Hammer-free cast-iron sewage SML: characteristics and applications

Bone-free cast-iron sewage SML is still considered the most reliable, high-quality and has been successfully used to assemble sewer systems of various kinds. A feature of the design is the execution of pipes from cast iron and their connection with a clamp.

General information

Pipes made of cast iron have special strength and can withstand heavy loads during the distillation of a liquid. This is due to the fact that the material is produced under pressure, while adding finely dispersed graphite mixture to it. This allows you to improve the characteristics of tensile strength due to the hardening of the structure. But that's not all - from the inside, such products are coated with epoxy resin with a layer of 130 microns. From the outside the sewer pipe is processed by polymeric structure 40 microns thick.

Thus, inside and outside the product is reliably protected from the detrimental effects of external influences, aggressive chemicals contained in water, and is not subject to corrosive processes.

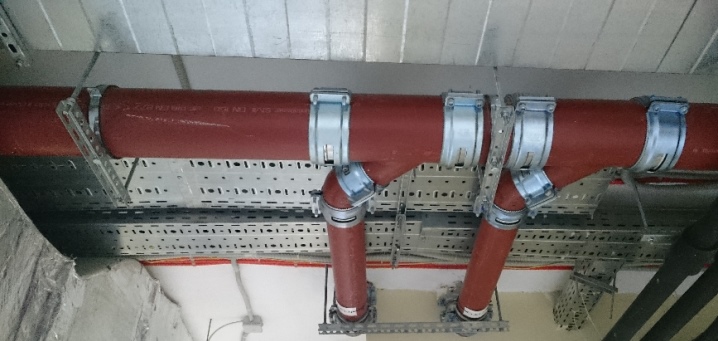

Hoseless pipe is perfectly smooth, and is connected to other similar elements by means of a device consisting of two special elements:

- clamp made of high quality stainless steel;

- durable elastomer cuff.

During installation, you can choose two options for clamps:

- Rapid - a device with one screw;

- CV - a part that has two screws.

For free-flow sewage with a pressure inside the system of 0.5 bar, conventional connecting clamps are used. But in the pressure structure, where pressure up to 10 bar can be observed, only reinforcing products can be used that are fixed on top of the pipes. Thanks to these elements, any replacements in case of damage to individual sections occur quickly, simply and efficiently.

Since this product is used for two types of sewers - with external discharge of wastewater and internal pipelines, it is also divided into two types of products adapted to specific conditions of operation.

Due to its many advantages, such pipes have found application both in the industrial field and in the public utilities of residential and public institutions.

Technical features: pros and cons

Cast-iron plumbing has its advantages and disadvantages, as well as features, the main of which is the lack of sockets.

The main parameters of pipes:

- standard length - 3 meters;

- diameter of pipes and fittings to them corresponds to the nominal value - 5; 7; eight; 10, 12.5; 15; 20; 25, 30 cm

Products of this type have established quality standards and have the following positive characteristics:

- high strength, including impact resistance, which distinguishes products from other modern materials, such as asbestos cement, plastic, and lead;

- immunity to low and high temperatures, physical and chemical influences;

- high level of noise suppression - sound-proof qualities of cast-iron sanitary ware are recognized as the best among their counterparts from other materials;

- good anti-corrosion properties;

- products do not require additional coating with flame retardants due to fire resistance and non-inflammability;

- increased wear resistance;

- due to the immaculately smooth surface of the pipes, the hydraulic resistance in the system is significantly reduced when the wastewater is drained.

The possibility of absolute tightness during installation can also be attributed to the number of advantages of these products, especially since there is no need to use glands, rags of seals made of silicone. However, the products have some drawbacks that should be considered. If the pipe is damaged, it can not be repaired, so the replacement from this situation is.

In addition, cast iron is a heavy material, and this creates certain difficulties during installation. In this regard, the assembly must adhere to specific requirements.

Kinds

The main purpose of socketless cast iron products SML - the formation of structures for the discharge of household wastewater, which is a liquid waste.

There are other varieties that serve for other purposes and are divided into internal and external forms, determined by the method of installation:

- RML products are required for the installation of ventilation systems;

- BML - for structures diverting water from bridges;

- TML - pipes for external discharge of groundwater;

- VML - products for domestic purposes for disposal of waste and rainwater, as well as protecting against condensate;

- KML - this type of product is necessary for the removal of recycled materials associated with aggressive chemical content.

As for SML, such a cast-iron plumbing is necessary for organizing the drainage of drains for private sector houses.

Important points during installation

The ability to use special clamps when laying allows you to work together, in the absence of a professional team, but you should choose high-quality fasteners, which should be designed for normal pressure inside the sewer. Before you start the assembly yourself, you should be familiar with the basic requirements for product standards (DIN EN 12056 and DIN 1986-100).

It is also necessary to follow certain rules:

- for cutting pipes does not apply welding with a gas torch;

- pruning is done with a conventional chain or circular saw with a manual roller pipe cutter;

- a wrench is used to fix the clamp;

- trimming should be carried out at an angle of 90 degrees in the direction of the pipe axis, which will ensure optimal tightness;

- purchased products with non-uniform surface, damages and chips are not used;

- before connecting the processing of pipes with special chemical compositions is not necessary.

For in-house sewer structures, besides pipes, other auxiliary details will be needed:

- taps (at 15, 30, 45, 68 and 88 degrees);

- viewing windows and knees;

- galvanized rubber support rings;

- support pipes for transition risers;

- siphons, tees, plugs and other elements, usually included in the set of socketless products.

Installation is carried out using a rubber coupling, which must be tightly pressed with a steel clamp. At the same time, on the inside of the cuff there is a restrictive protrusion, which should be located between the ends of the cast-iron pipes - this makes it possible to completely seal. It is necessary to pay special attention to the diameter of the joining elements - between them the difference in diameter is allowed, which is at least 0.9%.

Chinese products

To date, the most high-quality products recognized as SML cast iron pipes of the German manufacturer Duker - this is one of the leading companies engaged in the manufacture of socket-shaped and socket-less parts. Despite the high demand for German materials,because of the lower cost and quite decent quality, today Chinese sanitary ware, which is not inferior to its European counterparts, is increasingly coming to the fore.

At the moment, China produces the following types of external and internal materials:

- cast iron pipes for SML drainage, used for rainwater, domestic wastewater and ventilation;

- products used in the construction industry for optimal drainage over a long period of time;

- various drainage cast iron fittings.

The products are distinguished by high quality, any diameters of pipes, the adaptation of some materials to special climatic conditions. In addition, Chinese manufacturers produce a huge number of seamless steel pipes, including sewer pipes, designed for systems with low, medium and high pressure inside the pipeline, adapted for operation in high and low temperatures, high humidity, as well as special materials for laying under water, for transportation of oil, drilling. This is a good alternative to European products, the main component of which is, above all, the brand.

For information on how to install an iron-free cast-iron sewage system SML, see the following video.