Features of storm water inlets for storm sewers

Nowadays, not every homeowner can boast that his home is located on a plot with rather dry ground located on a hill. Often there are situations when the existing site is located in a valley where rainwater accumulates. This problem will be especially acute if there is frequent and heavy rainfall in the area where the house is located. In such circumstances, do not do without such facilities. as a storm water inlet for storm sewer. Today we will take a closer look at a similar object.

What it is?

Before you get acquainted with the features of rain receivers, you need to figure out what they are.

From the point of view of structural features, all storm water sewers for storm sewers are special reservoirs, into the interior of which fluid is sent from a drain pipe (metal,asbestos or corrugated / smooth plastic), or from a special rain channel. The very capacity of such structures are usually made of the most durable and reliable materials in order to seamlessly transfer the influence of external loads, and not to suffer from the powerful pressure of water and pressure from the ground. In addition, these elements should not corrode and contain hazardous / toxic components.

Purpose

A storm water inlet should be present in the stormwater flow system. This requirement is explained by the fact that through the specified part the liquid penetrates into the pipes or grooves. In simpler terms, such a receiver is designed to collect and purify water, as well as to send it to the construction of an outdoor storm sewer. Otherwise, this important detail is called "drainage."

The importance of the rain receiver lies in the fact that it can collect liquid not only from the gutters, which are located in the house, but also from the road surface. Thus, the appearance of puddles is effectively prevented.

Device and principle of operation

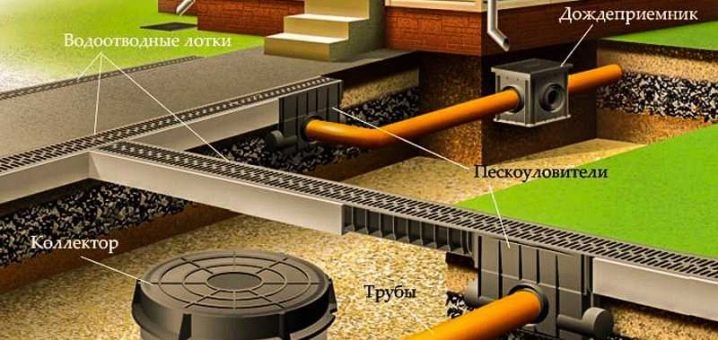

It is necessary to take into account that In the structure of absolutely any storm sewer type, such elements are present. as:

- gutters and pipes transporting fluid;

- receivers for sending fluid from the substrate, where it accumulated;

- drainage wells and drains - water is sent to them;

- filter barriers and grids that do not allow any kind of garbage into the system.

With the help of this system will be able to make watering planting with melt water. In addition, with its use will be able to increase the life of paths and sidewalks. Constructions standing on the site will also not be exposed to the detrimental effects of excessive moisture.

The traditional modern rain receiver consists of such essential elements.

- Lattice. This component is designed to close the structure from above. The lattice plays the role of not only a decorative addition, but also protects people from all sorts of injuries. Today such components made of cast iron or plastic are often used. They are good in that they additionally act as primary filter barriers (they do not allow large waste to enter the sewer system).

- Storm water inlet. The mentioned construction usually has a round or square structure. It is necessary to direct the fluid directly into the waste system.

- Sand trap filter (sand traps). This is a component that is not available in all structures. It is necessary so that pieces of earth, sandy inclusions and other similar garbage do not penetrate into the sewage system along with the liquid. The specified filtering part is located slightly lower than the tray related to the receiver. For this reason, any debris goes down on its bottom, and the liquid is lifted up to the exit mark from the receiver itself.

Not every user knows that the garbage filter in such a system needs to be cleaned regularly. Otherwise, over time, a very unpleasant characteristic odor may be formed that will be emitted during the evaporation of the liquid from the receiver tray.

Often, stormwater sewers are confused with the drainage system. Its distinctive feature from drainage lies in the fact that the latter is mounted below the foundation. As for the storm sewer, it usually has a more modest depth.So, around the perimeter of the roof of the house establish the construction of grooves, drains and funnels. Receivers are installed under all pipes. They are connected to a pipe structure, by which liquid is removed from the area.

Along the paths located on the site, as well as before entering the garage, a special system of trays covered with bars is installed. This structure is connected with a single pipe and a single drainage system from the territory. The system of trays of surface type is usually very modest, but in the storm sewer there are revision wells or special sand traps that catch large debris.

Kinds

Today, there are a number of subtypes of receivers. Each of them has its own distinctive features and characteristics.

Db

Such a storm water inlet has a characteristic rectangular structure. Designation DB stands for “large water intake”. Such parts are used on sections of the roadway, which are located at a fairly low level. With DB, inlets will be provided with high-quality liquid flow. The recommended slope parameter in this case is 0.005.

In accordance with GOST, the specified types of water receivers should be made exclusively from very strong and durable cast iron with a marking not lower than SC15.

These items should have the following characteristics:

- increased strength;

- long service life;

- effective functionality.

In the set with these rain receivers are often parts such as the body and grille. Some manufacturers also offer options in which the grid does not fit in the set - the choice of the appropriate option depends on the preferences of the consumer.

DM

A part with such an abbreviation is a small (or trunk) water inlet. Thanks to these options, it is possible to collect surface moisture from streets, private courtyards, park areas and other similar areas. Small receivers are characterized by high throughput. As a rule, they are used in areas with low-lying trays of highways that have a sawtooth longitudinal profile. In addition, similar elements are addressed when it comes to places with high traffic congestion, as well as areas where a large percentage of chemical compounds are present in the drains.

Such elements may have:

- round;

- square;

- rectangular shape.

DK

There are also rain receivers with the abbreviation DC. The indicated designation is denoted as “round inlet”. Similar options are used in the construction of bridges, roads and various industrial facilities. In most situations, you can find DK receivers made of strong cast iron.

Also, similar gully can be often found:

- on car parking;

- city roads;

- in the yard areas near residential buildings.

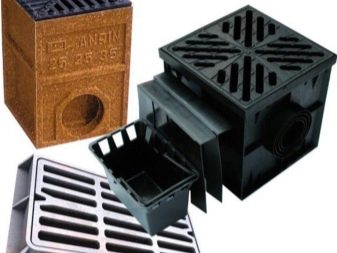

Materials and components

Storm water inlets are distinguished not only in size and shape, but also in the material of manufacture. Popular today are products made from such raw materials as cast iron, plastic or concrete. Consider the features and performance characteristics of each option in more detail.

Concrete

Concrete rain receivers are used in road construction. In addition, they are great for those conditions where a storm water collection facility is subjected to imposing loads. These gutters are made from both very heavy and high-strength reinforced concrete, and from lightweight fiber-reinforced concrete, which has a low cost.Moreover, these elements can be light, heavy or trunk.

The lighter options are often addressed when it comes to arranging the area under the sewer outlet. These parts are usually equipped with a plastic outlet. As for the shape of the lightweight receiver, in most cases it is cubic. The thickness of the walls in this case does not exceed the mark of 2 cm. Due to its structure, this type of water inlets can be installed several pieces, stacking them one on another. Carrying out such work may be necessary if it is necessary to increase the depth of the well.

The main advantages of lightweight concrete receivers are that they:

- boast a very long service life;

- smoothly resist sharp temperature jumps;

- not afraid of negative impacts from the outside;

- are relatively inexpensive.

As for the dimensions of lightweight concrete drainage systems, here the standard parameters are 40x40 cm.

As for the heavier rain receiver for storm sewers, it can withstand loads up to 3 tons without problems.That is why such structures are usually placed in areas where there is an average load.

These areas include:

- gas stations;

- squares near restaurants and cafes;

- streets, where there is not a very large traffic flow.

Modern heavy rain receivers are made of special vibrated fiber-reinforced concrete. The thickness of their walls is usually not less than 2 cm. The gratings for the above-mentioned water inlets are made of galvanized iron. Such raw materials easily tolerate the impact of impressive loads.

The main receiver subtype differs from other variants in that it has a composite structure. It is constructed from different parts, so the installation of such receivers does not involve the corresponding special equipment. In most cases, these products are made of reinforced reinforced concrete, which is not afraid of either temperature changes or increased humidity levels (the material is not afraid of water at all). As for the wall thickness of such receivers, they reach 5 cm (not less). Lattices for them are usually created from such practical material as cast iron.

Cast main type inlets are designed for significant loads. As a rule, they are installed in the conditions of the roadway.

It is worth noting that in private construction, concrete receivers are used very rarely. This is due to the fact that even with many positive qualities, such parts are heavy and quite large. In addition, their installation is not the easiest and fastest way, especially if you make a comparison with lightweight plastic options. In road works, parts made of concrete also began to be used less frequently, because instead of them instances of cast iron were more often used.

Cast iron

Strong and reliable receivers from such material are most often used in road construction for drainage from walkways, roadways and pavement structures. Produce similar products from raw materials labeled "SCh20". Such raw materials are characterized by an increased level of resistance to various potent compounds, as well as regular physical exertion. Such structures differ from each other in mass, shape, and the largest allowed loads.

The main advantages of cast iron rain receivers are:

- high throughput (such parts can easily pass an impressive volume of liquid per unit of time);

- increased strength characteristics;

- the ability to carry heavy loads from the outside;

- durability;

- environmental friendliness;

- resistance to rust (this quality is due to the fact that cast iron is usually treated with a special protective agent);

- relatively affordable price.

It is important to take into account not only the positive aspects of cast iron water inlets, but also their disadvantages, which include the following characteristics:

- too much weight, which affects the mass of the whole structure as a whole (because of this, its installation takes a lot of time and effort);

- if there is no special protective treatment on the cast iron, then it will start to become covered with corrosion unexpectedly quickly;

- When mounting cast iron elements, it is very important to provide for fixation of specialized locking mechanisms that will insure the part against theft.

In the conditions of private construction, cast-iron receivers with the marking “DB1” are usually used, since such parts have the most modest dimensions.The length of this product is 695 mm, height - 120 mm, and width - 470 mm. Grid parts for cast iron drainage systems in most cases are made from similar raw materials, so we can safely say about their high strength, practicality and resistance to wear. Grilles are attached to cast iron receivers on bolts or screws.

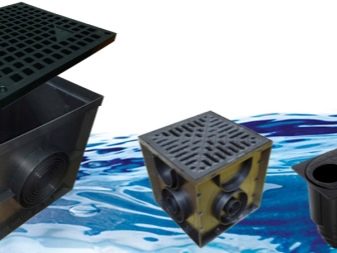

Plastic

One of the most popular and sought-after is recognized as a rain receiver made of plastic. Usually these elements are used in the conditions of summer cottages and personal plots. In the production of such receivers not simple plastic is used, but specialized frost-resistant polypropylene, which is not afraid of temperature changes, the impact of powerful chemical compounds, as well as the influence of significant external loads.

Standard dimensions of plastic drainage systems are:

- 300x300x300 mm;

- 400x400x400 mm;

- 500x500x500 mm.

There are several subtypes of plastic inlets. They are distinguished on the basis of the allowed force of external influence on the lattice.

Based on this parameter, there are several options.

- A. In such instances, the maximum load on the grid can be up to 1.5 tons.These products are usually used in the arrangement of homestead and suburban areas, as well as walking paths.

- B. Details of this class can withstand more serious loads - up to 12.5 tons. They are mounted in garage cooperatives, as well as parking lots.

- C. The grids of such drainage systems can withstand a load not exceeding 25 tons. Such elements are very often used in conditions of highways or gas station stations.

- D. In this case, the largest load can be up to 40 tons. Such designs can easily withstand the weight of the truck.

- E. Maximum load - 60 tons. Elements of this class can be installed on parking lots intended for trucks, as well as other similar places, which are distinguished by a sufficiently high external load.

- F. The largest load on such parts is 90 tons. They are assembled in areas set aside for the movement of heavy machinery.

Whatever the size of the plastic inlet, it will in any case consist of a number of specific components.

- Basket. This part serves as a protective element of the system. She insures her against the penetration of garbage.In most plastic models, waste is collected at the bottom of the basket, so you should not forget to periodically clean it.

- Siphon rubber. This important component prevents the spread of bad odor that can be formed when rotting debris and evaporation of liquid from the bottom of the basket.

- Partition. This item acts as a water seal. It is necessary in the process of connecting the receiver to the system.

- Cap. It is necessary for the absolute closure of the rain receiver. It is used when the yard is cold season. Also, the lid is useful if the receiver is not operated for one reason or another.

- Lattice. Through this detail, the fluid passes into the receiver. Usually the option of a round or square shape is selected based on the structure of the receiver itself.

- Luke. One cannot do without it if we are talking about closed-type wells.

- Extension. Thanks to this component it will turn out to increase the level of depth of the structure.

It should be borne in mind that plastic receivers are divided according to the type of drainage. It can occur downward or to the side (for accumulation of fluid from the blind area of the foundation).The specific choice of this characteristic directly depends on the distinctive features of the design of the existing storm sewage system, as well as the location of the receiver in it.

Many users are now accessing plastic specimens.

The popularity of such details is due to a number of positive qualities characteristic of them.

- Such instances are lightweight, especially when compared with other existing options.

- Due to their low weight, plastic structures are installed quickly and easily. To carry out such work do not have to apply to the attraction of special equipment.

- Plastic easily transfers any external negative effects. These include temperature jumps or strong chemicals.

- Such receivers are rightly recognized as one of the most unpretentious in matters of care (in this matter, they are ahead of the cast-iron options). To clean these elements, you just need to get the basket and remove everything that is in it, and then rinse thoroughly.

Lattices for plastic bases can be made from a similar polymeric material, as well as from cast iron or tin.The most durable is the cast-iron version. It is usually installed in areas with impressive external loads.

Installation

It is quite possible to install a storm water inlet for the sewage system with your own hands. To do this, you must strictly follow the instructions and take into account all the technical characteristics of the model chosen for installation.

It is necessary to put the rain receiver under the outlet of the drain pipe or in those areas where after passing of precipitation puddles accumulate. In the course of installation work, close attention should be paid to the depth of installation. In addition, experts advise to choose the location of the structure so that the liquid from the pipe goes to its central part. If it is not possible to place the drain at the maximum low point on the site, then special depths should be brought to it, along which the liquid will flow directly into the receiver.

Having chosen a construction of one type or another, as well as a specific place for its installation, it is permissible to proceed to fixing the storm water inlet.

Carrying out such work consists of several steps.

- First, dig a pit. The depth parameter depends on the receiver, to which an additional distance of 30-40 cm is added. The pit width must be larger than the part itself, 3 cm on all sides.

- At the bottom of the pit need to install a pillow made of sand. After backfilling sand it is necessary to fill with water and thoroughly tamp.

- Next, the receiver must be connected to pipes or trays. It is necessary to make sure that the entire structure was calibrated in terms of height parameters.

- At the bottom of the pit should put a small layer of the solution. The receiver will be placed in it. When installing this part with your own hands, you need to firmly place the structure in the concrete mix in order to avoid its future shifts.

- On the sides of the building must pour concrete solution. If you have installed a plastic construction, then in order to avoid its deformation, you need to strengthen the walls by connecting the metal grating.

- Now you can put partitions and receiver basket.

Note that the durability and efficiency of the receiver depends on whether the entire structure was installed correctly. Experts advise to carry out such work before installing the coating on the site.

Useful tips

When looking for a specific model of a storm water inlet, it is imperative to take into account the largest amount of precipitation in the available territory. This parameter can be found in the SNiP reference book. It should also learn about the maximum parameter of snow cover in the winter season.

Do not forget to periodically clean the filter in the rain receiver, so as not to encounter unpleasant odors.

Heavy-weight structures of angular forms are recommended to be laid using special equipment.

Choosing a receiver of a particular class, it is better to be safe and give preference to models designed for heavy loads than will actually occur.

If desired, the storm sewer itself can be made by hand from scrap materials. Such a structure would be low cost and inexpensive, but its preparation must be treated wisely.

Step-by-step installation instructions for the storm water inlet are presented in the video below.