Features of the powder coating process

Powder paint has been used for quite some time. But if you do not own the technology of its application to the necessary degree, if you do not have the necessary experience, you will have to thoroughly study all the information in order to avoid mistakes. It is precisely to their prevention that we dedicate this material.

Special features

Powder paint is made from polymers, which are powdered and then applied to a specific surface by spraying. To give the coating the desired properties, it is thermally treated, the molten powder turns into a uniform film in thickness. The key advantages of such a material are corrosion resistance, significant adhesion. Under the action of high temperatures, including when alternating with low, powder paint for a long time retains its positive qualities.Mechanical and chemical effects are also well tolerated by it, and contact with moisture does not violate the surface.

All these advantages powder paint retains for a long time along with the external attractiveness. You can paint the surface, achieving a variety of tonalities and textures, varying the input additives. Matte and glossy shine - only the most obvious examples, this decor is created with powder paint easily and quickly. But a more original painting is also possible: with a three-dimensional effect, with the reproduction of the appearance of wood, with an imitation of gold, marble and silver.

The undoubted advantage of powder coating is the ability to complete all the work with the application of a single layer, when working with liquid formulations this is unattainable. In addition, you will not need to use solvents, and monitor the viscosity of the paint and varnish composition. All unused powder that did not hold onto the desired surface can be collected (when working in a special chamber) and sprayed again. As a result, with constant use or with large one-off amounts of work, powder paint is more advantageous than others.And the good news is that there is no need to wait for the drying layer to dry.

All these advantages, as well as optimal environmental friendliness, no need for powerful ventilation, the ability to almost completely automate the work should be taken into account.

Do not forget about the negative aspects of this technique:

- If a defect appears, if the coating is damaged during operation or subsequent use, the entire object or at least one facet of it will have to be repainted from scratch.

- At home, powder painting is not carried out, it requires very sophisticated equipment, and the size of the chambers limits the size of the painted objects.

- It is impossible to tint the paint, it is also impossible to apply it to the parts, structures that are to be welded, because the burnt parts of the paint layer are not restored.

What surfaces can I use?

Powerful adhesion makes powder dyeing method ideal for stainless steels. In general, when processing metal products for household, industrial and transport purposes, powder is used much more often than liquid formulations.This is the way the components of warehouse and trade apparatuses, machine tools, metal pipelines and wells are painted. In addition to the ease of application, the attention of engineers to this method of treatment attracts the safety of paint in fire and sanitary terms, the zero level of its toxicity.

Forged structures, products made of aluminum and stainless steel may well be painted by powder method. Practiced this method of coating and the release of laboratory, medical equipment, sports equipment.

Products from ferrous metals, including those with an external zinc layer, ceramics, MDF, plastic, can also be a good substrate for powder coating.

Polyvinyl butyral-based dyes have enhanced decorative properties, are resistant to petrol, do not conduct electrical current, and tolerate contact with abrasives. The ability to survive the ingress of water, even saline, is very useful when creating pipelines, radiators, other communications that come into contact with the fluid.

When applying a special powder to the surface of the aluminum profile, the priority is not so much protection against corrosion, as giving a beautiful appearance.Be sure to select the mode of operation, depending on the composition of the dye and the characteristics of the substrate, to take into account the specific equipment. The aluminum profile with thermal insert is treated for at most 20 minutes when heated to no higher than 200 degrees. The electrostatic method is worse than tribostatic when painting metal products with blind holes.

The use of fluorescent powder paint is practiced when working on road signs and other informational designs, when the glow in the dark is more important. For the most part, aerosol formulations are used, as the most practical and creating the most even layer.

How to breed?

The question of how to dilute powder paint, in what proportion it is necessary to dilute it before applying the coating, in front of professionals is not worth it in principle. As you already know, staining with this kind of paint is made in a completely dry form, and no matter how much the experiment lovers try to dilute, dissolve this mixture, nothing good will come of it.

Consumption

The appeal of powder paint is beyond doubt. However, you need to accurately determine the need for it, find out how much the coloring composition leaves per m2.The minimum thickness of the created layer is 100 microns to reduce the use of the dye, it is desirable to spray it. Aerosol application allows you to spend from 0.12 to 0.14 kg of material per 1 square meter. But all these calculations are only approximate, and allow you to determine the order of numbers.

An accurate assessment can be given, knowing the properties of a particular type of paint. and the characteristics of the substrate on which it will be applied. Remember that the norm, indicated on labels and packages, painted on advertising posters, implies the coloring of the surface, which does not contain any pores at all. Plastic or metal have only a slight porosity, and therefore even painting them, you will need to use a little more dye than the manufacturer prescribed. When other materials need to be processed, costs will increase significantly. So you should not be indignant when you find “inflated” numbers in the bills for powder coating services.

There is a decorative, protective and combined coating, depending on the belonging to a particular group, a layer of different thickness is formed. Also take into account the geometric shape of the surface and the difficultiesworking with her.

Coloring

As you already know, at home you can not paint anything with powder paints. The main difficulties in using them on an industrial scale arise during the preparatory work. The technology provides that it is necessary to remove the slightest dirt from the surface and degrease it. Be sure to phosphate the surface so that the powder adheres better.

Failure to comply with the method of preparation will lead to a deterioration of the elasticity, strength and visual appeal of the coating. It is possible to remove dirt during mechanical or chemical cleaning, the choice of approach is determined by the decision of technologists.

To remove oxides, corroded areas and scale, often use blasting equipment, spray sand, or special granules of cast iron, steel. Abrasive particles throw compressed air or centrifugal force in the right direction. This process occurs at high speeds, so that foreign particles mechanically beat off the surface.

For chemical preparation of the painted surface (the so-called etching) used hydrochloric, nitric, phosphoric or sulfuric acid.This method is somewhat simpler, since there is no need for sophisticated equipment, and the overall performance increases. But immediately after etching, you need to wash off the remnants of acids and neutralize them. Then a special layer of phosphates is created, its formation plays the same role as applying the primer in other cases.

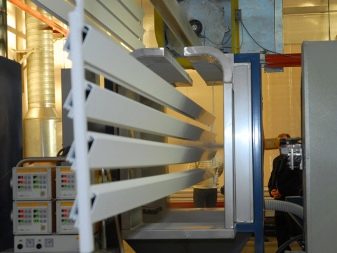

Next item must be put in a special chamber: it not only reduces the consumption of the working mixture, catching it, but also prevents the paint from contaminating the surrounding room. Modern technology is always equipped with bunkers, vibrating screens, means of suction. If you need to paint a big thing, use the type of cameras through passage, and relatively small details can be processed in dead-end devices.

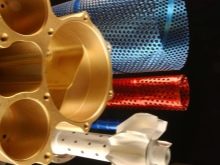

In large industries use automated cameras for painting., in which they build a pistol format manipulator. The cost of such devices is quite high, but obtaining fully finished products in seconds justifies all costs. Usually the sprayer uses an electrostatic effect, that is, the powder first receives a certain charge, and the surface - the same charge with the opposite sign.The pistol “shoots” not with powder gases, of course, but with compressed air.

Only this work does not end there. The billet is placed in a special oven, where it is covered with a viscous layer at an elevated temperature; with further aging, it dries and becomes uniform, as strong as possible. The processing rules are very strict, therefore it is required not only to use professional equipment, but also to entrust the whole process exclusively to specialists. The thickness of the paint layer will be small, and its exact value depends on the particular composition used. In some cases, you can replace the soil with another pre-applied paint, necessarily from inorganic components.

Please note that any material can be painted with powder only in a protective mask.regardless of whether you are sure of the tightness of the chamber. It is categorically impossible to polish the powder paint, it is applied once and then can only be repainted or removed completely. Always check the applied layer using a thickness gauge to verify the accuracy of the words of the masters and the accompanying documents.

The process of powder coating, see below.