Features of flange valve

Communication systems are an integral part of the life of modern man. The quality of work of public services depends on the standard of living of large cities, small towns and the work of industrial enterprises. For the organization of stable movement through pipelines of water and gas, experts install flanged gate valves. This detail is not only used to block the flow of different content in the plumbing or gas pipeline system, but also is used to adjust them. Locking parts have a simple design, an affordable price and a long period of operation.

The universal part has a wide scope and is a popular element in a complex utility system, on which its safety and stable operation depends.

Specifications

The flanged gate valve is a sought-after and effective stop valve, having a simple construction and belonging to the group of household taps. This part has in the center a special element for locking, the function of which depends on the purpose of the part itself, and flange rings located on the edges. Flange rings provide quick access to the system in case of repair or replacement. The size of the flange part should correspond to the diameter of the main plate in high-quality and reliable parts.

Positive sides:

- the implementation of repair or replacement of equipment in a short period of time;

- ease of installation and use;

- simple construction;

- durability;

- the possibility of repair and dismantling;

- reuse after a series of maintenance and repair work;

- flow of water, gas or steam in any direction;

- demand;

- durability and reliability;

- low resistance to hydraulic impact.

Disadvantages:

- big weight;

- high price range;

- manufacturing on specialized equipment and complex lathes;

- the inability to adjust the volume of floating flows;

- long opening or closing of valves;

- large sizes and dimensions;

- quick wear of consumables and seals.

Technical characteristics of operating conditions:

- wide range of pressure levels;

- temperature range from - 55 degrees to + 210 degrees;

- size range is between 50 mm and 1250 mm;

- for cast iron products, the maximum temperature threshold for gas is more than + 350 degrees, and for liquids - more than + 250 degrees.

The quality standards of these products are spelled out in special State Standards. The material of manufacture is indicated on the body of the parts, and the dimensions are specified in the accompanying documents. The dimensions of the pipe and the devices to be mounted must be identical, otherwise it would be inappropriate to carry out installation work.

Application area:

- parts up to DN80 are not used in central piping systems, but are manufactured for auxiliary systems, home appliances and small boilers;

- DU100 valves are installed in the main water supply and gas supply pipelines;

- DN200 devices are mounted on objects of civil, industrial or defense value, for their installation use special consumables with high strength and reliability.

Types

There are several types of closures, but The most popular are the following:

- disk locking;

- interflange wedge;

- hose with movable plates;

- ball rotary.

In the direction of the action I release parallel and perpendicular valves, according to the design features - gate, ball and wedge-shaped. Wedge-shaped parts (cast) are the classic elements of valves, having a high level of efficiency and great weight. Ball elements - analog locking household devices. Du50 ball devices are popular and inexpensive devices, and Du100 devices have special disk elements and are used in oil and gas systems.

According to the method of operation, two types of devices are produced.

- With manual control. Performance of work is carried out mechanically. This type of device has a long period of operation without repair and replacement of parts.

- With electrically driven fittings. Management is carried out with the help of an electric motor and electric drive. Blocking occurs independently after pressing on a special lever.

Experts also divide the products into types depending on the pressure of the medium and the diameter of the parts.

- Flat welded products with non-sliding elements. Made of sheet steel without protrusions. Apply on pipes with a small diameter. These products can be made both independently and at specialized industrial enterprises.

- Welded gate valves with connecting lugs. Used in systems with average atmospheric pressure.

- Gray cast iron flanged gate with groove or retractable protrusion. This device is manufactured in specialized workshops. The principle of sealing - the occurrence of a protrusion in the flange sinus.

- Locking parts with slotted joints, spindle or spikes. Are made on the special equipment. The principle of action - the entry into the grooves of the spikes.

- Welded flange valves without overhangs. For high-quality installation using flexible and non-rigid gaskets.

Materials

For the manufacture of valves manufacturers use several types of materials:

- cast iron;

- steel;

- bronze;

- brass;

- titanium.

The most popular flanges made of steel, galvanized and stainless material.

Steel valves are used to work with liquid media, gas, oil and aggressive compounds in conditions of low temperature conditions.Carbon steel valves are used in pipeline systems transporting air, steam, ammonia, water, gas, oil.

Stop valves with rubber wedge installed on water mains, moving cold and hot water. The pressure in the system should not exceed 25 atmospheres. Cast iron parts are mounted on pipes with alkali, acid, pulp, gasoline and kerosene. Titanium parts can be installed to transport chemical compounds and aggressive concentrated elements. Aluminum, brass and bronze valves are used to move alkaline and acid compounds with a small percentage of concentration, water and air.

Material for the manufacture of parts depends on the type of pipeline on which it will be installed.

There are several types of piping systems:

- energy;

- conventional industrial;

- specialized industrial;

- special;

- ship;

- sewer.

Device and principle of operation

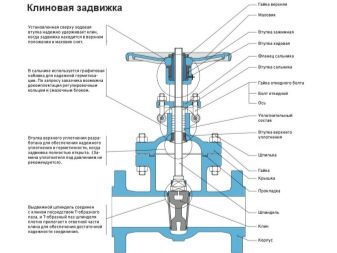

Valves consists of the following parts:

- housing;

- gate;

- cap;

- packing gland;

- stock;

- rack;

- running node;

- electric drive.

In the end parts of the device there is no special thread, and a flange is installed, manufactured according to GOST 12819. This part can be installed in areas with an atmospheric pressure of more than 200 atmospheres.

At the top of the working device there is an opening for flange connection. The diameter of the flange is installed and approved by technical regulatory documents specifically for each type of pipeline. Parts of the device are made of steel and cast iron in special forms. For systems with a high level of pressure, rigid valves are used, which allow you to create maximum tightness. Devices with dvukhskatnymi locking parts there is no need for accurate processing of the saddle, which significantly reduces the cost of manufacturing products.

The control unit consists of the following elements:

- stock;

- flywheel.

On the shelves of specialty stores you can purchase several types of flange valves having the same principle of operation. In the center of the structure, a disk or valve is installed at an angle of 90 degrees to the movement of any filler. When closing the valve, the plate is fixed with special seats and stops the movement of water or gas.To open the system, you need to turn the valve in the opposite direction, and the disk will automatically shift, freeing the passage.

Wedge in different types of valves has some differences:

- high level of tightness due to the stiffness of the wedge and the strength of the seats and discs;

- for two-disk wedges use durable parts, which reduces the percentage of possible jamming devices;

- elastic wedge is an improved part of double-disk devices, in the locking part of which an elastic element is mounted, which increases resistance to sudden temperature changes and reduces the likelihood of defects in the device;

- the use of a protective disc layer increases the resistance of internal parts to the destructive effect of corrosive processes;

- the operation of the valve can occur not only in manual mode, but also with the use of electrical devices that allow to carry out work, being at a distance from the system.

Flanged valves have a simple, but functional design that allows you to perform all the functions assigned to it.

Installation of devices is carried out in the classical way using a welding machine. To improve the hermetic performance used sealing rubber ring parts, which are placed in the flange channel. The working surface should not have defects and mechanical damage. The use of substandard parts in high pressure systems can cause depressurization and an accident. This situation can cause man-made disasters that pose a danger to the life and health of the population.

Modern industry and the daily life of an ordinary person is a complex system in which the important place is occupied by the transportation and movement of various chemical elements, water and oil products. To ensure the smooth operation of all civil, industrial and defense facilities, public utilities need to have high-quality and affordable equipment. The flanged gate valve is a versatile part with an affordable price and wide range of applications. The main advantage of flange valves is the ease of disassembly, unlike welded parts.To remove the valves, it is enough to unscrew it from the pipeline. This greatly simplifies the work of public utilities and reduces the cost of repair and operation of pipelines of different diameters and purposes.

The universal valve is widely used to connect various devices to the piping system. All modern developments and analogues have not been able to oust and replace simple parts, which play a large role in a complex system.

In the next video you will find a full overview of the flange valve with rubberized wedge Domex DN100 (model Domex F4 DN 100).