For what and where are used pads on window sills?

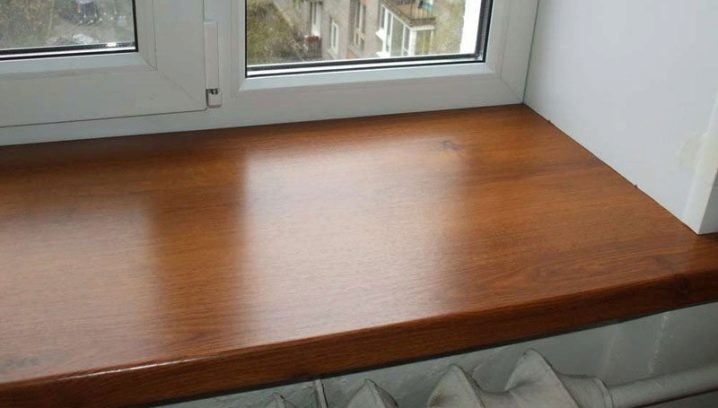

Today the window sill is not only an integral part of the window construction, but also a piece of furniture. Previously, it was made solely as an element that hides the bottom of the window opening, performing the function of saving it. But with the influence of progress and new design trends, the windows became larger, and window sills began to be used both as sofas and shelves. In short, from the usual part of the window that protects the opening from mechanical damage, they turned into a decorative detail adorning the room.

Replacement or restoration?

Many owners of apartments and private houses rework and sill when repairing, so that it does not stand out from the background of the updated furnishings and harmoniously fit into the interior.If the replacement is not included in the plans, then usually the window sill is strengthened by testing it for strength. Visually update the surface can be by ordinary decoration. To do this, use special devices sold in hardware stores.

Cover plate is the easiest way to restore the window sill. It allows you to return it to its former form (or make it visually new), adjust the shape for the particular room and the window itself. This type of work is performed in an extremely short time, it does not affect the interior decoration of the room, the window and its design. The important point is that for such work it is not necessary to invite a master. Installation is very simple, allowing you to perform all the necessary actions yourself.

This method can not only improve the appearance of the coating, but also restore the damaged sill. Special pads help you quickly and easily repair it with your own hands at home. If the board is cracked or cracked, you can fix it. It is much more difficult to fill the gap or clean the hole with the help of construction tools than to fasten the cover over the old coating without removing the structure.

With regard to appearance, you can pay attention to the veneered versions or products with end laminated film. The only caveat is that if the thickness of the window sill is more than 6 cm, then this update method will not work.

Design features and purpose

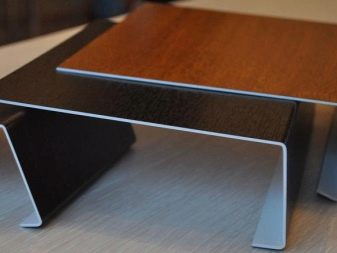

The main tasks of the lining on the windowsill are restoration, protection of the surface of the board from external influences, as well as giving the design an aesthetic look. They are made lining their prof. sheets, the main use of which are repair and finishing works.

Regardless of what the pad is made from, it is not responsible for the strength of the sill itself, because the main purpose of this part is to decorate, that is, the creation of the final (final) layer. Plates are combined with almost all options of materials. Pads are suitable for both plastic window sills and wooden. Sometimes there are concrete structures. Here this method of decorating is also valid.

The material used in the manufacture of such products is polyvinyl chloride, also used in many window designs.Due to this, the color palette is very extensive, as well as the size of products.

The maximum length of the plate is 3 meters, width - two times less. Plugs are also made from polyvinyl chloride. Thanks to a thin, but solid material, the window sill becomes resistant to flame, solar radiation, dampness, temperature changes.

Advantages and disadvantages

If we compare the repair by installing the plates and replacing the window board, the first method has both advantages and disadvantages.

The advantages are:

- low price;

- high installation speed during restoration;

- rapid partial repair (by correcting one link, and not replacing the entire element);

- a diverse color palette that can satisfy every taste and fit into any interior;

- the possibility of changing the shape of the sill design, as well as its size;

- high wear resistance.

Disadvantages are typical for any plastic elements, especially for window sills. This is a low strength of the coating, as well as low resistance to mechanical stress.

Application

There are various reasons for such work.

- Window slabs of stone (concrete, granite, marble) lose their former appearance, chips and cracks appear.

- There is a loss of color of plastic window sills (the appearance of yellow).

- Traces of hot objects, holes burned by cigarette butts, which also spoil the appearance of plastic.

- Residual pollution from interior items, tightly “eaten” into the casing (from flower pots, souvenirs, and so on).

- Poor cleaning (traces of chemicals).

- Mechanical damage (scratches, dents).

- Damage window sill pets.

- Just a desire to update the appearance of the room (change the shape, color or size of the window sill).

Kinds

Pads on the windowsill are of two types: polyvinyl chloride (abbreviated as PVC) and MDF panels (fibreboard).

- MDF is an abbreviation of the German name Mittel Dichte Fazerplatte.

- Plastic linings (PVC linings) are available in different shades. It can also be an imitation of natural materials such as marble, granite, wood, rubber, stone, etc.

Decorative elements of both types are mounted on window plates and boards made of any materials. It can be wood, concrete, tile, stone (natural, artificial).

Tips and tricks

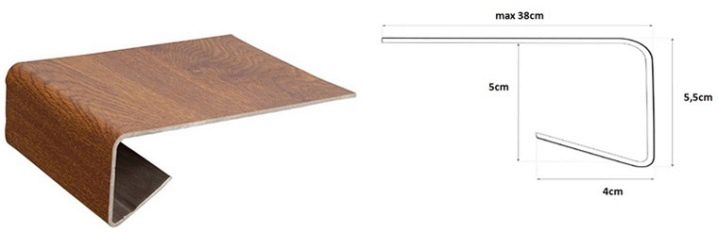

In order to prevent the appearance of a gap between the plate and the old board, it is necessary to choose the width of the product 2 cm larger than the old sill. Also, when buying, you need to immediately take and plugs that are suitable for color and material. PFH linings have a typical size, which is offered by manufacturers. The width is 15 to 52 cm, the thickness is 0.35 cm, and the maximum length is 300 cm.

You can also restore the window sill and using MDF panels. They have a very mediocre color palette, as well as the absence of caps. Because of their considerable price, they are not very popular in Russia, but they are more environmentally friendly than plastic products.

In this case, it is also necessary to prevent a gap between the panel and the window sill.

The drip closes by 7-8 cm. It performs not only its main function, but also helps to hide the old window-sill (or stove). Typical width is from 35 to 70 cm, thickness - from 0.15 to 0.18 cm, and the length of products is slightly longer than that of PVC panels (it reaches 400 cm).

Selection features

When choosing a decorative part it is necessary to consider some factors.

- The color of the product must be combined both with the window itself and with the interior as a whole (it should be borne in mind wallpaper, curtains, curtains, other decorative elements).

- The size of the product is selected under the window sill. It should be a little more, taking into account the stock, including the trimming.

- It is important to pay attention to the product specifications (moisture resistance, heat resistance, resistance to temperature extremes, to direct sunlight).

- Possibility of use for cleaning detergents.

- For PVC, there must be caps for the product that meet the necessary requirements in form and material.

Installation rules

To perform such work does not require the help of professionals. It is enough to follow simple and clear instructions and not to miss important points. Installation will take not so much time, because there is no need to dismantle the old window sill.

The work will require the following tools and materials:

- the pad itself with the plugs;

- special glue;

- silicone or sealant;

- a hacksaw (or a turbine with a special disk, or a jigsaw, or a regular jigsaw);

- roulette;

- level of at least half the length of the product.

After preparing the necessary tools, you can begin the installation process, which consists of several steps. You need to perform them in order, not running ahead, especially if you are not strong in construction.

- Preparatory stage. If there are defects in the form of cracks and chips on the window sill or board, it is necessary to remove the plane by sealing these places with plaster materials (for example, putty or gypsum glue). This does not apply to window sills made of wood and plastic, they are simply cleaned of debris and other foreign objects. Some advise treatment with septic tanks, but this is only for wood, which is usually forgotten to be mentioned. This is due to the uselessness of processing other materials with antiseptics, which is a waste of money.

- Accurately adjusted dimensions - next step. It is necessary to measure everything that will be important when cutting and trimming the product. These actions are carried out with a painting knife, jigsaw, a turbine with a special nozzle. The nozzle is needed because the plastic can melt and deform.

- Installation of panels for the window sill. Special mounting adhesive is applied on the back side of the panel. It is distributed by horizontal stripes over the entire area of the part, after which they are applied with zigzags or parabolas.After applying the glue lining is mounted on the window sill. It is necessary to press it tightly. Then it is recommended to take small weights (0.5 kg will suffice) to be placed at the corners of the panel for better “setting” of the glue.

Until the glue dries, it is forbidden to engage in further work. This is due to the fact that there may be a deformation of the panel itself, after which it will have to be thrown away. In this case, it will take quite a lot of time to prepare the window sill for applying a new layer of glue.

- Installation of plugs. In the form of the whole structure that you assembled, the plugs are cut out and installed on the ends.

- Applying sealant. A layer of sealant or silicone is applied along the junction (on the slopes, window frame). This is done in order to close the joints and protect them from moisture. It is necessary to apply sealant, after which you need to hold your finger along the bevel and get a flat and beautiful corner line. You can also use special rubber profiles or corners, but for better preservation of the design it is better to miss everything with sealant.

- When implementing the panel are protected by a special filmpreventing their damage during transportation and installation.After completion of all phases of work, the film must be carefully removed. Then wash the window sill with clean water.

Visual workshop on the installation of overlays on the window sill, see below.

Prices

Prices for products depend on many factors. But even with the purchase of expensive material, its use for repair will be much cheaper than replacing the window sill.

There are several basic parameters that make up the cost of decorative overlays.

- Material and its quality (must be indicated on the package along with all the technical characteristics of the product).

- Brand of manufacturer. Products of famous brands are more expensive. Matters and country of manufacture. For example, PVC panels from China and Germany, even one brand will differ markedly in price (the first option will be cheaper).

- Dimensions goods.

- Hue, texture, withthe falsity of the pattern (imitation of natural materials may cost more than the usual monophonic coating).

The cheapest and most popular on the market for such products are white plastic linings of standard sizes. Such products fit into many styles of interior because they are neutral.

Classic color also fits most windows, which developers traditionally make snow-white.

If we take the approximate prices for one running meter, then the plastic options will cost about 600 rubles, while the lining of MDF will cost about 2000 rubles. The average price of plugs is 250-270 rubles. for a couple.