoided.

For drainage, a material with a low density of 150 to 300 g / m is better. Experts calculated the ideal pore size - 175 microns. Relying on a small density is also not worth it, in this case, the material loses its strength and durability.

Filtration

Permeability is demonstrated by the filtration coefficient. And also the term is used - the transverse coefficient.This indicator is calculated by a special formula. The height of a column of water passed through the web at a certain time at a given pressure.

The optimum figure varies from 100 to 150 m / day., But can reach up to 300 m / day. The final choice is made taking into account the following factors: the volume of precipitation, the presence of groundwater and its height, the permeability of the soil. If there is a large amount of passing water on the territory of a particular site, then make a choice in favor of geofabric with a high filtration coefficient.

Mechanical characteristics

And also it is necessary to consider individual mechanical characteristics of the material. Ideal indicators of rupture strength: optimum longitudinal strength - from 1.9 to 3 kN / m; transverse - from 1.5 to 2.4 kN / m. During the choice of the canvas, namely: its resistance to bursting, it is necessary to take into account the material of the drainage layer, its depth of placement, the possibility of displacement and sagging.

Under standard conditions, durability from 400 to 500 N will be sufficient. If you plan to use large crushed stone or place the system at a great depth, it is recommended to choose a geofabric with increased density.The indicator must be indicated on the package.

Saving

The financial side of the issue has always been decisive. Every buyer is looking for the perfect match of value and quality. The market offers a huge price variety of products: from expensive to budget options. Most often, manufacturers indicate the price per square meter of canvas. The final cost depends not only on the manufacturer, but also on the store's mark-up, brand popularity and other factors.

As a rule, geofabric is an affordable material, but a quality product cannot be cheap. Most buyers choose between imported goods from foreign manufacturers or popular domestic brands.

Dimensions

Be sure to consider the size of the geomaterial. The minimum width of the canvas - 20 centimeters. Maximum - about five meters. Make a choice depending on the amount of work. If you choose a geofabric for decoration of a large area, it is recommended to choose a wide canvas. The material is easily cut, due to which its dimensions are easy to adjust.

For information on which geotextiles are suitable for the drainage system, see the following video.