Plastic window sills: types and selection criteria

The window sill is one of the important elements of the window opening. Its installation is necessary to perform several functions at once: it gives the window a complete look, closes the assembly joints, protects against drafts and serves as a shelf for indoor plants and other useful things. At production of window sills different materials are used, but plastic window sills use the most popular. The reason for the high demand of this product lies in the advantages inherent exclusively in PVC material.

Special features

Despite the relatively low cost, plastic window sills are not inferior in quality to wood, metal and marble analogues and have their advantages:

- plastic is moisture resistant, and therefore is not subject to the processes of decay and corrosion in rooms with high humidity;

- plastics are chemically resistant to solutions such as acetone and hydrogen peroxide;

- the cost of a plastic window sill is much lower than wood, marble and metal products;

- installation work does not require the presence of certain building knowledge or skills;

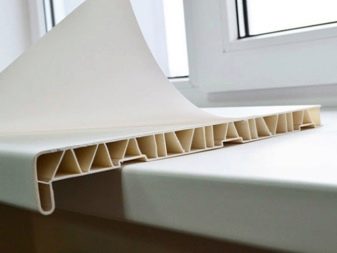

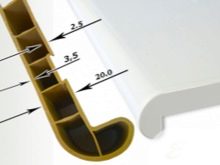

- Due to the fact that the PVC window sill has an internal division into chambers, the product can be considered heat-saving;

- plastic profile does not require shrinkage and warping, as is the case with wood;

- The surface of the plastic window sill is presented in different color shades, and can also imitate marble or wood textures;

- Strength and heat-resistant characteristics of PVC window-sill can be increased by applying a specialized composition.

This product has its drawbacks:

- relatively short lifetime;

- low thermal stability (it is not recommended to put hot objects on PVC window-sills, as this may lead to staining and deformation);

- plastic products are subject to mechanical stress (if for any reason cracks or chips appear on the sill surface, the only option would be to completely replace the product - local repair of the PVC window sill is impossible).

There is an opinion that the reinforced sill is a useless thing devoid of any functionality. In fact, the sill has at least two functional purposes:

- is a kind of barrier that does not allow cold air into the living space, and warm air is dissipated inside the subwindow structure;

- controls the warm air flows, directing them to the surface of the glass, and therefore the formation of condensate does not occur.

It turns out that the window sill forms a “warm air cushion”, which isolates the cold window glass and the atmosphere in the room. Refusing to install a window sill, there is a high risk of the formation of high humidity, and therefore the indoor climate may be violated.

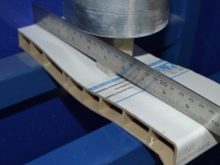

In the manufacture of plastic windowsill, a standard type PVC profile is used.Window profiles are extruded using an extruder, a specialized device that softens the plastic material and gives it the necessary shape by pushing through extrusion holes. Inside the space of plastic profiles is divided into several chambers, which are called honeycombs, as well as vertical and diagonal stiffeners. Similar design helps to increase the heat capacity and give rigidity to the window sill, not allowing it to sag and break. After that, the product is subjected to lamination.

Species

Replacing and installing new plastic windows according to GOST is always accompanied by the question: “Which sill to choose? ". The most common solution to this issue is the acquisition of plastic windowsill. Brands involved in the production of window sills, offer consumers a huge range of plastic window sills, including imitated a natural material, one of which is wood.

First of all, plastic analog "under the tree" much more hygienic than a natural product: it is not susceptible to absorbing an unpleasant odor, and the removal of pollution is carried out without the use of special chemicals.If the wood begins to rot after some time, then the service life of the plastic, while observing the requirements of operation, is more than thirty years.

Bilateral subwindow unit is extremely rare, but still found its use in high-functional interiors. Such a product is characterized by the presence of two edges. Depending on the installation method, the double-sided sill is easily modified into a one-sided model. In connection with the addition of wood or other filler, such window sills are quite durable.

If you plan to expose the window sill to serious loads, for example, to use it as a sunbed, it is recommended to purchase subwindow unit rugged. This product is characterized by greater thickness and increased number of ribs. This window sill is able to withstand more than one hundred kilograms.

Material

The plastic subwindow unit, due to its operational characteristics and relatively low cost, is the undoubted leader. By type of coating plastic window sill can be: matte, glossy, laminated.

Matte and glossy finish perfectly fit into the interior of any interior. They can be made in any color range - it all depends on your preferences. Matte finish has become popular not so long ago. If the glossy window sill instantly attracts consumers with its luxurious brilliance, then the matte finish gives a feeling of warmth and comfort. It is worth noting that, in contrast to the matte surface, the glossy analog absorbs less dust and dirt.

However, if damaged, the gloss is not amenable to restoration, and in the case of a matte finish, it is only necessary to purchase a special tool for surface restoration.

For more budget options plastic sill characteristic coating in the form of a laminated film. It was she who gives the product texture, as well as long service life and increased strength. For lamination of the surface, a polyvinyl chloride film is used, which is a thermoplastic colorless polymer. For the white sill, one layer of PVC film is used; for the manufacture of a color sill, repeated application is applied with the addition of a dye.

Another interesting option for the subwindow unit is wenge productmade from a mixture of PVC and wood flour.

The unique manufacturing technology gave the product the following advantages: scratch resistance, insensitivity to UV rays, preservation of the original appearance and long service life.

Dimensions

As is the case with the installation of plastic windows, the window sill is made individually (to order). This is due to the fact that even a standard multi-storey building has a window opening, the size of which can vary within 10 cm. In addition, the width of the plastic profile corresponds to the depth of the window opening and can also vary. In this regard, when making the order It is recommended to first use the services of a measurer, which will determine the dimensions of the window opening.

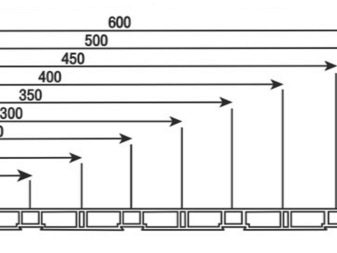

The plastic window sill is made of standard PVC standard size boards, the length of which ranges from 4050 to 6000 mm. As a result, a product that is made to order is limited to a length of 6 meters. The standard width of the PVC window-sill is in the range from 50 to 600 mm with a step of 50 mm and from 600 to 1000 mm with a step of 100 mm.For the manufacture of a windowsill, you will need to measure the width of the internal window openings. Then add 5–10 cm to the value obtained and round to the nearest standard size.

Suppose that the width of the window is 38 cm. To this value we add the minimum value of 5 cm and we get 43 cm. We round this value to the nearest standard size - 45 cm (450 mm). And it is for this indicator that the cost of the finished product will be determined.

The maximum thickness should not exceed 600 mm.

Colors

Most consumers are convinced that the usual plastic window sill is presented exclusively in white. Meanwhile, the development of modern technology today allows manufacturers of plastic window sills to make products in any possible color shades. On the shelves of construction stores, you can see various models: from imitation of different tree species to stylization under natural stones with a matte or glossy surface.

Today, color models are popular, as well as brown and gray versions. A brown profile is made by mixing white plastic and acrylic dye, after which the product is laminated.In the building stores you will encounter a huge color palette of brown hue: from light golden hazelnut to rich chocolate. A brown sub-window block will give your interior respectability and solidity. Gray window sill has some advantages, for which we love many consumers. First of all, the gray color is not as dirty as white, and the neutral tint allows it to fit into any interior.

Style and design

In addition, the window sill also has an aesthetic function. It gently smoothes the distinction between thick walls and window frames. As mentioned earlier, modern technologies allow the plastic surface to imitate any natural or artificial material. For example, imitation of natural rocks, such as marble, granite or asbestos, perfectly fit into the kitchen interior, and a unique range of natural shades will give the room sophistication and luxury.

Wooden window sill is an environmentally friendly material. Its high cost and demands for regular care of the surface stops many consumers from buying.A plastic analogue with imitation wood structure will not only be cheaper, but also give the interior of the living room warmth and comfort.

Stained glass window - This is one of the fastest and easiest methods to give the plastic surface of the window sill originality and practicality. The stained glass finish of the window sill implies gluing of the mesh glass mosaic to the surface of the window sill. You will need tile adhesive to fix the mosaic to the surface of the window sill and grout in a neutral color to prevent moisture and dust from entering the joints. The mosaic is presented in a wide variety of variations.

The mosaic formed from the color scale in harmony with the color of the wall surface will look great.

Accessories

In order to carry out installation work, it is not necessary to have certain building skills and knowledge. You can quite cope on your own, without resorting to the services of specialists. but you can not do without components, which can either be provided by the manufacturer immediately, complete with a window sill, or you have to buy them yourself.

So, for the installation of PVC windowsill, you will need: a double-sided end cap and connectors. End caps serve as a decorative frame for the end of the window sill. They have two "noses" that are cut in the middle. One part is fixed to the window sill on the left side, the second, respectively, on the right side. In order to dock the sill at an angle and connect it along the entire length, connectors are used.

Do not forget to purchase slopes, brackets, stand. The slope is the perimeter inside the window that runs from the frame to the edges of the wall surface. After dismantling the old window, the old slopes are often deformed, and therefore their repair is required. You may need brackets when installing a plastic window sill in order to avoid deforming the surface under considerable load. The window opening, as it is known, is often the ideal place for the location of indoor plants. If the dimensions of the window sill do not allow to place all the necessary flower pots, pay attention to the special supports for flowers.

Today, there are both suspended and desktop structures made of metal, wood or plastic.

How to choose?

One of the important aspects when choosing a PVC window-sill is the quality of the product. Despite the fact that most plastic blocks visually may look identical, however, their content and production technology may vary. Window sills, in the manufacture of which plastic was involved, are tacitly divided into economical, medium and luxury categories.

TO economy category This includes products manufactured in Russia and China. They are characterized by low price, poor choice of color shades, a rather small warranty period and light weight. Since products from this category have thin stiffening ribs, it is recommended not to subject the surface to heavy loads. Many consumers have noted that after some period of time, black stains appear on the surface of the sill made of thin PVC board, which are not cleaned.

For middle category characterized by denser stiffeners and increased strength properties.Often window sills from this category are covered with a protective polymer layer and have a rather large assortment of color shades. Belgium, Ukraine and Russia are the main producers of these plastic window sills.

Plastic window sill belonging to luxury category, has the highest cost. Similar products are manufactured in Germany and are popular all over the world. The sill of German production is more significant weight. This is due to the fact that the manufacturer covers the sub-window block with a protective layer of acrylic. This allows you to achieve the stability of the product to mechanical and thermal effects.

So, regardless of the selected price category, pay attention to the following recommendations that will help you choose a really high-quality product: the product must exactly match the size of your window opening, have a state-approved quality certificate and preferably have an acrylic coating.

Famous manufacturers and reviews

German brands are the undisputed leader in the PVC window-sill blocks market.Today the most popular and sought-after brand is Moeller. A specific feature of this manufacturer is the technology of manufacturing a plastic window sill: a mixture of polymer and wood flour. The finished material has a small coefficient of thermal expansion, does not change its shape even under mechanical stress, and is resistant to high humidity and sudden temperature fluctuations. A pleasant bonus is the absence of formaldehyde in the composition, which is a confirmation of the safety of these products for the human body.

Another German quality manufacturer of plastic window sills is the brand Werzalit. Their products have a unique feature: the subwindow unit is completely filled from the inside, which gives the product solidity and increased strength. Due to the fact that the manufacture uses exclusively natural materials, the window sill is recognized as environmentally friendly.

From domestic manufacturers can distinguish the company Vitrage. The brand, which was one of the first to use calcium, was a zinc production technology, which made it possible to abandon the lead stabilizer.This has a positive impact on the quality of the products and today provides an opportunity to expose the product one hundred percent processing. In addition to the standard sizes of window sills 500, 600, 700 and 800 mm, Vitrage produces a modification of 900 mm.

This is an extremely tempting offer for the domestic consumer, given the standard size of the window opening in a high-rise building.

Tips and tricks

So, when buying any product in advance, it is recommended that you carefully read the nuances inherent in the material. Consider those that are typical for a plastic window sill.

- Make sure that there is a protective layer on the product. Thanks to him, the subwindow unit is not deformed during installation.

- The manufacturer must provide a warranty period and service in the service center.

- A quality product withstands at least 2000 kg per 1 m3.

- Depending on where the product will be located, make sure that its characteristics are at the proper level. For a room with high humidity, you must purchase a material with high moisture resistance.The greater the number of ribs, the higher the strength of the product.

- The subwindow unit should be in harmony with the window profile.

- The material involved in the manufacture of the window sill is responsible for the quality of the product. Therefore, do not hesitate to ask the consultants about the raw materials used and its compliance with the state standard.

When specifying the above nuances, buying a plastic window sill will not cause you any difficulties.

Successful examples and options

Modern equipment allows manufacturers to produce plastic models of window sills, skillfully imitating expensive natural materials. The subwindow block “under wood” will add solidity and weight to your home. These qualities are a good combination of luxury and wealth.

It is difficult to imagine, but in this interior a PVC panel imitating a natural stone is used as a window-sill block. And the application of the acrylic layer has increased the strength and moisture-resistant characteristics of the product. Bright glossy iridescent surface of the window sill block, skillfully imitating natural stone,will give the interior of your room chic and aristocratic.

The standard white sub-window unit is characterized by low cost and high durability. This product is perfectly combined with a white plastic window profile, forming a single structure. In this case, the coincidence of technical parameters will greatly facilitate the care of the entire structure.

About how to choose a window sill, see the video below.