Drainage plastic trays: features of use and types

Plastic is commonly used to make all sorts of products and designs. Due to its qualitative characteristics, such products are widely used not only for indoor construction, but also for outdoor use. A similar trend applies to the drainage system, which uses plastic trays.

Specifications

Drain plastic trays are products that have a small weight, thereby facilitating their transportation to the destination, as well as installation work. The low cost of products makes it possible to actively use products for storm sewers,which is necessary in country houses, on private objects for different purposes, in addition, trays are used as gutters for draining water on sidewalks and walkways in the city.

Manufacturers of drainage trays made of plastic offer their products in a wide range, since the designs, which are manufactured according to GOST, may have a different shape, and in addition, sizes and configurations.

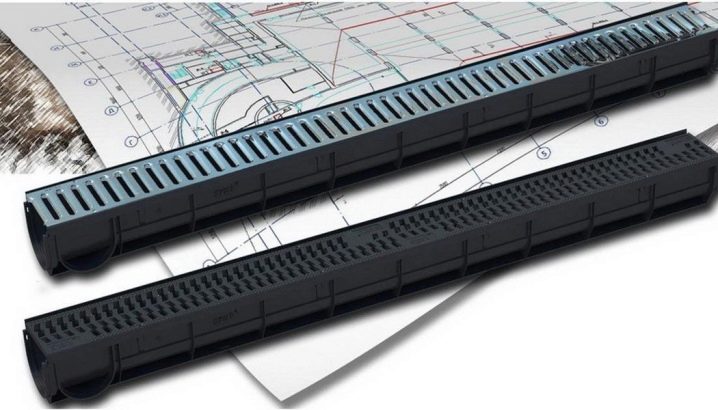

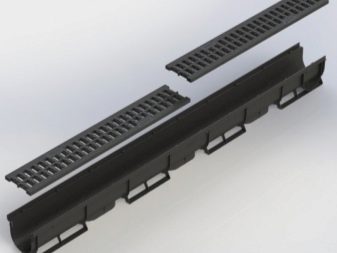

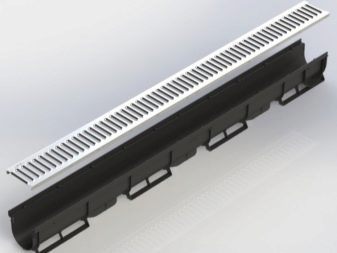

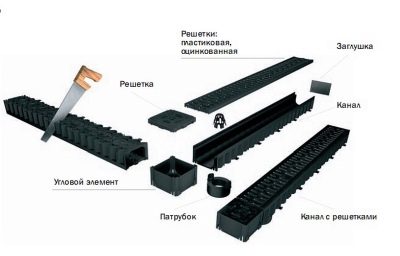

Trays are additionally equipped with special grids. There are products with a cast-iron grill, galvanized or with a steel protective structure on top.

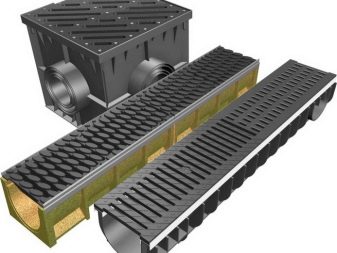

Trays for water drainage have a very simple configuration - they are part of a sewer system, made in a U-shape as a rectangular, square or rounded tank. Based on the technical characteristics, it can be said that the products are gutters equipped with various types of gratings, which provide protection to the channels from clogging with debris.

Lattices are made in such a way that large particles, for example, stones or branches, do not penetrate into the system through them, but remain on the surface.In addition, the grilles perform an aesthetic function, enhancing the presentable appearance of drainage trays. Most of the products additionally contain various shaped parts, as well as locks and latches.

Based on the width of the tray is determined by the capacity of the structure.

To choose the right size, you should take into account the average rate of precipitation on a given area per month, increasing this value by a quarter.

In addition, drainage elements are selected based on their location. The combination of these components will help determine the future load that will affect the product. Manufacturers indicate the level of permissible load on the structure by marking plastic trays, dividing them into classes.

There are models of drainage structures, which already have a 5% slope. Elements of drains with a slope are convenient in cases where the required angle of inclination during installation cannot be ensured.

The most popular plastic trays have the following dimensions:

- the height of the elements is from 6 to 30 cm;

- width - from 14 to 20 cm;

- length - 1 m.

Purpose

As for the scope of drainage trays, this is already evidenced by their name. The tray is the main element of the entire drainage system, it will help keep the area cleanas well as extend the operational life of nearby buildings, protecting the building foundation from the destructive effects of water.

The attractiveness of a plot of land or a local area will increase by several times, since, due to the presence of catchment trays, there will be no puddles on the tracks, and the existing plants will not suffer from an excess of moisture in the soil.

Designs are used in the following cases:

- collection and drainage of water from the base of the pedestrian paths, all sorts of grounds and pavilions;

- protection against flooding of basements of various buildings and structures, which, by virtue of their configuration, are recessed into the ground;

- maintaining the soil in a dry state;

- extending the life of sidewalks and roads;

- framing of highways and railways;

- discharge of water in industrial enterprises, from the territory of workshops or warehouses;

- as drain ladders in car parks and car washes;

- trays are commonly used in park areas, squares and other public spaces;

- plots of country households, where the withdrawal of accumulated moisture is required.

Near objects that are subject to increased safety requirements, trays are installed in a system of storm drains. It can be both urban and country type plots. Engineering and communication trays are placed under each pipe to drain water from the buildings. Road and communication elements require installation under the access routes, lawn paths, on the site near the garage-type buildings.

Advantages and disadvantages

The raw material for the production of plastic intake trays is polypropylene and polyethylene. Due to the characteristics of the material used for manufacturing, sewage elements have a high level of resistance to most of the chemical compounds that are present in rainwater and other types of sediments. The trays have high throughput due to the smooth walls of the base, on which debris does not accumulate. Products differ in small weight - up to 15 kg, which facilitates the installation of the structure with their own hands.

Among the number of positive features of plastic drainage trays, the following characteristics should be highlighted:

- speed and ease of installation - such properties of the elements provide constructive nuances. Trays are made with special grooves on the sides, which allows you to quickly join the products with each other;

- big operational term which is caused by properties of plastic. Raw materials have a high level of resistance to mechanical stress;

- the presence of grooves at the bottom of the trays makes it possible to hermetically connect the element to the pipes;

- plastic is very easy to cut, so if necessary, you can make a structure that has a length of less than one meter;

- when transporting products due to the minimum weight there is no need to involve additional specialized equipment for loading;

- the material used for the manufacture of drainage trays, has a high level of strength;

- products are not destroyed and do not fade under the action of sunlight;

- plastic trays can be operated in a wide temperature range, which ranges from -40 to + 95 ºС;

- plastic is resistant to contact with aggressive media, so that products are allowed to be used in production shops and on the roadway;

- polymeric elements are not subject to corrosion;

- most products have a high throughput rate;

- drainage trays are considered to be products related to the universal type;

- plastic products have a low cost.

Like any other product, some negative features are inherent in drainage trays. These should include a lower indicator of strength, if we compare products with structures for sewage of concrete.

Kinds

In the modern construction market there is a huge range of plastic gutters with different characteristics. It is possible to classify products according to two main criteria, such as:

- bore width;

- tray throughput rate.

These parameters are indicated when marking products. At the permissible level of load, the following types of drainage trays are distinguished:

- products of class A15 - the installation of such products is allowed on sports and playgrounds, on sidewalks and footpaths,cycling routes in the territory of private houses of the country type. The maximum load level is 1.5 tons;

- class B125 - trays of this category are established under the roads intended for passenger vehicles. Fasteners products available in car parks, on the territory of garage cooperatives. The load should not exceed 12.5 tons;

- class S250 - designs of this group can withstand loads up to 25 tons, so they are recommended for installation in car repair shops or car washes;

- class products D400 - its installation is allowed in industrial areas with the maximum possible load of not more than 40 tons;

- class E600 - trays of this group are located near industrial enterprises and warehouses. The load must not exceed 60 tons;

- group F900 - products are installed on airfields and military bases. The maximum load that can withstand products is 90 tons.

In addition, trays made of plastic can be divided into the following types:

- universal products;

- especially strong designs;

- wear resistant trays;

- deep gutter.

The optimal type of product is considered to be products belonging to the universal group of goods. They perfectly cope with the collection of precipitation, which exceeds the average rate. Reinforced constructions have additional stiffening ribs, thanks to which they can be exploited when arranging country houses, car parks and the roadway. Wear-resistant products can effectively divert large amounts of precipitation, as well as function productively in harsh climatic conditions.

For cases in which a structure that is able to cope with an increased level of moisture is required, preference should be given to deep trays, the distinguishing feature of which is wide width and depth.

A huge advantage of polymer products is a large range of sizes of products. The capacity depends on the dimensions of the plastic trays, the width of structures varies from 140 to 500 mm.

The height of the tray - this is another important indicator, due to which products for drainage differ. As a rule, this parameter does not exceed 800 mm. The most commonly used designs with a width of 60 to 120 mm.The mass of products ranges from 9 to 14 kg, depending on the size of the product and the type of raw material used to make the product.

In comparison with products of a similar scope of purpose, but made of concrete, the weight of the drainage trays with which the shower is settled is insignificant.

Installation rules

Laying plastic trays does not imply any specific nuances, so the installation technology is quite simple, even for a simple man in the street, who has no practical experience in arranging the system for drainage of moisture. First of all, you should study in detail the scheme of the drainage device and perform the necessary measurements. Plastic trays are selected based on the type of soil where the installation of products is expected.

Having decided on the peculiarities of the environment where the structure will be operated, it will be enough to simply select the required tray size and the required level of product throughput.

The following products and tools will be required for installation:

- trays with grids;

- concrete solution;

- shovel and hacksaw;

- saw, hammer, acrylic sealant.

Most often, the drainage system is installed around the perimeter of a building located in the territory, however, this is not at all necessary. Starting to dig a trench, it is necessary to take into account the need to create a concrete pad at the bottom. When laying trays, it is necessary to take into account that the grille should be located slightly below the level of the base, about 5–6 cm. After completing the work on creating the trench, a pad of concrete is poured in it, the height of which should be at least 10 cm.

Based on the characteristics of the soil, in some cases it is necessary to perform additional reinforcement of the structure with steel rods or wire.

Drainage trays are placed in the center of the channel, closed with grills and covered with a film in order to remove excess concrete at the edges. Between the tray and the walls of the channels cast supports of concrete. At the corner joints of the elements, the gaps formed in the fastenings are processed using a sealant.

When arranging the drainage system, over which asphalt will be subsequently laid, all channels should be covered with fiberboard. When carrying out regular cleaning and inspection of the moisture removal system, a properly equipped construction will be able to serve for more than a dozen years.

How to install drainage plastic trays with their own hands, see the next video.