Repair and restoration of laminate

Everything that is in use and often used is subject to wear and durable laminate flooring is no exception. After a period of time and under various circumstances, small defects and substantial damage may appear on it.

With high probability, problems arise in violation of the technology of laying boards or tiles, as well as violations of the basic rules of operation. Miscalculations when laying, flooding by water, walking in footwear and many other mechanical influences lead to inevitable consequences.

Restoration and restoration of laminate - work that requires attention and a serious approach. Removing minor scratches with your own hands is not difficult, whereas with significant damage you will need the help of professionals.

Causes of defects

Negligent handling of laminate boards or tiles leads to damage. Mechanical impact from walking in shoes, moving the overall furniture, dropping heavy objects lead to a violation of the integrity of the protective layer of the product. To reduce the risk of defects, it is recommended to sheathe the furniture legs with fabric covers, make rubberized wheels for computer chairs and lay mats in places of the greatest possible terrain. To the circumstances leading to the violation of the integrity of the coating, the flooding of the apartment and the breakthrough of the heating pipe are also counted.

Moisture irreversibly spoils unprotected lock joints and causes boards to be partially or completely unsuitable. As a result, flooring often requires replacement with new flooring.

In the case of improper installation, irregularities, bumps, dents creaking, swelling and other defects appear. This leads to aesthetic discomfort and unsightly view of the entire interior as a whole.

Possible problems

Repair and restoration of flooring is made in the following ways:

- Without disassembling the fabric.

- With the disassembly of the canvas.

It is possible to repair damaged laminate boards in the apartment by disassembling the floor, as well as using a cutting tool to eliminate areas with defects.

To replace the damaged part of the coating it is necessary to prepare a new panel of the same color and texture. It is best to dismantle the damaged product and try to find the right option in the store with it. Remember that a new laminate before laying should be maintained in room conditions for at least three days.

In the case where the coating is mounted with locking connections, the floor is disassembled. All you need is a mount, a chisel and a screwdriver. The method of sawing and removing the damaged board can be used. Repairing the floor with a parsing method is more difficult than replacing without disassembling the web. The first option will require expert advice.

To save time and money, order laminate with a complete spare kit. The advantage will be a pair of similar boards required for repairs.

Fails floor

In those cases, when under the cover is uneven ground, the plywood is rotted, the floor begins to sag, fall.To eliminate the defect, it is enough to disassemble the laminate in this area and mix the lining under the cover. The option is relevant for the castle type of laying. The lining material must be resistant to mold and tight against moisture. Such materials as polyfoam or plastic perfectly will be suitable for this purpose.

When the floor is disassembled, for convenience, each panel can be numbered. Some experts recommend to drill a small hole in the places where the floor falls, and pour mounting glue.

Broke up

Laminate flooring does not differ much in comfort when walking barefoot on it, therefore, for a pleasant movement, it is often used to heat the infrared system “warm floor” on which this flooring is laid. Its main difference is in the way of heating the room: heat is transferred to the wall, furniture, through them it passes into the air. There are cases when a laminate has led from overheating of the film floor, it diverges at the seams and joints. The reason may be poor installation and unevenness of the base. This is revealed when disassembling the laminate.

It is possible to eliminate the defect without disassembling the panels. If the seams are loose, and the gaps are insignificant, then they should be treated with a sealant. On wider gaps such a “patch” will be noticeable. In this case, the floor gets over and with the help of belts is tightened. Dismantling begins at the walls. A repair kit can be purchased at a specialty store or rented for the duration of the restoration of the floors. The set includes belts, wedges, podbivka and bar.

Also, the divergence of the panels is possible with insufficient bonding and poor-quality adhesive for laminate. Gluing the panels together with epoxy glue laminate quality bonded.

Swelling

Often a swelling forms on the coating. In this case, the floor covering bends and departs from the floor immediately or after a period of time after installation. Damage of this kind occurs in rooms where the screed has not been sufficiently dried. The bulging noticeably deforms the joints and the panels themselves, delivering inconvenience and giving an unaesthetic appearance to the coating.

You should move the furniture from this room and dismantle the baseboards. A common reason for the expansion of the laminate may be insufficiently wide gaps between the walls and panels.Laminate can rest against the wall and begins to swell under pressure. If the gaps are absent or very small, it is recommended to slightly trim the laminate with a chisel.

"Playing"

The reasons when under the feet of "playing" laminate is enough. Uneven floors can cause this defect. Even with a seemingly ideal laying job, there is a high probability that unsuccessful floor level drops will create some unevenness.

A non-sized substrate may also cause a defect. Under the castle types of laminate is recommended to use the appropriate substrate. Often the cork substrate layer under the floor becomes thinner, this creates unevenness on the surface. In this case, the laminate is dismantled to check the level of the floor and shift again.

Mold

There are cases when the humidity is not felt, but on the boards themselves there is a kind of bloom. This is a type of fungus, the cause of which is not always damp. Presumably, it is logged with already infected boards.

Mold formation is common. High humidity and high temperature are a convenient habitat for fungi and mold.The reason for its appearance can be spilled water, which is in contact with the laminate surface for a long time. If neighbors flooded you or pipes in an apartment started to flow, unfortunately, the appearance of mold cannot be avoided. It is not recommended to use laminate in the toilet and bathroom. The lack of good ventilation in the room can also be a cause of the appearance of a raid. Poor installation of laminate floor also leads to the formation of mold.

If fungi have already formed on the laminate or under it, you need:

- Disassemble the floor, regardless of whether the coating is of the castle or adhesive type of laying.

- Remove the panels, which are at least a little affected by the fungus.

- Treat the surface with special protective agents and a moisture-proof layer.

What if the floor gets wet?

Neighbors may pour water over the floor, water may be spilled on it, flooding from leaking pipes is also possible. For this reason, the individual floorboards will swell, their edges zaderut. If water has hit the surface, even a waterproof laminate cannot resist destruction, especially if the joints between the boards are not sealed.

The solution for repairing wet floor is simple:

- It is necessary to disassemble the flooring. Having identified the wet part of the base, make a quality replacement.

- With a small amount of water on the laminate coating, it can be removed with a dry sheet of paper. Sheets absorb moisture, freeing the surface from getting wet.

- A special sealant is used to seal the gaps. A good option at the completion of the repair is to wax the surface.

- Before you dry the floors from the flood, you need to detach the laminate from the baseboards. Drying of the laminate is made by air from the heater. The flow of warm air is directed upwards.

Why squeaks?

Over time, with the active use of the board begin to sag, there is a characteristic creak. Also, the creak that appeared in the first week after installation is considered to be the norm, since the material has not yet been adapted to the conditions created. When a new floor creaked after more time, you can try to fix the defect without parsing.

The creaking of the floors may occur due to accumulated debris that has fallen into the cracks, as well as dust in the locks and on the surface of the substrate. The vacuum cleaner can cope with clearing the gaps.If necessary, you need to make an analysis of the floor and cleaning the surface. Disassembly is possible to do it yourself.

In the case where the sounds are localized, the seams may creak. In this case, the coating is not dismantled, and dismantled in places of damage. Sometimes the reason is in a poorly fixed lock between laminate panels. The rubber outsole can also emit characteristic sounds when it comes into contact with the laminate. In this case, you should not walk in such shoes on the floor.

When a crack is heard along the walls, the reason may be the incorrect installation of the plinth.

Eliminate creaking without paring in the following ways:

- Pour the gap hot wax from the paraffin candles and wipe with a thin spatula.

- If the squeak appears on the walls, it is necessary to dismantle the plinth and fill the joints with foam and PVA glue.

- The creaking in the center of the room is corrected by drilling a hole and pouring PVA glue.

- Pouring oil in the gap.

How to upgrade?

After a while, the laminate loses its original shine. Even if there are no significant defects, it is better to carry out restoration work to update the surface. It is necessary to make it with the aesthetic purpose.In such a situation, the laminate is carefully polished.

For home restoration, a liquid polish or a viscous agent is used, as well as mastic.

Properly polish the floor surface while observing the following rules:

- Before applying the coating should be cleaned and dried thoroughly.

- Spray or viscous compositions are evenly distributed over the entire surface.

- Mastic is applied to the fabric and the surface of the laminate is polished with measured circular movements.

- Repair and rearrangement of the overall furniture will definitely cause the formation of scratches on the laminate floor. Their masking is possible with a wax pencil and polish. To begin with, the surface is cleaned of dirt, followed by the application of wax. At the end of the restoration, the floor is treated with a polish for reliable protection and moisture exposure.

- Over time, the protective layer of the laminate becomes thinner. As a result, deep scratches and cracks are formed. For the restoration works purchased spatula, special putty. The tool is applied to the defect and rubbed.

- The slots are plastered with a previously prepared composition using a spatula.Then the surface is polished with fine sandpaper.

Proper surface polishing is done as follows:

- The floor surface is cleaned from dirt and dust. Dry thoroughly.

- Apply the product evenly. Apply polish slowly, carefully processing the damaged surface. For this purpose cloth napkins with small pile are used.

Restore scuff

The rubbed surface can be easily restored at home, using special grout or household tools for this purpose.

A couple of tablespoons of baking soda should be mixed with warm water to make a pasty gruel. Then, using a soft cloth, apply the resulting paste to scrub, leave for a while and carefully rub. In the absence of soda, the expected effect will give the usual toothpaste.

Hard-to-wear scuffs can be tried to be removed by wiping the surface with a rag dipped in acetone. At the same time, care must be taken to prevent acetone from entering the joints of the laminate floor panels.

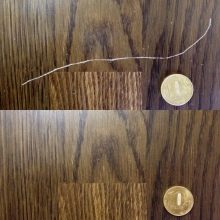

Dent

Dents on the floor can be formed when moving the overall furniture, the fall of heavy objects.Flaws of this kind are smeared with a special compound for repair. A two-color acrylic sealant can also do this perfectly.

A shallow dent on the laminate is masked by a mixture of construction repair paste, which is designed for similar floors. The color of the paste should be matched to the tone of the floor. When the coating dries, the treated surface takes on its original appearance.

In the case where the laminated coating is severely damaged, a simple restoration will not eliminate the dent. But the dismantling of the entire laminate coating is not required, it will be enough to cut out the damaged part and replace it with a new material of the same color spectrum.

At the completion of a surface damage correction, it is necessary to refresh it. For this, a layer of floor varnish is sprayed all over the floor.

Although laminate coatings are durable and high-quality products, they still require the most accurate operation at home.

How to paint?

Laminate has a high degree of resistance to mechanical damage, however, in the process of daily operation, it still causes minor damage that spoils the overall look of the interior.Also, sometimes there is a need to make a highlight in the surface design and update the interior. It is possible to decorate the floor if it is artificially aged with special means for painting.

For high-quality "aging", the protective layer is initially fixed on the surface. This coating will increase the degree of adhesion to the paint.

Algorithm works involves the following steps:

- From the floor it is necessary to remove dirt and debris.

- To eliminate damage, you can use a coarse sandpaper. After vacuuming the surface.

- Apply high-quality putty on the tree in several layers, until the surface of the floor is perfectly level.

- Dry the putty.

- To carry out painting.

- To give shine and additional protection of the surface to apply varnish.

Such a painted floor requires special attention. After wet cleaning, it is always necessary to dry the surface dry, avoid high humidity in the room and mechanical impact on the floor.

If you want to repaint the coating in darker colors, you can apply a tinting varnish on the surface. In addition to all the lacquer coating perfectly masks minor surface defects.

How to repair and restore laminate, see the next video.