Sewerage: types and features of choice

Sewage is a part of communications, without which it is impossible to imagine either a normal life or a stable production activity. But before installing such constructions, it is imperative to understand all the subtleties and nuances in order to avoid problems. Sewage systems should be arranged in strict accordance with state standards.

What it is?

The idea of a sewage system for many people is very limited primarily because it is only specialists who fully engage in it. But still for residents of both private and multi-storey buildings, it is very important to clearly understand what exactly the chosen scheme is and what to look for. Basic information about the normal structure of the sewage system is clearly reflected in the Russian GOST and other regulatory materials.According to them, sewage should leave mainly through closed pipelines in gravity mode. An exception is provided only for industrial effluents that do not give off a foul odor and do not pose a sanitary risk.

Each segment of the sewer line should be strictly rectilinear., and to change the route and add additional equipment using connecting parts. The creation of pressure systems requires the use of several different pipes than in the formation of a gravity route. The consistency of not only the diameters, but also the hydraulic parameters of all pipelines and all sanitary equipment is very important. Sewerage inside buildings is divided into hidden and open execution format. The most current moment - the choice of a centralized or autonomous device sewer circuit.

Immediately it is worth considering that the sewer can not be placed:

- in the walls and floors of living rooms;

- kitchen ceilings;

- in other places where the slightest excess of humidity is unacceptable for one reason or another.

Kinds

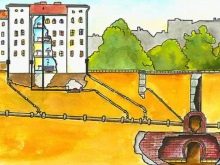

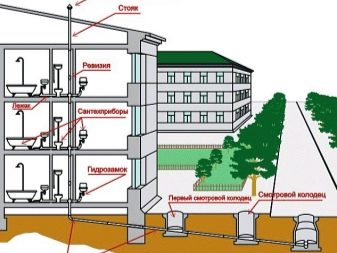

Dealing with a sewage system, one cannot restrict ourselves only to general information about what it should be.It is imperative to find out how the work of each type of the diverting system is organized, including the external component. It may seem that it is much simpler internal and is formed by a smaller number of components. But this does not mean that he needs to pay little attention. Along with the pipeline transporting drains, the external complex includes wells, with which various manipulations are carried out.

It is customary to divide wells into:

- intended for visual monitoring and cleaning of communications;

- used for drainage;

- placed in places where pipes turn;

- allowing to lay the pipeline at the changing height.

In addition to pipelines and wells, collectors are also included in the external sewage system of the centralized type. These are also pipes, but exceptionally cumbersome, which accumulate and transfer drains in huge quantities. The final stage of processing liquid waste passes into the cleaning facilities. In urban utilities, they are gigantic in size and in performance; in private homes, this is often just a cumulative capacity, periodically cleaned by overflow into the tank.

Any central sewage network is equipped with booster stations. In the private sector, they are needed only if the installation of biological treatment systems based on aerobic microorganisms. External sewer contours can be made on the basis of pipes from dissimilar materials.

It is not practical to use ceramic and glass elements for them. The experience of their use has so far been accumulated insufficient to draw certain conclusions.

When designing an external sewer system, the following are taken into account:

- the specificity of soils in chemical and physical terms;

- height of groundwater;

- climatic features of the territory;

- estimated daily and peak discharge of dirty fluid.

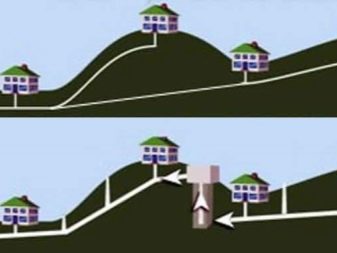

Its features has a pressure sewer. Despite the high prevalence of free-flow systems that operate due to the gravitational flow down a slope, it also has its advantages. So, the recommended depth of laying of pipes decreases and you can not follow its slope. The pressure helps to clean the internal surfaces much more efficiently than a simple drain. You can use pipes of reduced section, but only those that coincide with the nozzles of pumping units.

There are situations when it turns out to choose only pressure systems. These are cases with the placement of a building or structure lower than the central sewage system to which connection is planned. Also, the gravitational runoff does not allow to cope with the task, if the terrain on the way has an uneven, heterogeneous relief. Repairing the area through engineering is more expensive and more difficult than purchasing a reliable pump.

Also without pumps can not do:

- at installation of the sewerage of small section without slope;

- with an open passage of pipes (over roads, paths, ancillary buildings);

- when there is no opportunity to dig an inclined trench or it is extremely expensive.

From whatever materials a pressure sewage system was created, whatever objects it served, its project must be coordinated with the territorial engineering organizations, if there is at least a small intersection with other networks. Forced sewage disposal should also take into account environmental legislation, especially near water bodies, underground water intakes and specially protected areas.

Domestic sewers should be less coordinated with various organizations. But there is already a significant difference between networks in private and multi-family homes. Where there are a lot of residents and there is a high risk of infringement of interests in case of failure, a technical error - control is very strict. It is often possible to face the statement that increasing the thickness of pipes and their diameter increases throughput and reduces the danger of sagging communications. However, it is important to take into account the appearance, which in many respects makes it difficult to use very thick and powerful pipelines.

People often ask if there can be a quiet sewage system, or is it just a deft marketing maneuver. The question is not idle, because the movement of fluid in any material, by definition, should create sound. At the same time, even relatively quiet, but continuously present noises affect the state of health and the emotional sphere negatively. For the most part, sewers without noise are formed from polymeric materials, components for them are produced by many world-famous companies.

Noise reduction is most easily achieved using multilayer structures.To assess the compliance of purchased products with the necessary requirements, you need to ask the vendors for certificates according to DIN EN 14366. Fasteners for silent sewage are also selected in a specific way - they always have an insert made of polymers that additionally dampens the sound. There is also an alternative variant in which a typical pipeline is used, but it is supplemented with an absorbing shell and is mounted on special supports.

In sanitary practice, not only noiseless, but also corrugated sewer pipe has become quite widespread. It is customary to divide it into single-layer and two-layer types. The second is stronger and better suited for installation underground. It is possible to use a corrugated pipe both in pressure, and in pressureless, and in storm sewer systems. Feature - notches, the distance between which is very carefully measured, because they must match. Other things being the same, the corrugated product exceeds the smooth multiple times in endurance to the load and mechanical strength.

There are even such corrugated pipes that are able to withstand operation under the federal highway or railway line.For the drainage of rainwater used double-layer elements, which must have a mounting hole. If it is not, the speed of movement of water decreases markedly. With a significant amount of precipitation or rapid snow melting, this may be critical. Selecting a corrugated pipe, use designs from 11.5 to 21.5 cm.

When corrugated sewage products are mounted outside the building, when selecting them, it is important to take into account the chemical and mechanical composition of the soil and the load on the contour. The simplest format is selected for laying sewers under green areas. Heavy type is used where there is at least a slight traffic flow and / or vibration load. Rings of sewage pipes of corrugated execution with two layers allow the system to survive the pressure of the earth with a layer up to 25 m. When selecting, it is very important to pay attention to the thermal regime in which certain structures can be operated.

High-quality corrugated pipe of two layers of material confidently transfers strong heat and cold. She is also calmly experiencing the transport of even most industrial waste.The external sewage system at the dacha plots has its own specifics. There, for the most part, individual accumulation systems are formed. Only in the most elite settlements there are powerful cleaning systems that simultaneously process the drains from several cottages.

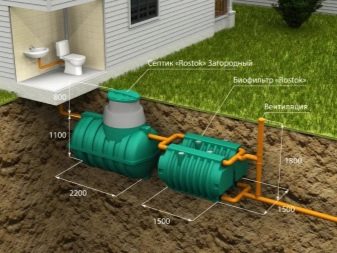

Internal wiring is limited almost everywhere by the sink and toilet, even washing machines are installed very rarely. It is practiced to use straight pipes for household waste, dumping of waste is carried out in cesspools, which are located taking into account the convenient movement of tank trucks. But there are more elegant solutions that involve the use of industrial concrete billets, ceramic or silicate bricks, tire covers, or branded containers made of advanced plastic. It is categorically unacceptable to use drain pits that are not equipped with sealed tanks, because this creates a tremendous danger in terms of health.

In order to do without pipelines at all, it will be necessary to partially remove the cesspool beyond the contours of the building and locate a technical cleaning hatch nearby.Even in a large area there is no special need for the most complex biological purification system, so it is worthwhile to limit ourselves only to the allocation of special drives for baths and houses separately. The movement of wastewater is almost everywhere carried out by gravity, only in exceptional cases it makes sense to resort to the use of pumps. The minimum cross-section of risers and street highways is 10 cm, the distance from the cesspool to the building should be 5-10 m.

It is impossible to lower the distance less than this value, since it is dangerous from the sanitary point of view. But it is undesirable to remove the cesspool, because then there may be problems with operation and simply with the laying of a long pipe. Instead of the classic earthen or reinforced with additional elements of the pit, septic tanks with two working chambers are increasingly used. Such designs are not only safer and more aesthetic, not only contribute to the reduction of bad odors, but also reduce the cost of calling evacuating cars.

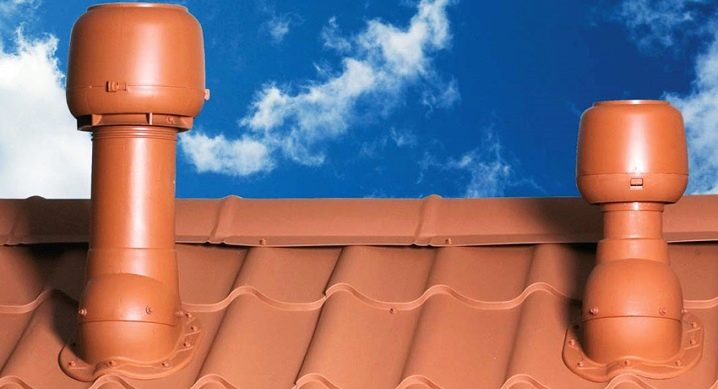

There is another important nuance. No matter where the sewage system is located - in an urban dwelling, in a country house or at a dacha, people want to save the bathroom itself as much as possible from the bad smell. A carefully selected and properly installed fan pipe helps to do this.There are other benefits from it, which are not so obvious at first, but still very significant. Smoothing decompression in liquid lines allows you to avoid violation of the flow itself.

An exhaust pipe from a fan pipe is almost always made straight; this is exactly what the official regulations require to do.

Creating a sewer in the bathroom is not so simple, for this purpose you have to work very carefully and prepare a professional scheme. Particular attention should be paid to the maximum tightness of the joints; in order to divert sewage from the bath, a siphon will be required that turns the liquid 90 degrees. When a bath and a washstand are nearby, the most logical and simplest solution is to use a tee. Wherever it is necessary to create long sewer lines or leave hard-to-reach areas, it will be necessary to provide for inspection hatches. Cleaning the drain pipes without them turns into a whole "adventure", which no one will be happy for sure.

To ensure that the drain from the bathroom always takes place steadily, regardless of the intensity of the drain, it is required to calculate the pipe cross section with all due care.The most active appliances that consume the most water (usually a toilet and a washing machine) should be connected to a drain pipe of at least 10 cm. The diameter should not be reduced as it approaches the main vertical section; moreover, it is recommended to increase the cross section to eliminate the appearance of a gap. But the exact calculation of the length in advance is unlikely, because the pipes are sold in the form of segments of different lengths.

To exclude the slightest surprises in the sewage of an apartment building, one should take into account not only the specifics of its own pipes, but also what kind of riser is used, how it is formed and works.

Strictly unacceptable passage of risers through:

- living spaces;

- kitchens;

- walls separating different rooms.

In addition, when the risers lead through the back rooms of any type, they are certainly trying to cover the mechanical box from mechanical defects. The riser can be located both in the corner and in a special mine, which is placed behind the sanitary equipment. But in both cases it is required to maintain a distance of at least 20 mm from the plane of the walls.If there is an opportunity to increase this distance, this opportunity should be used.

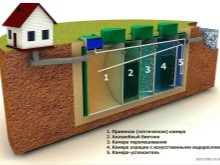

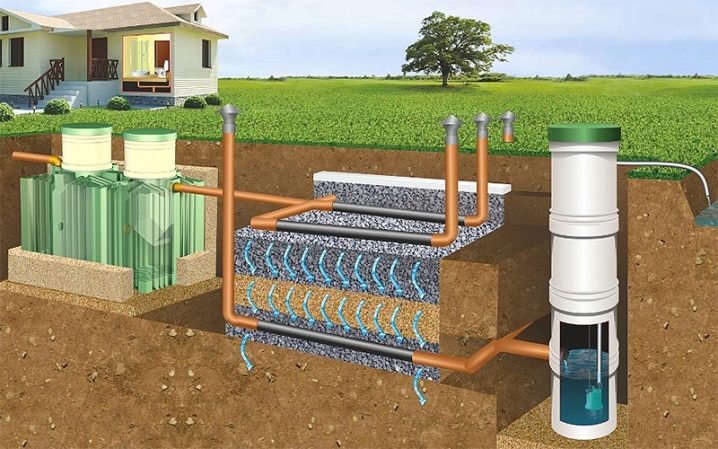

The bathroom in the urban dwelling, with the rarest exception, is connected through the sewage system of the room and house with the main network. But such a brilliant achievement of civilization is not found everywhere, because in country estates overflow configuration is more often used. Its essence is simple - only two components connected by a pipe. First, a large, impermeable storage container is installed. But the second block is indistinguishable in terms of the device from the cleaning sewer well.

At the same time, they deliberately refuse from inseparable stone slabs, they are replaced by a filtering layer, the vertical length of which is not less than 1 m.

To ensure cleaning, substances with special characteristics are taken for filters:

- gravel;

- rubble;

- slag;

- their combination with sand.

Reset can be implemented by various methods. Somewhere, the sewage liquid immediately goes into the soil, somewhere it is equipped with special ditches. Quite widespread cleaning fields. In some cases, specially used water bodies are used for filtration.Regardless of these nuances, “leaky” walls are preferable, because with their help the reset is activated as much as possible.

Overflow is a special tube that leans in the direction of the absorbing object. There is no universal depth of laying it and there cannot be: in the Irkutsk region it is clearly more than in the warm Krasnodar Territory. With regard to ventilation, the pipe designed for it is placed so that the bottom face remains clean and dry, no matter how many drains it has had time to enter the tank.

It is recommended to equip any parts of the treatment plant with personal airing systems, even the simplest ones by device.

Repeatedly already talked about a bunch of sewer devices with pipes. And if before such pipes always came out of blast furnaces, now the most practical transition is provided by the polypropylene variety.

The metal’s unshakable reputation is still not tarnished, but it has other flaws, such as:

- heaviness;

- strong pressure on the wallet;

- frequent jet blockage;

- corrosion weakness.

Polypropylene is much lighter; its color is determined by what the main production technology.Even high school students will be able to lift such a pipe. Along the exceptionally smooth, almost polished, internal interior, almost all the drains and solid inclusions slid into them. Consumers can safely apply any cleansing agent allowed for household use.

Even the most zealous owners in the sewer inevitably fall sharp and scratching objects, all sorts of fibers. A polypropylene pipe will survive their action (within reasonable limits, of course) as indifferently as a simple liquid. But there are reasons why even first-class polypropylene will never completely replace metal from plumbing. It is susceptible to destruction with significant overload; sometimes not just a strong blow, but also a long, palpable pressure damages the drain channel.

It is worth paying attention to the fact that polypropylene is not a monolith, there are as many as four of its subtypes. Portable pressure is 25 kg per 1 sq. cm, and to achieve such a result, insert aluminum foil or fiberglass into the pipes. For the most part, such products are needed for external sewage, they are rare guests in the walls of houses.If a pipe is classified as PN20, it will definitely be shock resistant. For information: pipes of this class are used not only in sewage systems, but also in other liquid routes of houses and apartments.

PN16 is needed when gravity gravity flow is chosen. The weakness of the products is that they should not receive water hotter than 40 degrees. Therefore, connecting them to the sink of a bath or even a kitchen sink is a very bad idea. Most homeowners choose (and plumbers welcome) the PN10 sewer pipe. It has a permitted heating up to 45 degrees, and the pressure limit is 1 MPa.

In conclusion, a few words should be said about industrial sewage. Even within the same plant or plant, there may be completely different drains, and if you mix them, you get a "fusion" mixture that you can not merge. The result will be unpredictable both for the communications themselves and for the environment.

Therefore, if the houses are trying to combine the drain contours as much as possible and manage with the least amount of pipes, in industry it is strictly the opposite. The separation is made by chemical aggressiveness and temperature first.

Materials

Talking about the properties of the sewage system and the problems it solves could be continued for a very long time. But it is also important with what materials all these functions are provided. The range of tools used for the formation of sewage, ultimately determines its mechanical resistance, chemical inertness, and uninterrupted service life. Despite the long-term efforts of engineers and chemists, the cast-iron sewage system continues to be in demand, plastic and other materials cannot finally displace it.

The undoubted advantage is the stability of use and long-term use, no risk of fire. Even with significant heating, even reaching melting, cast iron does not produce toxic substances. In a thick metal pipe, extraneous sounds are lost that cause so much inconvenience. But during casting, even strictly complying with the technological requirements, various voids and slag often appear.

The internal surface of the sewage from cast iron is subject to the accumulation of lime scale and other deposits.During the construction of residential buildings, such contours are no longer mounted, and during major repairs they are replaced. In the industrial sector, cast iron is still one of the most sought after options. A common household alternative is now sewage PVC. In addition to the main components, there are improving additives.

Polyvinyl chloride is plasticized or not passed the process of plasticization. In both cases, it turns out to be the cheapest and most practical solution, and among the structures mounted by the socket method, it is distinguished by its simplified installation. Subsequent repairs and final disassembly are notably easier, especially since there are many components that ensure the formation of complex contours. If it is required to pump over aggressive liquids, it is recommended to choose PVC-U products, they also differ in increased strength. The pressure inside can be 6-16 bar, it is determined by the thickness of the walls. PVC can not be operated at temperatures above 65 degrees. It is also bad in the cold from 10 degrees.

Regardless of the material of the pipes, it is important to take into account the arrangement of the reservoir where the effluent flows.In suburban and suburban settlements, drain holes are often formed from tractor or automobile tires. Such a solution turns out to be the simplest in execution and allows you to radically save power, which is very important for summer residents who are already busy with things.

It should not be assumed that the septic tank of tires is a simple analogue of the accumulating pit: it is a much more complex system. Tires can be obtained very easily, they are accumulated on their own or taken unnecessary at the nearest service stations. The installation process can be carried out on its own, eliminating the need for additional specialists. You don’t even need to use mechanical devices and complex machines.

It is worth remembering the limitations of tire septic tanks:

- they will not cope with the large volume of waste;

- characterized by poor performance in frosty weather;

- compulsory inspection annually;

- the maximum lifetime is no more than two decades.

Much more often due to increased reliability, concrete structures are used. If everything is carefully thought out, the end result is not inferior in quality to a septic tank divided into many sections with intensive oxygen treatment of the liquid.Usually, a pair of wells are installed, for which typical reinforced concrete rings are used. They are trying to connect them with each other by means of overflow collectors.

To maximize the productivity of processing, apply aeration.

Dimensions

The typical size of a sewer pipe (cast-iron or polymer - does not matter) is 5-11 cm. But this does not mean that the dimensions mastered by industry end there. Pipes designed for operation without pressure can have a size of 5, 9 or 11 cm, while the polymer wall has a thickness of 0.32 cm. The length of sewer pipes vary from 50 to 800 cm. This allows you to choose the ideal solution for almost any case.

The situation is different with non-pressure elements. They are characterized by a larger variation in typical sizes - a minimum of 6.3, and a maximum - 31.5 cm. The most popular formats are pipes by 10 and 11 cm, less often they buy pipe parts by 7.5 cm. Reduced versions are needed to divert drains from baths and shower cabins. The pipe of 20 and 30 cm, even in a large cottage is redundant, its place is in an industrial enterprise.

Accessories

In order for sewage systems to work stably and efficiently, it is not only necessary to choose good plastic pipes. A big role is played by the composition of components. Any plumbing fixture, except the toilet, is by default complemented with a hydraulic valve. From toilet bowls to the next link of the system, only pipes with a section of 11 cm are used. And sinks, sinks and washbasins are serviced by pipelines of 5 cm.

It is categorically unacceptable to use pipes that accept dirty water less than 50 mm in diameter. They are not only characterized by low productivity, but also become too easily clogged. Sometimes you have to solve the problem of joining pipes of various sizes. In such a situation, compensator brings invaluable help, which also allows to cope with non-uniform thermal expansion.

Such compensation is especially important for sewers hidden inside a wall or placed under a screed.

How to choose?

Speaking about plumbers reviews as the best source of information for the selection of sewage pipes and other parts, we should not forget about the difference of situations. For a private house recommendations should be completely different than for the inhabitants of the apartment on the top floor.The simplest cesspool can be made of brick, but only its ceramic variety will do. It is recommended to form a round container, then it will be stronger. The use of reinforced concrete rings is justified only for those people who can afford to order heavy construction equipment.

But this option has its advantages - it is used when it is important to guarantee the strength of the tank and prevent the collapse of the walls under the action of the underground fluid. Due to the chemical inertness of a specially selected compound, plastic storage devices will precisely resist moisture; even acid and alkali will not leave a mark. We'll have to choose the finished model. The drain pit formed from molded reinforced concrete must be protected from the outside by waterproofing; this option is justified only for those who can build independently. Any pit does not consume electricity and works stably even in its absence.

But the cesspool of the usual form must be systematically cleaned of liquid mud, and this requires overcoming disgust. The septic tank not only accumulates liquid, but also separates it, cleaning it with a different degree of efficiency.You can equip a complex of overflow wells without a visit by trained builders and reduce the burden on your personal budget. But filter wells are inefficient at a high location of groundwater and when placed on clay soil. Once in 6 years you need to change the pillow of sand and gravel at the bottom, which is very hard to do.

Septic tanks with filtration fields are the most eco-friendly solution of autonomous systems. The cleaning fields themselves are created from perforated pipelines and combined sand and gravel-based pillows. The minimum thickness of the cleaning layer starts from 1 m, its smaller size does not meet safety requirements. It is very important to select an area of 30 square meters. m for placement of cleaning components. The low labor intensity of work and the long intervals between maintenance are markedly overshadowed by the unsuitability of purified water for drinking and the considerable price of creating a system.

Tips

When choosing a suitable solution, it is important to pay attention not only to the service life of the sewage system, but also to how it will be dismantled. So, cast iron pipes, despite all their reliability, it is difficult to consider the optimal solution.A conventional plastic pipe works stably if the temperature of the fluid being passed does not exceed 75 degrees. If it grows to 95 degrees, a completely different kind of material is needed, the additional advantage of which will be resistance to freezing. It is unacceptable to lay steel pipes in the ground, because even the highest quality ones will quickly rust.

When changing the riser, it is recommended to simultaneously replace the plumbing and bends that are associated with it. It so happens that the owners or repairmen in the process of replacing the sewer pipeline change its route completely or partially. But you should still strictly comply with the requirements for the slope and cross-section of pipes.

It should be remembered that the dismantling of the old sewage system, especially one that was installed decades ago, is very complicated and even dangerous. It is therefore justified to turn to professionals, and not to risk your own property, reputation among neighbors, and health.

About the features of the choice of autonomous sewage, see the following video.