KNS: features, types and device of sewage pumping stations

Sewage pumping station (SPS) is an indispensable tool in the pumping and disposal of wastewater. It is rapidly gaining popularity and gradually displaces drain pits from the dacha and household plots.

Specifications

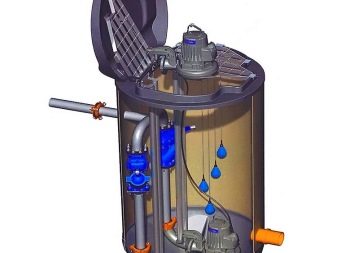

Structurally, the station is a mechanism consisting of several tanks and pumps, the number of which directly depends on the expected volume of effluents, the degree of their pollution and the type of pollution. The capacity of the station is made in the form of a polymer tank, dug into the ground. Above the surface of the ground, only the throat is left, which is caused by the need to conduct an audit, repair and, if necessary, measures to clean the tank.From above, the container is closed with a lid made of steel or polymers. The most durable containers are made of fiberglass.

Well proven and plastic models. These tanks do not need regular maintenance and can last for at least 50 years. The most budgetary options are concrete and metal tanks, the volume of which can reach several cubic meters. Inside the tank there is a pipeline and a bump stop, which ensures a uniform flow of fluid inside. An equally important element of the design is the water diversion wall, which prevents turbulence of the flow and facilitates the orderly movement of liquid masses.

Household KNS equipped with one or two pumps, and more serious industrial models can have up to four units of pumping equipment. Type of pumping equipment depends on the place of installation, purpose and operating conditions. So, for home stations it is more expedient to choose pumps equipped with a grinder. For industrial enterprises and utilities, on the contrary, the installation of cutting devices is not recommended.This is due to the risk of solid waste entering the wastewater, which can cause instrument breakage.

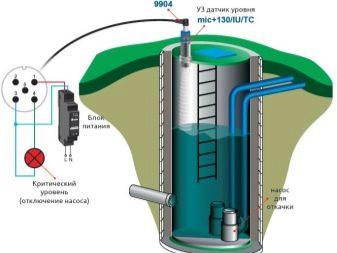

To ensure the flow of liquid masses in one direction, valves and valves are installed in the pipes., and in order for pumping equipment not to idle and shut off in time, floats. With a decrease in the level of contaminated masses, the float mechanism lowers, opens an electrical circuit and stops the pump. When the level of sewage rises, the circuit closes and the pumps begin their work. This scheme reduces the operational load on the pumps and extends their service life.

For safety net sometimes make the installation of backup floats. They are regulated in such a way that they close the circuit after the water exceeds the specified operating level. Thus, in case of breakdown of the main pump, the backup one will necessarily turn on and pump out the accumulated liquid. The installation of two main and two reserve floats is sufficient for a medium-sized station.

The installation of the KNS and the arrangement of sanitary control zones around them are governed by the norms of SNiP 2.04.01-85.

In addition to the overall stationary devices, there are miniature Sololift-type SPS. They are made in the form of a small tank, equipped with a pump with a cutting blade, engine, automatic and directly connected to the toilet drain hole. The installation of this equipment solves the problem of withdrawal of sewer masses in a private house with a minimum number of residents, and is quite suitable for a family of three. For the mini-station to work, it is enough to connect the pressure hose and sewer pipes to the device body, and plug it into an outlet. Sololifts have a sufficient number of positive reviews and are rapidly gaining popularity among owners of small houses and villas. Mini-stations go on sale completely ready for operation and do not need to acquire auxiliary devices.

Purpose and principle of operation

Sewage stations are designed for pumping rainwater and sewage masses in cases where their movement by gravity is impossible or difficult. This occurs when it is not possible to organize the inclination of the discharge pipe, at the location of the discharge of sewage and sanitary facilities below the level of the receiving collectors or cesspools, as well as at their distant location from the source of discharge.The stations are widely used in cottage settlements, country estates and industrial facilities, the significant removal of which does not allow them to connect to central sewer networks.

The principle of operation for all CNDs is about the same. Contaminated drains flow into the receptacle, from which they are pumped into the pressure pipeline system using pumping equipment. Then the masses are inside the distribution chamber, from where the pipeline system goes to the sewage treatment plant or sewage collector. All stations are equipped with a valve that does not allow fluid to flow back, and ensures its movement in one direction only.

The stations are equipped with an automatic monitoring system. So, monitoring the level of wastewater is performed by float sensors, which are located at different levels. In the event of a serious accident and failure of both pumps, sensors that are configured at a critical level for the system automatically turn on an alarm signal notifying the owners that the system is not coping with the volume of sewage masses or has failed.During repairs or startup, the station switches to manual control mode.

Stationary mini-stations with a grinder work on a similar principle. When liquid masses enter the device, automatic sensors are triggered, which, in turn, start the engine. As a result, the liquid from the tank is pumped into the pressure pipe, through which it goes into the manifold. For more efficient disposal of sewage, compact stations are equipped with a special impeller, which is engaged in grinding large fragments, which prevents the likelihood of pipe clogging. Usually in the case of sololift is located from 2 to 5 holes for connecting plumbing: toilets, sinks, sinks and showers. At the top of the station there is an air valve that provides air supply during the pump operation and eliminates disruption of hydraulic locks in the siphon of the device.

Types and categories

Sewage stations are classified according to several criteria.

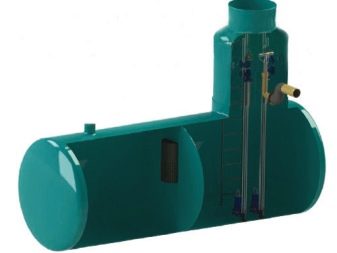

type of instalation

KNS can have vertical and horizontal execution. The latter are often equipped with a self-priming pump, which forcibly pumps contaminated masses into the KNS body and removes them after cleaning.Sometimes the tank tank may have an additional horizontal compartment at the bottom. This design contributes to the uniform distribution of silty deposits at the bottom of the tank and increases the time it fills.

This, in turn, allows the tank to be cleaned not so often, which significantly saves manpower and money.

Vertical KNS do not have additional tanks and are used for private houses and cottages, where their power is enough for timely and uninterrupted removal of sewage.

Location

According to the location relative to the surface of the earth, KNS can be buried, partially buried and have a ground location. Ground stations are represented by mini-installations located in kitchens, bathrooms and toilets. The recessed ones are traditional models with a storage unit dug into the ground, while for partially recessed tanks, equipped with sensors, a pump and valves, they are located in the ground at the neck. The automatic monitoring and control system is thus brought to the surface.

Equipment management

CNS are equipped with manual, remote and automatic control.

- With manual mode the inclusion of modular equipment is carried out in manual mode by station workers who independently check the level of sewage in the tank.

- With remote control data on the state of the system and the height of the liquid level is fed to the control panel. It is very convenient to control a radio-controlled station: the equipment does not require the constant presence of a person, and in case of a malfunction, it reports it promptly.

- Automatic system control is the most common, and is in the management of the station with the help of relays and sensors that can be located both on the station body and nearby on the panel.

The most budgetary option is the station with a manual control system. They are established in country houses and are able to serve one or two families.

The nature of sewage

Wastewater is divided into domestic, industrial, stormwater and sedimentary.

- For industrial waste Tanks and pumps should be made of materials with high resistance to aggressive chemicals and high temperatures.

- Stormwater Removal Stations The sewers are equipped with additional cleaning systems for sand and mechanical debris that rain can bring.

- KNS for sedimentary runoff used in sewage treatment plants and equipped with specialized devices, processing sediment.

Type of pumping equipment

On KNS three types of pumps are installed.

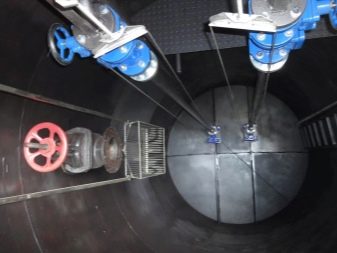

- Submersible pumps with pressure function require full immersion in water. The devices have a sealed case, which is made of high-strength, non-corrosive materials. Fecal pumps are effective and fairly simple to use, they do not need to be additionally fixed or equipped for them with a platform. The device is able to work at low temperatures, and the cooling of its engine occurs naturally from the surrounding liquid.

- Cantilever pumps installed in a dry place and used in large industrial stations. For complex modular CND devices are not suitable. Pumps require the construction of a separate site with a foundation, are distinguished by high cost and reliability. The advantages include ease of access for repair and maintenance,the possibility of replacing the motor with a weaker / more powerful, and long service life of the device.

- Self-priming pump for fecal waste it is used for pumping highly contaminated liquid and is installed at industrial and utilities facilities. The device is not subject to clogging and is effective in conditions of negative temperatures. The freezing of the device is eliminated due to a special heating element, which is turned on at the moment when the temperature drops and passes the critical point. This type of pump is recognized as the most reliable and convenient to use. The only drawback of the device is its high cost, which, however, is justified by the high performance and durability of the device.

Installation

Installation of KNS begin with digging the pit. With the right tools and at least one assistant, you can dig a hole for the tank with your own hands. The depth calculation is done individually and depends on the type of installation and the size of the tank. The optimum position is considered to be the position of the tank in which the tank lid protrudes 80-100 cm from the ground.

A sand pad is formed at the bottom of the pit and a tank is installed on top. After the tank is installed and leveled, proceed to the attachment of pipes and backfilling of the pit. Condense the ground around the tank should be very carefully, alternately tamping each layer. The density of the backfill should be 90% of the natural density of the surrounding soil.

After the tank is firmly in place, begin installing the pumps and adjust the floats. As an example, the floats of the first level are usually located at a distance of 15-30 cm from the bottom of the tank. However, this is the recommended height, and it can be changed based on the estimated amount of wastewater and the size of the tank. The next float is installed one meter and a half higher than the previous one, after which the installation of the electric cable is started, grounding is performed, the ventilation is arranged and the power is connected.

After all the work is completed, test run the system using clean tap water. In the case of a successful test, you can proceed to the construction of a protective pavilion, and in the absence of the need for construction - immediately to the commissioning of the station.The pavilion can be built from metal or brick.

Service and operation

Stations need constant monitoring of the state of the main systems. However, when performing independent maintenance of a CNS, one should strictly observe the safety requirements and clearly understand that it is strictly prohibited to descend into the tank and clean it without personal protective equipment. Poisoning sewage occurs instantly, and its result is often loss of consciousness and death.

Therefore, before proceeding with the inspection of the tank, you should wear a gas mask with the function of compulsory supply of clean air and a safety cable. But the best option is to sign an agreement with special services, which will exercise control over the operation of the system.

Scheduled maintenance of the station is carried out on a quarterly basis, and in the case of a large number of wastewaters - monthly. During the inspection, the operation of the automatics is checked, diagnostics of the pumping equipment and control of the oil level are carried out, debris is removed from the filters and sludge deposits are removed. All work must be done in the presence of an assistant, in the presence of rope insurance and a respirator.

Remote system maintenance is a bit easier.Automation control allows you to monitor the status of the tank, without going down into the tank, and in real-time monitor the health of electrical equipment.

Maintenance of a pump station must begin with a general inspection of the state of valves and verification of the indicators of sensors located on the control panel of automated models. In case of unstable operation of pumping equipment, the device is removed from the station, washed and subjected to diagnostics. The pump and the housing are cleaned under the pressure of clean water from a hose using a stiff brush. Use of detergents is undesirable.

When washing, it is necessary to control the direction and force of pressure, and to prevent droplets from falling on the control panel. From time to time it is necessary to check the reliability of the threaded fasteners and, if necessary, pull the nuts and fasteners. Dismantling of pumping equipment should be done only after the unit has cooled down, disconnecting the power supply and relieving the pressure in the system.

With careful operation and regular maintenance, sewage pumping stations can serve for more than a dozen years, ensuring uninterrupted removal of polluted effluents and increasing the comfort of others.

An overview of Unipump Sanivort sewage pumping stations see below.