Characteristics and subtleties of the selection of sewer pipes with a diameter of 110 mm

In order to drain and drain water in the sewer passed without problems, it is necessary to use special pipes. They have differences in diameter and material of manufacture, and this has an impact on the quality and service life. The most commonly used pipe diameter is 110 mm.

Special features

Sewer pipes with a diameter of 110 millimeters can be pressure and non-pressure. Their difference in scope. For example, pressure is used to transfer water that is under pressure, this is relevant in the case of water supply serving the city apartments. Free-flow found the application in the organization of the sewerage indoors, and also for private houses.

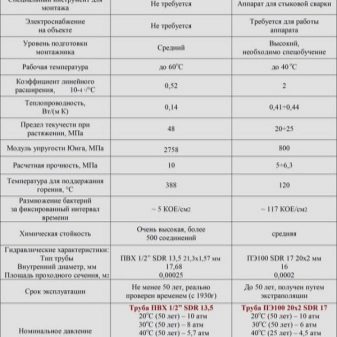

The most commonly used pipes are plastic, this is due to several reasons. They can be used in both open and closed. Such products are resistant to corrosion and negative elements. Despite the fact that cast iron pipes have a longer life, plastic can last for 50 years. They are virtually silent, as they have a smooth surface that does not interfere with the passage of fluid.

The materials are environmentally friendly and suitable for domestic use. Due to the low thermal conductivity they can be used for hot water. Plastic pipes withstand pressure and temperature drops well. Since the products are lightweight, they do not create problems during installation. Unlike cast iron, plastics do not require welding, installation is carried out using special fastening elements, which ensures tightness and strength of connections.

So that the pipes for sewage do not cause problems during operation, it is necessary to choose the right thickness. The liquid passing inside pushes against the walls, so you need to choose products that can withstand pressure.

However, in the case where drainage is used, this moment is not relevant, respectively, it is possible to use pipes of smaller thickness.

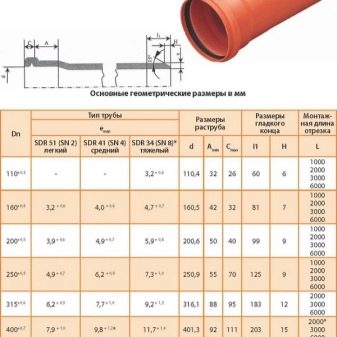

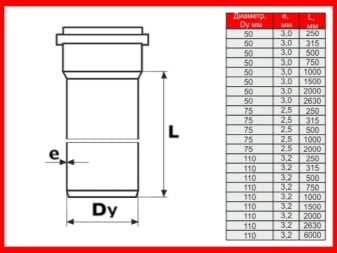

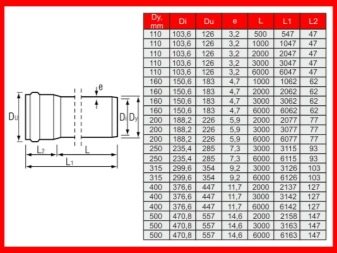

As for the technical characteristics, most often the thickness depends on the diameter of the products. Its standard value for pipes with a diameter of 110 millimeters is 3 millimeters. The larger the diameter of the pipes, the greater their thickness. This applies to both cast iron and plastic materials. Pipes 110 millimeters have an internal diameter of 103.6 millimeters.

The choice of diameter depends on customer requirements and operating conditions. There are pipes 110x500, 110x1000, 110x2000, 110x3000 mm and others.

Kinds

These pipes are divided into several types. First of all, they differ in functionality. Electrical pipes have average flexibility and strength. Single-layer are distinguished by increased flexibility, double-layer - by special strength and resistance to chemicals, which makes them indispensable in the construction of sewage. Double-layer hoses are used to protect cable ducts and can be applied in areas where there is a likelihood of damage.

And also the pipes are divided by weight. There are three varieties:

- lungs;

- heavy;

- super heavy

Light pipes are used exclusively for outdoor work, heavy ones are used for underground communications, and super heavy ones are used in areas where special strength is required, for example, under highways and in places where the railway passes.

The most commonly used material from which products are made may be as follows:

- plastic;

- PVC;

- PDN;

- NPVH.

Plastic pipes are resistant to corrosion and different temperatures, do not wear out when in contact with sand and gravel, and are also easy to install. PVC pipes are based on polyvinyl chloride, due to this they tolerate ultraviolet light and have high strength, are not grounded. They are also fire resistant, do not conduct electrical current and are resistant to aggressive substances such as acids and alkalis.

PVC-U pipes consist of unmodified polyvinyl chloride and are used mostly in the installation of external sewage systems, are resistant to corrosion and chemical elements, are easy to process, can be operated at temperatures from -5 to +60 degrees.In pipes PVC-U, used for pressure sewage, there is no socket, and they should be joined by welding.

However, such elements can withstand not only the loads created by the action of the soil, but also the work of the pumps connected to them.

Cast-iron 110-mm pipes are used primarily for drainage from the toilet bowl. The diameter of such products depends on the wall thickness. They can be bell-shaped and socketless.

HDPE pipes are made of low pressure polyethylene. An example would be the frequently used double-wall corrugated d110. It is able to withstand severe loads, can be installed in various ways, easy to install. However, the product has a feature - it fits exclusively in the ground or inside the concrete structures.

Corrugation can not be used in areas with a constant too low temperature. However, this disadvantage is more than offset by a large number of advantages. For example, it is not affected by the temperature of the liquid used and its differences, chemical and acid solutions, short-term effects of frost.Such pipes are practically not clogged, which eliminates the need for their frequent cleaning.

Double-wall corrugated piping is easy to install and connect to various types of structures. The use of fittings also simplifies the installation process. It can be used in outdoor advertising, as well as in works on the conduct of high-voltage cable.

Sewer pipes can have different colors, and this distinguishes them in terms of use and type of work. If the product has a gray color, it should be used when arranging the house pipeline, while in red the pipes that are laid on the street are painted.

With the help of green underground drainage is prepared. Black pipes are used to protect communication cables. Products of white color are rarely found on the market, they are intended for installation of the pipeline inside the house and are analogous to gray.

How to choose?

The first thing to consider when choosing a sewer pipe with a diameter of 110 millimeters is the wall thickness. Since most of the sewer systems are free-flow, it is not worthwhile to focus on the pressure in them.The main thing - the strength of the product, which must withstand the liquid in large quantities. Also important is the ability of the wall to withstand adverse external influences and mechanical loads. Therefore, when choosing products of this type, you should pay attention to the basic conditions - thickness and internal diameter.

When arranging the internal sewage system it is recommended to use gray pipes. They have a smooth inner surface and a socket. Wall thickness should be selected based on working conditions. If the sewage is gravity, the minimum figure is 1.8 millimeters.

The installation of 110-mm pipes is quite simple and fast, it is carried out by a socket connection, and a different fitting is used for the connection between them.

The outdoor sewage system is mounted out of orange pipes. In some cases, they are colored bright yellow. Due to the harsh operating conditions, different diameters have a certain thickness, in addition, it is necessary to pay attention to some nuances.

First of all, the indicators of resistance to dynamic as well as static effects play a major role. In addition, the strength of products becomes an important condition. They should not be deformed by the pressure of the soil, and must also withstand the load from the pressure of vehicles and pedestrians.

The length, thickness and other dimensions of the products must be chosen correctly depending on the operating conditions. The right choice is the key to successful work and long-term use of these materials.

Tips

Work on laying 110-mm sewer pipes can be both independent and with the involvement of professionals in the field of construction and repair. In any case, it is useful to listen to the recommendations of experts.

If an external sewage system is laid, the use of a pipe with a diameter of 110 millimeters will be optimal. It possesses sufficient passability for high-quality and reliable operation of the system. Need to pay attention to product labeling.

If plastic pipes need to be joined to a structure that is made of a different material, you need to use fittings that have rubber-based seals. In this case, the maximum tightness of the connection will be achieved.

An annular gasket will protect the joint from possible vibrations and mechanical impact.

The use of special fittings is very important, since it is responsible for the strength and reliability of the connection of materials. If the 110-mm pipes need to be combined with elements of a different diameter, it is possible to use a gearbox, but this is not a prerequisite. To close the holes located at the end of the pipeline, you should use a plug. If the outlet is located in two different planes, special crosses are used for its installation.

When arranging the sewer system, an important point is the formation of its slope. Since not only liquid but also more solid organic elements pass through the pipe, it is necessary to eliminate as much as possible the formation of blockages, which will require serious work to eliminate them. The correct slope for the external sewage system when using 110-mm pipes, according to regulations, should be 0.2. The top reference point is considered to be the exit of the riser outside the house, and the gasket should be located below the freezing level.

You can learn more about how to install sewage pipes in the house yourself.