How to pick up the valve for sewage?

No sewage system can be created without a valve. In most cases even a few such parts are mounted. Let's see why it is extremely important to choose a suitable design.

Varieties and their device

Klinovy type of fittings is made of cast iron. It differs in simplicity of the device and operation: it is quite easy to block the flow of liquid. Klinovy apparatus works fine, even if the flow moves quickly. An example of such a device is a 30ch6br modification.

The quality of the construction is such that it can be used not only in sewage, but also in:

- water mains;

- steam lines;

- oil pipelines;

- gas pipelines.

Cast iron is chemically neutral with respect to the contents of the sewage system.In addition to the simple cast-iron parts, there are rubber-covered products. Both versions are fully compliant with GOST standards, which allows not to be afraid of the violation of the pipeline. The wedge valve has the advantage that its maintenance takes place without particularly complicated operations. The locking block moves progressively or returning at right angles to the fluid flow and blocks its movement or opens the way.

When mounting cast iron or other valves, it is required to check:

- their compliance with the technical parameters of the pressure in the pipe;

- install the filter (it will clear the working environment);

- Is the system under pressure?

Read more about 30ch6br

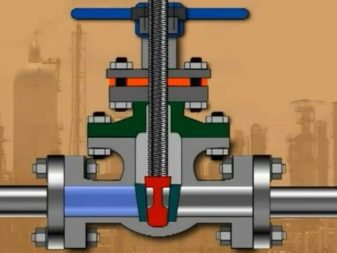

Cast iron structures are also distinguished by a low hydraulic resistance. This circumstance allows liquids to move as freely as possible. But it should be noted that to open or block the pipe in a short time will not work. Cast iron gate valve is wedge-shaped with two discs and a retractable spindle. The reinforcing body is equipped with a lid holding the paronite gasket.

The spindle is delimited from the cover with a stuffed stuffing box.This solution allows to achieve sealing of the block.

The locking block is formed by:

- brass rings;

- arching axle;

- compensating gaskets.

Close the valve by turning the handle clockwise. When this happens, the spindle begins to rotate, the disks move down, and the flow of fluid is blocked. The greatest pressure of the working medium is 16 bar. The diameter of the part is 5–30 cm. Its mass is 11.5–270 kg, depending on the size.

The entire product line can be installed in a horizontal, vertical or inclined pipeline. There are only two main points: open and closed. Flow adjustment not possible. The parallel valve DN 50 can operate at a pressure of not more than 1 MPa. Such properties make it possible to apply 30ch6br even in very complex sewer systems. In production, equipment is subjected to both hydraulic testing and testing for action in the air.

Additional recommendations on the selection and installation

Fittings with lids should be mounted:

- where plums from washing and dishwashers will be connected;

- on inserts of the internal pipeline in risers;

- where several relatively small tubes are connected;

- as backup entrances for additional hoses.

Valve gate valves for flanges are not the only option. There is also a welded view of the plugs and damping caps under the rubber sealing rings. In addition to these designs, grids can be used to block the movement of solid waste, as well as pneumatic plugs mounted to detach the risers from the entire system. The gate valve is designed to crush the pulp, it is also installed at the outlets of the systems that process heavy heavy waste. An increase in the square output cross-section, compared with a circular inlet, helps to eliminate the accumulation of solid matter in the valve and guarantee the non-stop movement of the knife.

Knife-type gate valves are most often placed horizontally, they are characterized by increased reliability, can serve any pipe and technically complex system. The index “H” or “C” denotes, respectively, a body made of cast iron or steel, and “SM” shows the manufacture of non-ferrous metals. The letter "F" in the marking shows that the body is lined.All these parameters suggest that gate valves are ideal for various branches of modern industry. Some of them are even equipped with electric drives, because manual control is impractical and unreliable.

Cast iron valve, which is optimized for low pressure operation, is always flat. If it is necessary to transfer medium pressure, the shape is closer to the oval. But those devices that are designed for high load, are made in the form of a ball. It is also necessary to distinguish parts by the performance of the working unit, which can have a retractable or stationary spindle. All this refers to the wedge valves, otherwise parallel-type systems are arranged.

The principle of their operation implies blocking the flow due to the sideways successively fixed disks. They diverge because the wedge located in the gap goes down. Sealing rings both in the valve body and on the working discs are placed at an angle of 90 degrees to the axis of the apparatus. Parallel cast-iron valves are designed for a nominal pressure of up to 10 bar, the calculated diameter can vary from 5 to 42 cm.It is necessary to choose valves equipped with an electric motor if remote control is needed (usually it is practiced when the device is mounted in a hard-to-reach place).

Not all electric drives are equally effective. Those of them that are equipped with a return spring, somewhat faster than usual respond to incoming signals. A parallel valve is better than a wedge, because there is less risk of wedge seizing when used infrequently, and the wear of the sealing rings also decreases. For your information, these negative points are less pronounced for wedges with a rubber sheath.

Other advantages of its availability are:

- suitability for contact with liquids moving at speeds up to 4 m / s;

- reduction of effort for unlocking and blocking the access channel;

- increase fortress;

- increased tightness;

- reduced torque and increased smoothness.

The hose format of the valve is so named because there is an elastic channel inside (actually, the hose in some cases, the pipe in the other). This channel may shrink or become less dense, depending on the pressure exerted on it by the spindle.The elastic course from rubber allows to cover metal elements of a latch from the transported liquids. A retractable spindle means positioning outside. When the flywheel is spinning, the working part is screwed into it or goes out strictly by the magnitude of the shutter. This solution is good because it facilitates the control of the health of the site and simplifies the technical service.

In underground sewer passages, this advantage is not very significant, spindles that do not move outward manifest themselves much better: they take up less space. At the same time, one has to put up with an increased wear rate. The suspension assembly, sealed by the omental type, is considered the most reliable, the bellows is somewhat worse, and the self-sealing one should be considered only last. It is recommended to use valves collected by welding.

How to eliminate or prevent unpleasant odors from the sewage, see the video below.