How to choose the laminate?

Laminated flooring is used everywhere and has long occupied its niche in the consumer market. In construction hypermarkets you can see a rich selection of laminate of different colors, types and quality of materials. The buyer, who first encounters such diversity, always asks the question to himself and the seller: how to choose the right laminate flooring for the room? In order to make the right choice, it will not hurt to become more familiar with the specifics of this material, its characteristics, advantages and disadvantages and only after that make a decision.

What is laminate flooring?

In everyday life laminate flooring is called laminated flooring. Its price is much lower than that of parquet made of natural wood.Of course, the aesthetic characteristics of the laminate is always very high, and the cost is directly dependent on what materials and technologies are used in its manufacture.

The word "laminate" in translation from English means nothing more than "material from several layers." It is based on chipboard, paper laid in layers, and laminated film in the form of melamine or acrylic resin. It is this film that serves to protect the main layers from contamination, moisture and possible mechanical damage.

In the production of chipboard, the underlying laminated coatings, wood materials are associated with composites and are compressed under high temperatures. This process provides boards density and increased degree of strength. Laminated film or paper having a moisture resistant impregnation is applied on top of the coating. It can be depicted woody texture, the pattern can be "marbled" or any other, thanks to the achievements of modern design developments and technologies.

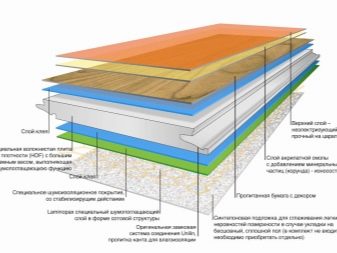

Usually laminate has four layers, each of which performs a specific function:

- The layer "overlay" is on top, you can touch it and see. This is the same film that prevents not only moisture and dirt, but also protects the coating from the sun, preventing it from fading. Depending on the quality level of the laminate, the film can also be laid in two or even three layers, which gives it additional protection.

- The transparent film is followed by a decorative layer. This is an external design, made in the form of any pattern or pattern. The decorative part is made of paper, its color and texture can be any.

- The main layer that is under the picture is the carrier part, which determines how long the laminate will last. To put it in simple terms, this is the very board of wood chips, which has a different degree of resistance to stress and moisture, as well as to mechanical stress.

- The last coating layer is also represented by paper, which is impregnated with resin with a special composition. This is done to protect the inner surface of the wood from deformation and moisture in a changing temperature.

Kinds

There are a large number of varieties of laminate that can be used in different places and rooms, depending on the needs of customers. One of the most fashionable and popular is laminate, made "under the stone." Statistics show that the level of production of such coverage is about 15 percent of all produced copies: their demand is growing.

Stone imitations have many advantages, both aesthetic and practical. Thanks to modern equipment, the level of imitation is so high that, at first glance, it is impossible to distinguish such a floor from a real stone one. Not just the appearance of the stone is copied, but also its structure (natural unevenness, defects). The moisture resistance and durability of this laminate is beyond doubt, and natural stone is also cold, and the laminated coating retains heat well thanks to wood components.

If you think about which laminate is best suited for a living room, it is important to take into account its high permeability: after all, it is often where all family members and guests gather.Therefore, first of all, it is worth thinking about buying a high-end product so that in a short time it does not have to be changed urgently.

The class of the product should come first, however, and the color scheme is also important. You should choose a color that will fit well with the furniture, living room style, the color of its walls. The choice of colors always allows you to choose the best option for any living room, and if it is small, designers recommend to opt for any light shade, for example, to imitate a coating under bleached oak, ash or maple.

It is possible that many will be surprised, but there is also a street laminate that can withstand all weather and humidity conditions. It has its own specifics and is not deformed when the temperature fluctuates from minus 20 to plus 30 degrees. There are companies that specialize in the manufacture of outdoor types of laminate, producing coatings of a high degree of strength and reliability, which can serve in street conditions for at least 15 years.

Outdoor laminate is made of sturdy plastic, which has been subjected to special processing technology.The drawings have a beautiful structure, most often they imitate natural wood. Assembly is easy, without the use of adhesive materials, with the help of special locks. The main subtlety that should be taken into account in the process of laying: since with increased strength the thickness of such a coating does not exceed five and a half millimeters, the surface must be absolutely flat.

Material selection

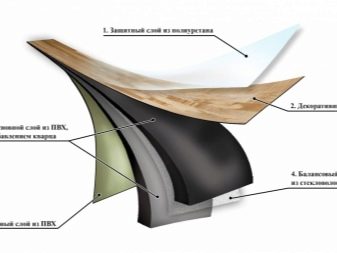

Laminated coatings are made not only from chipboard. For those consumers who have no prejudice against cutting-edge types of material, the developers have invented a flexible laminate, which is also called soft, rubber or vinyl flooring. These are usually rectangular tiles, but sometimes square elements can be found.

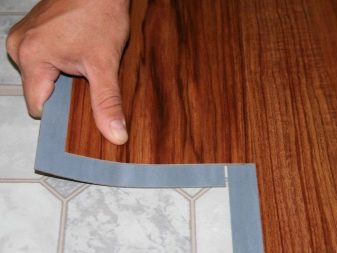

"Rubber" laminate, in contrast to the multi-layered chipboard version consists of only two parts: on top there is a dense vinyl structure consisting of a special type of PVC film. The composition of the upper part includes a large amount of quartz sand, which suggests a high performance of the product in terms of its operation.Below is a rigid base, shifted slightly to the left and equipped with adhesive tape.

Any vinyl coating is ideal for those rooms in which there is an increased level of humidity. The range of its application is very wide: it is found in residential buildings and premises for commercial purposes. Halls, kitchens, corridors, bathrooms and hallways - the most popular places in the residential sector, in which this cover is simply indispensable. Its color can be any: if you wish, you can find or order such a laminate with imitation “under a stone” or under a tree: birch, beech, wenge, bamboo, depending on which style or tone is preferable and most suitable.

There are different types of vinyl laminate. For example, the vinyl-quartz version is very practical and durable due to the quartz crumb present in the composition. Its other type is PVC tile, which is produced by strong pressing with the addition of vinyl materials and epoxy resins. Perhaps the most unusual of all is a vinyl laminate with a mirror coating that helps to realize the original design ideas.

Dimensions

When choosing, it should be borne in mind that the board size often depends on its strength. Typical parameters of boards - thickness from 7 to 12 mm, their length is from one to two and a half meters. As for the thickness of the board, its size varies from 6 to 12 mm. The thicker the chipboard, the higher the cost of the coating as a whole, but the sound-proofing characteristics increase significantly.

A wide laminate should have an appropriate thickness, proportional to the possible load.

Colors and colors

As already mentioned, regardless of the nature of the material that is used in the manufacture of laminate, its colors can be any. Construction hypermarkets abound in high-end products from light to very dark colors, between which there are a lot of shades, and therefore a wide choice.

Products made of chipboard skillfully convey not only the color of the nut, but all shades of brown. For lovers of brighter tones there is a beige, cream or even peach laminate on sale. Vinyl coverings do not lag behind the chipboard in terms of a variety of colors: one of the most popular shades is smoky, and if you like, you can even find a color laminate replete with fancy patterns.

additional characteristics

Waterproof and wear-resistant types of coatings are products of a higher class than the "two", from the production of which many firms have already refused. Moreover, in addition to the coating layers already listed, manufacturers can add several additional layers to their product in order to maximize its quality. In order to increase the level of strength, a layer of corundum or aluminum dioxide can be added to the laminated coating.

An antistatic layer is also sometimes added to prevent dust from sticking to the surface. This is very important for those rooms in which wet cleaning is done less frequently. Of course, the addition of additional layers increases the weight of the laminated blocks, which should be borne in mind when mounting the structure.

Classification and labeling

Each laminated coating is characterized by varying degrees of strength. Depending on this, the laminate is divided into classes after eighteen tests. There is a so-called European norm, on the basis of which the laminate is assigned the marking accepted by the norm. It consists of a two-digit number.The first number indicates the type of premises in which it is recommended to lay this type of laminate, and the second indicates how intensively it can be used. In this case, 2 is the residential sector, 3 is commercial, and 4 are production facilities:

- First group coatings, labeled 21 to 23, are recommended for residential use. This group is called "household laminate." Laminate, having such a marking, is designed for operation in residential buildings or in rooms with low traffic, in which the load on the floor surface is low.

Such coverage does not last long - from three to five years, but it may well be suitable for a bedroom or basement. Due to the low wear resistance in the leading manufacturers of laminate such marking is discontinued.

- Second group of coatings, marked with markings from 31 to 37, was called “commercial laminate” and was initially used in offices, banks, shopping centers - where the permeability is higher and the floor load is much greater. Later, these coatings were used in residential areas, because the first group did not justify itself in terms of strength and longevity, which was the reason for the termination of the production of laminate markings 21-23.The cost of such coverage is much higher, but it fully justifies the money spent on it and can serve from 6 to 10 years.

- Third group It is presented with markings from 41 to 43 and is made more often by special orders for production premises. It is called "premium laminate", which is the most durable and wear-resistant. For example, the 42nd class of laminate can be found at the Moscow Sheremetyevo Airport.

Types of Mounts

There are two methods by which laminated plates are attached to each other. They are fixed either with glue or special "locks". Laying boards with glue is much less common than with locks, mainly because of the complexity and duration of the process.

However, provided that the work is carried out with high-quality glue, the quick-drying glue provides a reliable connection of the panels, leaving no gaps. Increases the level of resistance of the product to moisture.

A significant disadvantage of glue fixing is that partial repair of the coating becomes impossible.

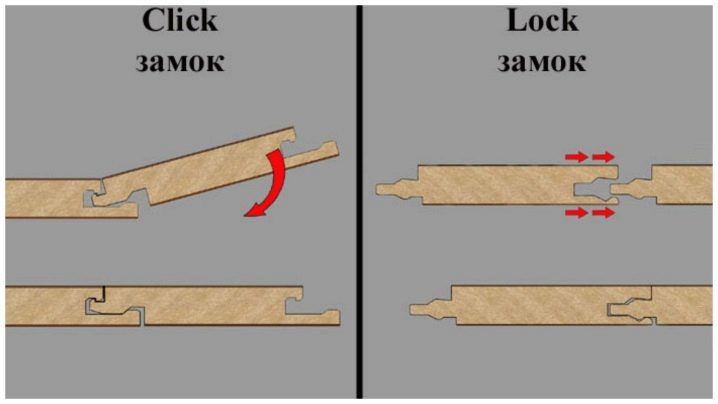

Leading companies for the production of laminate no longer use adhesive fasteners and believe that locks are the most convenient and fastest way of laying.At the edge of each laminated plate there is a special mount that can vary, depending on the type of construction. Locks come in two forms: “lok” and “click”. “Lock” is very simple: on both sides of the panel there is a “groove” and “thorn” of a certain shape. When the panels are assembled with each other, one “thorn” is gently hammered with a hammer into the “groove” of the neighboring one and just snaps into place.

Laying models with a similar design of locks is best done by professional experts. Locks are quite fragile, and are very easily damaged if the handler does not know about their features.

If you plan to disassemble the coating or install it in another place, you will not be able to do it yourself.

Locks of the "click" type are mounts collapsible type. They are more modern and developed much later than the more primitive and fragile “lok” locks. Their construction itself is more complicated, it eliminates all possible disadvantages of the previous type, but the assembly process is much easier: even a not very experienced amateur can assemble such fixings. To do this, connect the panels at an angle of 45 degrees, without using any scrap materials additionally.

Thanks to this modern and simple way of laying, there was a great opportunity to lay a laminated coating without causing him any damage. Moreover, this method prevents deformation of the panels, which may appear during intensive use. Since the glue is not used for this installation, and additional protection against moisture never hurts, you can handle the joints and the locks themselves with any sealant.

Accessories

The set of components required for laying laminate is quite simple and differs little from the set of tools and accessories that are used for other construction works.

On the substrate of cork or polyethylene foam laminated panels are laid. A jigsaw complete with a knife designed for laminate, will help to "fit" the lamella to the desired size. Glue-sealant will strengthen the moisture-insulating properties, and to eliminate small technical gaps will need corners, wedges and plastic linings for pipes. As for the walls, you will need to pre-purchase baseboards of the appropriate color and quality: it is important to remember that cheap plastic baseboards will not fit into the big picture if the floor itself looks expensive and solid.

Of the tools, except the jigsaw, always have a tape measure, a hammer, a ruler, wooden cant and a square at hand.

Style

Like many other floor coverings, laminate can be made in one or another style, especially considering the possibilities of modern technologies and design skills:

- Classic style ideal for arranging an office or living room. Furniture in the style of classic is usually massive, heavy, dark tones, made of natural wood. For solid furniture and strict lines should select a high quality laminate, made with imitation wood. It is better to choose colors and shades of dark - everything will depend on what the overall picture is formed in the living room, based on the overall color scheme.

- If the room is decorated Provence styleThis implies furniture and flooring, which are “aged” using special techniques. This creates an atmosphere of a cozy village mansion in bright colors. Sometimes it is believed that neither linoleum nor laminate is suitable for the design of such a room, but now it is possible to find a laminated coating with the effect of “aging”, which will look like natural wood floorboards. Colors are better to choose white, cream or peach.You can limit the choice of high-quality white laminate, while vinyl products are not recommended to use, it is better to give preference to the more natural options.

- Laminate country style also applies to coatings that mimic natural wood materials, and each of its elements is made with a real presence of reliefs and bumps and is very similar to a piece of wood processed by hand. There is also grinding and varnishing.

Decor

Decorative laminate is different. Panels can have beautiful glossy gloss with a silky shade. The surface can be covered with a waxed layer or create the effect of natural wood, which is covered with oil paints. Also on the panel skillfully applied unusual texture in the form of three-dimensional drawings to give them even greater naturalness.

Laminate with a glossy design looks very bright and attractive, but it has one big disadvantage: it slides a lot and there are always traces of bare feet on it. This is the most common and inexpensive type of laminate.

The surface that imitates natural tree species has a high-quality drawing of all the details: from knots with a characteristic texture to wood pores.Waxed panels are very reminiscent of vintage style: it is known that it has long been popular to rub wooden floor with natural wax to make it smooth and shiny. Also, a vintage variety can be considered a laminate with the effect of wood, painted with oil paints.

Design

Among the models of laminated products, you can find options of both conventional design and very original ones that look very special and do not fit into generally accepted standards. This is a separate segment of the market, which is commonly called a design laminate - models with a specific appearance. Their colors can be the most incredible: bright blue or light green, silver or golden - due to the fact that there are no technical obstacles in the production of decorative varieties for a long time. There are options that very successfully imitate natural grass, stone, sea surface.

Also popular laminate with registration in the form of geometric shapes of varying degrees of complexity. By the way, the laminate of completely white color also belongs to the design direction.

Non-standard appearance and its originality can lead the buyer to the idea that when creating such masterpieces some special production technologies are used. In fact, this is not the case, and the main technical characteristics and operating properties of this type of laminate have no differences from the most common coatings. Their structure has four layers, and resistance to moisture and shock is very high.

The only difference, of course, is, and it is in the technique of the top layer of decor. This is a special kind of strong paper or cardboard. It is based on polymeric materials, which provides high-quality application of the desired image. Drawing is applied using industrial printers, its texture and style are absolutely unlimited.

How to choose?

The right choice of laminated coating depends largely on how intensively its use is planned. As already mentioned, if the room will have a large permeability, the quality should choose a laminate with high technical characteristics of strength and durability.It is known that some Chinese firms still allow for retail sale of cheap laminate class 21-23. Despite the temptation of the price, it should not be purchased even in order to lay in the bedroom, where, seemingly, the patency is not as intense as in the living room or in the kitchen.

Regardless of where the laying of the laminated coating is planned, it is better to buy models with markings from 31 to 37. It is among the “representatives” of this marking that it’s realistic to choose a coating that will serve for many years.

Many buyers often ask sellers the question of whether there is a natural laminate and where to buy it. If you know that any laminated coating has several layers, including both natural and synthetic components, such questions do not arise. When it comes to a solid wooden board, it will no longer be a laminate, by definition, since the plank floor does not provide for any additional layers.

As for the concept of naturalness and naturalness, then if a person wants to choose a laminate with more close to nature characteristics, it makes sense to immediately offer him high-strength options, which are based on chipboard.Such a coating looks more natural than vinyl or plastic, and its versatility allows it to organically fit into any interior style, regardless of its level.

For a home or apartment, it is best to buy a laminate of chipboard of good quality. It can be laid in any room, it will look natural and comfortable. If the house has small children or animals, you should not opt for an attractive glossy finish, which is prone to dirt. It is better to give preference to unobtrusive matte options with a reliable upper layer, which is unpretentious to external influences and does not require special treatment.

In places with high humidity (for example, in bathrooms or basements, as well as places of industrial use), vinyl laminate class 31-37 is ideal. It should be remembered that some vinyl coatings after they are laid, it takes some time to weather toxic substances of polymeric origin. Also, allergy sufferers are not recommended to stop their choice on them, despite the fact that the increased resistance to moisture and unpretentiousness of this option seem very attractive.

Designer types of laminate, ranging from products of classic soft white color to models with bright color drawings, are ideal for decoration of art studios, art spaces, clubs with certain specificities, psychological counseling rooms.

Advantages and disadvantages

Like any material, laminate has its advantages and disadvantages:

- Its main advantage is the ease of care, as well as resistance to mechanical stress in the form of legs and wheels of furniture, studs, sharp heels. Good quality products are manufactured with waterproof coatings of various levels, all of which are environmentally safe. Due to heat treatment in the manufacturing process, the product withstands high temperatures: for example, if a cigarette butt or a match falls on it, the coating will not melt and not deteriorate.

- Also, the laminate is well tolerated by chemicals that may be randomly on its surface. Nail polish and paint can be safely removed with acetone without damaging the color or structure of the coating, without leaving any traces of the solvent.

- Laminated flooring, unlike parquet, can be purchased at a reasonable price.

- As for technical issues, it is quite simple to lay laminate on your own - it is enough to have simple construction skills for this.

- Of the minuses, it is worth noting that the edges with which the boards are held together with each other may not be of very good quality, which leads to the “razdezhaniyu” boards during operation.

- Also, not all types of coatings are durable and durable: it is known that cheap brands, which can still be found on sale, serve no more than seven years. Thus, when buying it is worth paying close attention to the class and labeling, and not to be conducted on cheap options that will not justify themselves.

- Parquet, of course, is much more expensive, but its experienced owners know such a “salvation” method of its restoration as scraping. Laminate can not be scraped because of the layering of its material. If any boards are suddenly damaged, they will have to be completely changed, therefore, when buying a floor covering, it is better to purchase several spare boards of the same color and quality.

- And the last minus of a laminate to which especially sensitive customers can pay attention is its high resonating ability. If any object falls on the cover (and it doesn't matter if it is light or heavy), the sound from falling will always be very loud. This is due to the properties of chipboard, which are the basis of the composition: when something falls to the surface, they amplify the sound.

Useful stuff

If in the rooms where the laminate is laid, there are pieces of furniture on wheels (working chairs, mobile bedside tables), a polycarbonate mat for parquet and laminate can be a very useful additional acquisition. Even if the coating class is the highest, one should take into account the fact that with a regular and uniform mechanical impact on it in the same place, traces may eventually appear. Therefore, the acquisition of such a simple and inexpensive things will never be over.

The mat for parquet and laminate is completely transparent and may not even be immediately noticeable. It does not spoil the interior of the room at all, is easy to clean and is resistant to any mechanical stress.You can lay it not only in the apartment, but also in the office, for example, in those places where the “trampling” of the laminated coating increases dramatically: office reception, installation of a printer or a shared computer, coffee makers, etc. 2000 rubles. Polycarbonate does not turn yellow with time, it always remains transparent, without losing its aesthetic properties, which is important in the presence of a high-quality and beautiful laminated coating.

The rug is interesting in that it can appear both opaque and transparent at the same time. It has a rough surface, which is very convenient when moving the wheels of the chairs: they do not roll back beyond the area of the rug. When buying, you should pay attention to the edges so that they do not look slovenly, and also to ensure that the chair slides off the edges as gently as possible (a special cut is provided for this on high-quality floor mats).

There are also cheaper options for such rugs made of PVC, but they are not as durable and aesthetic as polycarbonate products.

Famous manufacturers - firms and customer reviews

Among the most popular manufacturers include the followingcompany:

- Swedish company Pergo the first in the world began mass production of laminated flooring. It has been operating in the market since the late 70s of the last century and is still the recognized world leader in the production of laminates of various types. The company's specialists carry out a clear control of each stage of the production cycle, which is an indisputable guarantee of quality and reliability. The class of laminate produced by this company is 32-34. She also makes resistant vinyl and parquet flooring.

- Brand "Berry Allock", according to customer reviews, is the most worthy Belgian brand of laminate. It appeared through the merger of several Belgian and Norwegian companies with vast experience in the production of laminate and parquet. The HPL technology, successfully applied by specialists, ensures the production of high pressure pressed coatings that have the highest degree of strength.

- Family business from Germany Kaindl Flooring It has been around for 120 years, its history is closely connected with the development of woodworking. This is the largest full-cycle plant, engaged in the manufacture of laminated coatings under this brand for a long time.Brand "Kaindle" in other countries is clearly associated with buyers with high-quality goods. It was this company that in 2009 won the competition for the best European manufacturer.

- German firm Haro It produces not only laminated coatings, but also durable cork substrates. Products of this company are supplied more than in 80 world countries, and trendy finishes of the decor are becoming increasingly popular with consumers. The class of laminate that Haro manufactures is represented by grades 31-33 with an impressive thickness of coatings: from seven to ten millimeters. Pictures perfectly imitate the surface of any tree, and special substrates that prevent excessive sound effect have long become a kind of business card of this company.

- Co-production Tarkett (Russia-Germany) specialized in the manufacture of coatings of vinyl and carpet type since the late 80s of the XX century. However, after ten years Tarkett has time to develop into a concern and starts producing laminated coatings of various directions. The largest plant was launched in 2010 in the town of Mytishchi, Moscow Region. Brand coatings - 32-33, it presents at least 30 different collections.Due to the fact that the largest enterprise Tarkett is located in Russia, a great opportunity has arisen for the domestic consumer to purchase high-quality laminated coating at a very reasonable price.

- Belorussian manufacturers The laminate is represented by two well-known competing plants: Kronospan and Gomeldrev. Kronospan started producing laminate not so long ago, in 2014, but already managed to acquire fans of its products, having established itself as a manufacturer of high-class coatings 31 and 32. Among them are more than 20 decorative varieties, whose scope of application expands from year to year. As for the company “Gomeldrev” - due to the presence of modern German equipment, it represents a serious competitor for Kronospan in all respects and even slightly ahead of it, standing at the turn of the manufacture of coatings of class 33 and above.

Modern news and options

One of the worthy innovations in the market of laminated coatings is the Aqua floor from the company HDM. The class of laminate is 31, it is characterized by absolute water resistance and enviable durability, which makes it possible to use it for facing a kitchen apron and even for finishing a balcony.Decorative design fully adopts the color and texture of wood, and such a laminate looks exactly like a real wooden floor. Due to the presence of a special protective film, it is not affected by direct solar radiation, does not fade and does not lose over the years neither color nor properties. This laminate can be laid even if the floor heating system is planned to be installed in the room.

The same company HDM has released a design coating Superglanz, which translated from German means "supergloss, mirror." Mirror shine surprisingly combined with the original color compositions in the form of "expensive" finishes: precious woods, parquet, polished varieties of stone. Wear resistance is very high, and the production technology due to the presence of such a component as acrylic resins is absolutely safe.

The priceless novelty of 2017 is a “quiet” laminate, the name of which speaks for itself. The German company Haro has created the most silent type of laminate in the world. Specialists invented the coating Tritty Silent ST, which has unique insulating properties.The noise level can be reduced by more than 50 percent, which is confirmed by both consumers and numerous experiments. This view is also well combined with the “warm floor” system.

"Quiet" laminate attached to the floor is very reliable - using self-adhesive material, does not leave gaps and gaps when laying and has a layer thickness of at least ten millimeters. It is also famous for almost a hundred color options and a 25-year warranty. It is pleasant to the touch, it does not require “drying out” before use, it is ready for operation immediately after the completion of all work.

Professional tips

- The service life of a good laminated coating with a decent handling can last up to 15-20 years. When planning its purchase, it will be useful to remind once again that laminate is not parquet, and any attempt to revise it, remove the top layer or make “deep cleaning” can be fatal. The wooden board is a solid piece, and the laminate is made of several layers of different materials.

- You need to take care of him as you would any floor: sweep with a broom, clean with brushes.He does not resist wet cleaning, but does not tolerate any polishing agents or wax. In case of serious contamination, it is recommended to use products that are specifically designed to care for the laminate. Despite the fact that such funds are expensive, they will not leave unnecessary stains and are safe to cover, because neither soap nor acidic substances are included in their composition. After cleaning on the surface should go with a damp cloth dipped in clean water.

- When rearranging furniture, moving it indoors with a laminate should be as carefully as possible so as not to damage the decorative coating. If there is furniture in the room that is rearranged from time to time, it is recommended to uphols her legs and other parts that will come into contact with the floor. It is best to lift the furniture when moving, it will help once again keep the cover in its original form. If any liquid is spilled on the laminated coating, it is desirable to immediately remove it, because the stain may appear very quickly and will have to be cleaned very long and hard.

- It is good to clean greasy and sticky dirt using a comfortable mop with a soft brush.The brush should not be very wet, its moisture is enough to remove these contaminants. It should be borne in mind that not all laminated coatings have a sufficient degree of moisture resistance.

- Movement should be carried out parallel to the laminate strips, more precisely, their long sides. It is recommended to change the water more often than when cleaning the usual floor - this will help to avoid hard parts of the dirt getting on the coating again. Products specifically designed for cleaning laminate can be added to clean water in small portions. Usually, the instructions indicate the amount that should be added, it depends on the type of product and the concentration of cleaning components contained in it.

- If you buy special equipment is too expensive, you can use the usual soap solution - alkali laminate does not hurt, and cleaning will be good. By the way, there is a wonderful popular recipe that will significantly save money. For five liters of pure warm water, add one tablespoon of vinegar. In the case of heavy dirt, the hallway can be washed with a simple shampoo solution,intended for children in the ratio of one tablespoon to two liters of shampoo.

- The appearance of stains on the laminated coating should always be carefully monitored. But if, however, it happened to encounter a complex spot, it can be removed in the following way: first, the stain should be treated with neutral acid cleanser. If there is no effect, try rubbing it with alcohol.

- Stains appearing from lipstick and shoe polish are well removed with cotton pads of white spirit or acetone. Also traces from pencils and felt-tip pens are also displayed. In the case when the spot from the marker can not be, it can be smeared with ordinary toothpaste, leave for a few minutes, and then wipe with a dry and soft cloth.

- Black marks from rubber soles are well cleaned with a dry sponge for kitchen utensils, more precisely, its reverse, more rigid side. Often they are well cleaned with a regular eraser or a weak solution of soda. Nail polish can be cleaned with ordinary laundry detergent.

- Chewing gum and wax from candles should not be removed immediately after falling on the laminate. You need to wait for the moment when they completely harden, and then carefully remove them with a soft plastic scraper.The process of complete curing of chewing gum can be accelerated by putting a bag with some frozen product on it. Do not use a metal spatula in order not to scratch the surface.

- Despite its high strength and durability, the laminate needs special care. It is not difficult to get used to it, and if all the necessary recommendations are followed along with careful handling, it will serve the prescribed 15-20 years, and maybe even longer.

Our video will tell you how to choose laminate and how to combine colors in the interior.