Sewage troughs: what it is, types and installation

Wastewater that has undergone treatment is discharged into the reservoir system or the ground. Therefore, the state of ecosystems and, as a consequence, the health and well-being of people depend on the level of their residual pollution. The important role of treatment facilities is difficult to overestimate. Cleaning systems are used in all spheres of human activity, be it a housing and communal complex or industrial enterprises. The first, mechanical stage of purification, is carried out in special tanks - settling tanks, the effectiveness of which depends on the effectiveness of the following stages and the cleaning process as a whole.

Special features

The septic tanks are specialized sealed tanks in which the drains fall from sewer systems.Purification of contaminated liquid occurs due to the action of gravitational forces, forcing large and heavy fragments to settle to the bottom of the tank. The septic tanks do the dirtiest wastewater treatment work. They receive fecal matter from sanitary facilities and sewage systems. As a result of separation, heavy fragments precipitate, and light ones, such as fats and hydrocarbons, form a film on the surface.

The resulting liquid acquires some transparency and goes to the next levels of purification. In some cases, the septic tanks are the final version of the treatment plant, after which the treated water goes into the ground. However, such a short cleaning cycle is typical for private houses and suburban areas. After passing through a septic tank, liquid from utilities and industrial enterprises is subjected to biological and physico-chemical treatment, as well as undergoing a disinfection stage.

The efficiency of the sump is determined by the residual amount of solid impurities. With proper operation of the device, the purified liquid should not contain more than 150 mg of suspensions per liter.The result of cleaning is decisive for the duration of the stay of polluted water in the tank. On average, it takes one and a half to two hours for the coarse fractions to fall to the bottom of the settler.

Modern septic tanks are flow-through devices, and sedimentation of solid particles occurs in them with a continuous flow of water. However, the speed of its movement in them is so small that there is practically no intensive turbulent mixing of the masses. This allows the suspension to settle to the bottom with the same intensity with which they would settle in the standing liquid, and not to rise up. However, the use of sedimentation tanks is not limited to the purification of fecal waste. The scheme of operation of the devices is similar to the principle of the coarse filter; therefore, tanks are successfully used in water supply systems, waterworks and to remove oil residues from water.

Species

At the place of installation, the settling tanks are divided into the structures of the primary and secondary level. The primary ones are installed before the facilities where biochemical purification is performed, and the secondary ones - on the contrary, after such facilities.Septic tanks are also classified by operation. Most of the tanks are arranged according to the dynamic type, that is, the fluid in such structures moves continuously.

Static models, on the other hand, are designed for periodic action: in them the formation of sediment occurs at rest after dosed filling. Such structures are used in cases when it is necessary to remove oil impurities from the water. These are usually capacious tanks made of steel or reinforced concrete.

Dynamic clarifiers are subdivided, in turn, into structures of vertical, horizontal, and radial types.

- Horizontal installations They have a rectangular cross-section, are equipped with several compartments, as well as water distribution and drainage devices. Contaminated water in such devices moves horizontally. Supply and removal of fluid through the side nozzles, and to collect the bottom sediments using a special scraper.

With the help of the scraper device, not only the sludge is collected from the bottom of the tank, but also the gathering of the floating up particles into the specially designated chute.The use of horizontal installations equipped with a gutter occurs at water intake stations before supplying water to the pipeline system.

Along with the scraper conveyors, large industrial installations are equipped with perforated pipes and a pumping system. This allows you to cope with a high content of impurities and to facilitate the removal of sedimentary masses from the sump. The bottom of the accumulation zone is made with a slope, the reverse flow of water, and the dimensions of the structure are governed by the SNiP. For the consolidation of suspensions and an increase in their sedimentation rate, a coagulant in the form of aluminum sulphate, ferric chloride and ferrous sulfate is added to the polluted liquid.

- Vertical installation they are characterized by the fact that the contaminated liquid in them moves upwards, which is why the performance of such installations is not too high. The tank can have both a circular and a rectangular cross-section, with a dedicated sedimentation chamber and a drain for the care of partially purified liquid. The main area of application of vertical structures is the treatment of wastewater of domestic origin, they are not suitable for the purification of industrial waters.

The principle of operation of such facilities is quite simple: a dirty liquid enters the base of the working chamber through the nozzle system, with most of the suspended matter falling as it moves from the central part of the tank towards the walls. Thus, an increase in the sump radius automatically entails an increase in the time for cleaning.

The bottom sediment in vertical installations is removed by gravity as a result of the hydrostatic pressure of the fluid. In order to better sediment out of the installation, the lower part of the tank has a conical or pyramidal shape, where the angle of inclination of the walls does not exceed 50 degrees. All vertical sedimentation tanks are equipped with special catching devices, with the help of which the retention of pop-up particles, which did not have time to precipitate, occurs.

The upward flow rate of contaminated fluid in vertical tanks should not exceed the sedimentation rate of suspensions. The capacity of such septic tanks is no more than 20,000 cubic meters per day, and the effect of water purification corresponds to 50%.

- Radial sumps They are considered one of the horizontal varieties, although some sources distinguish them into a separate group of treatment plants.The flow of polluted masses in such devices occurs from the center, where the dirty water flows, to the walls of the tank. At the center of the reservoir, the fluid has a maximum speed, while at the periphery it drops to its minimum. The cleaned fluid is discharged using a circular gutter.

At the same time, sedimentary masses flow into the center of the settler or are forced into special pits by force, using scrapers. However, there are peripheral inlet installations. In such devices, dirty water is supplied with minimal speeds. Purified liquid is discharged through the central ring tray system.

Radial settlers are characterized by high productivity, which allows their use at industrial cleaning stations. The planned load on each square meter of surface is from one and a half to three and a half cubic meters of water per hour. Therefore, the more voluminous the installation will be, the more liquid it will be able to clean. Removal of sediment from radial sumps is done with pumps. Installations can be used as both primary and secondary cleaners.

- Thin-bed sedimentation tanks also used in dynamic structures and are characterized by the presence of devices that change the direction of flow at different angles. This technology can significantly reduce the water layer and accelerate the precipitation. Due to the constant repetition of this process, the capacity of the settling tanks increases dramatically, and the quality of clarification of the liquid becomes much higher.

Thin-layer installation is divided into tubular and plate. The first option is a plastic pipe with a section of 25-50 mm, installed at a given angle. The length of such a pipe depends on the degree of pollution of wastewater and the speed of their movement. Considered the best pipe length of one meter.

Lamellar devices are distinguished by the fact that instead of pipes, special plates are used, and dirty water, passing between them, changes its direction at the right angle. Installations equipped with such devices are characterized by maximum efficiency, reaching in some cases 85%.

Tubular models can have a constant and periodic cycle. Periodically work pipes, located at a small angle of inclination.First, dirty water flows through them, leaving their suspended matter and solid particles on their inner walls. Then a stream of pure liquid flows and washes away the precipitate formed.

If the slope of the pipe is large enough, then the fluid flow is carried out continuously. The precipitate in this case is removed by creeping under its own weight, and rinsing the pipes is not required.

Installation

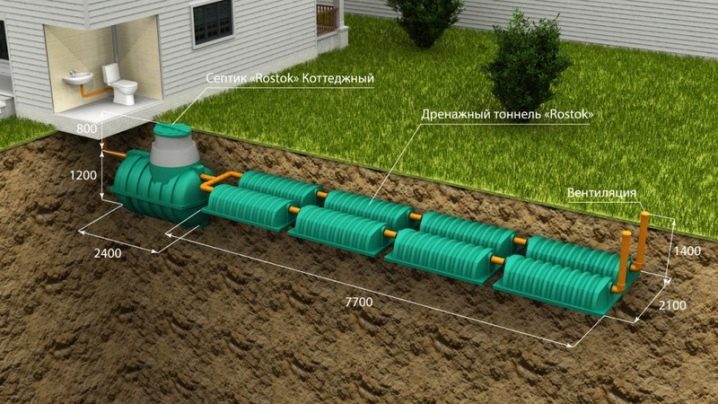

Structurally, the sump is arranged quite simply, so making the tank with your own hands will not be difficult. In private homes and on summer cottages the most common type of sump is a sealed well of concrete rings. However, such a structure requires expensive transportation of concrete products to the site and laborious work on their instillation. Practical and cheap solution will be a sump for sewage, made of old tires.

The only condition for the construction of such a structure should be full tightness of the docking joints. Otherwise, sewage will begin to seep into the soil and cause biological contamination of the soil and drinking water sources.Therefore, when choosing a place for a septic tank, it is necessary to consider the location of the house, the well and the adjacent plot. You should also take care of that assenizatorskaya machine, if necessary, was able to drive up to him and make cleaning.

After selecting the site and preparing the tires, you can proceed to the sewer pipe, which should be laid to such a depth that the drains do not freeze during the winter period. On top of the pipe you need to wrap any heat insulator that is resistant to the negative effects of external factors. When installing the pipe, it is necessary to form a slope necessary for free flowing of liquid into the reservoir. In addition, such an arrangement of the pipe will prevent the water from freezing during the winter period: it simply will not have time to freeze before it enters the septic tank.

After laying the pipe, the reservoir of tires should be buried in the ground in such a way that the assumed liquid level is slightly lower than the soil freezing line. It is recommended to put roofing material or dense polyethylene under the bottom of the settler. And in order that the tires do not move relative to each other, it is recommended to reinforce them with vertically dug poles or posts.

Sewage septic tanks are an important part of the sewage treatment plant, doing the dirtiest and most difficult work and preventing pollution of the soil, drinking water sources and groundwater.

For information on how to install a sump for sewage, see the following video.