Sewage check valve: what is needed, how it works and how to install?

When organizing a sewage system, various devices are used, one of which is a check valve. This is an important element necessary for comfortable operation of the sewer system. It is enough just to choose and install a check valve correctly so that it faithfully serves for at least 5 years.

Purpose

A check valve is designed to block the flow of a liquid medium flowing in the opposite direction to flow. These are shut-off valves installed in sewage systems of apartments, private households, offices and production workshops. Less commonly, they are mounted in heating and water heating circuits.The device at the right time closes the shutter in the pressure sewer pipe.

The installation of a check valve has positive and negative sides.

The positive points include:

- prevent ingress of sewage and unpleasant odors into the house through sanitary fittings;

- lack of water hammer during operation;

- quick opening and closing valves;

- the installation is carried out either vertically or horizontally, as a result of which an optimal method of installation is selected for each dwelling;

- no pressure loss in the pipe;

- ensuring high tightness of the circuit.

Available negative features of check valves:

- the formation of excess pressure, which leads to the failure of sewage equipment;

- the installation of the device involves the formation of additional nodes, which are areas with possible leaks.

Only with the right choice of equipment, you can enjoy the comfort and proper, durable operation of the check valve. Non-return valves have fairly large dimensions, which complicates their installation in small apartments.In such cases, the reinforcement is mounted in the wall. It is advisable to install the locking element in front of the riser, but it is very difficult to do this if the house has been finished.

You can install valves on any plumbing equipment, for example, to drain the washing machine or air conditioner.

Kinds

The following types of reinforcement are distinguished:

- air;

- ball;

- reception room;

- vacuum;

- interflange;

- fan

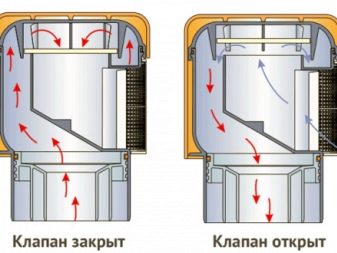

Air devices are designed to prevent unpleasant odors in the house from the sewer system. They are able to maintain stable pressure. The valve works according to the elementary scheme, it is equipped with a membrane. This element opens when water comes from the sanitary equipment. Under the influence of air pressure, the membrane returns to the opposite position, while the riser is blocked, which allows to prevent the fluid from moving backwards.

The air valve is very easy to operate, but can fail. This is easily identified by the appearance of an unpleasant smell in a residential area.

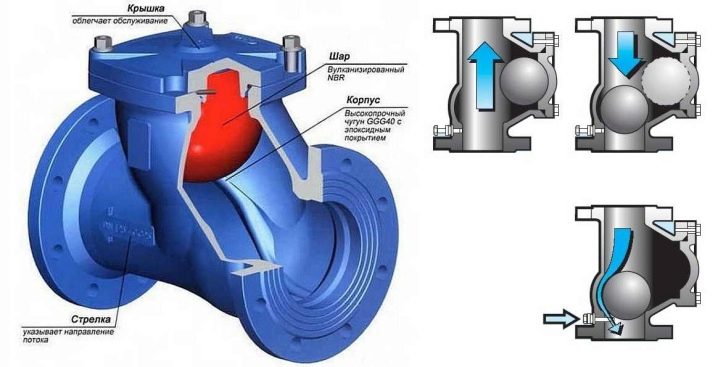

In the ball valve, the cross section is overlapped with a special rubber or metal dry ball.In the process of the appearance of water in the sewer system, a vacuum is formed, which pushes this working element, so that water is sent to the sewer. With increasing pressure, the ball returns to its original position.

Ball type check valves are the most efficient and high quality. Mounted in the sewage systems of apartment buildings, where there is intense drainage.

Receiving fittings are designed to protect against leakage, which is formed during distillation or pumping. Therefore, it is most often mounted in water extraction systems, and it is not installed in residential apartments.

Vacuum valves are ideal for homes in the absence of external devices to control and regulate the pressure in the sewer system. Valves are equipped with such details as the housing, the membrane and the air-intake chamber. The principle of the check valve: with increasing pressure, excess air is automatically emitted. And with a decrease - on the membrane is the force that closes it. This opens the air intake pipe.

To ensure the high efficiency of the equipment, it is necessary to correctly install it, since installation errors lead to poor performance. Vacuum valves are mounted on the highest points of the pipes.

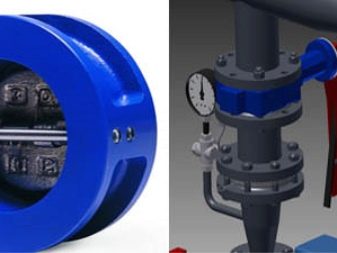

Wafer reinforcement is installed between two flanges in the pipe. Installation is carried out in the process of manufacturing the pipe, as this significantly increases its length. Shut-off valves are selected in accordance with the pipe material, thereby increasing the reliability and efficiency of the finished structure.

The working element here is one or a couple of valves, which raise an increased pressure, and the valves become horizontal, which allows to block access to the flow of water. When the pressure decreases, the gate valves return to the vertical position. Inter-flange devices are installed in the sewer systems of apartment buildings and industrial buildings.

Waste fittings are used exclusively for waste pipelines.

Depending on the material of manufacture, the following types of reinforcement are distinguished:

- Plastic - most common for indoor installation in apartments, easy to install, repair and clean, has a low cost;

- Cast iron - the most durable and durable option, while it has an inflated price;

- Steel - most resistant to aggressive media;

- Bronze - differs in high cost, and also resistance to aggressive influence of environment and long service life.

Also, check valves are classified according to overall dimensions, they are determined based on the cross-section of sewer pipes. Valves of 32, 50 mm as well as 110, 200 and 300 mm are available.

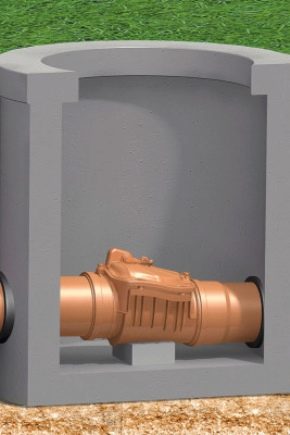

Valves can be installed in wells, from where water is pumped out by an electrically driven pumping unit.

Operating principle

Mechanical check valve device:

- branch pipes for an entrance and an exit of liquid;

- a lever device for the forced flow of wastewater;

- membrane element to close the passage of the riser;

- cover for cleaning and maintenance.

As the membrane can act as a ball of rubber, damper and other parts that can completely block the diameter of the pipeline.

The shut-off valve works due to the effect of excessive pressure on it. The inner membrane rises, as a result of which sewage flows into the sewage system. Then the pressure decreases, and the membrane returns to its original position. In the case when sewage discharges are moved back, the cover rests against the walls of the pipeline, which helps prevent the return flow of fluid into the sanitary appliances.

Proper operation and durability of this device depend on proper installation, in which it is important to observe a certain inclination of the device. Otherwise, all wastewater will be returned to the plumbing. As a working body in each type of check valve, various elements are used. So, in spherical devices it is a rubber ball, in circulating - a spool, rotary - a slamming part, and interflange - a shutter.

How to choose and mount?

Before choosing valves for installation in the sewer system of residential premises, it is necessary to carefully study the parameters of the sewage system.

In selecting the optimal device, the following points should be considered:

- bell section;

- production material;

- overall dimensions of the product;

- installation process;

- quality of materials and warranty period;

- price policy.

According to customers, the cost of the valve does not depend on the quality or functionality, so it is in last place.

The cross section of the socket is the most important nuance. It must be the same size with the cross-section of the sewer pipeline, where this part is installed. If the product is larger or smaller, the harmonious mechanism of the circuit operation will be disturbed, and the throughput of the pipeline will deteriorate.

Material for the manufacture of check valves: plastic, steel, cast iron, bronze, etc. Best of all, if the material of the check valve will coincide with the material of sewer pipes. It would be inappropriate to put a valve in plastic pipes in cast iron pipes.

The overall dimensions of the valves are determined on the basis of the availability of free space for its installation. Among the vertical and horizontal valves, it is recommended to prefer the latter. If there is little space for installation, then choose vertical products. The cost of installation depends on its complexity in case you need the help of an experienced specialist.

Simple plastic models can be mounted even without the participation of plumbing and the use of special tools.

Also, before buying it is recommended to carefully examine the device in order to avoid marriage. Make sure that there is an arrow from the manufacturer on the top of the valve. The arrow indicates the direction of movement of the wastewater, thus avoiding improper installation.

Installation of a check valve for sewage is most often done during construction or repair work. Then it will be very convenient to calculate the optimal length of the pipelines. Thus, the valves will be installed in the process of organizing the sewage system.

Depending on what materials were used in the manufacture of pipes, the method of installation of a check valve is determined. Cost also varies. For example, the installation of a device for cast iron pipes will be much more expensive compared to the installation of a plastic product.

When installing the valve by a plumber, it is necessary to control the process and quality of work. With self-assembly, it is necessary to study the theory of work and read the instructions for installing valves. Before installing the device, you must test it in action.After testing and making sure that the valve fluid is directed only in one direction, you can go directly to the installation work.

At the second stage, it is necessary to measure the length of the stop valves and mark the site of its installation, taking into account the data obtained. Leave some space for the valve for periodic maintenance. After marking it is necessary to cut the pipe section where the check valve will be installed. During installation, it is necessary to use sealing rings, sealant, FUM tape to ensure maximum tightness of the connection to avoid leaks. If it is necessary to install several locking devices, the installation process will be similar.

It is very important to properly install the valve in accordance with the instructions, and we should not forget about the manufacturer’s arrow on the top of the device, indicating the direction of flow.

After careful isolation of the locking devices, it is necessary to test the work done by opening the valve. If there is no leakage, it means that the installation was performed with high quality and reliable.

For details on how to install a check valve for sewage, see the following video.