Sewer coupling: dimensions and characteristics

The sewer coupling is one of the most important shaped parts of the pipeline and is widely used for construction and repair of networks.

Device and purpose

Structurally, the sewer coupling is a section of pipe with sockets located at both ends, with which the part is installed into the system. Couplings used in pressure networks are additionally equipped with stiffeners, which increase the overall strength of the structure under high pressure. The scope of application of couplings includes repair and connecting functions.

In the first case, parts are used during pipeline repair. They are set as a temporary tie-in instead of a damaged pipe section.

In the second, the couplings act as a connector for two pipes and are used to form a sealed network. The design of many types of pipes does not provide for the presence of special sockets at their ends. Couplings completely solve this problem and ensure reliable joining of two pipes.

In addition, some types of sewage couplings can be used to connect two dissimilar pipelines into a single network. This need often arises in the repair of sewer lines in the old housing stock, in the case when you need to connect the old cast-iron riser with a new plastic pipe.

Manufacturing materials

The most common raw material for the manufacture of sewage couplings is plastic. Fittings are made from two types of modern polymers: from polyvinyl chloride (PVC) and polypropylene (PP). The main advantage of these materials is absolute resistance to corrosive processes, sufficient resistance to some not very aggressive chemical compounds, and long service life.

Plastic products are distinguished by their low weight, low cost and wide consumer accessibility. The smooth surface of plastic couplings helps to increase system capacity and prevents the risk of blockages at the junction of two pipes.

In addition, the products are easy to install, and are fully compatible with steel and cast iron pipes.

If we consider the performance characteristics of materials, then they are undoubtedly higher for polypropylene products. So pipes from PP are capable of tolerating rather low temperatures, which allows them to be installed in external systems deep underground. The frost resistance of polypropylene couplings is influenced by their high elasticity, due to which the part will not crack if ice forms, but only slightly expand, and after melting of the ice block will find its original forms.

Another advantage of polypropylene couplings is their resistance to elevated temperatures. Therefore, when forming shower sinks, washing machines, dishwashers, bathtubs and sinks, it is recommended to install fittings of this material.The only disadvantage of PP couplings is their higher cost compared to PVC products.

The advantages of PVC couplings include an inexpensive price, service life of up to 50 years and ease of installation. The material is well tolerated by exposure to ultraviolet radiation and can be installed on outdoor systems. The disadvantages of models include their lower than that of products made of PP, heat resistance, and the lack of elasticity.

In addition to synthetic polymers, for the manufacture of couplings used steel and cast iron. A distinctive feature of metal models is the presence of thread. Such a connection is considered to be more durable than glue or crimping, and is used in cases where there are threads on the pipes to be joined.

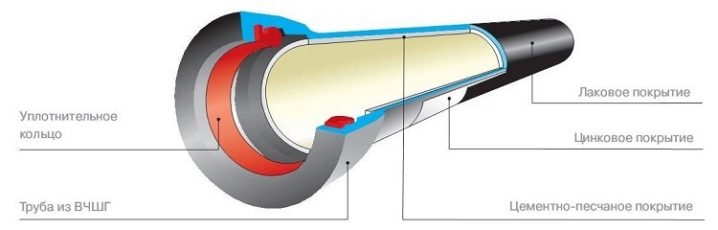

The advantage of metal products is resistance to high and low temperatures, as well as the possibility of installation in systems through which the removal of toxic chemical compounds is expected. Cast iron couplings have a very long service life, which can reach 80 years.

The disadvantages include the brittleness of cast iron elements, low corrosion resistance of steel products and a large weight of metal models.

Sewer couplings can also be made of rubber. In this case, they are called cuffs and are used to connect dissimilar pipes of different sections. Cuffs are often installed at the junction of a plastic pipe and a cast-iron socket, for example, when connecting old-style toilet bowls. With irregularities on the surface of the socket, the cuff is mounted using a silicone sealant, after which you can not worry about the reliability of the connection.

Kinds

The modern market offers a huge selection of sewage couplings, which differ among themselves in a number of important features. Structurally, the products are divided into three types.

Smooth

Classic models are installed on most sewage systems and are distinguished by low cost and simple construction. The fitting has a straightforward design with two sockets at both ends, and is used in low or medium load pressureless networks.

Corrugated

Such couplings have a more versatile design. The middle part of the product can bend in different directions, without losing its capacity and performance.The ends of the fitting are also equipped with sockets, which, in combination with the ability to rotate the pipeline, significantly expands the scope of their application. For example, corrugated couplings are successfully used as bends. And if the installation of a branch requires the preparation of a detailed scheme of the pipeline with an accurate calculation of the angles of inclination of the networks, the use of corrugated couplings relieves the consumer from this hard work.

The disadvantage of the technology of using couplings as taps is the probability of blockage of the pipeline at the bend. However, modern multi-layer corrugated sleeves with a smooth polyethylene inner layer completely solve this problem.

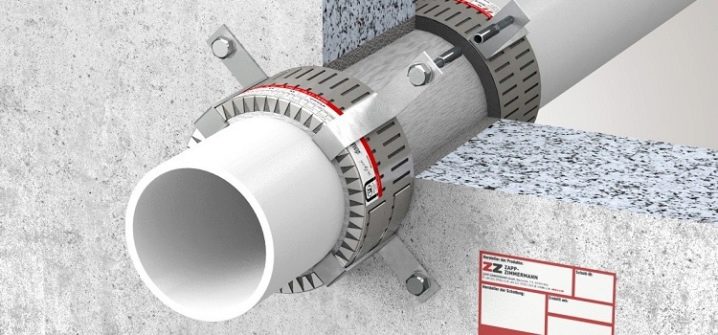

With stiffeners

These models are used to form pressure sewage pipelines and are designed to work in networks equipped with pumps. The products are distinguished by a small diameter seal, due to which they are able to withstand sudden and frequent pressure drops in the system.

The second criterion by which the couplings differ is their purpose. On this basis, the products are divided into three types.

Connecting

These couplings are presented in the form of a straight pipe segment with two multi-directional sockets. The middle part of the products is narrowed, which allows you to insert connecting pipes up to the stop at the same depth. The most common sizes of couplings are 50, 110 and 160 mm, and their cost is 20-35, 45 and 80 rubles, respectively.

The downside of the use of couplings in the sewage system is the fact that the socket, located in the direction of movement of wastewater, clings to the remnants of hair, thread and fat deposits. Therefore, when installing a new pipeline, the use of couplings should be avoided whenever possible.

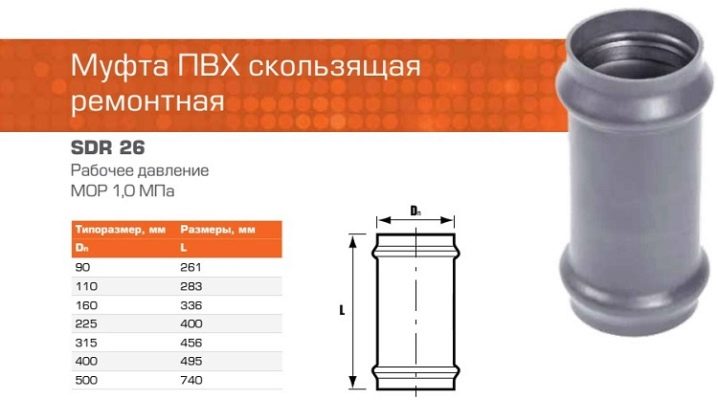

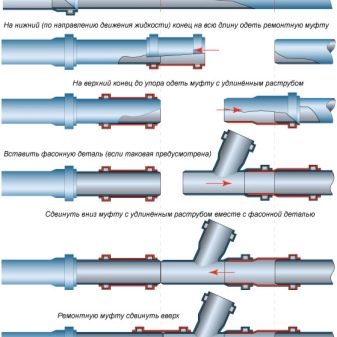

Repair

They differ from connecting ones by the absence of a narrow section in the middle of the product and are used for troubleshooting on permanent parts of the highway. Detachable couplings also belong to the repair and are made of cast iron. Products are made in the form of wide detachable clamps with rubber seals, which are put on the damaged area and tightened with bolts. However, more and more often the repair of pipes is carried out with the help of connecting models and a compensating pipe.

Fireproof

They serve to prevent the spread of fire through pipelines and are presented in the form of metal cylinders with non-flammable liners. When the temperature rises, the liners bulge and block access to the spread of fire.

Differ couplings and types of connections, among which are:

- threaded;

- glue;

- welded.

However, the simplest and most reliable is sliding sliding mount with a rubber ring. This type does not require the use of special tools and can be performed independently.

For information on how to properly lay sewer pipes, see the following video.