Rules for the selection and installation of window sills

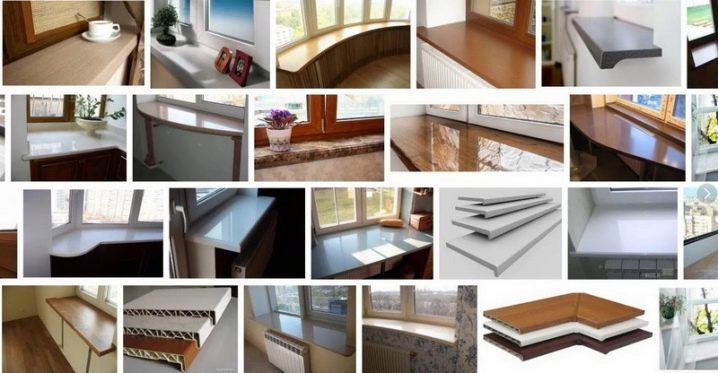

Presenting modern window systems without windowsills is almost impossible, because this accessory not only serves as an additional protection against the cold, but can also be used to place flowers, books or play the role of a table top. In addition, the window sill is a favorite place for children and animals, who can look out of the window and learn about the world around them. Concrete options are long gone. Today, plastic or wooden products are being installed everywhere.

Special features

On the modern market there is a huge number of window sills, which are distinguished by their size, shape, material manufacturing and other criteria.Despite this, most people pay minimal attention to the choice of this accessory and prefer to purchase standard solutions offered by window companies. Let us see which sill is considered optimal and preferable, of which materials it should be made in order to preserve its attractive appearance as long as possible.

Kinds

Various materials can be used for the production of window sills. In this case, the choice depends on the financial capacity of the person, his personal preferences, the interior decoration and the conditions of the room. In addition, it is necessary to consider which window is installed in the room. The most popular materials used for the production of window sills include the following:

- polyvinyl chloride, which is often called ordinary plastic;

- wood, including chipboard and MDF;

- natural and artificial quartz stones.

Very often in the modern market one can see non-standard solutions, which are made of ceramic tiles, mosaics, porcelain stoneware, or trimmed with expensive fabrics.

You should also pay attention to the shape of the product, which can be not only rectangular, but also round or square.It all depends on the material used to make the window sill, as well as the interior features of an apartment or a country house.

In recent years, plastic wide window sills, which have already pushed all other options out of the market, have become extremely popular. The huge demand for this product is due to its unique performance properties and affordable cost. Products are made of conventional PVC profile, include several cameras and vertical stiffeners.

The thickness of plastic laminated window sills usually does not exceed 25 mm, however, for visual increase often the design is equipped with a nose, with the result that the total thickness is about 40 mm. The upper part of the product is covered with a film, which not only provides an attractive appearance of the product, but also protects it from mechanical damage, scratches and fading.

The huge popularity and demand for plastic window sills in the market is dictated by a huge number of advantages, among which are the following:

- An impressive level of strength, which is provided by the presence of ribs.You can not worry that after a while, the window sill will begin to bend and not withstand the loads that were originally invested in it by the manufacturer.

- Resistant to moisture, ultraviolet rays and chemical agents. Due to this, these products are distinguished by unpretentious care.

- Low weight, which greatly simplifies the process of mounting the product.

- The presence of a convector and a special film, which is covered with plastic. The peculiarity of this film is that it can be of any color or imitate a certain image. The standard version is usually painted white, however, even in this case, it can mimic the texture of wood or stone. Due to this, very often wooden window sills are fitted with plastic window sills that are suitable for color and texture.

Another advantage of plastic window sills is their affordable price, so you can install windows without affecting your budget.

Despite the huge number of advantages, these types of products are also not without drawbacks.Among the drawbacks can be noted the fact that over time, the surface of even the highest quality system begins to turn yellow, absorb pollution or deform under the influence of high or low temperatures. In addition, such natural window sills will not work.

Products covered with conventional PVC film. If you want to ensure the maximum level of resistance to wear, you can purchase options that are covered with a melamine film.

The second most popular today is wooden window sills, which have already become an integral part of a wooden window. Previously, only similar products were used in residential buildings, however, today they are already being replaced by cheap and practical plastic. Despite this, there is a huge amount of wooden window sills, as they can boast many advantages and strengths:

- High level of strength, especially if oak, beech or larch wood was used in the manufacturing process.

- Naturalness and environmental friendliness. If you are a supporter of the most safe and environmentally friendly materials, then these windows are exactly what you need.

- Attractive appearance and unique surface that is smooth.

- Impressive thermal insulation properties.

Of course, this type of window sills is not without its drawbacks. The main disadvantage of this product is its cost, which in some cases can be 2-3 times higher than the cost of plastic window sills. In addition, wood products can not boast resistance to temperature and high humidity. If they are used in a room where cooking takes place constantly and a lot of steam is released, then after a while, the product may start to rot and lose its original appearance.

On such windowsills it is better not to spill water and do not put hot dishes, as the surface will crack. Wooden window sills also can not boast of their resistance to ultraviolet rays, fire, and are also a place of active reproduction of microorganisms and insects.

Today, manufacturers are making as much effort as possible in order to improve the performance properties of wooden window sills and maximize their lifespan.Before processing, the wood is dried, after which a special antiseptic is applied to it, and the surface is coated with varnishes and paints. They are designed to protect the material from moisture, microorganisms and temperature extremes.

In addition, these manipulations provide a unique structure of the material and allow it to give an attractive appearance. No matter how hard the modern industry tries, the tree still requires steadfast care, so after a few years, such window sills will have to be covered with special varnishes and wax. In the modern market the following options are most popular:

- Conifers. For example, larch boasts excellent strength properties, and pine, spruce or cedar have an attractive appearance. The lack of conifers is that they have soft wood, which is not able to withstand changes in humidity and temperature, so you need to be careful with such products.

- Deciduous species, including oak, cherry and ash. This is an expensive pleasure, however, by its durability this option is largely superior to conifers made of softwood.

- Red and black wood. If you want to buy something exclusive and exquisite, then the window sills of such materials is exactly what you need. They cost a lot of money, but can be a central element of the interior, made in a classic style.

For the production of window sills is extremely rarely used solid wood, in most cases, manufacturers prefer logs. People who want to choose from the array of options, have to get ready for the huge money spending. Stick together thin layers of wood under the influence of high temperatures and pressure. The result is a product that is not inferior to the array in its strength characteristics and even boasts additional qualities.

For example, similar window sills are practically not subject to deformation even after many years after use. In the process of choosing such a window sill, one should take into account the fact that its thickness should not be less than 28 mm.

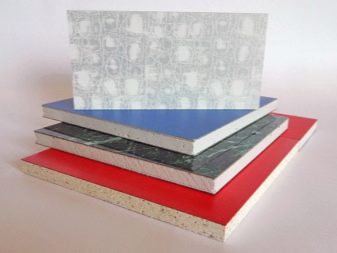

If you can not afford to buy window sills made of natural wood or stone, and plastic leans as an option, you can choose products from MDF and chipboard. Such accessories are made using resins, which during operation can release formaldehyde. That is why you should be as careful as possible with such windowsills and always check the accompanying documentation in order to assess the level of formaldehyde emissions.

MDF boards are a bit more expensive than windowsills made of chipboard. However, they can boast greater safety for health, as during manufacture no toxic substances are used. Among the common features of window sills from particle board and MDF, one can distinguish their affordable cost, as well as unique operational properties. The upper part of the slab can be finished with natural wood, which ensures a refined and elegant appearance.

In addition, lamination can be used for finishing, so that manufacturers protect the base plate from the effects of negative environmental factors.

The simplest and most affordable option is to veneer such a window sill with plastic or PVC film. However, this adversely affects the durability of the product, since moisture gets through the ends or cracks on the bends of the film and very often leads to delamination or rotting of the material.In addition, the film has one negative property - to stretch or tighten, which also leads to the ingress of water to the material and creates the risk that the plate will swell.

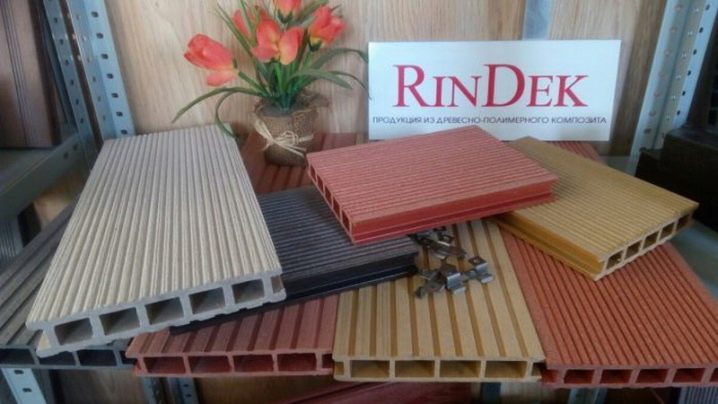

Often, modern consumers prefer sills, which are made of wood-polymer composite. It should be noted that the decking, which is used for the production of such a window sill, also performed well in the role of flooring on balconies and terraces. In addition, this material can be used to create garden paths and areas near the pool.

The peculiarity of the material is that organic and mineral fillers are used for its production, including fiberglass and limestone flour. And in combination with a bonding material in the form of polyvinyl chloride, polypropylene or grain starch, it is possible to provide incredible strength and attractive appearance of the material. From a mixture of these boards are obtained, characterized by a unique relief and voids inside.

The use of this production technology makes it possible to talk about the following advantages of this kind of window sills:

- High level of resistance to moisture, fungus and temperature extremes. Due to this, such window sills can be used in almost any conditions, regardless of the interior features and climate in the region.

- High strength, which makes the window sill an ideal solution for the kitchen, where very often various accessories are put on the products.

- Resistance to direct sunlight. Unlike other models, similar window sills under the influence of ultraviolet do not fade, do not lose their attractive and original appearance.

- Huge selection of colors, so you can choose the best option for any interior.

Next in popularity and demand are windowsills, which are made of natural and artificial stone. Today, not everyone can afford expensive natural stone, however, artificial variants clearly imitate natural ones and practically do not differ from them. As a result, you can get a sample that is almost the same as in strength and static characteristics, however, it has a more affordable mass and cost.

Artificial stones look very beautiful, and they are used mainly to create exclusive interiors.

Among the basic materials can highlight their high strength, resistance to moisture, ultraviolet rays and temperature changes. In addition, window sills made of artificial and natural stones do an excellent job with fire, do not require special attention and are easy to maintain. Such windowsills are also often chosen by people who prefer environmentally friendly materials that do not emit any harmful vapors during operation.

In addition, such window sills can boast an impressive appearance, and a large selection of colors and textures allows each person to choose the most preferred option for your room.

A distinctive feature of natural stones is that they can be heterogeneous in structure and have internal defects, so it is difficult to obtain products of various shapes from them. In addition, the surface of the product is cold. Depending on the breed and processing, the color solution of the surface may differ in its roughness or smoothness.For the production of window sills, manufacturers mainly use such natural stones as marble and onyx.

Marble is distinguished by its impressively beautiful texture, however, it absorbs dirt, moisture and scratches extremely quickly. As for granite, it is famous for its resistance to any external mechanical stress, but it has a less pronounced texture, which affects the attractiveness of the finished product.

Onyx is chosen by people who require maximum hardness and strength from a windowsill. In addition, this material transmits light, so that it can be used in places with light for the organization of exclusive interiors.

Artificial stones can be made on the basis of a number of technologies, including sinter, acrylic stone or cast marble. In addition, various mineral fillers are used, as well as dyes and polymer resin. Basically, these types of window sills differ in the percentage ratio of components and features of the processing technology used.

The advantages of artificial stone sills are that they can be given almost any shape.In addition, they have a pleasant to the touch surface, do not absorb dirt, and are also able to withstand high temperature extremes.

The main difference between artificial stone and natural stone is that it is not a breeding ground for bacteria, so you can forget about the formation of fungus, mold and other pathogens on the surface of the windowsill. If in the process of using scratches or stains begin to appear, then you can get rid of them extremely quickly using the polishing method.

Dimensions

The peculiarity of the window sills is that they can be made according to individual sizes. This is due to the fact that even in standard multi-storey buildings the size of window openings differ from each other. In addition, the width of the window sill is determined by the depth of installation of the window profile and may vary depending on the characteristics of the wizard.

That is why in the process of ordering windows and their elements, a measurer leaves the place, who with the help of special tools and equipment determines the dimensions of the future window sill with an accuracy of one millimeter.

For the production of plastic window sills are used ordinary PVC boards, whose length ranges from 400 to 600 cm. That is why the length of the window sill, produced to order, can not be more than 6 meters. The standard dimensions of window sills range from 50 to 600 mm in increments of 50 mm.

When ordering an internal sill, it is necessary to change the width of the internal opening and add 5–10 cm to it. This is necessary in order to take into account the width of the part of the sill protruding beyond the wall.

Design

The appearance of the window sill, its resistance to mechanical damage and quality indicators depend primarily on the material used for production. In addition, this affects the coating. Among the most popular types of coatings that are used by modern manufacturers, can be identified veneer, PVC film and laminates. The veneer is a unique facing material, which is made in the form of thin sheets of wood and is obtained by planing the boards of valuable species. One of the most used oak veneer is considered, which boasts its strength and durability.

The main disadvantage of veneered window sills is the darkening and burning of veneer under the influence of ultraviolet rays. In addition, veneer is characterized by extremely high sensitivity to room humidity. Most manufacturers today as the main coating using polyvinyl chloride, which is a thin film that resembles paper.

This coating can be found mainly on the windowsill of economy class. It is characterized by an average level of resistance to temperature extremes, resistance to chemicals, and can also be washed with liquid cleaners.

Plastic window sills covered with PVC film are usually used to decorate ordinary interiors, since the product rather quickly loses its original appearance. A distinctive feature of this window sill is their rough surface, which, after some time, begins to absorb dust and dirt, fade under the influence of ultraviolet radiation and loses its attractiveness.

The coating of decorative paper laminate is considered the most modern and high quality.Due to the whole set of unique characteristics, this coating has received huge demand in various areas. The versatility allows to obtain on its basis different types of surfaces, including gloss, stone, imitation of marble wood and so on.

In addition, the coating is famous for its excellent properties, including resistance to moisture, scratching, the effects of temperature and household solvents.

How to choose?

In order for the window sill to fully perform the functions assigned to it, it is necessary to pay close attention to its choice. In the selection process should pay attention to the following details.

- Cold protection. A well-made and installed sill always provides reliable protection from cold from the street and is a barrier to indoor heat in the room.

- Decorative and attractive appearance. He is the link between the window, the slopes of the wall and the radiator. With proper installation and approach from the window sill can make an attractive flower bed. The versatility of the product allows you to show imagination and turn it into a real decoration of the room.

- Proper distribution of heat in the room. The protrusion of the window sill does not allow the warm air from the battery to immediately rise, it sends it to different parts of the room. The sill should protrude no more than 6 cm from the wall level. If it closes the radiator by more than half, you need to take care of the holes to improve air convection.

- Resistance to mechanical stress, the effect of detergents and direct UV rays, as well as the ability to cope with various loads. This is an extremely important criterion, since it is often the case that flowerpots, books or pots are placed on the windowsill.

- Resistance to moisture. If the window sill is installed in the kitchen or in the bathroom, then it is necessary to choose the options that are intended for use in rooms with high levels of humidity.

It is necessary to pay attention not only to these criteria and requirements, but also to the material that was used in the process of creating the sill. After all, it is thanks to him that almost all of the above requirements will be fulfilled. It is best to choose a window sill from the same material that was used to manufacture the window frame.

Making your own hands

There may be several reasons that may lead to the manufacture of a window sill. For example, a person wants to simply make a beautiful thing with his own hands, or he needs to create a product of the original shape and size. In addition, self-production allows for the restoration and decoration of the window sill based on personal preferences. Often, people decide to make their own windowsill with the aim of making a comfortable kitchen or writing desk under the window.

In the latter case, there is a huge variety of options for the execution of ideas. Each of them requires certain materials (plugs, seals), tools and skills.

So, independent creation of a window sill should occur in the following stages:

- To determine the size of the product. First of all, it is necessary to accurately and correctly measure the area where the window sill will be installed. After that, you can pick up a well-dried board, on which there will be no defects and problems.

- Give the board the necessary form with the help of tools.

- Pick a drip off and trim it in length.

- Finish surface treatment with the skin, thereby achieving the desired surface roughness.

- To carry out the treatment with the help of an antiseptic, which will provide reliable protection of the window sill from rotting and multiplication of bacteria.

- Coat gel varnish.

Manufacturers and reviews

On the modern market there are a huge number of manufacturers who produce window sills with increased strength and reliability. Due to this, each person can choose the optimal product for the peculiarities of their interior and personal preferences. In the domestic market plastic windowsills from the company Crystallit, which manufactures products with incredible hardness and a large selection of colors, are very popular.

The innovative concept of this company lies in the combination of the smooth texture and durable surface of the window sill, as well as in the use of multi-layer ultra-modern films that do not lose their attractive appearance even when exposed to ultraviolet rays.

A distinctive feature of such window sills is that they are made of acrylic resins produced in Germany, so they are even visually different.The surface of the window sills of the company is famous for its resistance to the effects of chemical cleaning agents, and does not fade under the sunlight. The Russian company produces window sills with a special high-strength wall structure and stiffeners, characterized by incredible durability in use.

In addition, today the German window sills Werzalit, which are considered the leading brand in the premium class, are in great demand. Unique high-quality window sills of the company are created using advanced technologies and taking into account environmental safety. A patented wood-plastic mixture is used for production, which provides a harmonious combination of the best properties of this material with the environment.

Among the main advantages of the window sills of the German company can be identified the presence of high-quality coating made of multi-layer laminate. It is developed on the basis of acrylic resins, which are reliable in use and do not require special treatment. Among the features of the window sills of the company, it is possible to highlight the incredibly high-quality performance, as well as high resistance to abrasion of the surface and scratches,resistance to chemicals and cleaning agents, as well as mechanical stress. In addition, these products can be used in rooms that are characterized by increased fire hazard and high levels of humidity.

Tips

In the process of selection, it is first necessary to take measurements, and then determine the length of the product. To do this, you can measure the width of the window opening, add 10 cm to the resulting indicator.

To determine the width of the window sill with a film, it is necessary to measure the distance between the edge of the wall and the installed window, after which add 12 cm, depending on the size of the overhang above the radiator.

Window sills should be placed near the frame. To do this, you can use trim boards with a suitable thickness. Before the start of all work, workplaces must be cleaned of dust and moistened with water. And the free area under the frame is filled with polyurethane foam, after which the window sill is immediately inserted. For a few days, it is necessary to place a load on it so that the space under the bar completely hesitates and the window sill clutches.

Beautiful examples in the interior

A great way to decorate the window sill in the nursery is to arrange it in the form of a corner where the child can sit at the laptop, do homework or read a book. In the living room, the windowsills are usually large, so you can make room for a small desktop or place soft pillows, so this area will look spectacular.

In the kitchen, the window sill can be made retractable, which will allow to use it as an additional table.

See how to install the windowsill yourself in the next video.