Drainage pipes: technical characteristics and operation features

Building a variety of objects without the use of drainage pipes led to negative consequences, because products were invented to help them avoid them. With the help of drainage it became possible to effectively remove moisture, which somehow accumulated under buildings and structures.

Such pipes became effective assistants in country farms, draining the overmoistened earth. The correct choice and operation of such pipes make it possible to provide a dry foundation in the house and the removal of unnecessary moisture from the soil.

Design features

The drainage system was invented a long time ago, but was improved every year. Now it is a network of pipes that are in the soil and help remove excess moisture from the ground.This is true for summer residents, especially in those areas where it often rains, and in winter a lot of snow. With the help of drainage moisture is removed from the site far beyond its limits.

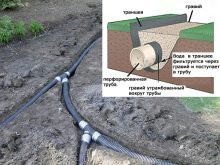

The drain pipe, which is used for such tasks, must be made of a certain material, properly laid to have the necessary slope, which will ensure the flow of water in the right direction. Such a system fits when building a house, at the stage of preparing the foundation and when planning a garden. External indicators of such pipes are different from ordinary ones, because the upper part is dotted with small holes, through which moisture comes in from the soil.

There are two main types of pipes:

- with perforated holes;

- wrapped with filter materials.

Depending on the holes in the pipes, they can be:

- suction;

- collectively.

If the perforation of the pipe is full, then the holes of 1.3 mm are located relative to the circumference of the pipe every 60 degrees, but in the case of a partial perforation there are only three holes on top of the pipe. These holes are made in places of folds, corrugations, which helps to make the structure more durable.If the drainage system is installed shallowly under the ground, then the materials for it may be single-layered with drainage, where the hardness class will be 2-4 kN / m2.

In the case of a deeper immersion system in the ground, you need to use a two-layer type of products that have more durable characteristics. Such a double-wall construction will have a red color with a diameter of 110 mm and a length of 6 meters.

If there is a risk of severe clogging of drainage tubules with sand and other substances, you can use an additional filter that will prevent foreign objects from entering the pipe.

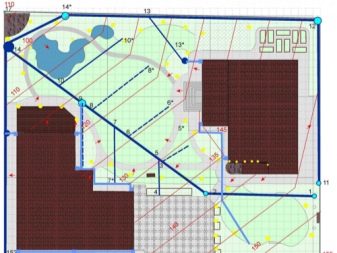

Being engaged in laying drainage, it is important to comply with the rules and regulations of this process. Work begins with the creation of a drawing system, according to the SNiP which will have information about:

- wells and pipes of warming;

- slope of the drainage system;

- pipe size and diameter;

- material that is used as fasteners.

These data help to approve the budget and the project, which is approved at the state level. In addition to SNiP, It is important to take into account also GOST 1839-80, where there is an indication that:

- laying of drainage pipes in relation to groundwater should not exceed 70-150 cm;

- trench need to dig a width in the range of 25-50 cm;

- laying drainage is made under the slope of the meter by 2 cm;

- installation of septic tanks helps to control the system and the amount of wastewater;

- necessary laying insulation at the bottom of the trench;

- formation of the drainage system, which can be fully used.

The distribution tube of the drainage system may have a different internal diameter - 50, 110 and 160 mm. Another important element in the design are slotted caps that help distribute the flow of moisture in the filters. They are effective in sewage treatment, on muddy territory, as well as for aerating water with air. There are options with double-sided, upper and lower slotted cap, which are made of steel with a diameter of 70 and 100 mm.

Production of drainage pipes is not in place, and at the moment there are such types of these products:

- plastic;

- with coconut filter;

- chrysotile cement, they are also concrete, made with the help of special cement and asbestos fiber.

Due to the availability of options for each task, you can choose the right equipment, which provides the best result.

Purpose

Drainage is a complexwith the help of which it is possible to obtain sufficient knowledge of the soil in a certain area and for the proper termination of the soil, which will be devoid of unnecessary wastewater To make a drainage system, you need to understand the soils well, understand how the filter layers are arranged, properly assemble a device that allows drainage.

Soil preparation is important not only in the case of agriculture, but also for the construction of any house, because fragile and excessively wet soils will not allow even the smallest house to be built. The stage of soil drainage will be dominant, and by its outcome it will be possible to determine whether the place is suitable for buildings or not.

Since there may be several drainage functions, the installation may take place in different ways:

- the use of deep drainage is used to remove groundwater, where perforated pipes are used;

- open drainage is used for storm sewers, which helps to remove excess moisture after doge and snowfalls.

The drainage system is a pressure and non-pressure pipes that collect moisture for the well, which eventually all flows.You can also make a filtration field for a septic tank, for which you need to choose a place for it and dig a trench. Its dimensions can be different, each determines them on the basis of necessity.

The depth of such a pit should be about two meters. The bottom layer is laid with soil, which has a good capacity, then a 30-centimeter layer of rubble is poured into which the drainage pipes go no more than 25 meters long.

These pipes are connected to a septic tank and ventilation, and another 10 cm of rubble is added on top, onto which geotextiles are laid, which will help in effective thermal insulation. Soil with a minimum height of 30 cm is poured onto the finished structure. When creating drainage for a septic tank, it is important to make the same slope for each pipe.

Any activities related to the soil and its rational use should be studied and properly organized, then the result will not take long.

Species

For arranging the drainage system, you can use three main types of drainage pipes:

- asbestos-cement variant;

- perforated ceramic;

- polymeric.

With regards to the first and second types, now they are used very rarely due to the large number of disadvantages:

- Weight. Pipes made of cement and ceramics are very heavy, therefore it is difficult and inconvenient to work with them, besides, it is impossible to do without special equipment.

- Installation. Due to the nature of materials, installation is much more difficult than in modern pipes. For the assembly you need to have the skills of such work, and the work itself takes a lot of time. Drainage holes allow sand and small debris to pass through, so they quickly become clogged, and very soon the system will need cleaning, which makes its operation inconvenient.

- Using. The maximum period for which such systems are designed is 30 years, after which time it is necessary to make a replacement.

- High cost. Due to the material and design features, such pipes need to be cleaned from time to time, and pleasure is not cheap.

Along with such old heavy structures began to appear new - plastic. They compare favorably with their predecessors:

- The term of use increased to 60 years.

- Design features allow you to make products very durable. If it is a two-layer drainage pipe, then it has stiffening ribs that help distribute the load correctly and evenly, so that the product does not have overloads in any particular place.

- Thanks to modern material, the products are not threatened by corrosion and exposure to aggressive media. In addition, the pipes are very light compared to the outdated versions, which helps to easily and quickly complete the installation, even without special knowledge and skills.

- Such structures have a very important quality - they are able to clean themselves. This was made possible by the completely smooth inner walls of the product, on which dirt does not stick and there is no sediment.

- Plastic pipes are practically not filled, and the best option is a product in geotextiles. Matter becomes a kind of filter, which, passing water, does not allow large particles of sand and other elements of the soil to get inside.

- The low cost of plastic products and the possibility of self-installation add another plus to these pipes, making them attractive from different sides.

- The presence of dimensional variations, which makes it possible to create a variety of drainage structures. Small pipes can have a size of 63 mm, and larger ones - 200 and 300 mm.

Production of plastic pipes was not limited to production, gradually new types began to appear: polyethylene,polypropylene and PVC pipes. The most popular are PVC options, which are divided into:

- Single-layer and double-layer version with different ring strength.

- Flexible type, where the length of the pipe can be up to 50 meters. They are produced in reels

- Hard version, the length of which is equal to 6 and 12 m.

- Bare variety or with the presence of a filter sheath (geofabric or coconut fiber).

Polypropylene products are also very popular. Such a pipe can be bare or corrugated. The smallest diameter is 50 mm. Such pipes are made of high and low pressure polyethylene. One of the leading manufacturers of modern drainage pipes is Perfokor, which combines optimal prices and high quality products.

If we talk about other areas of application of tubes made from modern materials, the most important is surgery - it uses a silicone drainage pipe, through which unnecessary liquid is pumped out of the patient's body. Such an invention made it possible to optimize the operation process, to make it more convenient, and the outcome as positive as possible.

Criterias of choice

When planning the installation of drainage on the site, it is important to know how to choose the right pipe for this procedure. In order not to be mistaken, you need to pay attention to the following parameters:

- Diameter. Choosing pipes it is important to pay attention to their size - the larger they are, the more abundant they will be in wastewater, but at the same time there is also a minus of large diameter - such products are more difficult to transport and install on their own. If we talk about thinner structural elements, they are appropriate in a situation with very little rainfall that will fall into them. In that case, if the cavity is filled completely and the frost suddenly appears, the water will freeze, increase in volume and break the pipes. When making a choice, it is worthwhile to analyze which diameter of pipes is suitable for a particular section.

- Material for pipes. Iron products used to be used to be, but they were very heavy and welding needed to be used for installation. In addition, this material is subject to corrosion, which means that sooner or later problems will begin with it. Current trends suggest that plastic is the best option for drainage pipes.Polypropylene products are well established in practice.

- The shape of the inner and outer tubes. Modern products can have the most diverse look. The most interesting representative is the corrugated tube, which is outwardly wavy, but inside is flat. Almost all products are created with even internal cavities, so that friction does not occur and there are no reasons for clogging of the drainage. The most popular at the moment multilayer structures due to the ability to screen out large and small debris that enters the drainage channels. This innovation has significantly increased the life of the product and simplify the care of him. Of the minuses, you can only note a higher cost compared to peers.

- With additional features. For the maximum service of the product, it is important not to let it get into the excess soil particles, which affect the final term of operation. To achieve maximum results, it is best to lay pipes with a filter. This can be a special fabric or the product can be wrapped in a coconut filter. Each option has its advantages and disadvantages and differs in cost,therefore, before purchasing, you need to familiarize yourself with the basic information about those products that can be purchased, and make the right choice.

Since pipes are planned for ditches or other underground use, you need to choose them correctly. This will affect the diameter of the pipes, the presence of impurities in the soil, which necessitates filters.

System device

The drainage system is created by man in order to be able to control the process of draining the soil where it is needed. Often such structures are used in places with a large amount of groundwater, which interfere with the normal growth of plants in the garden, trees and shrubs, but in addition, they still do not allow to build a capital house in such a territory. If the soil is regularly drained and no flooding occurs, then a small, but fully habitable mansion can be built on such a site.

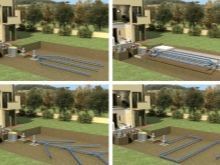

If we talk about the drainage system itself, then this is a pipeline that goes in a given territory, collecting excess moisture and diverting them as far as possible outside the site. The design is quite simple and consists of trenches with pipes that go into wells, and drainage pumps.The principle of operation is to lay such communications under the ground, to wait until the moisture itself soaks deep into the pipes themselves, penetrating inside and not spreading further. Almost everybody can arrange such a system on his own plot, the main thing is to deal with some nuances.

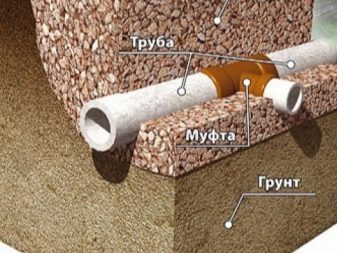

Laying drainage for the construction of the house is the first stage, and only after this the foundation and the building itself, otherwise you would have to dig under the finished house, which is very inconvenient. The pipes can be joined by a butt joint between themselves or with the help of couplings, which is more often the case when you need to turn a branch, lower it or raise it. An important feature of the pipeline for the implementation of drainage of the soil is that it has filters that allow moisture to pass through, but to delay everything else that goes with it. This helps to avoid clogging of the structure and removes the need to clean it.

As for wells or catchment basins, they should be placed at the turn of the whole structure and deepened as much as possible into the soil. Placement is very easy to calculate - it’s enough to know which way the slope goes on the plot.At the lowest point and should do the capacity for collecting groundwater.

It is important to observe the slope of all pipes in the same direction in order to facilitate the passage of the contents into the well.

Such a structure helps to avoid stagnant moisture inside, which does not clog the pipes and reduces the risk of freezing during frost. This ensures the longest possible service life of the drainage system. If suddenly the content in the pipes becomes very much or there is a lot of excess garbage inside, this makes it difficult for the outflow of moisture. In order not to leave the entire system in such a state, it is necessary to use a drainage pump, which enhances the movement of the contents and helps to cope with unforeseen circumstances more easily.

To connect it, you need to immerse one end of the system in the well, and direct the outlet to the place where the water will flow. It is necessary to choose the device based on the needs - for a bulky drainage system with a strong clogging will need a powerful pump, and for a small structure, you can use medium-strength equipment.

Drainage systems may have variations that depend on the climate in which they will be placed, and the requirements for how long the structure should last.On the basis of this, a simplified version is distinguished, which is laid shallowly and has the name “open”. For laying dig trenches at the right angle, where the pipes are placed.

The maximum deepening of such holes can reach a meter, and the width - half a meter. To make the structure strong, after laying it is poured with concrete.

Most often, this option is used in the mountains, where you need to deal with melt water. The disadvantage of such a device system is the frequent need to clean the entire structure. If there is an opportunity, it is worth choosing the second option of laying which assumes process of deeper laying of pipes. Not everywhere it can be applied, because you need to navigate the terrain.

The closed type of drainage is different in that instead of pouring concrete, pipes are poured with rubble, stone or pieces of brick, and on top also with sand. This structure allows you to make an artificial filter for the water that falls from the surface into the depths. Large particles remain in the artificial cushion, which serves as a natural filter. As for the disadvantages, this system is not designed for significant precipitation in the form of heavy rains or heavy snow melting.Tanks for draining quickly overflow and drainage channel will cease to function.

To avoid those and other problems when installing drainage structures, you need to use corrugated plastic pipes, which, if properly laid, are able to cope with a large flow of moisture and serve for a sufficiently long time.

Installation Tips

When planning the installation of a drainage system, it is important to correctly calculate certain parameters, without which it will not be possible to make an effective construction. These include:

- depth of future drainage;

- the distance separating the channels;

- the slope of the whole structure;

- required length of pipes;

- optimal diameter of the pipeline;

- the organization of the place for collecting drains.

Pipe laying will depend primarily on the type of soil that is available on the site. If the work will be conducted on clay, then the channels should be located at a distance of up to 10 meters from each other, if the soil is loose, then the distance can be doubled. In this case, the principle of laying depth still works: the deeper into the ground, the greater the distance between the pipes can be.

For a trench, clear parameters are usually determined - the width is 50 cm, and the depth is from a meter to 1.2 m. The difference can vary depending on additional indicators. When it comes to drainage under the house, it is usually deepened to the foundation of the foundation. Do not forget about the bias of the whole structure, without which it will not work effectively. For each meter of pipe it should be 2 cm.

If narrow pipes are used to build channels, you need to make a greater inclination of the entire system.

If it is necessary to build such communications, it is better and more efficient to use pipes with a larger diameter, which can receive more water, less clogging and do not require additional bias. The optimal diameter will be 10 cm. On average, 250 m of pipes are used for a 10 hectare site, and as many as 620 m for 50 hectares. To correctly calculate the trench width, you need to add the number 40 to its diameter.

An important event will be the work on the organization of water discharge, the manufacture of wells in the territory. To do everything right, you need to have with you:

- enough gravel;

- different variants of crushed stone in size;

- sand;

- geotextile to organize the filter on the pipe;

- the pipes themselves;

- wells for collecting water from drainage systems;

- shovel.

Laying the drainage system can be done by hand or with the help of a team of professionals. In the case of independent work, the sequence of actions will be as follows:

- digging ditches for pipes;

- tamping the bottom of the finished trench;

- falling asleep on the bottom of sand and rubble;

- placement of geotextiles greater than the width of the excavated trench;

- washing the gravel and placing it on the bottom of the 20-cm layer;

- then you need to lower the drain pipe into a trench and wrap it in geotextiles;

- connect pipes with couplings; grease joints;

- every 50 meters installation of manholes is carried out, with the help of which it is possible to monitor the operation of the system, clean it and wash it if necessary;

- backfilling with smaller gravel or gravel;

- then you need to cover the system with remnants of geotextiles;

- laying a layer of fertile soil;

- checking the system by draining water into the nearest canal.

It is important to bury such a thorough drainage system to a depth in order for it to work well and maintain efficiency for a long time.But there are more lightweight designs that are designed to collect rainwater. Water intakes are installed on the house, along which the water from the roofs flows down, and rain drainage is located at the base of the house. For this purpose, point drainage systems are made under the house, which drain the sediments into the general drainage system.

During the installation of the drainage system such errors may occur:

- wrong choice of pipe diameter for the whole structure;

- Incorrect calculation of the angle of inclination of the entire system;

- the absence of a layer of rubble and gravel, which serve as a natural filter;

- untimely withdrawal of water from wells, or lack of control over its filling.

In order for the drainage system to work qualitatively, you should pay attention to such aspects:

- On a flat area, where there is no drainage ditch, it is worthwhile to additionally equip the drainage with a pump that will help to cope with excess moisture.

- If you need to make a drainage system on a large area and create a multi-channel network, then you should enlist the help of specialists, especially in view of the lack of experience in such matters.

- Being engaged in drainage, it is necessary to strengthen the waterproofing of the foundation in the house, which is suitable bitumen mastic and reinforcing mesh.

- It is better to organize drainage wells along the entire perimeter of the system, which will make it possible to control the amount of groundwater and look at the efficiency of the entire structure.

- In the process of channel filling, it is necessary to use gravel, which is much larger than the drainage holes, so as not to litter the structure itself with the help of an auxiliary material.

- Inspection wells, it is nothing like pipes that are stacked vertically and are closed from above with the help of covers.

- The manhole should have a diameter of 50 cm, which makes it convenient for easy access if the element needs to be rinsed.

- Fixation of geotextiles on the pipes is carried out with the help of polypropylene or nylon filament.

- The process of laying drainage occurs in July, when surface water leaves the surface.

- Installation work lasts from one month to two. It is important to have time to finish everything before the onset of cold weather, so that the design does not remain unfinished in winter.

Work on the arrangement of the drainage system is not the most difficult, but requires certain skills.

In addition, having no idea about all sorts of trifles associated with the process of choosing equipment or the stages of its installation,it will be difficult to organize an effective system that will serve for a long time and bring the expected effect both on the plot under the garden and under the foundation of the house.

For how to choose a drain pipe, see the following video.