Sewer tees: description of varieties and scope

Tee for sewage is one of the most important shaped elements used in the construction of communications. The fitting is universal, and can be used not only for internal, but also for external wiring.

Features and Purpose

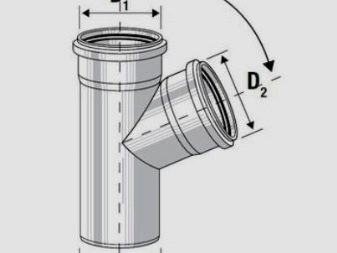

The sewer fitting is a special device, made in the form of a socket, the sleeves of which can be located relative to each other at different angles and have a different cross-sectional diameter. The entrance part of the tee is made in the form of a pipe, the edges of which are rolled, and the other two parts are equipped with sockets, into which sewage pipes of suitable diameter are inserted.

To ensure maximum tightness, the tees are equipped with special rubber sealing rings that can serve without replacement for 20 years.

The role of tees in the sewage system is difficult to overestimate: with their help, the angle of inclination of pipes, as well as their spatial direction, is changed. In addition, fittings play an important role in connecting pipes of different diameters to each other, which contributes to the formation of a single sealed pipeline system. Details are widely used in the construction of sewage in buildings and structures for any purpose, are used for arranging drainage, construction of septic tanks, drainage systems and water drainage, as well as when connecting washing machines and dishwashers.

Among the advantages of tees can be noted low cost, wide consumer accessibility, resistance to corrosive processes, ease of installation and long service life, reaching 50 years. The disadvantages include a large weight of cast-iron copies and some difficulties during their installation.

Kinds

In arranging the sewer system, several types of connecting fittings are used, differing in size, configuration, and functional purpose.

- Straight tees. Fittings have a straight angle of inclination and are designed to connect horizontal and vertical risers. This type of fittings is the most common, and is used in almost all sewer systems.

- Inclined tees. They have a tilt angle of 45 degrees and are used for piping in toilets, bathrooms and kitchens. The advantage of these fittings is the complete absence of the risk of blockage due to the absence of problem areas.

- Couplings revisions. They are a type of tees and are used to control the sewer system, and, if necessary, to clean it. The models are equipped with a special screw-in valve, which is located on the additional branch, and allows you to quickly enter the system and clean it with a cable. Couplings are installed on problem areas that have difficult transitions and are most prone to clogging.

By the size of the sections, the tees are classified into equal pass and cross pass. The former are characterized by the same diameter of all sockets and are used to connect pipes of the same size. The latter differ in different sections of the inlet and branch pipes, and are widely used for sewage plants in apartments and private houses. This is due to the fact that the diameter of the internal networks is usually 50 mm, while the external one reaches 110 mm.

Different fittings and fastening method. Traditional transition tees are equipped with a press sleeve and a nut, while the combined models have an internal thread or are equipped with a cap nut. The diameter of the pipes is also varied.

In addition to the standard sections, the most common of which are 50, 110 and 160 mm, there are tees of sufficiently large sizes, with a diameter of 400 to 500 mm.

Materials

Sewer tees are made from various materials. In addition to the popular polymer models, metal, ceramic and asbestos-cement fittings are also widely used and have a definite demand. Such parts are used to connect pipes made of the same materials, according to the requirements of GOST.So, for cast-iron systems, the use of tees made strictly according to GOST 6942-1469 is allowed, which is explained by the peculiarity of the connection and operation of these pipelines.

The type of the joint depends on the material from which the fitting is made. For example, for ceramic and asbestos-cement tees, only socket joints are allowed, while for other types, threaded and socketless can be used.

The above tees have a fairly narrow specialization, therefore The most common and purchased are plastic models of PVC, which, in turn, are divided into products made of polyethylene (HDPE) and polypropylene (PP).

- PND tee it is intended for use in a non-pressure sewer system and allows connection and branching of pipes without the use of welding. The fitting is made by casting and is subjected to special machining. The connection to the pipes is carried out using compression couplings equipped with clamps, which significantly reduces the time of work and simplifies installation.A limitation in the use of this method of connection are pressure systems, through which the fluid passes under high pressure and can break the clip.

- PP tee it is applied practically in all systems of sewerage and differs in high resistance to high and low temperatures, and also the general durability. The fitting can be connected with a socket, and compatible with all types of pipes. An important nuance when installing polypropylene models is their ability to expand, resulting from contact with a hot liquid. Therefore, when installing the pipe inside the socket, it is necessary to leave a gap of 1 cm. For ease of installation, a mark should be placed on the fitting, indicating how long the pipe should go.

Plastic tees vary in the degree of permissible load, which is indicated by the color of the product. So, gray models have a softer single-layer structure and are characterized by high thermal conductivity. This allows you to drop hot water into the system with a temperature of up to 60 degrees, without fearing for the reliability of the tee connection to the pipeline. Redhead fittings are designed for installation in external networks and are characterized by increased resistance to weight and mechanical loads.This allows them to easily withstand the movement and swelling of soils, as well as the impact caused by the movement of people and vehicles.

There are tees for corrugated pipes. They are also made of plastic, have a two-layer structure, a smooth internal surface and are connected to the pipes by means of sockets.

Connection methods

The method of connecting the tee to the pipes of the system depends on the material of manufacture, the purpose of the fitting and its size. So, PP products have a socket connection, while HDPE models can be connected using not only couplings, but also welding. The electrofusion method has also established itself well, the essence of which is as follows: an electric heater with a soldering iron inserted into it is placed in the fitting and heated until the edges of the coupling are softened. This usually happens at a temperature of 260 degrees.

After which the electrical equipment is removed, and the parts are connected to the stop and held for some time. This method is somewhat similar to the butt, during which the heating of the pipe joint occurs, followed by its combination with the tee socket.

Crimping and pressing methods are used for metal-plastic pipes.

Cast iron fittings are mounted using threaded connections using gaskets.

Installation Tips

Thanks to the simplicity and minimal labor-intensiveness of the process, the work on dismantling old pipes, replacing the sanitary standpipe and arranging the sewage system can be performed independently.

In order to avoid difficulties when installing fittings, and the work yielded the desired result, it is recommended to take into account the following recommendations of experienced craftsmen.

- When forming horizontal wiring, use oblique fittings with a 45 degree angle of inclination. The use of such connectors will minimize the risk of blockage and increase the trouble-free service life of the pipeline. It is for this reason that straight tees are not recommended for use in arranging horizontal sewers.

- Before replacing or installing a new fitting or changing the gasket, remember that trimming or removing the O-rings is strictly prohibited. Even in the case when the twisting is very tight, it should not be done.Otherwise, the system may not be tight enough, which will create serious problems during operation. Slightly facilitate the task will help lubricate the internal surfaces of the parts to be joined with liquid soap. This will allow the pipes to enter the socket and provide the necessary bond strength.

- Installation of audit sleeves is desirable to produce in open, not blocked up sections of the pipeline. This makes it easy to remove the plug, easily penetrate into the system and clean it.

- Thick and medium sections of the pipeline with a cross-section diameter greater than 50 mm, it is advisable to attach to the bearing surface using special brackets.

- The coupling end of the tee should always look at the starting point of the sewer system. This will help ensure proper fluid flow and prevent clogging of the fittings.

Tees for sewage are the main link of the pipeline, and allow you to create a sealed system that can serve reliably for many years.

For information on how to make the transition from a cast iron pipe to plastic, see the following video.