Drainage trays: what they are made of, how they are arranged and how to install them?

Drainage trays are intended for removal of storm, thawed, ground waters. They transport water from the site to the sewer in order to avoid its accumulation in an inappropriate place. Although the installation does not require a lot of preparatory and installation work, it is necessary to master some subtleties in order to install the drainage trays correctly.

Features and Purpose

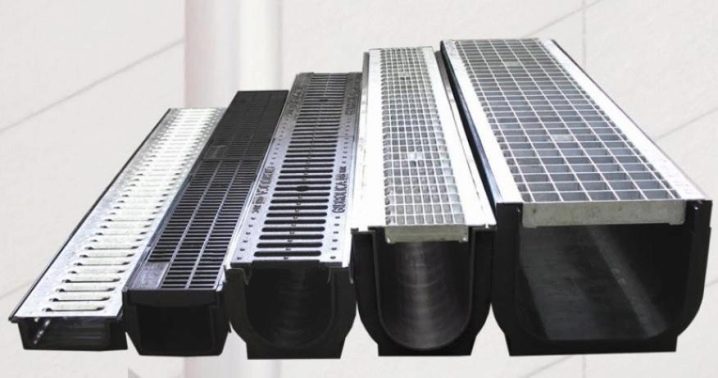

Drainage drainage is a groove made of plastic, metal or concrete, which is designed to drain water from sites, roads, sidewalks and redirect it to the necessary places.Drainage gutter is usually equipped with a grill, designed to prevent large debris from entering the storm sewer and clog it.

In some cases, resourceful owners redirect water using such trays to the beds or to the trees, facilitating irrigation work. However, this is possible only in those areas where the rains are not very intense, otherwise the plants will be supplied with too much water, which will wash away the soil. As a result, such an approach may lead to waterlogging of the soil.

For household needs, two types of trays are used: engineering and communication and road and communication. The first type is mounted under each pipe so that in case of an accident the water does not spill. The second type is located along the paths, sidewalks, next to the garage. In both cases it is important to pay attention to the strength of the tray and the grid, the load it can withstand, as well as the ability of the grid to deform.

Device and species

The storm sewer is fairly simple. Drainage tray is a gutter, which can be U-shaped or U-shaped, depending on the material.On top of this drainage drain there is a grate into which the rainwater is drained and subsequently redirected to the sewer.

Depending on the permissible load, such drainage canals are divided into groups:

- A15 have a low degree of load, so they can be mounted only in relatively dry places: on the sports ground, along the tracks of country houses, in the areas of park and bicycle paths;

- B125 have greater stability, so they can be mounted along the roads for cars;

- S250 suitable for installation in car washes and car services;

- D400 suitable for installation along roads intended for all types of transport, as well as in industrial zones;

- E600 stack near industrial enterprises and warehouses;

- F900 suitable for installation near military bases, airports and airfields.

Drains are divided into groups not only on the basis of the load falling on them, but also on the basis of the materials from which they are made. The most common groups of raw materials used for the manufacture of gutters should be considered in more detail.

Plastic

For the manufacture of plastic stormwater using polypropylene and HDPE - low pressure polyethylene. All plastic models due to the fact that they can not be called durable, can only be attributed to the categories AC. Plastic models are lightweight, and their installation with their own hands will not cause any difficulties. If there is a task to equip the territory of a country house with gutters for water drainage, then it is recommended to choose plastic models.

To increase the strength of such drainage systems, they are equipped with stiffening ribs. Reinforced plastic options are recommended to be installed next to garages, since there just need to use catchment flows of categories BC.

Without a lattice, the weight of one plastic gutter does not exceed one and a half kilograms with a standard length of 1 m. The width may vary between 7-30 cm.

Additionally purchased grille.

It is recommended to choose a relatively lightweight version, for example, made of galvanized steel. And also suitable options from the "stainless steel". Depending on where it is planned to locate the drain, the strength of the lattice should also vary.

For example, near the garage, the grille should be such as to withstand the weight of the car, if you accidentally drive it.

Polymer sand variants are used on objects under construction, as well as on underground parking lots. There are classes A and B.

Metallic

Metal storm trays are a relic, as it seems to many. Most remember the times when such gutters were everywhere on the streets. However, the metal does not lose its relevance to this day. It is difficult to find a material stronger and more convenient to use. The only unpleasant moment is that most metal products corrode sooner or later.

The most reliable are cast iron gutters. For strength, they can be compared only with concrete products, while they are able to withstand a lot of weight. Cast iron storm water can be found near military bases and other military facilities, where there is a large flow of water. Unfortunately, cast iron products have an impressive weight, which makes them not the most convenient for installation. However, this is where their flaws end.

Steel gutters can be of two types: galvanized and stainless steel. And in fact, and in another case, the options are designed for a much smaller load than the cast-iron ones, but this does not mean that for them there are no places of use. With proper shapes and placement, they will serve no less. So, steel metal structures can be placed along the roads for passenger cars, and they will also fit perfectly into park areas.

Reinforced concrete

These drainage systems combine all the advantages of concrete and metal structures. They are just as strong, have a huge range of categories in resistance to loads. Working with reinforced concrete is easier than just with iron, so there is a fairly large selection of forms of drains. There are not only traditional rectangular options, but also round ones.

Reinforced concrete trays are used not only for industrial, but also for household construction. They are easy to install, despite the relatively large weight (which, however, is much less than that of cast iron or plain concrete). Both usual drainage trays and slotted trays for heating mains are produced.

Remarkably, concrete trays should be used when the water has an aggressive composition.For example, it violates the acid-base balance of pH. Depending on the composition of the water, a similar construction is chosen, since some brands of concrete simply dissolve under the influence of alkali.

Reinforced concrete drains are cheaper than metal counterparts, if we compare samples of one category in resistance to loads. During transportation, it is necessary to adhere to some rules, among which is to try to avoid shock loads, otherwise the chute may break.

Composite

Composite trays are a modern version of concrete. Trenches of this type serve several times longer than concrete counterparts, but they are not inferior to them in performance. Composite variations have some advantages:

- smaller weight in comparison with concrete drains;

- ease of installation;

- ease of transportation;

- increased water permeability due to smooth surface.

Due to the special properties of the materials used to manufacture this type of gutter, they can be cleaned not only manually, but also mechanically. The trays have anti-vandal properties, despite the fact that they are assembled manually. Disconnecting the details in the future is not so easy.

Composite gutters are recommended to be installed in areas with a cold climate, since composite materials are well tolerated in extremely low temperatures, without shrinking or deforming. But it should also be noted that in the mixture used for the manufacture of such trays, there are no harmful substances that can harm human health or the environment.

If there is a risk that water will be supplied with such force that it will splash and blur the soil around, then it is better to give preference to composite water receiving trays - their design prevents splashing. And also because of the small weight, the chute will not move under its own weight and under the weight of water if it is located on a slope.

Polymer concrete

Polymer concrete channels do not have a large variation in load. As a rule, they belong only to classes А-С, but at the same time they handle the discharge of storm, thawed and ground water perfectly. They combine in themselves some advantages of concrete and plastic trays, but at the moment there are various materials that exceed polymer concrete in their characteristics, so they practically refused to use polymer concrete drains.

Polymer concrete gutter is smooth inside, which significantly increases its ability to pass water. And also due to the smoothness of the tray does not require frequent cleaning, because self-cleaning during the passage of water through it. Preventive cleansing needs to be done twice a year: in early spring after a significant part of the snow has come down, and in autumn in the fall after falling leaves.

Polymer concrete is characterized by increased service life. Thus, with proper care and compliance with the established norms of loading, the polymer concrete tray will be able to last up to 30 years. The seams are fixed to each other with waterproof sealant FIX-O-FIX, which securely glues the parts together and prevents them from disengaging.

Polymer concrete products have a lower weight than concrete, so they are easier to transport and assemble.

Manual installation is not allowed. Be sure to use a special technique.

Specifications

Depending on the material from which the trays are made, they may have a number of features. To date, the most commonly used plastic options, so it makes sense to consider them in more detail. So, polymeric products are divided into the following types:

- universal;

- extremely durable;

- wear resistant;

- deep.

The first trays in this classification - universal - are recognized as the best choice by most specialists. This is due to the fact that they are able to divert fairly large amounts of water, while they have small dimensions.

Especially strong products are designed to be located in "difficult" places, such as military bases, for example. They have stiffening ribs that increase their strength properties. In a private house, such a tray is suitable for location near the garage.

Wear-resistant trays are needed in order to divert a large amount of water for a long time. They combine the properties of extra strong gutters and anti-vandal installations, have a solid grille, and are equipped with stiffeners. Mainly suitable for location on the plots of land, and not for industrial needs.

Deep trays are needed to increase throughput. They have large dimensions, width and depth, therefore they are excellent for low-lying areas where water accumulates.

Criterias of choice

To make the right choice, you must consider several parameters at once. From how correctly each of them is evaluated, depends on the durability and relevance of the chosen option in each specific situation.

- First you need to determine the degree of permissible load. If you select a tray with a lower bandwidth, it will not cope and will quickly fail. If you buy a tray of too high a class of load, it will be an unreasonable waste of funds, and also cause some difficulties during installation.

- The second criterion is the dimensions of the tray. A narrow slit article is not always suitable, since an abundance of water can be observed in the area, which cannot be adequately eliminated through a small hole. For example, in rainy areas along roads, large gutters are placed so that all storm water is removed from the asphalt pavement in time.

In order to make the right choice of gutter dimensions, you can use special programs or contact a specialized service. They will calculate the volume of water passing through the drain, taking into account the area of the site and the correction factor for drainage.

Section Calculation

In order to select a tray with the desired cross section, the experts came up with the following table. It should be borne in mind that all calculations are only advisory in nature and in no case are not the reference.

Bias | Diameter, mm | ||

100 | 150 | 200 | |

0-0,3 | 3,89 | 12,21 | 29,82 |

0,3-0,5 | 5,02 | 16,76 | 38,50 |

0,5-1,0 | 7,10 | 22,29 | 54,45 |

1,0-1,5 | 8,69 | 27,31 | 66,69 |

1,5-2,0 | 10,03 | 31,53 | 77,01 |

Please note that this table has been compiled to determine the diameter of the rainwater drainage pipes, however it is also suitable for gutters.

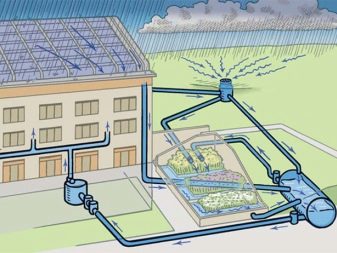

Surface Drainage System

Drainage systems are intended mainly for collecting rainwater and melt water, not groundwater. In the future, they should transfer water to the sewage system, where such water will be filtered and return to nature, for example, it will evaporate or merge into rivers. Surface drainage is imperative during construction. According to engineering standards, every construction object must be equipped with such a system even at the planning stage.

Surface drainage systems are available in several configurations, which are expressed in assembly systems. Thus, each of the systems is designed for a certain amount of water, loads and other things. Drainage trays are used in linear surface drainage, the purpose of which is to collect water in large volumes.Most successfully, this kind of function when it comes to asphalt areas, highways and the like.

A prerequisite for the installation of such a system is the slope. If the terrain is flat and has no slope, it is necessary to look at other types.

In some cases, it is required to install sand traps, the purpose of which is garbage collection, filtration of sand, large particles, which in theory can clog gutters. Their presence greatly increases the service life of storm drains.

Components

If we talk about industrial storm sewers, it consists of several elements.

- Storm water inlet. It is designed to divert water from the surface locally. In order for garbage, leaves, etc. not to clog the gully and other elements, a siphon is used. It serves as a kind of partition. A special basket is used for garbage collection.

- Rain well. It is used to transport wastewater. It is constructed only at the end of the assembly of the entire storm sewer. They are also needed in cases where it is necessary to regularly drain large areas of soil in a short period of time.

- Tray. Actually, what we see on the surface: a trench made of materials resistant to water. The tray transports water by moving it from the site.

- Pipes. Mounted in rain trays. Through these pipes, the water is subsequently transferred to the sewage system itself. Pipes are located underground, so as not to spoil the general appearance of the site.

Installation Tools

In order to install water intakes, you will need to buy some tools. It may turn out that you already have some of these tools, after which you will have to go to the special equipment store. In any case, the tools can not be called scarce - they can be found in any large construction hypermarket.

- Shovel. It will serve to make a trench under the tray. Make sure that the nozzle is sharply sharpened. This will greatly facilitate the work.

- Buckets. It is advisable to have at least two buckets. They are useful for transporting sand to the place of installation.

- Concrete mixer. In some cases, the owners decide to firmly secure the chute in place with concrete. In these cases, it is better not to mix it manually, but with the help of a special machine.Then the concrete will be homogeneous and will lie evenly.

- Hacksaw. With this simple tool to be cut parts. Depending on what material the drain is made of, you will need a hacksaw of a certain type: for metal, capable of sawing concrete, and so on.

- Hammer. It is needed to fasten parts with each other, to fit the forms and simply tamping the tray in place.

- Saw or grinder. If a metal chute is chosen, then get a diamond saw or diamond blade for the grinder, especially if you are dealing with durable metals such as cast iron. Then problems with fast cutting parts will not arise.

Mounting technology

It does not make sense to consider the installation technology in public buildings or on commercial objects, since for such works, as a rule, they hire a brigade of professionals. It is quite another thing - installation on your own personal plot. Then it really is worthwhile to get a better look at the work in order to carry out the installation yourself if necessary, or immediately see if your workers violate the technology.

After the tray is selected, the tools are prepared, it is necessary to carry out some preparatory work. These include markings on the ground.This is done in order to clearly understand where the drainage system will be located, how wide it can be. Keep in mind that it is best to have such objects in the lowlands, on the slopes of the hills, if they are on your site. Then the water will collect there, rather than accumulate somewhere on the site, leading to the leaching of useful substances from the soil.

And also it is necessary to take into account which type of tray connection was chosen by you. This refers to its connection to the sewer. It is necessary to perform work in a strictly defined sequence, and the connection should be carried out only when all parts of the drain are assembled, sealed and sealed.

Sequence

To make an independent installation of the drainage tray, use the following step-by-step instruction.

- Dig trenches for installing trays. There should be as many of them as drainage systems planned to be installed. Pay attention to the dimensions of the grooves, their depth and width: the drainage channel must be completely placed there.

- For full installation and subsequent work, you need to have a shower at an angle.If you make them on a plane, then the water will stagnate in them, and not flow where it should. The slope varies greatly: it can be meter, and it can be only 1 cm.

- Trenches dug in compliance with the above conditions must be well sealed. For this you can use ordinary sand, which has a drainage effect.

- Pay special attention to the next item, if your plans - the installation of plastic products. Sand compaction alone is not enough here. Be sure to create a concrete base, because without it the strength of the polymer drain will drop dramatically. The box of concrete is made in the form of a tray. It also serves to compensate for temperatures. In it, the plastic gutter will not be deformed, compressed by the surrounding earth.

- The presence of the grille is optional, but desirable as it provides additional protection. Garbage, leaves and other large items will not fall into the storm sewer, clogging it. Pay attention to the rules for installing sewers. It must be placed half a centimeter below the ground level, otherwise it will protrude and interfere.

- To connect the trays, it is necessary to insert one into the other at the location of the grooves. In the future, you need a good sealing joints. For this fit high strength silicone sealant.

It is not necessary to seal the grate, as it will have to be dismantled from time to time to clean the storm sewer.

Connection Types

This refers to the direction in which water should flow through the tray. Depending on this, the grooves are calculated. It is impossible to locate the channel in any other way, and not as indicated in the diagram. By the way, the layout of the tray itself, as well as its individual elements, is attached to each individual set, so it’s impossible to consider any common sequence.

Recommendations

Experts share some recommendations on how best to make the selection and installation of storm drains.

- Be sure to start all the installation work on the gutter only after the concrete base has been prepared. It should be no thinner than 7-10 cm.

- The dead-end part of the tray must be well sealed by fitting the end cap, which is included in the kit.

- After installation, you need to strengthen the walls of the tray.For this you need to use concreting. If the storm sewage system is located along the path (asphalted or paved with paving stones, tiles), then the tray should be concreted only from the side that does not adjoin the path.

When carrying out all the work on cutting gutters, remember about safety precautions: be sure to use protective equipment such as goggles, a mask, gloves.

- The end cap is needed not only for the “beginning” of the gutter, but also for its “end”. It is important to seal the tray very well in this place to prevent leaks and water from entering the area.

- The grill should be installed immediately after the tray is reinforced with concrete. Installing the grid on the frozen concrete can be problematic.

- At the end, powder the concrete with primer and tamp to hide the reinforcement.

For information on how to install a drainage tray on the pavement, see the following video.