Whirlwind drainage pumps: design features and range overview

Drainage pumps "Whirlwind" are popular pumping equipment and are widely known to the domestic consumer. The first batch of pumps were released by the company more than 40 years ago. At that time, the production facilities of the enterprise were located in the Novosibirsk region.

Today, production is fully located in China, which allows you to significantly reduce the cost of products and make it the most popular in its segment.

Specifications

Drainage pumps are widely used in the household, construction and everyday life. With their help, the water is pumped out from the flooded basements, bowls of pools and wells.The most powerful models are designed for the extraction of very dirty liquid with inclusions of large fractions and impurities. Pumps are irreplaceable when cleaning waste holes and construction ditches, cellars, sewer capacities and country toilets. A characteristic feature of the device is the ability of the pump to carry out a rapid pumping of fluid without increasing the pressure. Thus, “Whirlwind” is designed not only for water intake, but can be used when watering, and to ensure uninterrupted water supply for cottages and cottages.

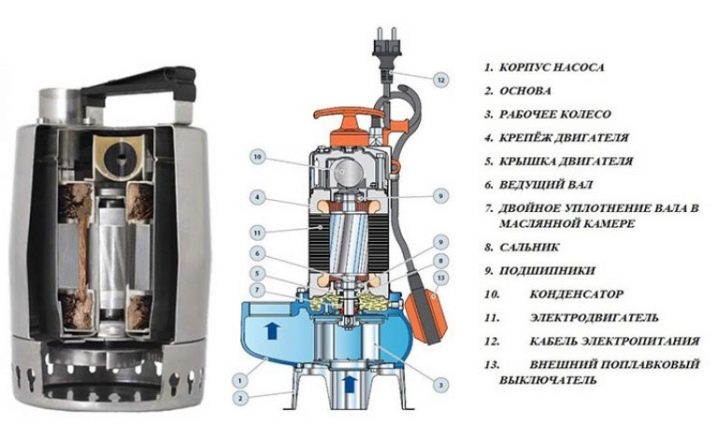

Pump "Whirlwind" is a centrifugal structure consisting of a housing, an engine and a pump. The housing includes a motorized and float-equipped working chamber. The motor starts immediately after the chambers are filled with water, while the impeller is driven by the rotor, and under the influence of centrifugal force pushes the liquid to the diffuser walls. As a result, a discharged area is formed in the area of the inlet valves, which ensures the automatic suction of new portions of fluid. On the diffuser outlet, on the contrary, an increased pressure is formed, which ensures the movement of water.

Excellent pumping capacity, providing a free flow of fluid containing various suspensions, due to the absence of thin tubes, channels and small elements in the design of the pump.

The device is installed at the bottom of the tank, which is why this type of pump is called submersible. Workflow management is carried out thanks to the float mechanismlocated in the working chamber: when the water level reaches the optimum level for operation, the float automatically turns on the motor and, conversely, turns it off when the level drops below the critical point. The device is equipped with a reliable electrical insulation system that prevents water from entering the engine and to the elements of electrical wiring.

Advantages and disadvantages

A large number of positive reviews and high consumer demand for pumps "Whirlwind" are due to a number of indisputable advantages of these units:

- Compact size and low weight make the device mobile and convenient to use.

- The ideal ratio of price and quality makes it possible to purchase a high-quality and reliable device for little money.This product "Whirlwind" favorably with the pumping equipment of well-known foreign brands, in no way inferior to them in efficiency and durability.

- The robust case tolerates shock and mechanical loads, has high anti-corrosion properties and is characterized by complete tightness. It is allowed to immerse the pump to a depth of 8 to 10 meters.

- A wide range of products allows you to choose a device for any household and technical needs.

- High performance and resistance to extreme temperatures significantly expand the range of application of pumps. The capacity of the apparatus varies from 5 to 15 cubic meters of water per hour and depends on the purpose and power of the device.

- Thanks to the equipment of the pump with the float system, the device is reliably protected from idling the engine. In the case of lowering the water level below a certain mark, the float will turn off the motor, preventing breakage and overheating.

The disadvantages include the mandatory presence of electrical wiring and extension wire when the pump is connected and the impossibility of pumping liquid with large-fractional inclusions,whose size exceeds 35 mm.

Kinds

Drainage pumps "Whirlwind" are submersible models and are labeled "DN".

According to the degree of contamination of the pumped liquid, they are divided into three groups:

- devices for the supply of clean drinking water;

- devices for liquids with moderate pollution, capable of pumping water with inclusions from 5 to 12 mm;

- pumps for water with a high degree of pollution, designed for pumping out liquids with large fractional suspensions ranging in size from 12 to 35 mm.

Apparatus is classified and by appointment. There are professional and non-professional models. The first ones are distinguished by high productivity and are used for drawing water from construction pits and pools, as well as for professional cleaning of cesspools and septic tanks.

Drainage pumps "Whirlwind" designed just for domestic needs and can pump from 5 to 16 cubic meters of water per hour, while specialized models are able to cope with a volume of from 100 to 700 cubes. According to the mode of operation, there are pumps with continuous operation and units with the possibility of interrupting the workflow.

Popular models

The model range of the company is represented by a large number of pumps, differing in their purpose, power and cost.

Consider some of them:

- DN 300. This pump is the most low-power of the entire series of products "Whirlwind" and is designed for temporary use in the suburban period. With it, it is possible to pump water from a flooded basement, supply water for irrigation from a natural pond and pump the fluid between two tanks. The model is equipped with a float and a single-phase electric motor, whose power is 300 watts. The capacity of DN 300 corresponds to 11 cubic meters of fluid per hour, the allowable depth of operation does not exceed 8 meters, the time of continuous operation is limited to 20 hours, and the size of the solid particles of the pumped-out water cannot be more than 5 mm. The pump is connected to a source with a voltage of 220 V, the average cost of the unit is 2 thousand rubles.

Similar characteristics have the model DN 350, which has a slightly more powerful engine of 350 watts.

- DN 400. Structurally, it resembles the models DN 300 and DN 350, from which it differs only in engine power, which is 400 watts.The pump is equipped with a float system that protects the unit from overheating and a durable plastic casing. The performance of the model is 11.3 m³ / h, the maximum immersion depth is 8 m, the time of uninterrupted work cannot exceed 20 hours.

The pump is used for autonomous pumping of liquid from wells, pumping water between tanks and its supply for irrigation.

Continuous operation is not recommended. The cost of DN 400 is 2 600 rubles.

- DN 550N. Medium-power unit with a stainless steel case and a 550-watt single-phase electric motor. The diameter of the discharge pipe made of polymers is 1.5 inches. This allows you to connect to the pump wide hoses or plastic pipes. The device is able to pass particles of up to 35 mm in size, which makes it possible to use it widely at construction sites, as well as for cleaning wells and pools. The model capacity is 10 m³ / h, the maximum immersion depth is 8 m, and the time of continuous work should not exceed 20 hours. It should be pump 4000 rubles.

- DN 750. The case of the model is made of highly durable plastic, and its lower part is equipped with a special stand that provides space for unobstructed suction of water.The pump is equipped with a float system that turns off the power supply in case of insufficient liquid level. The capacity of the unit is 15.3 m³ / h, the depth of immersion is 8 meters, the carrying capacity is limited by suspensions no more than 25 mm in diameter. The pump operates at a voltage of 220 V, the motor power is 750 watts.

The model is designed for pumping liquid with an average degree of pollution and is recommended for use in construction and everyday life.

The cost of the device - 3.2 thousand rubles.

- DN 900. The model is not equipped with a float system and is not used for offline operation. Thanks to the high stand and the coarse-grained filter, the pump is capable of passing solid fractional suspensions with a diameter of up to 35 mm. The unit is equipped with a cable with a length of 8 m and is designed to work from a source of 220 and 240 V. The performance of the model is 15.5 m³ / h, the maximum immersion is 8 meters, the time of continuous work is 20 hours.

The 900 W single-phase motor is capable of carrying out rapid pumping of water of medium and high degree of pollution and is intended for professional use in industry, construction and housing and communal services.

The cost of DN 900 is 3.5 thousand rubles.

- DN 1100N. The model is the most productive of the entire series and is capable of pumping up to 16 cubic meters per hour. It is used for drainage of mines and wells, as well as as a pumping device in case of sewage system accidents. The pump casing is made of steel, the power of a single-phase electric motor is 1.1 kW. The discharge port has a universal design that allows you to attach any hoses and pipelines to the pump. The depth of maximum immersion - 10 m, which is the maximum indicator of immersion among the models "Whirlwind". The cost of the pump - 5 000 rubles.

Criterias of choice

Before you begin to purchase a drainage pump, you should decide on the operating conditions of the unit, on the basis of which and select the required power. For seasonal use in country and garden plots, for watering the garden and the vegetable garden, as well as for pumping water into the summer shower and bath tanks, you can opt for low-power household units DN 300. The performance and throughput of these models are designed specifically for this type of operation. With careful use and proper storage, units can last for many years without the need for replacement or repair.

For individual housing and sanitary needs, you should purchase more powerful and productive models DN 900 and DN 1000N, able to pump out very polluted water with abundant inclusions of suspended solids. The bodies of these units are made of stainless steel, which makes the pumps shockproof and resistant to corrosion and any kind of mechanical effects.

If the pump is purchased to take care of the drainage system or a pool with an average degree of contamination, then there is no point in overpaying for powerful models: DN 550N and DN 750 will do the job perfectly.

Operating rules

Strict compliance with the instructions for use of the device will ensure uninterrupted operation of the pumps and significantly prolong their service life.

It is forbidden to pump and pump water with stones, large tangled fibers, metal elements and solid objects whose size exceeds the maximum permissible norms for each model.

Do not use pumps if there are people in the water. This applies to both open natural reservoirs and pools, as well as flooded basements.

It is not recommended to pump out and pump over liquids containing chemically active substances.. Interaction with aggressive components can adversely affect the design elements of the pump and disable them.

Before lowering the pump into the water, it is necessary to make sure that the device is disconnected from the electrical network. It is possible to turn on the device only after its complete immersion and reaching the bottom.

Vortex drainage pumps help solve the problem of draining flooded basements, provide uninterrupted water supply to country houses and help to quickly transfer water from one reservoir to another. The wide model range significantly expands the scope of their application, and the low price distinguishes the products of this company from the pump equipment of other manufacturers.

On the types of drainage pumps and their application, see the following video.