Drain pipe 110 mm in the filter: geotextiles

If the soil is characterized by the presence of a large amount of moisture, it is necessary to take care of the drainage system. For its creation today used plastic pipes with perforations. The lion's share of sales comes from a drainage pipe with a diameter of 110 mm in a geotextile filter.

What is it?

Drainage pipe 110 in a geotextile filter is a corrugated pipe with a winding made at the production stage from a special material. The winding serves as a filter and, depending on the type of material, can have a different density (from 100 to 150 g / m2). Due to the corrugated structure, the pipe is rigid but flexible. That is why it is used in the device channel.To ensure drainage, the pipe may have holes or slots.

Typically, the perforation is located on all sides of the product. Its degree is different and has its own designations. The function of the filter is to prevent the holes from clogging with debris or a fraction of the soil. The wrapping fabric increases the strength level of the pipe itself, which affects the duration of product operation.

Kinds

Today, drainage pipes with nonwoven winding and perforations are made from different raw materials. More often on store shelves you can buy products:

- polyethylene (HDPE, LDPE);

- polypropylene;

- plastic (NPVH).

All types of drainage pipes are divided into 2 categories: single and double layer. Ring stiffness is achieved through stiffeners. No dirt accumulates inside these varieties.

Geotextiles are dense shells and the second filter of all types of such pipes. Depending on whether it is single-wall or double-wall, the weight of pipes with non-woven wrapper is different. For example, a 50 m single-wall bay in a filter weighs about 24.3 kg. Double-walled analogue with perforation 50 m long will weigh 22.5 kg.

The best option is a corrugated pipe with a double structure (double layer). In it, 1 layer of wrapper stiffens, and the second is responsible for the free transmission of water. Such a system eliminates the accumulation of litter or sludge inside. An additional bonus is the length of the material: coils of 50 m eliminate the need for docking when laying drainage.

These pipes are in demand in cases when the territory of the site does not exceed the area of 150-200 square meters. When laying the pipes, taking into account the length of the side of the section from 50 m and more (perimeter - from 200 to 630 m), it is advisable to use pipes with a different section (for example, 160 mm). If the area is near the forest or has a slope in the direction of the plot, the diameter is increased to 200 mm.

Advantages and disadvantages

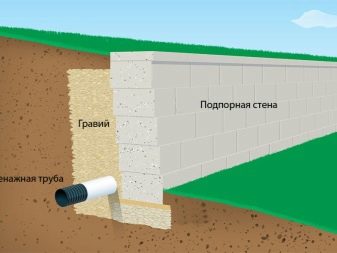

The use of a drainage pipe 110 in a geotextile filter makes it possible to effectively discharge groundwater from the structure. This system protects the foundation, is used for drainage and reclamation of the house adjoining area and the site as a whole.

Such products are used for:

- equipment for storm sewer systems (including roads, sidewalks, parking lots);

- creation of the foundation of structures, including basements;

- landscaping, areas of sports complexes;

- drainage of wetland plots for agriculture.

Such pipes have high performance. Depending on the variety, they can be bought, for example, by the meter (the minimum cut is 10 m). Products are distinguished by a small weight in comparison with analogues. It facilitates transportation and stowage. Installation is carried out parallel to the sewer system.

Perforated corrugated pipe with geotextile wrapping is notable for a larger working surface in comparison with analogues. Therefore, the absorption of water in it is faster and better. Inside it is smooth, which ensures the smooth movement of water.

The shell is distinguished by excellent hygroscopicity. All varieties are universal and are characterized by high efficiency.

They:

- easy to install (do not require special equipment);

- suitable for different types of soil (sandy, clayey, loamy, combined);

- designed for high soil loads;

- differ in durability (25-50 years);

- do not decompose with time;

- easy to maintain;

- suitable for laying deep water;

- resistant to corrosion, the effects of negative climate factors;

- cope with the tasks.

Disadvantages:

- The disadvantage can be called a different class of ring strength. Depending on the carrying capacity, the pipes have to be laid at different depths. So it is impossible to call drainage pipes of this type universal. For example, products of the category SN2 are the lowest grades of stiffness. These pipes can be laid to a depth of 2 m, which does not always allow for the drainage of water. It is necessary to use options with a level of rigidity SN3 or 4 for laying to a depth of 5 m.

- Some products for transportation can be rolled up into reels, others have to be cut into 6-12 meters.

- Depending on the type, their capacity may be less than that of analogs with a coil of coconut fiber.

- It is impossible to open the geofabric before wiring pipes. The material reacts to ultraviolet rays. With a long stay under them, he will begin to lose its properties.

- According to reviews of the masters servicing the system, over time, the nonwoven web of the drainage pipe becomes clogged with small particles of soil. This causes a drop in the filtration rate.Water continues to seep into the pipe, but with less efficiency. However, the situation is not so terrible, because the stagnation of water is not observed, according to the same experts. The minimum effective service life of pipes exceeds 20 years.

Dimensions

Depending on the type of pipe with a diameter of 110 mm, its parameters are different. The diameter of 110 mm is considered to be rather large, therefore such pipes are used for closed drainage (systematic highway, annular, head and onshore). The flexible pipe is available in coils of 50 m. The size of the coil is different and can be 0.7, 0.9, 1.2 m, depending on the degree of rigidity of the variety.

Rigid pipes differ in smaller sizes (from 6 to 12 m). In the production of the wrapper using a nonwoven fabric with a thickness of 1.7 mm.

Manufacturers Overview

Today in the market for such products, the attention of the buyer has been offered a lot of products from competing firms. In their product lines there are other diameters of such products (for example, 63, 160, 200 mm).

Among the goods under consideration, you can choose a few, marked by the high appreciation of the masters in the field of construction and repair.

- "Taipar". The company offers single-wall drainage pipes with a diameter of 110 mm.

- Sibur Geotextiles. Drainage pipes with high quality and performance.

- SK "Plast". Single-layer and double-layer products with a long service life and low cost.

- ObstroyTech. Drainage pipes with one and two layers of geotextiles, having an average price segment.

- "Europlast". Options budget type with one and two layers of the wrapper.

The prices of pipes at purchase specify in running meters. The most accessible materials of the companies IC "Plast" and "Evroplast". It is worth noting that bilayer varieties often cost twice as much as single-wall modifications. For example, a single-layer pipe with a diameter of 110 mm of the company IC "Plast" will cost 58 rubles per meter. The price of a two-layer analogue is 95 rubles.

The cost of pipes with geotextile is different from the options with a wrap of coconut fiber, in this regard, they are cheaper. However, due to the synthetic base, it is more durable than the natural counterpart.

How to lay?

The drainage area is carried out diagonally, along the center and along the borders. The scheme of the drainage system for a typical project consists of:

- surface systems for collecting moisture under the drain, near the blind area;

- pipes of transport routes;

- special wells to remove blockages in the complex nodes of the system;

- storage capacity.

Laying drainage pipe 110 in the filter is carried out according to a specific scheme.

- Prepare a drainage channel. Pit trench depth below the approximate points of soil freezing in winter. The trench width should be 40 cm larger than the pipe diameter.

- When digging make a small bias. Otherwise, the water through the pipeline will not flow. The tilt angle is approximately 5 mm per 1 running meter.

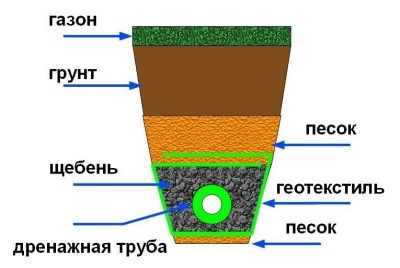

- When the channel is dug, a layer of rubble is poured at its bottom and leveled. Otherwise, the angle of inclination will be broken, and the water will stagnate.

- Lay pipe in geotextiles. Moving it over the stones for adjustment is absolutely unacceptable. This can lead to disruption of the structure of the nonwoven material.

- When the pipes are laid, the trench is covered with rubble.

- After the soil layer reaches a thickness of 30 cm, the pipeline is sealed.

After rubble sand is poured, then soil and sod. If the soil in the area is sandy, you need to take care of an additional filtering layer of nonwoven fabric. If the soil is rocky or clay, one layer is enough. If you need to increase the length of the pipeline or joining its elements, use connecting fittings for sewage systems made of PVC.

Useful tips

Despite the large list of these products in the store, you need to buy them carefully. To do this, contact the proven store with a good reputation. Geotextiles are different, which allows the buyer to choose his carrying capacity as accurately as possible, taking into account the needs. The choice will depend primarily on the type of soil.

In addition, there are several important factors to consider.

- The depth of the trench is subject to the view of the drainage system with geotextiles. In the superficial case, 50 cm is enough; for deep-seated options, it is worthwhile to find out the type of soil and the project conditions.

- The shape of the channel may be different. Usually its section resembles a rectangle or a trapezoid. Regardless, communications pave 40 cm below the soil freezing level.

- The maximum channel slope angle should not exceed 0.7%. When making a sand cushion, it is important to observe the same slope, filling the rubble with an even layer.

- The perforated holes in the pipes should be located at the bottom when partial drained perforations are used.

It is necessary to lay pipes with geofabric from the drainage well. If the pipeline is not laid in a linear pattern,the system will have to include inspection wells. They will simplify maintenance of the drainage system. This is especially true with a pipe length of 50 m.

A layer of rubble when falling asleep pipes with insulation should not be less than 2 cm. Sand is poured from above, its layer should not be less than rubble. Compaction is carried out gradually after a layer of sand.

An overview of the drainage pipe 110 in a geotextile filter is below.